ADCERAX® Zirconia Ceramic Blades are manufactured through high-pressure forming, precision sintering, and multi-step edge grinding using stabilized high-purity zirconia powder. These blades offer long-term cutting stability under harsh conditions due to their resistance to heat, corrosion, magnetization, and oxidation. Their non-conductive and chemically inert surface ensures clean, particulate-free performance in sensitive industrial applications.

Technical Features of Zirconia Ceramic Blades

-

High surface hardness

Tested Vickers hardness reaches ≥12.5 GPa, maintaining edge sharpness across prolonged use cycles. -

Minimal abrasive wear

Under dry film cutting, edge degradation is reduced by >90% compared to carbide tools. -

Stable micro-edge structure

Mirror-finished blades with Ra ≤ 0.02 μm prevent burr formation and particulate shedding. -

Resistance to mechanical impact

Fracture toughness is measured at 8–10 MPa·m¹ᐟ², enabling use in high-pressure cutting heads. -

No chipping under load

Crack propagation is significantly lower than alumina blades, improving operational uptime. -

Suitable for high-speed slitting

Blades perform reliably at >300 m/min feed speeds in PET and PVC films. -

Thermal expansion compatibility

Linear expansion coefficient of 10.3 × 10⁻⁶ /K reduces misfit with mounting holders. -

Edge integrity under heat

Blades retain sharpness with <2% edge deformation after 100h at 800 °C. -

No thermal oxidation

Surface remains oxide-free even in oxygen-rich thermal processes.

Technical Properties of Zirconia Ceramic Blades

Zirconia Ceramic Blades offer a combination of high mechanical strength, thermal reliability, chemical inertness, and surface precision that supports clean and stable cutting performance across demanding industrial and cleanroom environments.

| Property | Specification |

|---|---|

| Material Composition | Yttria-Stabilized ZrO₂ ≥ 94% |

| Density | 6.0 g/cm³ |

| Vickers Hardness | ≥ 12.5 GPa |

| Flexural Strength | ≥ 1,000 MPa |

| Compressive Strength | > 2,000 MPa |

| Fracture Toughness | 8–10 MPa·m¹ᐟ² |

| Thermal Conductivity | 2.2 W/m·K (at 20 °C) |

| Thermal Expansion | 10.3 × 10⁻⁶ /K (25–600 °C) |

| Electrical Resistivity | > 10¹² Ω·cm |

| Surface Roughness (Ra) | ≤ 0.02 μm |

| Magnetic Permeability | ≈ 0 μr (non-magnetic) |

| Chemical Stability | Acid & alkali resistant |

| Biocompatibility | ISO 6474 compliant |

| Maximum Service Temp. | ≥ 1,000 °C (air atmosphere) |

Specifications of Zirconia Ceramic Blades

| Square Zirconia Ceramic Blades | |||||

| Item No. | Length(mm) | Width (mm) | Thickness(mm) | Purity(%) | Blade |

| AT-YHG-D001 | 43 | 22 | 0.2 | 95 | Single-sided edge |

| AT-YHG-D002 | 22 | 10 | 0.7 | 95 | Single-sided edge |

| AT-YHG-D003 | 38 | 8 | 0.3 | 95 | Single-sided edge |

| AT-YHG-D004 | 47 | 10 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D005 | 75 | 10 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D006 | 85 | 10 | 0.9 | 95 | Single-sided edge |

| AT-YHG-D007 | 90 | 15 | 0.9 | 95 | Single-sided edge |

| AT-YHG-D008 | 125 | 10 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D009 | 131 | 10 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D010 | 135 | 8 | 0.3 | 95 | Single-sided edge |

| AT-YHG-D011 | 151 | 10 | 0.13 | 95 | Single-sided edge |

| AT-YHG-D012 | 152.8 | 10 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D013 | 152.8 | 8 | 0.9 | 95 | Single-sided edge |

| AT-YHG-D014 | 190 | 10 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D015 | 210 | 10 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D016 | 244 | 10 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D017 | 310 | 10 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D018 | 311 | 10 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D019 | 38.5 | 19 | 0.25 | 95 | Single-sided edge |

| AT-YHG-D020 | 38.5 | 19 | 0.35 | 95 | Single-sided edge |

| AT-YHG-D021 | 43 | 22 | 0.25 | 95 | Single-sided edge |

| AT-YHG-D022 | 100 | 18 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D023 | 80 | 9.2 | 0.4 | 95 | Single-sided edge |

