ADCERAX® Magnesia Stabilized Zirconia Ceramic Piston offers a high-performance solution for demanding reciprocating pump systems operating under aggressive thermal, chemical, and mechanical environments. Engineered with a dense ceramic matrix stabilized by magnesium oxide, it delivers exceptional impact resistance, wear durability, and thermal shock stability. Its proven reliability across pharmaceutical processing, chemical dosing, environmental treatment, and petrochemical applications ensures consistent performance and extended service life under continuous operation.

Key Material and Performance Features of Magnesia Stabilized Zirconia Ceramic Piston

-

High fracture toughness of 9–10 MPa·m¹ᐟ²

This allows the piston to withstand repeated reciprocating loads without cracking or microfracture initiation. It performs reliably in systems exceeding 2 million cycles under high-pressure conditions.

-

Compressive strength > 2,000 MPa

The piston maintains structural integrity under sustained axial loads in metering systems with operating pressures above 30 MPa, reducing breakage risk.

-

Hardness rating of HRA 88–90

With this high surface hardness, it resists abrasive wear even when exposed to slurries containing 5–10% solid content, maintaining performance over time.

-

Working temperature exceeding 1,000°C

The piston remains dimensionally stable in hot fluid dosing systems, such as chemical reactors and heated pipelines operating above 850°C.

-

Thermal shock resistance up to 300°C delta

It survives rapid transitions from ambient to hot service conditions without cracking, enabling use in start-stop dosing cycles and CIP/SIP cleaning procedures.

-

Low thermal expansion coefficient of 10.2 × 10⁻⁶/K

This allows tight sealing even under variable thermal gradients, ensuring stroke accuracy in precision pumps.

-

No corrosion in pH 1–14 environments

The piston maintains chemical integrity in high-acidity (HCl, H₂SO₄) and strong base (NaOH, KOH) dosing applications without surface degradation.

-

Surface roughness Ra ≤ 0.2 μm

The ultra-smooth surface reduces friction and wear on mating seals, enabling lubrication-free operation in dry-running or sterile environments.

-

Zero metal ion release

The dense MSZ ceramic structure ensures no leaching of contaminants, meeting purity standards required in pharmaceutical and biotech systems (ISO 10993, USP <87>).

Technical Specifications of Magnesia Stabilized Zirconia Ceramic Piston

Magnesia Stabilized Zirconia Ceramic Piston is engineered for high-demand applications requiring outstanding thermal stability, mechanical strength, and corrosion resistance. Its fully sintered microstructure, combined with enhanced fracture toughness and chemical inertness, makes it highly suitable for aggressive fluid handling systems in precision industrial environments.

