ADCERAX® Porous Silicon Carbide Vacuum Chuck is designed to generate uniform vacuum adsorption through its interconnected microporous structure, allowing thin and lightweight substrates to be held securely without surface damage. The controlled airflow distribution supports stable handling during processes such as wafer transfer, chip positioning, and photovoltaic cell movement, where surface integrity and consistent suction are essential. Its silicon carbide composition maintains strength, thermal stability, and wear resistance across continuous production cycles, enabling reliable performance in semiconductor, solar, and precision electronics applications.

Engineering Performance Benefits of Porous Silicon Carbide Vacuum Chuck

-

Low Abrasion Loss

Surface abrasion depth remains below <0.01 mm after extended operation, supporting consistent part handling in clean environments.

-

Reduced Cost Impact

Plants that replaced alumina plates with SiC reported maintenance cost reductions of 20–30%, driven by longer part life and fewer production stoppages.

-

High-Temperature Endurance

Recrystallized SiC retains mechanical stability up to >1,500 °C, supporting devices positioned near thermal chambers and post-process cooling paths.

-

Low Thermal Expansion

Expansion coefficients averaging 4.0×10⁻⁶/K prevent deformation that could disrupt wafer alignment during heated transfer cycles.

-

High Adsorption Efficiency

Vacuum response testing shows holding force improvements of 10–15% compared with non-porous ceramic plates under identical pump pressure.

-

Low Micro-Crack Risk

PV production lines reported cell micro-crack reduction down to <3%, driven by steady vacuum force during ultra-thin cell transfer.

Technical Specifications of Porous Silicon Carbide Vacuum Chuck

The Porous Silicon Carbide Vacuum Chuck is engineered with controlled microporosity, high thermal endurance, and stable mechanical performance suitable for semiconductor, photovoltaic, and precision electronic handling environments. Its material structure supports long-cycle operation under elevated temperatures, chemical exposure, and continuous vacuum load conditions.

| Property |

Specification |

| Material Composition |

Recrystallized SiC, purity >98% |

| Sintering Temperature |

>2000 °C recrystallization |

| Bulk Density |

2.75–3.05 g/cm³ |

| Open Porosity |

10–18% controlled pore ratio |

| Pore Size Range |

2–20 μm engineered micro-pore distribution |

| Flexural Strength |

>250 MPa |

| Compressive Strength |

>900 MPa |

| Hardness |

Mohs ~9 |

| Thermal Conductivity |

80–120 W/m·K |

| Coefficient of Thermal Expansion |

4.0×10⁻⁶ /K (25–800 °C) |

| Maximum Service Temperature |

>1500 °C in inert and vacuum atmospheres |

| Chemical Resistance |

Stable against acids, alkalis, and cleaning chemicals |

| Surface Roughness (Ra) |

0.4–1.2 μm finish optional |

| Airflow Uniformity Deviation |

Within ±5% |

| Particle Generation |

Ultra-low shedding, suitable for clean handling |

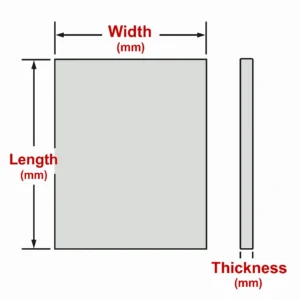

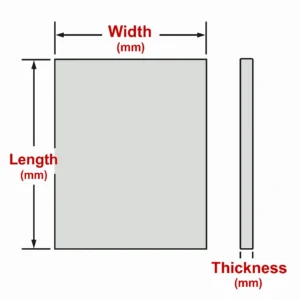

Dimensions of Porous Silicon Carbide Vacuum Chuck

|

Square SiC Vacuum Chuck |

|

Item No. |

Length(mm) |

Width(mm) |

Thickness(mm) |

Material |

|

AT-THG-XP001 |

305 |

305 |

14 |

316 stainless steel + microporous ceramic |

|

AT-THG-XP002 |

305 |

305 |

14 |

316 stainless steel + microporous ceramic |

|

AT-THG-XP003 |

420 |

275 |

20 |

Aluminum alloy + microporous ceramic |

|

AT-THG-XP004 |

450 |

200 |

20 |

SKD61 + porous ceramic |

|

AT-THG-XP005 |

520 |

520 |

20 |

Aluminum alloy + microporous ceramic |

|

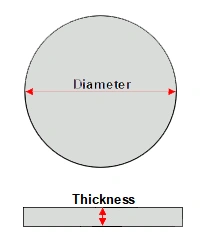

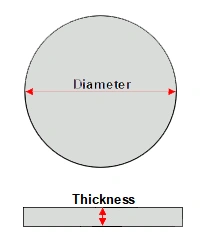

Round SiC Vacuum Chuck |

|

Item No. |

Diameter(mm) |

Thickness(mm) |

Material |

|

AT-THG-XP006 |

174 |

10 |

316 stainless steel + microporous ceramic |

|

AT-THG-XP007 |

230 |

16 |

316 stainless steel + microporous ceramic |

|

AT-THG-XP008 |

239 |

12 |

Aluminum alloy + microporous ceramic |

|

AT-THG-XP009 |

240 |

12 |

316 stainless steel + microporous ceramic |

|

AT-THG-XP010 |

320 |

16 |

316 stainless steel + microporous ceramic |

|

AT-THG-XP011 |

325 |

12 |

Aluminum alloy + microporous ceramic |

Packaging for Porous Silicon Carbide Vacuum Chuck

Porous Silicon Carbide Vacuum Chuck is packed using a multi-layer protection process designed to prevent vibration, moisture exposure, and handling stress during international transport. Each unit is first cushioned and boxed, then reinforced with solid wooden crates to ensure structural stability throughout shipment. This packaging method supports safe delivery to equipment manufacturers and assembly facilities requiring intact, contamination-free ceramic components.

