Silicon carbide thermal conductive ceramic plates are for demanding thermal management applications in power electronics, automotive control systems, and industrial laser equipment. With high thermal conductivity, low thermal expansion, and excellent mechanical strength, these plates provide reliable performance under high thermal loads.

Silicon Carbide Ceramic Plate Advantages

- High thermal conductivity (≥120 W/m·K) ensures rapid heat transfer in high-power modules.

- Excellent thermal shock resistance minimizes cracking during rapid temperature changes.

- Electrically insulating and mechanically strong, suitable for high-voltage applications.

- Dimensional precision up to ±0.1mm supports tight assembly tolerances.

- Compatible with metalized surfaces for direct bonding or soldering.

Specifications of SiC Ceramic Plate

| Silicon Carbide Tray for ICP | ||||

| Item No. | Length(mm) | Width(mm) | Thickness(%) | Shape |

| AT-SIC-P1047 | 10 | 10 | 1.5 | Tablet |

| AT-SIC-P1048 | 10 | 10 | 2 | Tablet |

| AT-SIC-P1049 | 10 | 10 | 3 | Tablet |

| AT-SIC-P1050 | 10 | 10 | 5 | Tablet |

| AT-SIC-P1051 | 10 | 12 | 2.5 | Tablet |

| AT-SIC-P1052 | 10 | 15 | 2 | Tablet |

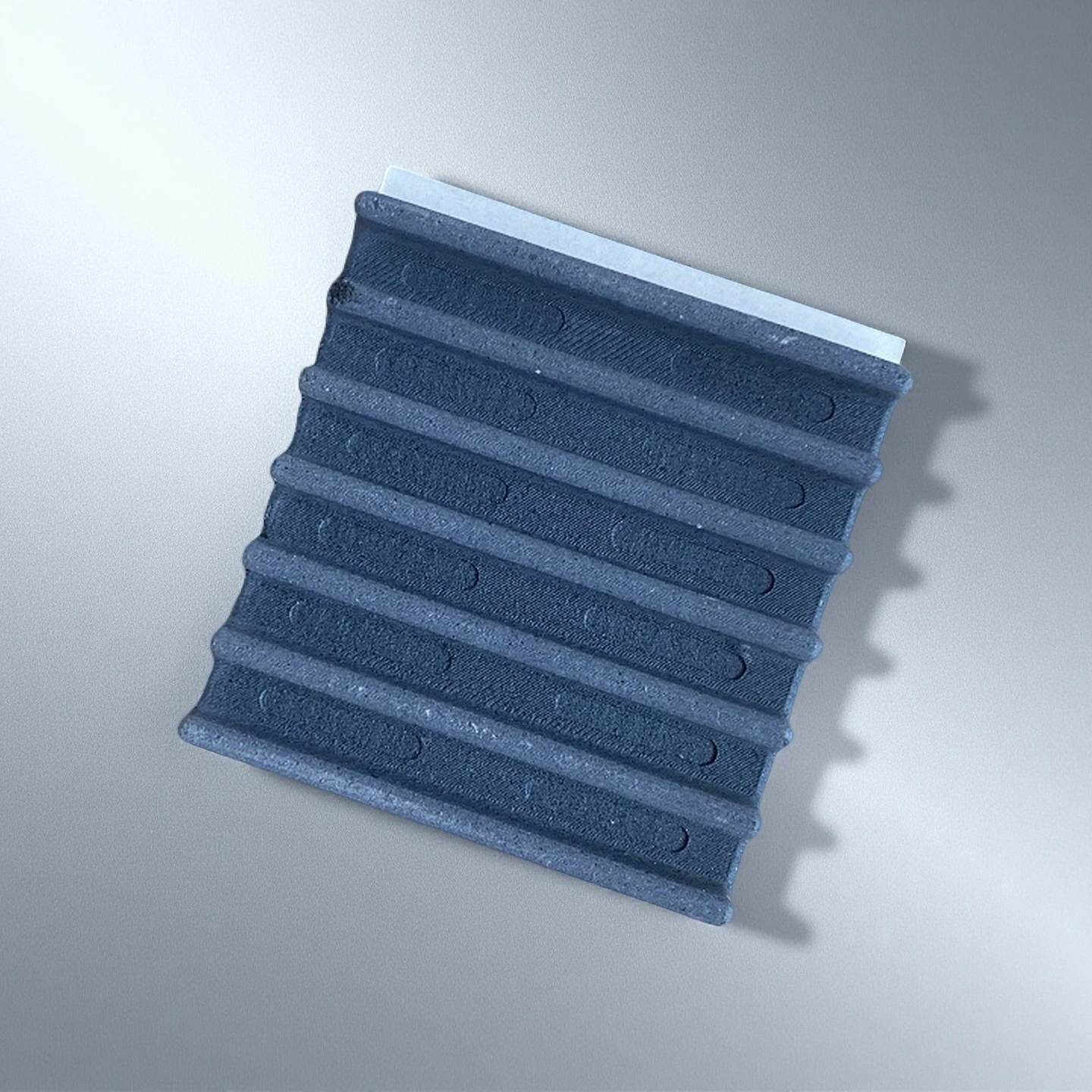

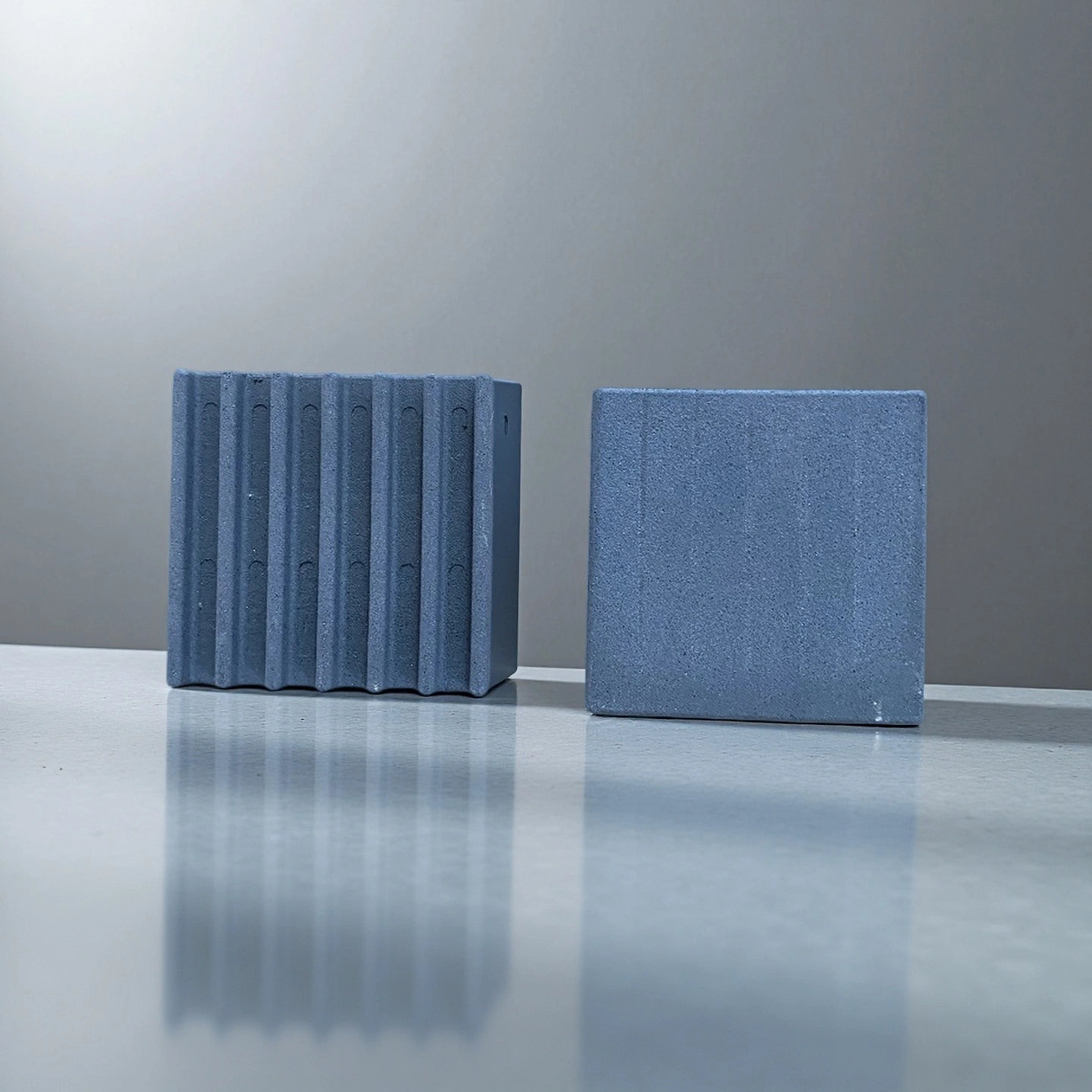

| AT-SIC-P1053 | 11 | 13 | 5 | Ripple |

| AT-SIC-P1054 | 15 | 15 | 2 | Tablet |

| AT-SIC-P1055 | 15 | 15 | 3 | Tablet |

| AT-SIC-P1056 | 15 | 15 | 4 | Tablet |

| AT-SIC-P1057 | 15 | 15 | 5 | Tablet |

| AT-SIC-P1058 | 20 | 20 | 10 | Tablet |

| AT-SIC-P1059 | 20 | 20 | 10 | Groove |

| AT-SIC-P1060 | 20 | 20 | 2.5 | Tablet |

| AT-SIC-P1061 | 20 | 20 | 2 | Tablet |

| AT-SIC-P1062 | 20 | 20 | 5 | Tablet |

| AT-SIC-P1063 | 20 | 20 | 5 | Ripple |

| AT-SIC-P1064 | 25 | 25 | 10 | Ripple |

