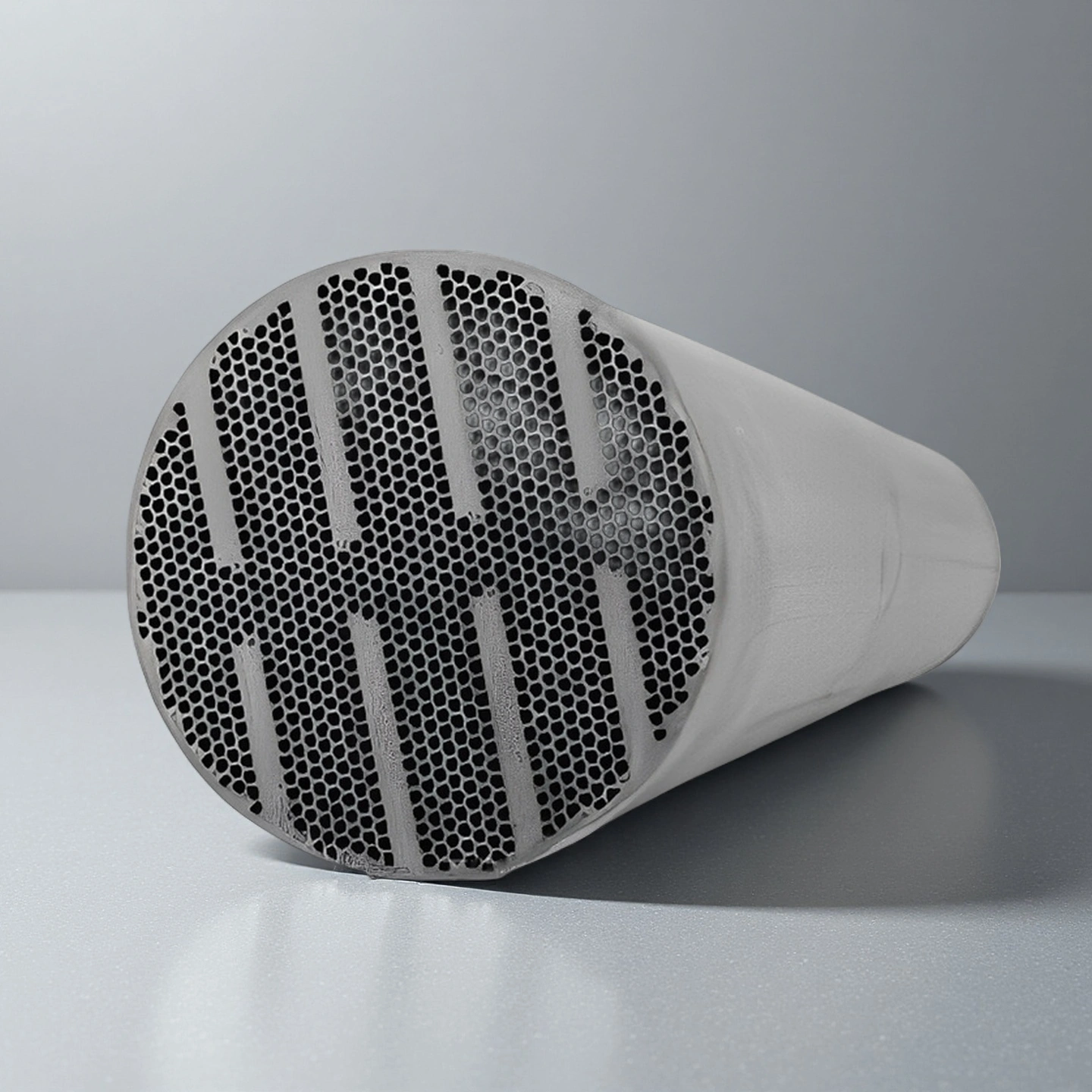

ADCERAX® Silicon Carbide Ceramic Column Membrane Module is engineered for stable ultrafiltration performance in municipal and industrial treatment systems where chemical variability, high suspended solids, and long operating cycles are common. Its recrystallized SiC structure, intrinsic hydrophilicity, and multi-channel flow design enable predictable permeability and reduced fouling under changing feedwater conditions. These characteristics allow continuous operation in applications such as drinking water purification, RO/NF pretreatment, mining wastewater, and chemical processing, ensuring consistent filtrate quality and reliable system uptime.

