ADCERAX® Magnesia Stabilized Zirconia Crucible is designed for industries that operate under extreme thermal and chemical conditions. It maintains structural integrity up to 2000 °C and provides reliable resistance against acids, alkalis, slags, and molten metals. With non-wetting behavior toward titanium, zirconium, and tungsten melts, it ensures clean results in metallurgy and alloy development. This combination of durability and performance makes Magnesia Stabilized Zirconia Crucible a trusted choice for research laboratories, energy projects, and high-temperature metal processing.

Features of Magnesia Stabilized Zirconia Crucible

- Withstands continuous operation up to 2000 °C, enabling safe use in refractory metal melting. This ensures reliability in processes involving titanium, zirconium, and tungsten.

- Provides resistance to thermal shock with tolerance up to 450 ΔT°C in water quenching. This reduces cracking risks during rapid heating and cooling.

- Demonstrates compressive strength of 2500 MPa, allowing safe handling of heavy molten metal batches. This ensures consistent outcomes in production environments.

- Features hardness of 1100 HV0.5, minimizing surface wear. This property extends crucible usability during repeated alloy development tests.

- Weight loss under 60% nitric acid at 90 °C is only 0.1 mg/cm²/day. This guarantees protection against strong acids in laboratory use.

- In 95% sulfuric acid at 95 °C, weight loss remains at 0.34 mg/cm²/day. This ensures stability in aggressive industrial chemical environments.

- Shows 0.95 mg/cm²/day weight loss in 30% sodium hydroxide at 80 °C. This resistance supports long-term crucible use in alkaline conditions.

Technical Properties for Magnesia Stabilized Zirconia Crucible

The following section provides the core technical parameters of Magnesia Stabilized Zirconia Crucible, including material properties and performance data.