| Property |

Specification |

| Material Density |

5.6–5.9 g/cm³ |

| Fracture Toughness |

9–10 MPa·m¹ᐟ² |

| Compressive Strength |

>2,000 MPa |

| Flexural Strength |

≥800 MPa |

| Vickers Hardness |

≥1,100 HV |

| Thermal Conductivity |

2.5 W/m·K @ 25°C |

| Maximum Operating Temperature |

>1,000°C |

| Thermal Shock Resistance |

ΔT ≥ 300°C |

| Coefficient of Thermal Expansion |

~10.2 × 10⁻⁶/K (25–1000°C) |

| Electrical Resistivity |

>10¹² Ω·cm @ 25°C |

| Chemical Resistance |

Stable in pH 1–14 |

| Surface Roughness (Ra) |

≤ 0.2 μm |

| Metal Ion Leaching |

Non-detectable |

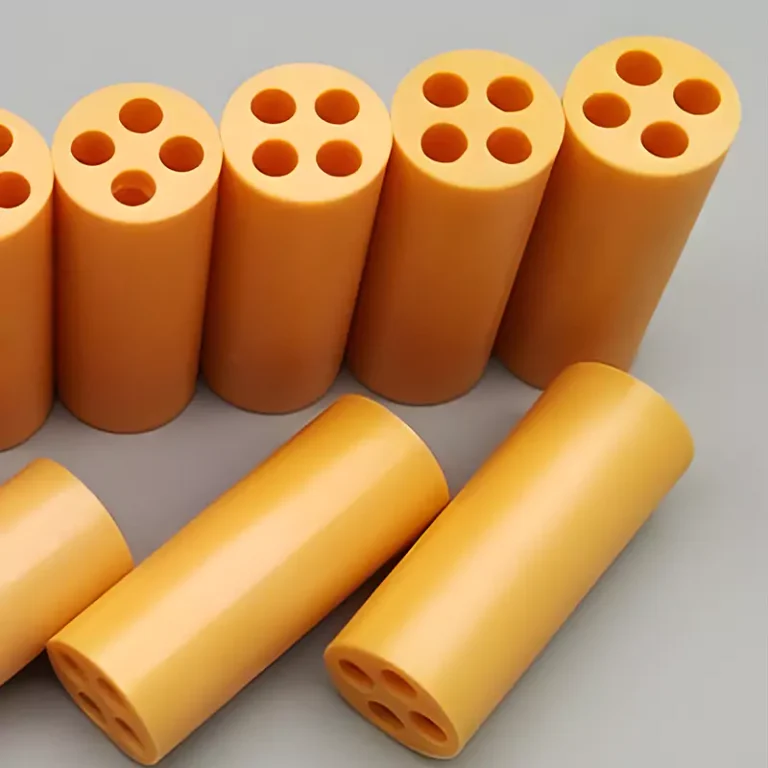

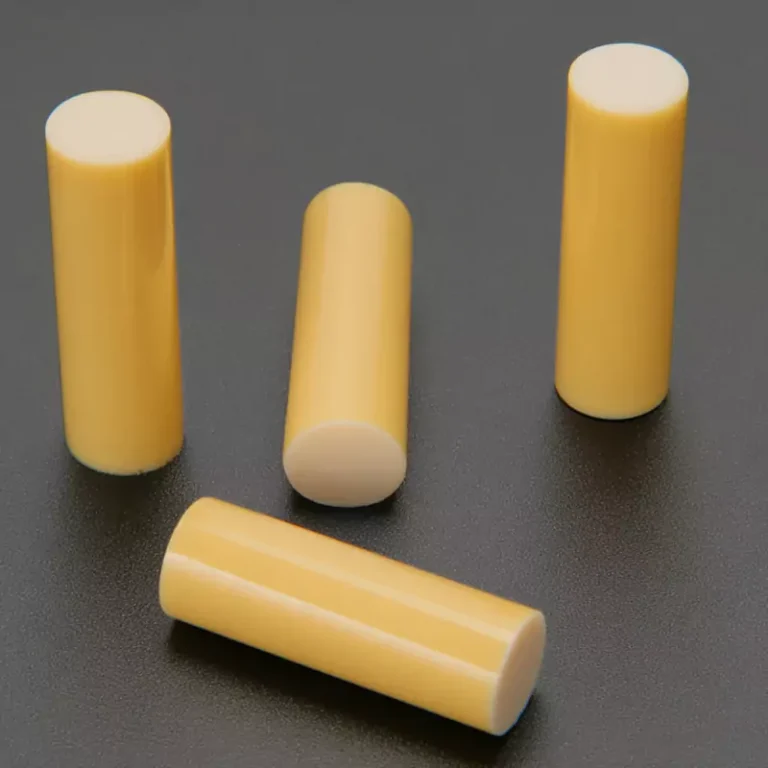

Dimensions of Magnesia Stabilized Zirconia Ceramic Piston

|

Mg-PSZ Ceramic Piston |

|

Item No. |

Diameter(mm) |

Height (mm) |

|

AT-MG-Z001 |

Customize |

Secure Packaging of Magnesia Stabilized Zirconia Ceramic Piston

Magnesia Stabilized Zirconia Ceramic Piston is packed in high-strength plywood crates with reinforced strapping to ensure safe international transport. Each piston is individually cushioned with foam and sealed in protective film to prevent vibration damage. The interior layout is optimized for impact resistance and moisture control during long-haul logistics.

ADCERAX® Magnesia Stabilized Zirconia Ceramic Piston Enhances System Reliability in Precision Fluid Applications

ADCERAX® Magnesia Stabilized Zirconia Ceramic Piston is engineered to address critical challenges in industrial systems where corrosive fluids, abrasive particulates, and thermal fluctuations impact pump performance. Through its superior fracture toughness, high compressive strength, and chemical inertness, this component ensures operational stability in highly specific, high-value engineering environments that demand consistent reciprocating motion and long service life.

-

Chemical Injection Systems for Acidic Desulfurization in Refineries

✅Key Advantages

1. Acid-Etch Resistance in H₂SO₄/HCl

The piston maintains surface integrity after >1000 hours of exposure to concentrated H₂SO₄ at 80 °C. No visible pitting or degradation was observed in field tests across sulfur treatment skids.

2. Stable Geometry at 120 °C Cycles

Engineered for dimensional consistency under thermal fluctuation up to ΔT 250 °C. Maintains <1% stroke variance in continuous duty dosing over 2 million reciprocating cycles.

3. Extended Replacement Interval

Outperforms stainless steel pistons by a factor of 6× in acid metering systems. Replacement cycle extended from 90 days to 540+ days, minimizing plant disruptions.

✅ ️Problem Solved

Downtime from Corrosion and Deformation

A Middle Eastern refinery using HCl injection pumps faced monthly shutdowns due to piston corrosion and dosing drift. Stainless steel plungers exhibited etching after 6 weeks, causing O-ring leakage and dosing errors above ±8%. After retrofitting with ADCERAX® Magnesia Stabilized Zirconia Ceramic Pistons, the plant achieved stable metering performance for over 14 months, saving USD 42,000 annually in maintenance costs and acid overdosing.