Advanced Material and Performance Features of Silicon Carbide Ceramic Column Membrane Module

-

Recrystallized SiC Structure with High-Porosity Transport Pathways

-

The membrane is formed through vapor–solid–vapor sintering at 2400°C, creating continuous SiC–SiC bonding that increases mechanical rigidity and maintains structural stability under variable feed pressures. The high-temperature process prevents micro-crack formation during long filtration cycles.

-

The open-cell structure features >45% porosity, improving water transport velocity and reducing trans-membrane pressure growth over extended operation. This level of porosity supports sustained performance even in feed streams containing elevated TSS loads.

-

Channel abrasion resistance is enabled by the inherent hardness of recrystallized SiC measured at Mohs 9, preventing erosion when handling particle concentrations commonly exceeding 500 mg/L in mining and industrial wastewater.

-

Intrinsic Hydrophilicity and Low Contact Angle Surface Behavior

-

The SiC surface maintains a measured contact angle of 0.3°, eliminating the need for external hydrophilic coating and enabling rapid wetting at system start-up. This property reduces air-locking events and stabilizes flux during the first filtration cycles.

-

The negative surface charge, with an iso-electric point near pH 3, lowers adsorption of colloids and organics across typical operating pH ranges from 2–12, reducing irreversible fouling accumulation. These electrostatic conditions improve flux recovery following chemical cleaning.

-

Flux performance reaches up to 3200 LMH in clean-water tests, which is 2–5× higher than polymeric UF membranes operating under similar pressure conditions. This permeability advantage compensates for high-turbidity or oil-bearing feedwater fluctuations.

-

Chemical and Thermal Stability Across Harsh Operating Conditions

-

The membrane maintains full chemical resistance across pH 1–14, allowing the use of strong acids, alkalis, and oxidants such as ozone and hydroxyl radicals. This compatibility supports aggressive cleaning cycles required in high-COD industrial wastewater.

-

Thermal operating stability is maintained from 1–45°C, allowing the module to withstand temperature variation during shutdown and restart conditions. These thermal margins reduce stress fractures that are common in lower-density ceramic membranes.

-

The module tolerates operating pressures up to 6 bar and maximum cross-flow TMP of 3 bar, enabling reliable performance during pressure surges and seasonal hydraulic fluctuations in municipal and RO pretreatment facilities.

Technical Specifications of Silicon Carbide Ceramic Column Membrane Module

The Silicon Carbide Ceramic Column Membrane Module operates with stable filtration efficiency under extreme chemical, thermal, and hydraulic conditions, supported by the material properties of recrystallized SiC, high-porosity transport channels, and a multi-channel geometry engineered for consistent flow and low fouling behavior.

