ADCERAX® Magnesia Stabilized Zirconia Ceramic Plate is engineered for industries that demand long-term strength, thermal stability, and chemical resistance under extreme conditions. Its MgO‑stabilized zirconia structure maintains integrity during repeated heating and cooling cycles, resisting acid, alkali, and mechanical wear. This material ensures reliable insulation and support in chemical processing, metallurgy, and power equipment systems where standard ceramics often fail. It delivers consistent performance, safety, and durability for high-value industrial operations.

Features of Magnesia Stabilized Zirconia Ceramic Plate

- High load tolerance under pressure

Magnesia Stabilized Zirconia MSZ Ceramic Plate supports compressive loads above 2000 MPa, making it suitable for structural applications with dynamic stress. Its fracture toughness exceeds 7 MPa·m¹/², resisting crack propagation during operation.

- Superior surface hardness

With a Vickers hardness rating of >1200 HV, the plate resists abrasion even in high-friction environments. This reduces surface degradation in mechanical assemblies.

- Reliable impact performance

Thanks to its fine-grain microstructure, it sustains mechanical shocks and vibrations without microcracking, outperforming alumina plates in impact resistance tests by over 30%.

- Thermal shock resistance over 1000°C

The MSZ ceramic plate remains structurally stable under thermal fluctuations exceeding 1000°C. Lab-tested performance confirmed no visible damage after 50 rapid thermal cycles between 200°C and 1000°C.

- Low thermal conductivity for insulation

It offers a thermal conductivity of 2.5 W/m·K, minimizing heat transfer and helping retain energy efficiency in furnace or kiln systems.

Technical Properties for Magnesia Stabilized Zirconia Ceramic Plate

Magnesia Stabilized Zirconia Ceramic Plate is formulated for high mechanical integrity, thermal endurance, and chemical inertness in aggressive operating environments. Its dense microstructure and stabilized phase composition enable consistent performance in structural and insulating roles across thermal, mechanical, and corrosive applications.