-

Flocculant Dosing Systems in Municipal Wastewater Plants

✅Key Advantages

1. High Hardness Against Solid-Laden Media

With a surface hardness of HRA 88–90, the piston resists abrasion from suspended particles like aluminum hydroxide and iron salts even in 10–15% sludge concentration.

2. Non-Degrading in pH 3–11 Slurries

Zero structural degradation observed after 12 weeks continuous operation in ferric chloride solutions at 40–50 °C. Chemical stability ensures piston dimensional consistency.

3. Low Downtime Operation

Pump service intervals increased from 6 weeks to 9+ months after switch to ADCERAX® pistons in high-volume clarifier dosing applications, reducing technician intervention frequency by 80%.

✅ ️Problem Solved

Abrasive Wear in Slurry Contact

A European municipal treatment facility using aluminum sulfate flocculants reported piston surface failure every 45 days due to abrasive sludge. The issue caused inconsistent flocculant delivery and required frequent pump disassembly. Following the deployment of ADCERAX® Magnesia Stabilized Zirconia Ceramic Pistons, the wear rate dropped significantly, allowing uninterrupted operation for over 280 days with no stroke inconsistency, cutting maintenance labor hours by 60%.

-

Buffer and Additive Dispensing in Battery Material Precursor Synthesis

✅Key Advantages

1. Zero Ionic Contamination in Li⁺/Co²⁺ Solutions

In certified testing, zirconia pistons released <0.01 ppm metal ions, preserving electrolyte and precursor purity for high-quality cathode materials.

2. No Swelling in Solvent-Rich Slurries

Unlike PTFE components, ADCERAX® pistons retain geometry in NMP and DI water-based systems. No swelling observed after 480 hours immersion at 60 °C.

3. Tight Surface Finish for Flow Control

Ra ≤ 0.2 μm finish reduces shear and boundary turbulence. Enables consistent 0.5–2.5 mL precision dosing per stroke across >1 million cycles.

✅ ️Problem Solved

Contamination in High-Purity Slurry Transfer

A Japanese battery materials OEM reported batch rejections due to cobalt contamination traced to stainless steel pump pistons. Post-replacement with ADCERAX® Magnesia Stabilized Zirconia Ceramic Pistons, contamination fell below ICP-MS detection limits (<0.005 ppm), enabling over 150,000 liters of precursor solution production without rejection. Total yield efficiency improved by 11.2%, avoiding USD 30,000 in losses per production quarter.

ADCERAX® Magnesia Stabilized Zirconia Ceramic Piston User Guide for Optimal Operation and Longevity

Proper handling and operation of Magnesia Stabilized Zirconia Ceramic Piston are essential to fully benefit from its thermal stability, chemical resistance, and mechanical durability. This guide outlines best practices across installation, pre-operation checks, routine maintenance, and long-term storage to help ensure reliable performance and minimize premature wear or failure in industrial dosing systems.

-

Installation Guidelines for Precision Fit and Safety

1. Ensure alignment with the pump cylinder bore before securing the piston.

Misalignment can lead to lateral stress and edge chipping during reciprocation.

2. Avoid direct impact or force during installation.

Use soft-jaw tools and avoid hammering or press-fitting to prevent microcrack formation.

3. Inspect sealing interfaces and sleeves before assembly.

Damaged seals or debris may compromise tightness and affect dosing accuracy.

-

Pre-Operation Checks Before System Start-Up

1. Conduct visual inspection of the ceramic surface.

Look for cracks, scratches, or coating residue before engaging the piston in any cycle.

2. Verify correct fluid compatibility with zirconia ceramics.

Avoid unverified chemical blends that may contain fluorides or reactive halogens.

3. Calibrate stroke displacement and monitor stroke smoothness.

Inconsistent motion or abnormal noise may indicate improper alignment or seal deformation.

-

Routine Maintenance and Monitoring Practices

1. Clean the piston regularly with neutral pH solutions.

Acidic or alkaline cleaners may cause seal degradation and reduce system lifespan.

2. Monitor stroke frequency and operating load trends.

Excessive vibration or friction may indicate misalignment or contamination inside the pump.

3. Inspect and replace seals and sleeves as needed.

Seal fatigue or swelling can lead to piston scoring or dosage instability.

-

Storage and Handling Recommendations

1. Store pistons in their original foam-protected packaging.

This helps maintain cleanliness and protects against accidental impact.

2. Avoid high-humidity or chemically active environments during storage.

Condensation or vapor exposure may affect surface polish and dimension.

3. Label and track pistons by batch for quality traceability.

Proper inventory records improve reordering, batch analysis, and performance validation.