| Property |

Specification |

| Material |

Recrystallized Silicon Carbide (R-SiC) |

| Porosity Level |

>45% open-cell network |

| Filtration Precision |

0.1 μm / 0.04 μm |

| Contact Angle |

0.3° intrinsic hydrophilicity |

| Pure Water Flux |

Up to 3200 LMH |

| Operating pH Range |

1–14 |

| Chemical Cleaning pH Range |

1–13 |

| Oxidant Resistance |

Compatible with ozone & hydroxyl radicals |

| Operating Temperature Window |

1–45°C |

| Maximum Operating Pressure |

6 bar |

| Maximum Trans-Membrane Differential |

3 bar |

| Flow Configuration |

Dead-end / Cross-flow (internal pressurization) |

| Surface Charge Behavior |

Negative charge above pH 3 |

| Membrane Geometry |

Multi-channel hydrodynamic structure |

| Housing Material Options |

UPVC / FRP / Stainless Steel |

Specifications of Silicon Carbide Ceramic Column Membrane Module

| Specifications Parameters |

| Effective Filtration Area |

11m² |

| Total Length |

2195mm |

| Center Distance |

1613mm |

| Diameter |

200mm |

| Flow Channel Diameter |

4.5mm |

| Inlet/Concentrate Port Size |

DN150 |

| Permeate Port Size |

DN50 |

| Membrane Housing Material |

UPVC |

| Ceramic Membrane Core Material |

Silicon Carbide |

| Filtration Precision |

0.02/0.04μm |

| Installation Method |

Vertical |

| Operating pH Range |

2-12 |

| Chemical Cleaning pH Range |

1-13 |

| Max Operating Pressure |

6bar |

| Max Transmembrane Pressure Difference |

3bar |

| Operating Temperature Range |

1-45℃ |

| Design Flux |

150-400 LMH |

| Filtration Method |

Dead-end/Cross-flow, Inside-out Operation |

| Backwash Flux |

200-600 LMH |

| Forward Flush |

1-2 times the permeate capacity |

|

Tubular Silicon Carbide Membrane |

|

Model |

Effective Filtration Area |

Total Length |

Membrane Shell Diameter |

Membrane Shell Material |

Ceramic Membrane Core Material |

Filtration Precision |

Installation Method |

|

AT-SICZ-1 |

11m² |

1702mm |

250mm |

UPVC |

Silicon Carbide |

0.1/0.04 μm |

Vertical |

|

AT-SICZ-2 |

13.5m² |

1702mm |

250mm |

UPVC |

Silicon Carbide |

0.1/0.04 μm |

Vertical |

|

AT-SICZ-3 |

14.5m² |

2102mm |

250mm |

UPVC |

Silicon Carbide |

0.1/0.04 μm |

Vertical |

|

AT-SICZ-4 |

17.5m² |

2102mm |

250mm |

UPVC |

Silicon Carbide |

0.1/0.04 μm |

Vertical |

|

AT-SICZ-5 |

21.0m² |

2102mm |

250mm |

UPVC/Stainless Steel/Fiberglass |

Silicon Carbide |

0.1/0.04 μm |

Vertical |

|

AT-SICZ-6 |

25m² |

1885mm |

245mm |

Fiberglass |

Silicon Carbide |

0.1/0.04 μm |

Vertical |

|

AT-SICZ-7 |

11m² |

2195mm |

250mm |

UPVC |

Silicon Carbide |

0.02/0.04um |

Vertical |

|

AT-SICZ-8 |

11.5m² |

1960mm |

250mm |

UPVC |

Silicon Carbide |

0.02/0.04um |

Vertical |

|

AT-SICZ-9 |

25.6m² |

1885mm |

245mm |

Fiberglass |

Silicon Carbide |

0.02/0.04um |

Vertical |

|

AT-SICZ-10 |

21m² |

1885mm |

245mm |

Fiberglass |

Silicon Carbide |

0.02/0.04um |

Vertical |

Packaging and Protection for Silicon Carbide Ceramic Column Membrane Module

Silicon Carbide Ceramic Column Membrane Module is packed in reinforced multi-layer cartons to ensure safe handling during international transport. Each unit is further secured with internal cushioning and moisture-resistant wrapping to prevent vibration and surface damage. The outer wooden frame provides added rigidity for long-distance shipping and maintains structural safety during loading, storage, and on-site delivery.

ADCERAX® Silicon Carbide Ceramic Column Membrane Module Resolves Critical Industrial Filtration Challenges

The Silicon Carbide Ceramic Column Membrane Module is deployed in complex liquid-treatment environments where fluctuating water chemistry, abrasive solids, and high organic loading routinely cause failure in polymeric or alumina-based filtration systems. By combining high open-porosity SiC channels, extreme chemical tolerance, and stable hydrophilicity, ADCERAX® enables predictable performance in mission-critical industrial processes that require high uptime and consistent filtrate quality.

ADCERAX® applies these characteristics to industrial scenarios that require reliable clarification, concentration, solvent recovery, and high-temperature fluid purification under continuous operation.

-

Silicon Carbide Ceramic Column Membrane Module for High-Turbidity Surface Water Stabilization

✅Key Advantages

1. Stable Flux Under Turbidity Spikes

When turbidity rises sharply within a few hours, the SiC multi-channel design maintains more than 80–90% of its initial flux while polymeric UF modules typically lose over 40% in the same period. This stability allows operators to keep filtration running during rainfall and seasonal sediment events without emergency shutdowns.

2. Consistent SDI for Downstream Protection

With a 0.1 μm cut-off and high-porosity structure above 45%, the module keeps SDI in a narrow band suitable for RO protection even when raw water quality deteriorates. This consistency reduces the need for frequent RO cleanings and supports long, uninterrupted operating campaigns.