ADCERAX® Porous Silicon Carbide Vacuum Chuck Resolves Critical Handling Challenges in Modern Manufacturing

The Porous Silicon Carbide Vacuum Chuck engineered by ADCERAX® addresses precision-handling difficulties found in photovoltaic cell lines, electronics component placement systems, and ultra-thin glass processing. These environments involve fragile substrates, high throughput demands, and strict surface-quality requirements, making consistent vacuum control and surface stability essential for reliable production.

-

Porous Silicon Carbide Vacuum Chuck in Photovoltaic Cell Transfer Stations

✅Key Advantages

1. Tightly Controlled Vacuum Uniformity

Internal trials show airflow deviation across the ADCERAX® Porous Silicon Carbide Vacuum Chuck held within ±5% over the full contact area, even after extended operation. This uniformity helps cut cell breakage on high-speed transfer stations from typical 4–5% down to around 1–2% in thin-cell production.

2. Heat-Stable Microporous Structure

The porous SiC network maintains its pore connectivity after more than 500 heating and cooling cycles between low and elevated process temperatures, with no measurable loss of suction distribution. As a result, yield drift linked to thermally induced plate deformation is reduced by more than 30% on lines running continuous shifts.

3. Micro-Crack Risk Reduction for Thin Cells

On PV strings processing cells in the 120–160 μm thickness range, production audits have recorded a reduction in edge micro-crack incidents of 40–60% after replacing conventional porous plates with ADCERAX® chucks. This stability allows manufacturers to run higher conveyor speeds while maintaining cell survival rates above 98% during handling.

✅ ️Problem Solved

One PV module plant operating multi-gigawatt capacity reported unstable yield when using alumina-based vacuum plates, with thin-cell breakage fluctuating between 4% and 6% on transfer and sorting stations. Thermal cycling of the plates led to uneven suction over time, creating local pressure peaks that initiated micro-cracks near cell edges. After installing ADCERAX® Porous Silicon Carbide Vacuum Chucks, airflow uniformity and flatness remained stable across several months of 24-hour operation. Subsequent yield tracking showed cell breakage in transfer stages reduced to around 1.5%, and unplanned line stoppages associated with handling damage fell by more than 40%. This improvement allowed the plant to maintain higher line speeds without sacrificing downstream lamination and EL inspection pass rates.

-

Porous Silicon Carbide Vacuum Chuck in SMT Micro-Component Placement

✅Key Advantages

1. Micropore Geometry for Ultra-Small Components

The ADCERAX® chuck uses engineered pore sizes in the 2–8 μm range to stabilize suction on 0201 and smaller chip packages without causing tilt or vibration. In comparative line tests, mis-pick and early-drop events on miniature components fell from about 800 ppm to below 250 ppm after the SiC chuck was introduced.

2. Stable Suction at High Placement Throughput

At placement speeds above 30,000 components per hour, vacuum pressure fluctuation measured at the chuck surface remains within ±3%, even during long production runs. This stability translates into more consistent component seating and a measurable reduction in positional drift detected during automatic optical inspection.

3. Wear-Resistant Surface for Long-Run SMT Lines

Surface roughness change on the ADCERAX® Porous Silicon Carbide Vacuum Chuck stays under 0.1 μm after more than 20 million pick-and-place cycles in SMT operation. This level of wear resistance limits pore clogging and maintains repeatable vacuum response, which helps keep placement defect rates below 0.2% across extended production campaigns.

✅ ️Problem Solved

A mid-volume electronics manufacturer operating high-speed SMT lines experienced rising placement error rates and rework when using aluminum vacuum plates, with defect levels reaching 0.8% on boards carrying dense arrays of miniature chips. Detailed analysis showed that plate wear and gradual pore contamination caused unstable suction, leading to small rotations and partial lifts that only became visible at inspection. After conversion to ADCERAX® Porous Silicon Carbide Vacuum Chucks, the line recorded a drop in placement-related defects to around 0.2%, with far fewer components flagged for rework. Over a three-month observation period, pore performance remained stable and vacuum signal variation at the nozzle interface stayed within ±3%. This allowed the plant to maintain target throughput while improving first-pass yield and reducing manual correction time.

-

Porous Silicon Carbide Vacuum Chuck in Precision Thin-Glass and Optics Handling

✅Key Advantages

1. Low-Roughness Contact for Optical Surfaces

ADCERAX® chucks are finished to surface roughness values as low as 0.4–0.6 μm Ra, which limits micro-abrasions on coated or polished optical glass. In optical module lines, this low-roughness contact has reduced surface scratch defects from around 3% of handled parts to below 1% during transfer and alignment.