| Property |

Specification |

| Density |

5.7 g/cm³ |

| Flexural Strength |

500 MPa |

| Compressive Strength |

2500 MPa |

| Fracture Toughness |

6–7 MPa·m½ |

| Vickers Hardness |

1100 HV0.5 |

| Elastic Modulus |

250 GPa |

| Thermal Conductivity |

3 W/m·K |

| Thermal Expansion Coefficient |

10 ×10⁻⁶/K |

| Volume Resistivity (20 °C) |

>10¹⁴ Ω·cm |

| Dielectric Constant |

28 εr |

| Dielectric Strength |

13 ×10⁵ V/m |

| Acid Resistance (HNO₃, 60%, 90 °C) |

0.1 mg/cm²/day weight loss |

| Alkali Resistance (NaOH, 30%, 80 °C) |

0.95 mg/cm²/day weight loss |

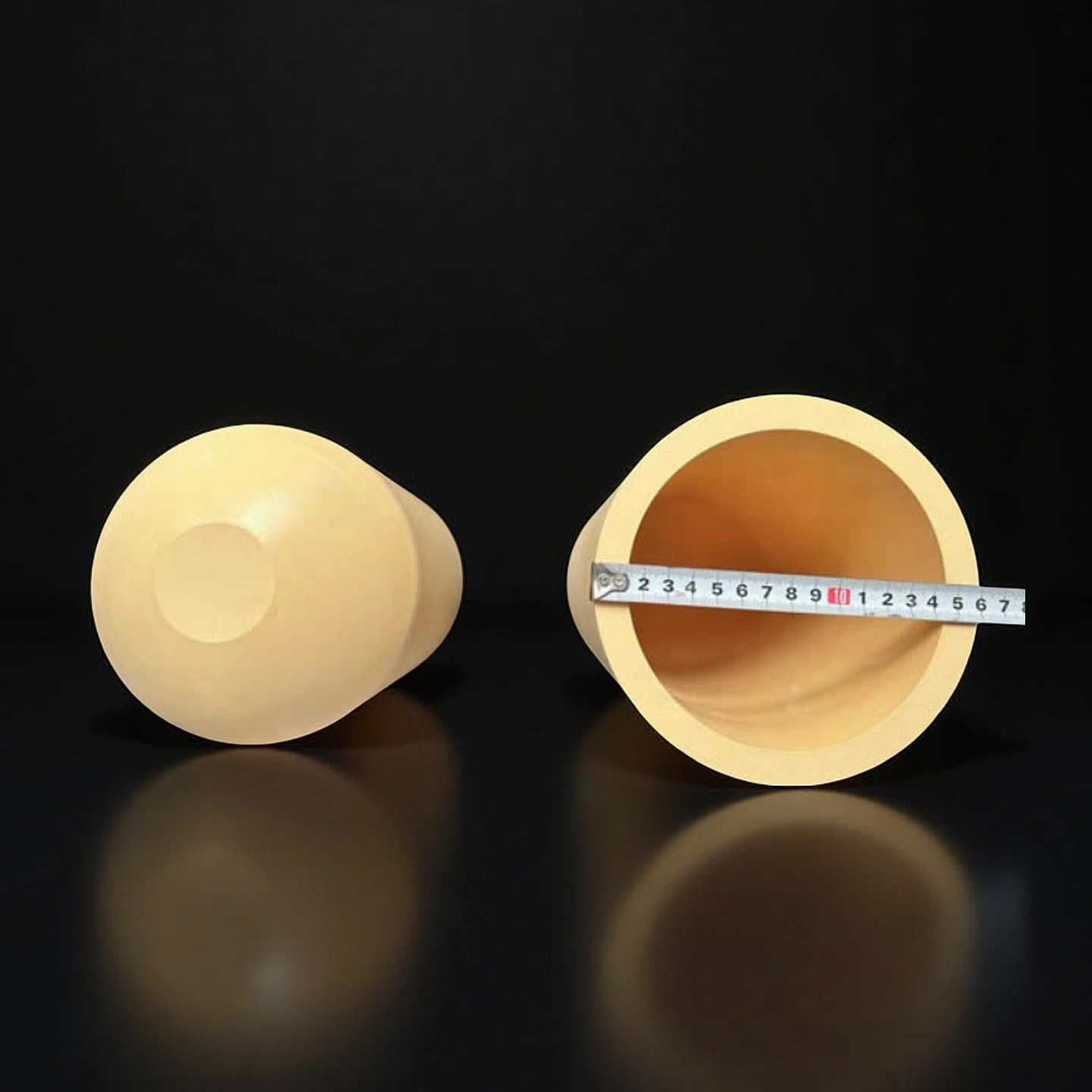

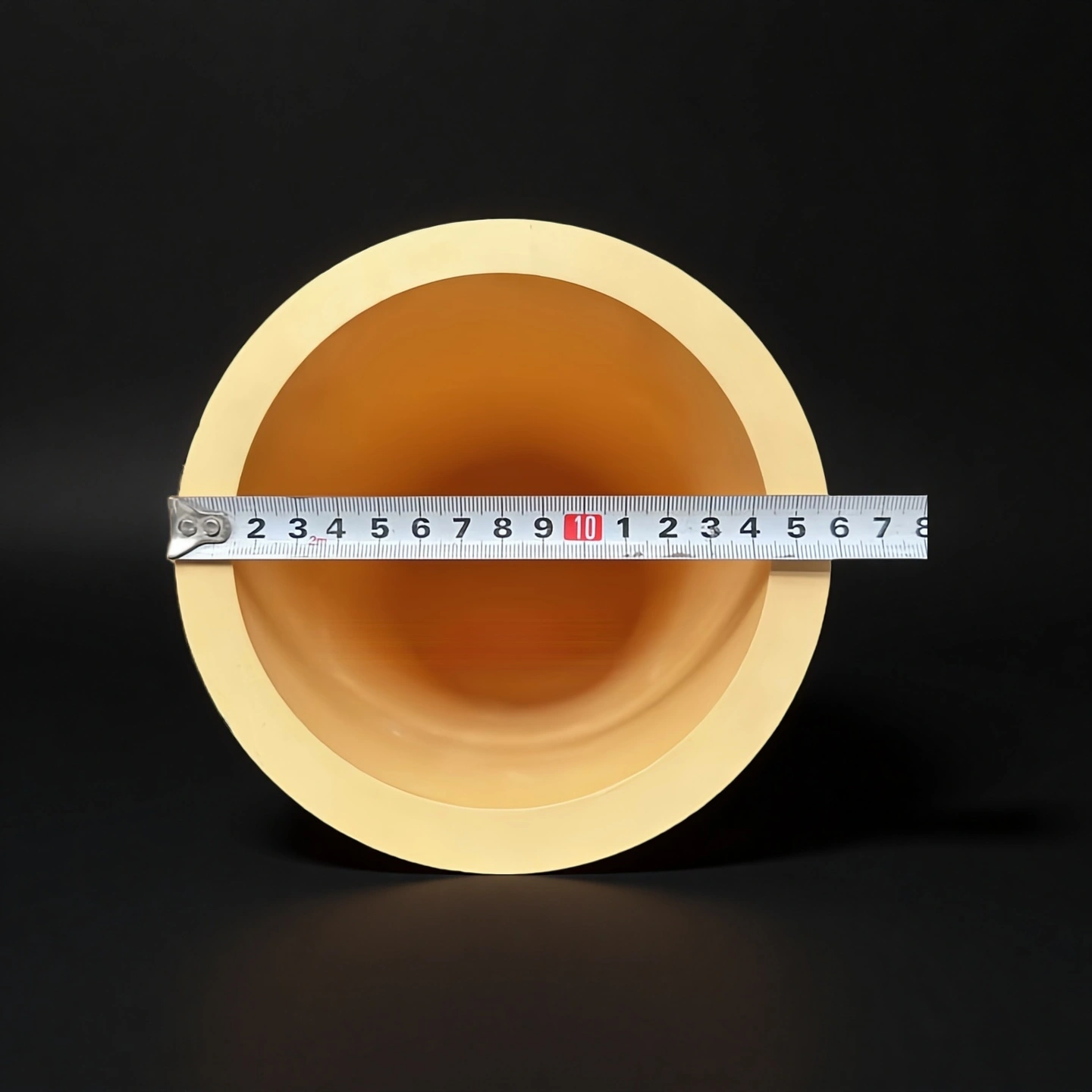

Dimensions of Magnesia Stabilized Zirconia Crucible

|

Mg-PSZ Crucible |

|

Item No. |

Diameter(mm) |

Height (mm) |

|

AT-MGO-GG1001 |

Customize |

Packaging of Magnesia Stabilized Zirconia Crucible

Each Magnesia Stabilized Zirconia Crucible is first packed in a protective cardboard box to prevent vibration damage. Multiple boxes of MSZ Crucible are reinforced with tape and placed into wooden cases for safe handling. The final export package of MSZ Ceramic Crucible is secured with steel straps, ensuring stability during international shipping.

Addressing Industry Challenges with ADCERAX® Magnesia Stabilized Zirconia Crucible

Magnesia Stabilized Zirconia Crucible is applied in critical industrial environments where ordinary ceramic crucibles fail. Its unique combination of high-temperature tolerance, non-wetting surfaces, and corrosion resistance directly responds to challenges faced in metallurgy, aerospace alloy development, and advanced energy material research.