| AT-YHG-D024 | 60 | 12 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D025 | 57 | 18 | 0.2-0.6 | 95 | Single-sided edge |

| AT-YHG-D026 | 58 | 13 | 0.2 | 95 | Single-sided edge |

| AT-YHG-D027 | 100 | 22 | 0.2 | 95 | Single-sided edge |

| AT-YHG-D028 | 100 | 22 | 0.4 | 95 | Single-sided edge |

| AT-YHG-D029 | 51 | 10 | 0.6 | 95 | Single-sided edge |

| AT-YHG-D030 | 60 | 33 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D031 | 56 | 8 | 0.2-0.6 | 95 | Single-sided edge |

| AT-YHG-D032 | 46 | 13 | 0.9 | 95 | Single-sided edge |

| AT-YHG-D033 | 45 | 31 | 0.7 | 95 | Single-sided edge |

| AT-YHG-D034 | 25 | 7.1 | 0.25 | 95 | Single-sided edge |

| AT-YHG-D035 | 122 | 19 | 0.5 | 95 | Single-sided edge |

| AT-YHG-D036 | 39 | 25 | 0.4 | 95 | Single-sided edge |

| AT-YHG-D037 | 44 | 13 | 0.8 | 95 | Single-sided edge |

| AT-YHG-D038 | 48 | 26 | 0.9 | 95 | Single-sided edge |

| AT-YHG-D039 | 50 | 19 | 0.6 | 95 | Single-sided edge |

| AT-YHG-D040 | 60 | 22 | 0.2-0.6 | 95 | Double-sided edge |

| AT-YHG-D041 | 43 | 22 | 0.2-0.6 | 95 | Double-sided edge |