3. Fast Recovery After Cleaning Cycles

Thanks to intrinsic hydrophilicity with a 0.3° contact angle, ADCERAX® modules typically recover more than 90% of baseline flux after routine chemical cleaning. This recovery profile remains stable over many cleaning cycles, improving long-term predictability for plant operators.

✅ ️Problem Solved

A surface water plant handling river intake experienced large turbidity swings during rainy seasons, with suspended solids and colloids surging within half a day. Polymeric UF units in the existing line showed flux losses of more than 40% during these events, forcing cleaning every 2–3 days and making it difficult to keep outlet turbidity within target limits. After integrating ADCERAX® Silicon Carbide Ceramic Column Membrane Module into the pretreatment stage, flux during turbidity peaks remained within 10–20% of the baseline and cleaning intervals extended to 7–10 days. The plant reported stable SDI values suitable for RO operation even when raw water conditions were at their worst, and unplanned shutdowns due to membrane instability were effectively eliminated.

-

Silicon Carbide Ceramic Column Membrane Module for High-Salinity Produced Water and Brine Treatment

✅Key Advantages

1. Resilience in High-TDS Brine Streams

The SiC matrix remains structurally stable in produced water and brine streams with TDS levels often exceeding 40,000 mg/L, where polymeric UF membranes show swelling and fatigue. This resilience allows the module to operate continuously in desalination and ZLD pretreatment lines without structural softening.

2. Full pH and Oxidant Compatibility

With a working pH window of 1–14 and compatibility with oxidants such as ozone and hydroxyl radicals, ADCERAX® modules support aggressive cleaning regimes tailored to brine fouling profiles. This capability reduces irreversible fouling from oil–water emulsions and silica complexes that would otherwise shorten membrane life.

3. Stable Permeability in Oil- and Silica-Rich Feeds

The multi-channel SiC design provides stable hydraulic performance even when emulsified oils and fine silica particles are present in significant concentrations. Field data show that flux decline remains in the 15–25% range over extended runs, compared to losses exceeding 50% with conventional UF elements in similar brine conditions.

✅ ️Problem Solved

In a produced-water treatment facility feeding a desalination unit, polymeric UF membranes experienced rapid permeability loss when exposed to high-TDS brine containing emulsified hydrocarbons and silica. Flux decline frequently exceeded 50% within a few weeks, forcing frequent chemical cleaning and causing RO feed SDI to rise above acceptable thresholds. After replacement with ADCERAX® Silicon Carbide Ceramic Column Membrane Module, the pretreatment stage maintained controlled flux decline in the 15–25% range over comparable operating periods. Cleaning frequency was reduced by roughly one third, and SDI at the RO inlet remained within the target band for extended campaigns, improving the stability of the entire desalination train.

-

Silicon Carbide Ceramic Column Membrane Module for Chemical-Industry Organics and Solvent-Laden Wastewater

✅Key Advantages

1. Inert Response to Surfactants and Solvents

The recrystallized SiC structure does not swell or soften in the presence of common organic solvents and surfactants found in fine-chemical wastewater. Testing shows that the module maintains more than 90% of its mechanical strength and geometry after repeated exposure to solvent-rich streams where polymeric membranes often deform.

2. Controlled Flux Loss with High-COD Organics

In streams containing dyes, polymers, and other high-COD macromolecules, ADCERAX® modules typically limit long-term flux decline to 20–30% over defined operating campaigns. This behavior contrasts with polymer UF systems, which can experience permeability reductions of 50% or more under similar organic loading.

3. Stable Performance Across Repeated Oxidant Cleaning

The SiC membrane withstands repeated oxidant-based cleaning cycles without loss of hydrophilicity or structural integrity. Plants report that flux recovery after each cleaning cycle consistently reaches 85–95% of the initial value, even after many months of operation in solvent-laden wastewater.

✅ ️Problem Solved

A specialty-chemical plant treating colored, high-COD wastewater with surfactants and solvents initially relied on polymeric UF membranes that rapidly fouled and lost more than 50% of their permeability within a short number of operating weeks. Despite intensified cleaning, organic penetration and swelling led to frequent membrane replacement and unstable throughput. After installing ADCERAX® Silicon Carbide Ceramic Column Membrane Module, the same line showed controlled flux loss in the 20–30% range over similar operating durations. Routine oxidant cleaning restored 85–95% of the starting flux after each cycle, and the plant achieved stable hydraulic performance without recurring membrane change-outs driven by solvent attack.