-

Titanium and Zirconium Melting

✅Key Advantages

1. High-Temperature Integrity — Operates safely at 2000–2100 °C in continuous melts. ΔT 450 °C thermal-shock tolerance limits crack initiation during hot-cold cycles.

2. Toughened Mg-PSZ Strength — Fracture toughness 6–7 MPa·m½ resists crack growth under thermal stress. Flexural strength 500 MPa maintains vessel rigidity at peak heat.

3. Controlled Thermal Gradients — Low thermal conductivity 3 W/m·K moderates heat flow through the wall. CTE 10×10⁻⁶/K reduces thermal strain at the metal–ceramic interface.

✅ ️Problem Solved

A titanium melt line running near 1850 °C reported frequent crucible cracks during fast turnarounds and purity loss from metal wetting. After switching to ADCERAX® Magnesia Stabilized Zirconia Crucible rated 2100 °C and operating within the recommended ramps (<4 °C/min above 1200 °C), the campaign completed high-heat cycles without crack events. The ΔT 450 °C tolerance handled mandated thermal transitions between charges. Non-wetting behavior maintained clean pool surfaces, stabilizing melt quality across sequential runs. Overall process interruptions tied to crucible failure were removed from the shift reports.

-

Aerospace Alloy Sintering

✅Key Advantages

1. Dimensional Stability at Heat — CTE 10×10⁻⁶/K controls distortion through long soaks. Maximum service temperature 2100 °C supports high-enthalpy alloy programs.