| AT-YHG-D042 | 43 | 22 | 0.3 | 95 | Double-sided edge |

| AT-YHG-D043 | 43 | 22 | 0.15-0.5 | 95 | Double-sided edge |

| Zirconia Ceramic Blades | |||||

| Item No. | Length(mm) | Width (mm) | Thickness(mm) | Purity(%) | Blade |

| AT-YHG-D1001 | 65 | 10 | 0.5 | 95 | Round |

| AT-YHG-D1002 | 45 | 8 | 0.3 | 95 | Round |

| AT-YHG-D1003 | 50 | 15 | 0.6 | 95 | Round |

| AT-YHG-D1004 | 52 | 10 | 1 | 95 | Round |

| AT-YHG-D1005 | 60 | 12 | 0.5 | 95 | Round |

| AT-YHG-D1006 | 60 | 12 | 1 | 95 | Round |

| AT-YHG-D1007 | 63 | 8 | 0.5 | 95 | Round |

| AT-YHG-D1008 | 63 | 8 | 1 | 95 | Round |

| AT-YHG-D1009 | 65 | 20 | 0.8 | 95 | Round |

| AT-YHG-D1010 | 25 | 8 | 0.63 | 95 | Round |

| AT-YHG-D1011 | 28 | 8 | 0.6 | 95 | Round |

| AT-YHG-D1012 | 32 | 8 | 0.6 | 95 | Round |

| AT-YHG-D1013 | 34 | 8 | 0.63 | 95 | Round |

| AT-YHG-D1014 | 36 | 8 | 0.63 | 95 | Round |

| AT-YHG-D1015 | 38 | 8 | 0.63 | 95 | Round |

| AT-YHG-D1016 | 40 | 8 | 0.63 | 95 | Round |

| AT-YHG-D1017 | 45 | 8 | 0.63 | 95 | Round |

| AT-YHG-D1018 | 20 | 12 | 0.6 | 95 | Round |