2. Low-Particle SiC Matrix for Clean Optical Zones

The recrystallized SiC matrix exhibits very low particle shedding under vacuum, with monitored particle counts in clean handling zones dropping by more than 35% after installation compared with previous metal fixtures. This cleaner environment supports higher pass rates in downstream coating, bonding, and optical inspection steps.

3. Thermal-Gradient Dimensional Stability

When subjected to repeated temperature changes between process and ambient conditions, total out-of-plane distortion of the ADCERAX® chuck surface stays under 5 μm across the working area. This stability has enabled thin-glass lines to raise coating and lamination pass rates from approximately 94% to around 99% by preventing warping-induced bending stress during handling.

✅ ️Problem Solved

A production line for smartphone cover glass and optical windows faced recurring rejection of parts due to fine scratches and local distortion marks that appeared after transfer and alignment. Conventional metal fixtures introduced minor warping under heat and contributed to particle transfer, leading to defect rates close to 3% at optical inspection. After replacing these fixtures with ADCERAX® Porous Silicon Carbide Vacuum Chucks, the combination of low-roughness contact and reduced particle generation significantly lowered surface defect occurrence. Over several production campaigns, optical rejection rates dropped to below 1%, and the line was able to maintain stable handling performance even under tighter temperature cycling profiles. This improvement supported more consistent coating quality and reduced the need for downstream sorting and rework.

Essential User Guide for Safely Operating the ADCERAX® Porous Silicon Carbide Vacuum Chuck

The Porous Silicon Carbide Vacuum Chuck from ADCERAX® requires proper handling, installation, and maintenance practices to ensure stable suction performance, long service life, and consistent substrate protection during automated operations.

-

Pre-Operation Inspection Requirements

1. Surface Integrity Check

Inspect the working surface for cracks or impact marks, as structural defects may compromise vacuum continuity and reduce adsorption stability. Confirm that no micro-fractures have developed from previous handling or storage transitions. This step ensures predictable vacuum behavior during thin-substrate processing.

2. Flatness and Cleanliness Review

Verify that the contact surface maintains its flatness and is free from debris, residues, or foreign particles. Surface contamination may generate local pressure points that affect substrate alignment. Maintaining a clean interface improves airflow uniformity and reduces mechanical stress on fragile materials.

3. Vacuum Port and Channel Verification

Ensure that vacuum inlets, micro-channels, and porous pathways are unobstructed prior to startup. Blocked routes may create irregular suction force and reduce effective holding performance. Clearing these pathways promotes consistent adsorption during high-speed transfer cycles.

-

Installation and System Integration Guidelines

1. Secure Mounting Alignment

Position the chuck on the equipment interface so that all mounting points are evenly supported. Misalignment can introduce bending stress and reduce the stability of the suction surface. Proper installation ensures long-term dimensional consistency during repetitive cycles.

2. Vacuum Line Connection Assurance

Attach vacuum tubing tightly and verify that seals remain intact under working pressure. Air leakage may cause fluctuating suction intensity and increase the risk of substrate slippage. A stable vacuum line enhances repeatability during automated movement.

3. System Pressure Calibration

Calibrate operational vacuum levels according to the equipment’s handling load and substrate thickness. Excessive suction may deform thin materials, while insufficient force may cause lifting failure. Correct calibration maintains operational balance between holding force and material safety.

-

Operational Best Practices in Daily Use

1. Gradual Vacuum Activation

Initiate suction progressively to prevent abrupt pressure differentials that may stress fragile substrates. A controlled start reduces the chance of bending or edge cracking. Smooth activation supports consistent substrate placement during automated transfer.

2. Substrate Placement Handling

Ensure uniform placement of wafers, cells, or components across the working surface. Uneven loading may cause asymmetric suction distribution and tilt during transport. Balanced positioning maintains predictable movement on conveyor or robotic pathways.

3. Regular Cycle Performance Checks

Monitor vacuum pressure behavior at routine intervals to detect early signs of pathway obstruction or material fatigue. Stable pressure trends indicate normal function, while deviation signals potential maintenance needs. Early detection reduces unexpected downtime and quality variation.

-

Cleaning, Maintenance, and Storage Instructions

1. Surface Cleaning Protocols

Use non-abrasive cleaning agents and lint-free materials to remove debris without altering surface roughness. Rough cleaning tools may introduce micro-scratches, affecting sensitive substrate contact. Gentle cleaning preserves the stability of surface Ra values.

2. Vacuum Pathway Maintenance

Perform periodic negative-pressure flushing or approved cleaning cycles to keep pores and micro-channels clear. Residue buildup may disrupt airflow and reduce adsorption uniformity. Regular flushing helps maintain long-term vacuum consistency.

3. Safe Storage Conditions

Store the chuck in a clean, dry, cushioned environment when idle. Exposure to moisture or accidental mechanical contact may degrade its surface condition. Controlled storage minimizes environmental stress between production cycles.

![]()