2. Low Inclusion Risk — Hardness 1100 HV0.5 minimizes abrasion and particle shedding. Non-reactive surfaces limit alloy pickup during sintering holds.

3. Multi-Cycle Durability — Compressive strength 2500 MPa resists load-induced creep. Flexural strength 500 MPa sustains geometry through repeated thermal cycles.

✅ ️Problem Solved

An aerospace shop reported density spread and inclusion alerts when standard ceramics degraded during hot holds. With ADCERAX® Magnesia Stabilized Zirconia Crucible, sintering profiles up to ~2000 °C run under controlled ramps (<4 °C/min) proceeded without wall spallation. Mechanical robustness (500 MPa flexural, 2500 MPa compressive) preserved vessel geometry through back-to-back cycles. The stable CTE (10×10⁻⁶/K) kept parts within target form during cool-down. NCRs linked to crucible interaction were cleared over the evaluated batches.

-

Energy and Advanced Material Research

✅Key Advantages

1. Acid Corrosion Resistance — Mass loss only 0.1 mg/cm²/day in 60% HNO₃ at 90 °C. Supports repeat assays without vessel drift.

2. Alkali Corrosion Resistance — Mass loss 0.95 mg/cm²/day in 30% NaOH at 80 °C. Enables sustained alkaline processing under heat.

3. Cycle-Stable Toughness — 6–7 MPa·m½ toughness plus ΔT 450 °C shock tolerance extends re-use. Consistent behavior improves data reproducibility across runs.

✅ ️Problem Solved

A materials lab performing heated acid and alkali protocols saw rapid erosion and drifting baselines with generic ceramics. Using ADCERAX® Magnesia Stabilized Zirconia Crucible, measured mass loss aligned with the stated corrosion rates (0.1–0.95 mg/cm²/day under the specified media and temperatures). Repeated thermal steps within ΔT 450 °C tolerance maintained vessel integrity and tare mass. Result variance from container wear was removed from method uncertainty. The program sustained long sequences without unplanned crucible replacement.

User Guide for Magnesia Stabilized Zirconia Crucible

The Magnesia Stabilized Zirconia Crucible is designed for reliable use in high-temperature and chemically aggressive environments. To maximize service life and ensure consistent performance, customers should follow clear guidelines on preparation, heating, handling, and storage. These recommendations help reduce operational risks, avoid premature failure, and maintain product integrity during industrial or research applications.

-

Preparation Before First Use

1. Pre-baking required: Always heat the crucible at 105 °C for at least 120 minutes to remove residual moisture. This step prevents micro-cracking during the first high-temperature cycle.

2. Visual inspection: Check the surface for scratches or chips before use. Minor flaws may lead to premature failure during heating.

3. Gradual preheating: Begin with a controlled low-temperature ramp-up. This allows the Magnesia Stabilized Zirconia Crucible to adapt to the furnace environment smoothly.

-

Handling During Operation

1. Correct loading: Avoid filling the crucible too tightly. Overpacking leads to thermal expansion of metals and possible crucible rupture.

2. Metal removal: Prefer ladles or spoons when extracting molten material. Improper tools or force can shorten crucible lifespan.

3. Protective equipment: Operators should wear heat-resistant gloves, goggles, and protective clothing when handling hot crucibles.

-

Heating and Cooling Practices

1. Controlled temperature change: Keep heating/cooling rates below 5 °C/min under 1200 °C and below 4 °C/min above 1200 °C. Faster rates can cause cracks or spalling.

2. Safe distance from heating elements: Maintain at least 2 cm clearance from SiC rods, MoSi₂ rods, or heating wires. Direct exposure can damage crucible walls.

3. Stable support: Place the crucible on alumina or refractory plates rather than the furnace floor. This creates airflow, improving thermal balance.

-

Storage and Maintenance

1. Dry environment: Store the Magnesia Stabilized Zirconia Crucible in a well-ventilated and moisture-free location to prevent surface degradation.

2. Avoid impact: Do not stack crucibles directly or allow heavy objects to contact them. Mechanical stress can create hidden cracks.

3. Regular inspection: After each cycle, check for surface changes or erosion. Early detection ensures safe re-use and reduces the risk of failure.