| AT-YHG-D1019 | 28 | 8 | 0.5 | 95 | Round |

| AT-YHG-D1020 | 65 | 8 | 0.63 | 95 | Round |

| AT-YHG-D1021 | 28 | 8 | 0.63 | 95 | Round |

| AT-YHG-D1022 | 32 | 8 | 0.63 | 95 | Round |

| AT-YHG-D1023 | 65 | 10 | 0.4 | 95 | Round |

| AT-YHG-D1024 | 45 | 8 | 0.5 | 95 | Round |

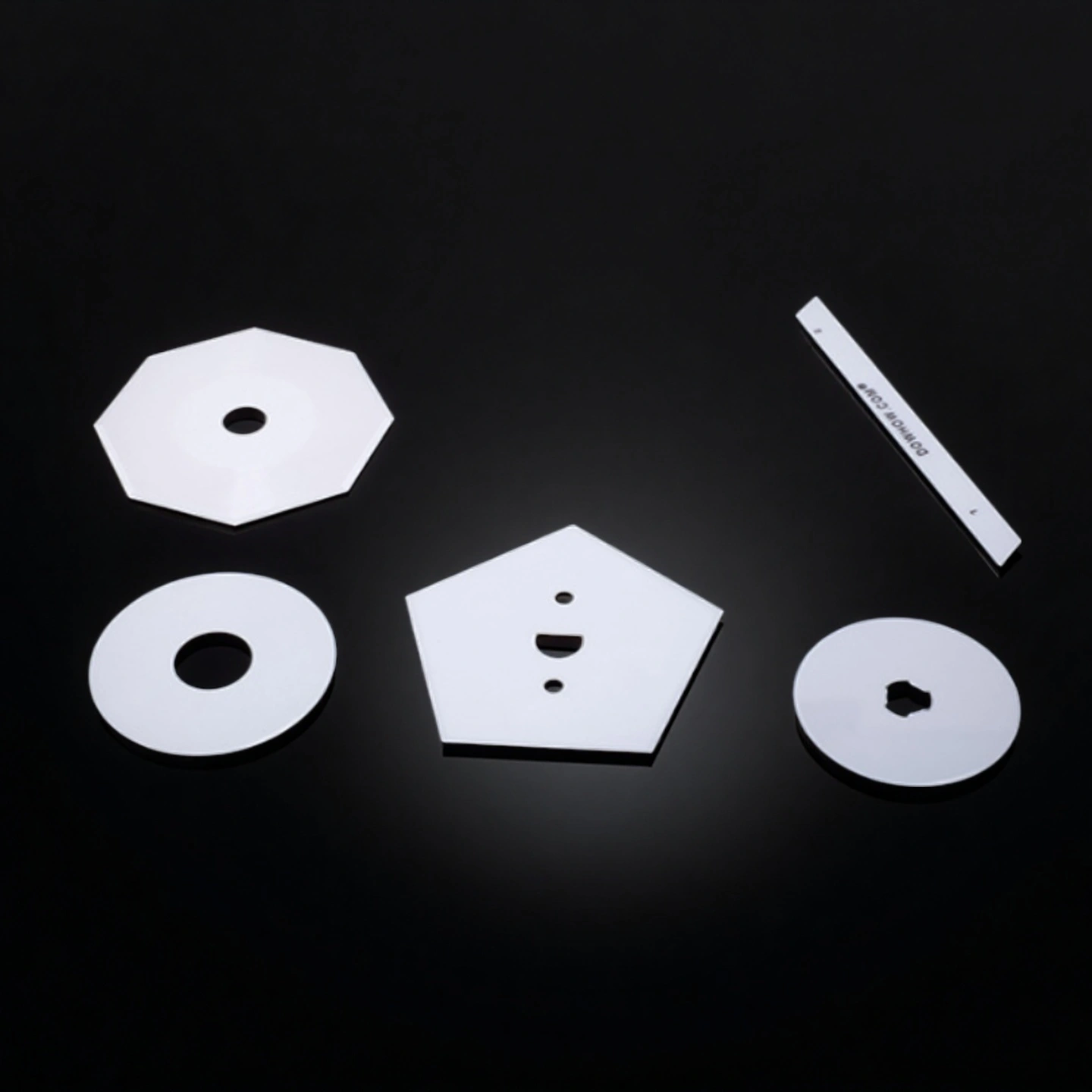

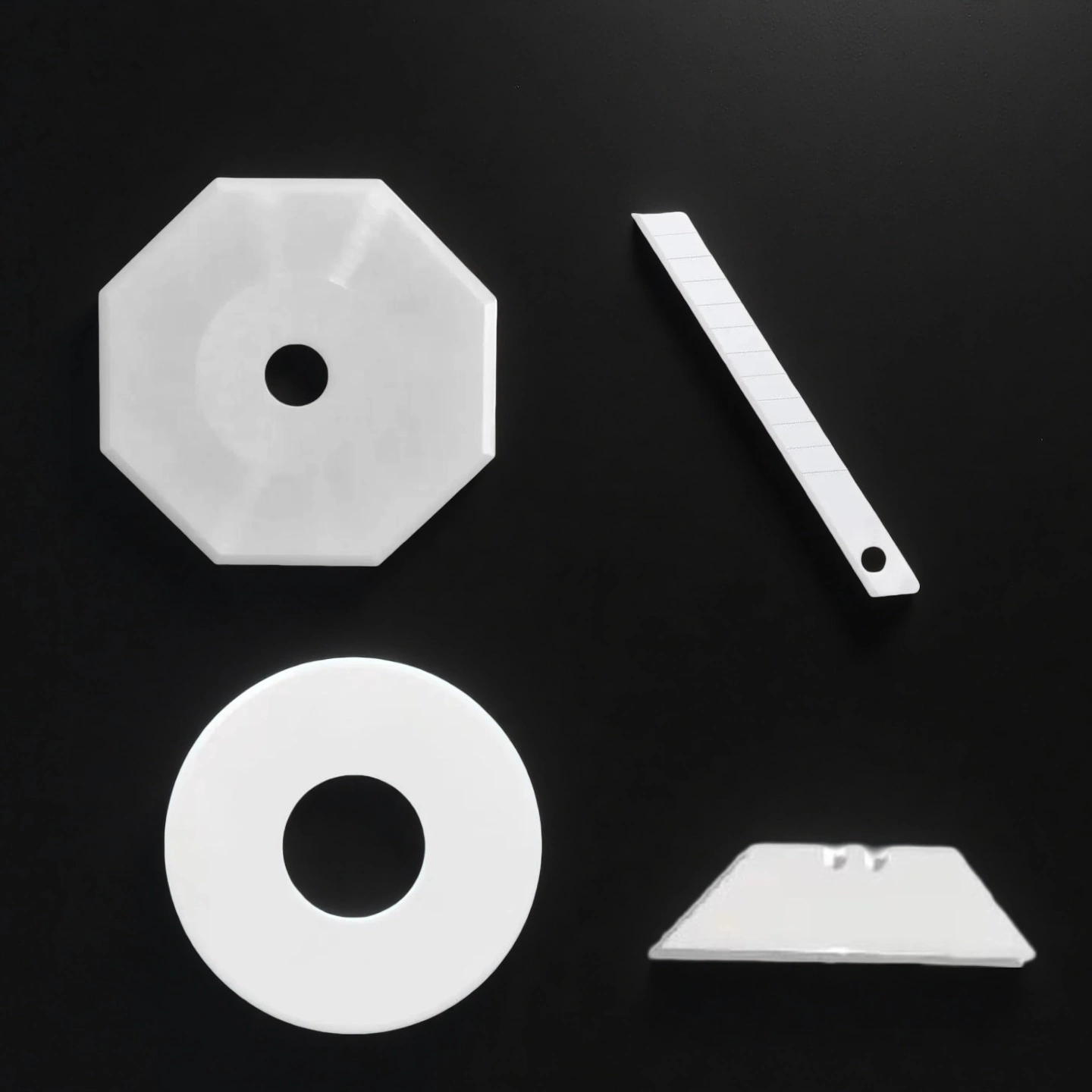

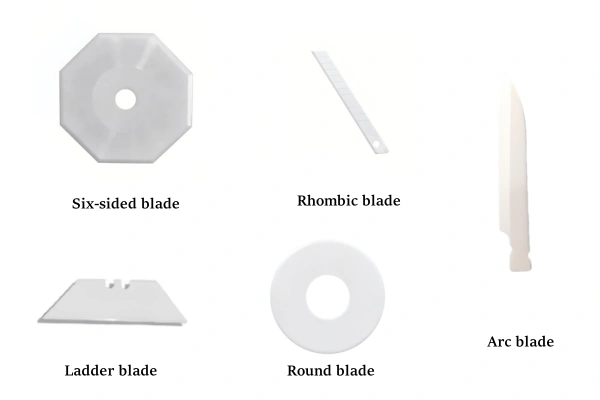

| AT-YHG-D1025 | 68 | 10 | 0.5 | 95 | Octagon |

| AT-YHG-D1026 | 68 | 10 | 1 | 95 | Octagon |

| AT-YHG-D1027 | 70 | 16.5 | 0.5 | 95 | Octagon |

| AT-YHG-D1028 | 28 | 8 | 0.63 | 95 | Decagon |

| AT-YHG-D1029 | 25 | 8 | 0.63 | 95 | Sixteen-sided shape |

Packaging of Zirconia Ceramic Blades

Zirconia Ceramic Blades are securely packed using multilayer foam padding and separated by structured inserts to prevent contact during transit. Each blade is individually sealed and immobilized within a reinforced corrugated carton. This packaging method ensures mechanical integrity and eliminates edge chipping or vibration damage during international shipping.