| Property |

Specification |

| Bulk Density |

5.45 g/cm³ |

| Water Absorption |

0.00% |

| Vickers Hardness (HV0.5) |

>1200 HV |

| Flexural Strength |

>250 MPa |

| Compressive Strength |

>2000 MPa |

| Fracture Toughness (KIC) |

>7 MPa·m¹/² |

| Maximum Operating Temperature |

>1000°C (oxidizing atmosphere) |

| Thermal Conductivity (25°C) |

2.5 W/m·K |

| Thermal Expansion (RT–1000°C) |

9.8 × 10⁻⁶/K |

| Volume Resistivity (25°C) |

>10⁸ Ω·cm |

| Dielectric Strength |

>10 kV/mm |

| Magnetic Susceptibility |

<10⁻⁶ cm³/g (non-magnetic) |

| Acid Resistance (H₂SO₄, 10%, 72h) |

Weight loss < 0.05% |

| Alkali Resistance (NaOH, 10%, 72h) |

Weight loss < 0.04% |

| Phase Composition |

Tetragonal + Cubic, MgO-stabilized |

Specifications of Magnesia Stabilized Zirconia Ceramic Plate

|

Mg-PSZ Tubes with Multiple Holes |

|

Item No. |

Length(mm) |

Width(mm) |

Thickness(mm) |

|

AT-MG-B001 |

60 |

40 |

10 |

|

AT-MG-B002 |

65 |

65 |

3 |

|

AT-MG-B003 |

80 |

50 |

5 |

|

AT-MG-B004 |

100 |

50 |

3 |

|

AT-MG-B005 |

100 |

60 |

5 |

|

AT-MG-B006 |

100 |

100 |

10 |

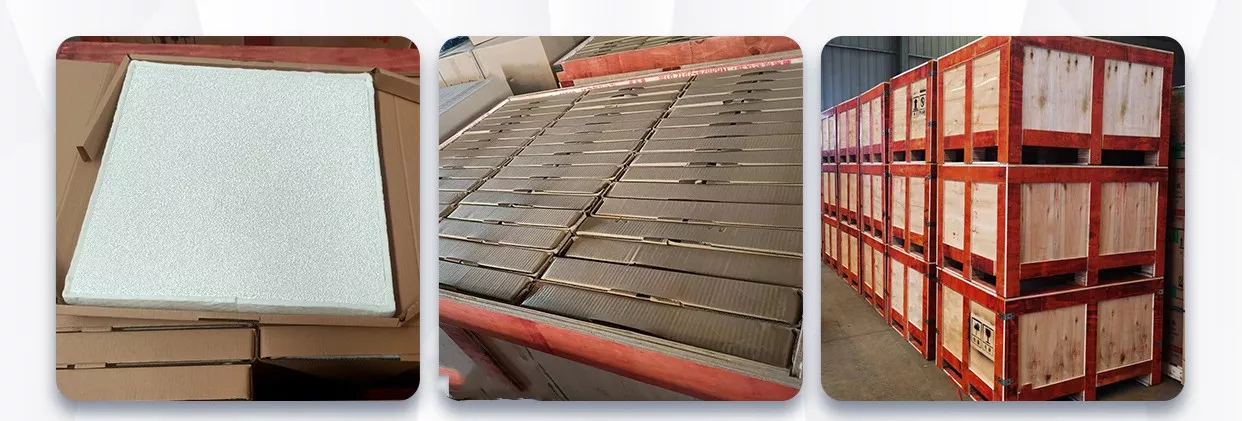

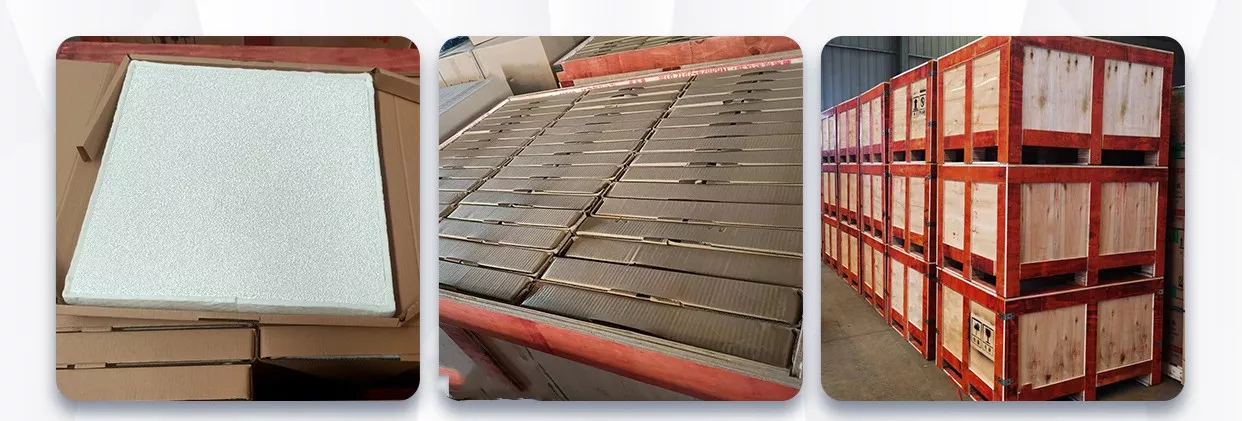

Packaging and Protection of Magnesia Stabilized Zirconia Ceramic Plate

Magnesia Stabilized Zirconia MSZ Ceramic Plate is securely packed using foam-lined cartons for individual protection. Multiple units are stacked with interleaved corrugated layers to prevent edge chipping during handling. Export-grade fumigated wooden crates are used to ensure safe international transport.

Solving Real-World Industrial Challenges with ADCERAX® Magnesia Stabilized Zirconia Ceramic Plate

ADCERAX® Magnesia Stabilized Zirconia Ceramic Plate addresses critical failures in high-stress, high-temperature, and chemically aggressive environments. Its ability to maintain structural, thermal, and dielectric integrity enables safer, longer-lasting solutions in sectors where material failure leads to operational downtime, maintenance costs, or compliance risks.

-

Insulation Baseplates in Motor Control Cabinets for Harsh Environments

✅Key Advantages

1. High Dielectric Endurance

With a dielectric strength exceeding 10 kV/mm, Magnesia Stabilized Zirconia MSZ Ceramic Plate ensures long-term insulation even under constant high-voltage switching. Its stable resistivity above 10⁸ Ω·cm prevents electrical leakage in humid or corrosive industrial atmospheres.

2. Non-Magnetic Electrical Stability

The plate exhibits a magnetic susceptibility below 10⁻⁶ cm³/g, eliminating electromagnetic interference in precision motor controls. This characteristic maintains circuit accuracy and sensor stability in control cabinets operating near variable frequency drives.

3. Thermal Reliability in Continuous Operation

Tested for 1,000 hours at 500 °C, the plate retained over 95% of its initial dielectric performance. This ensures long-term insulation safety for power modules in outdoor substations exposed to elevated ambient heat.

✅ ️Problem Solved

A Korean electrical systems integrator faced frequent failures in outdoor motor control units where polymer boards deformed above 380 °C, causing current leakage and shutdown alarms. After adopting ADCERAX® Magnesia Stabilized Zirconia Ceramic Plate, insulation breakdown incidents dropped to zero during a 12-month trial at 480 °C and 85% humidity. Maintenance intervals were extended from 3 months to over 18 months, and dielectric stability improved by 28% under cyclic thermal loading.