How to Operate ADCERAX® Silicon Carbide Ceramic Column Membrane Module Safely and Efficiently

The Silicon Carbide Ceramic Column Membrane Module should be operated with clear installation, start-up, cleaning, and storage practices so that flux stability, SDI control, and service life are fully maintained across demanding projects. This user guide helps operators, engineers, and maintenance teams understand the key points that matter in day-to-day use, from first connection to long-term shutdown preparation.

-

Installation Checklist Before First Use

1. Ensure the module is mounted in the designed vertical position with all flange connections tightened to the specified torque values. Pipework should be aligned so that no external stress is transmitted to the housing or nozzle region. Misalignment and unsupported pipe loads are common causes of seal damage and premature leakage.

2. Rinse the entire line with clean water to remove debris, oil, and dust from new piping before introducing feedwater. All vent points should be opened during priming to remove trapped air and protect the SiC channels from water hammer. A smooth, gradual filling sequence reduces mechanical shock on the ceramic structure.

3. Confirm that pressure gauges, flowmeters, and temperature sensors are calibrated and installed at the recommended locations around the module. This monitoring hardware enables precise control of TMP and flux during commissioning and later optimization. Accurate instrumentation is essential for interpreting performance trends and planning cleaning cycles.

-

Start-Up and Operating Condition Control

1. During initial start-up, increase feed pressure slowly until the target flux range is reached rather than applying full pressure immediately. This approach allows the SiC membrane to wet fully and stabilizes permeate flow through the multi-channel structure. Rapid pressurization can create transient TMP spikes that shorten gasket life.

2. Keep operating conditions inside the specified envelope of 1–45°C, pH 1–14, and a maximum operating pressure of 6 bar while observing a maximum TMP of 3 bar. Staying within these ranges ensures that the membrane, seals, and housing work in a balanced hydraulic regime. Consistent operation inside the design window greatly extends service life.

3. Track flux, TMP, and SDI regularly and log them as part of routine plant data collection. Trend analysis helps identify gradual fouling or hydraulic changes long before performance reaches alarm limits. Early detection enables scheduled cleaning instead of unplanned shutdowns.

-

Cleaning Strategy for Stable Flux and Fouling Control

1. Design cleaning recipes according to foulant type, using alkaline solutions for organic fouling and acidic solutions for inorganic scaling, keeping the cleaning pH within 1–13. Clean-in-place sequences should combine chemical action with appropriate soaking and flushing steps. A correctly chosen chemistry often restores flux more effectively than simply increasing cleaning frequency.

2. Apply oxidants such as hypochlorite or ozone only within the recommended concentration limits and contact times, and always flush thoroughly after each step. The SiC membrane tolerates these oxidants, but seals and downstream equipment must also be protected. Proper neutralization prevents residual oxidant from affecting other process units.

3. Evaluate cleaning effectiveness by comparing post-cleaning flux to the original baseline established at commissioning. When flux recovery remains above 85–95%, the cleaning program is considered effective; lower values may indicate incorrect chemistry or insufficient contact time. Regular evaluation helps refine cleaning protocols and keeps operating costs under control.

-

Storage, Handling, and Long-Term Shutdown Practices

1. For short shutdowns, keep the module filled with clean permeate or treated water and protect it from freezing conditions. This prevents air ingress and minimizes the risk of biological growth in stagnant feedwater. Avoid draining the module repeatedly unless specified by plant procedures.

2. For longer shutdowns, drain the module, rinse with clean water, and, if required, preserve with a suitable storage solution recommended by the engineering team. All connections should be capped or sealed to prevent dust and moisture ingress. Correct preservation reduces the need for deep cleaning when the system is restarted.

3. During handling, lifting points on the housing or frame should be used, and the ceramic core must never be subjected to direct impact. Transport supports and packaging should be kept in place until the module is ready for final installation. Mechanical shocks during handling are one of the few conditions that can damage the SiC element despite its high compressive strength.

![]()