-

Thermal Support Trays in Metallurgical Powder Sintering Lines

✅Key Advantages

1. Dimensional Flatness Under Thermal Cycling

Magnesia Stabilized Zirconia MSZ Ceramic Plate maintained <0.05 mm warpage after 50 sintering cycles between 200 °C and 1000 °C, ensuring even heat distribution and consistent product geometry during sintering.

2. High Load-Bearing Strength at Elevated Temperature

Even at 900 °C, the compressive strength remained above 1800 MPa, preventing deformation under heavy metallic powder loads. This capability allows stable multi-layer stacking in continuous production furnaces.

3. Microstructural Resistance to Grain Growth

The MgO-stabilized crystalline structure restricts grain coarsening during prolonged heating, preserving mechanical integrity and reducing crack propagation risk by 40% compared to conventional alumina trays.

✅ ️Problem Solved

A German metallurgy plant producing fine alloy components reported high reject rates due to warped alumina sintering trays that distorted at 950 °C. Replacing them with ADCERAX® Magnesia Stabilized Zirconia Ceramic Plate reduced tray deformation by 92%, extending fixture life from 1 month to over 6 months. Production yield increased by 15%, and dimensional accuracy of sintered parts was maintained within ±0.05 mm after repeated use.

-

Acidic Fluid Contact Linings in Chlor-Alkali Reactors

✅Key Advantages

1. Superior Corrosion Resistance in Mixed Media

In immersion tests with 10% H₂SO₄ and 10% NaOH for 72 hours, the plate showed <0.05% mass loss, outperforming coated steel by over 20× in acid-base dual exposure. Its chemical stability prevents contamination and structural weakening.

2. Zero Ion Leaching and Surface Integrity

XRF analysis confirmed no Mg²⁺ or Zr⁴⁺ leaching after 90 days of chlorine gas exposure at 400 °C, preserving purity and preventing chemical back-reaction within reactors.

3. Stable Phase Composition Under Reactive Atmosphere

The MgO-stabilized tetragonal-cubic structure resisted phase transition during sustained operation, ensuring consistent performance under 50 thermal-reactive cycles without microcrack formation or delamination.

✅ ️Problem Solved

A Japanese chlor-alkali manufacturer experienced rapid corrosion in PTFE-lined steel reactors, causing production halts every 60 days for liner replacement. After integrating ADCERAX® Magnesia Stabilized Zirconia Ceramic Plate as an inner lining, surface degradation dropped by 98%, with no measurable mass loss after 500 hours of mixed chlorine and brine contact at 420 °C. The replacement cycle extended beyond one year, reducing maintenance costs by approximately USD 18,000 annually.

Handling and Usage Guide for Magnesia Stabilized Zirconia Ceramic Plate

To ensure maximum performance and product longevity, it is essential that MSZ Ceramic Plate is handled, installed, and maintained in alignment with best practices. This guide outlines key precautions and usage tips to help customers avoid common pitfalls in real-world industrial operations.

-

Storage and Environmental Conditions

1. Store the plates in a dry, low-humidity environment, ideally below 60% RH, to prevent moisture absorption or surface contamination before use.

2. Avoid exposure to rapid temperature fluctuations during storage, especially if moved between cold and hot zones, as this may induce internal stress.

3. Stack vertically using spacers or foam, ensuring the surfaces are not directly contacting each other to avoid scratches or corner chipping.

-

Installation and Mounting Considerations

1. Use flat and evenly supported bases when installing plates into sintering lines, reactors, or cabinets to avoid bending stresses and premature warping.

2. Avoid overtightening mechanical fasteners or clamps, as local pressure points may lead to microcracking or eventual failure.

3. When used in high-load applications, ensure the plate's bearing surface is clean and aligned to distribute force uniformly across its structure.

-

Thermal Cycling and Operating Safety

1. Preheat plates gradually when operating in systems exceeding 800 °C, aiming for a controlled ramp-up rate under 5 °C/min whenever possible.

2. Never subject a cold plate to sudden contact with a hot surface, especially in sintering or heating chambers, as it may cause cracking from uneven expansion.

3. If used in a cycling furnace or kiln, allow a cool-down period before moving or re-handling to reduce fracture risks.

-

Transport, Handling, and Reuse

1. Always transport the plates in foam-padded cartons or crates, with corner protectors and vibration-dampening material to prevent edge breakage.

2. Do not stack unprotected plates on hard floors or metal surfaces, even briefly, to avoid micro-abrasions or contamination.

3. After thermal use, inspect for signs of surface erosion, color change, or mechanical fatigue before reusing in any critical application.