| AT-SIC-P1065 | 25 | 25 | 2.5 | Tablet |

| AT-SIC-P1066 | 25 | 25 | 3 | Tablet |

| AT-SIC-P1067 | 25 | 25 | 5 | Tablet |

| AT-SIC-P1068 | 25 | 25 | 5 | Ripple |

| AT-SIC-P1069 | 25 | 25 | 8 | Ripple |

| AT-SIC-P1070 | 30 | 30 | 10 | Ripple |

| AT-SIC-P1071 | 30 | 30 | 2.5 | Tablet |

| AT-SIC-P1072 | 30 | 30 | 5 | Tablet |

| AT-SIC-P1073 | 30 | 30 | 5 | Ripple |

| AT-SIC-P1074 | 30 | 30 | 8 | Ripple |

| AT-SIC-P1075 | 35 | 35 | 10 | Ripple |

| AT-SIC-P1076 | 40 | 40 | 3 | Tablet |

| AT-SIC-P1077 | 40 | 40 | 4 | Tablet |

| AT-SIC-P1078 | 40 | 40 | 5 | Tablet |

| AT-SIC-P1079 | 40 | 40 | 5 | Ripple |

| AT-SIC-P1080 | 40 | 40 | 7 | Ripple |

| AT-SIC-P1081 | 40 | 40 | 8 | Ripple |

| AT-SIC-P1082 | 50 | 50 | 5 | Tablet |

| AT-SIC-P1083 | 50 | 50 | 5 | With hole |

| AT-SIC-P1084 | 60 | 60 | 5 | Tablet |

| AT-SIC-P1085 | 60 | 60 | 8 | Tablet |

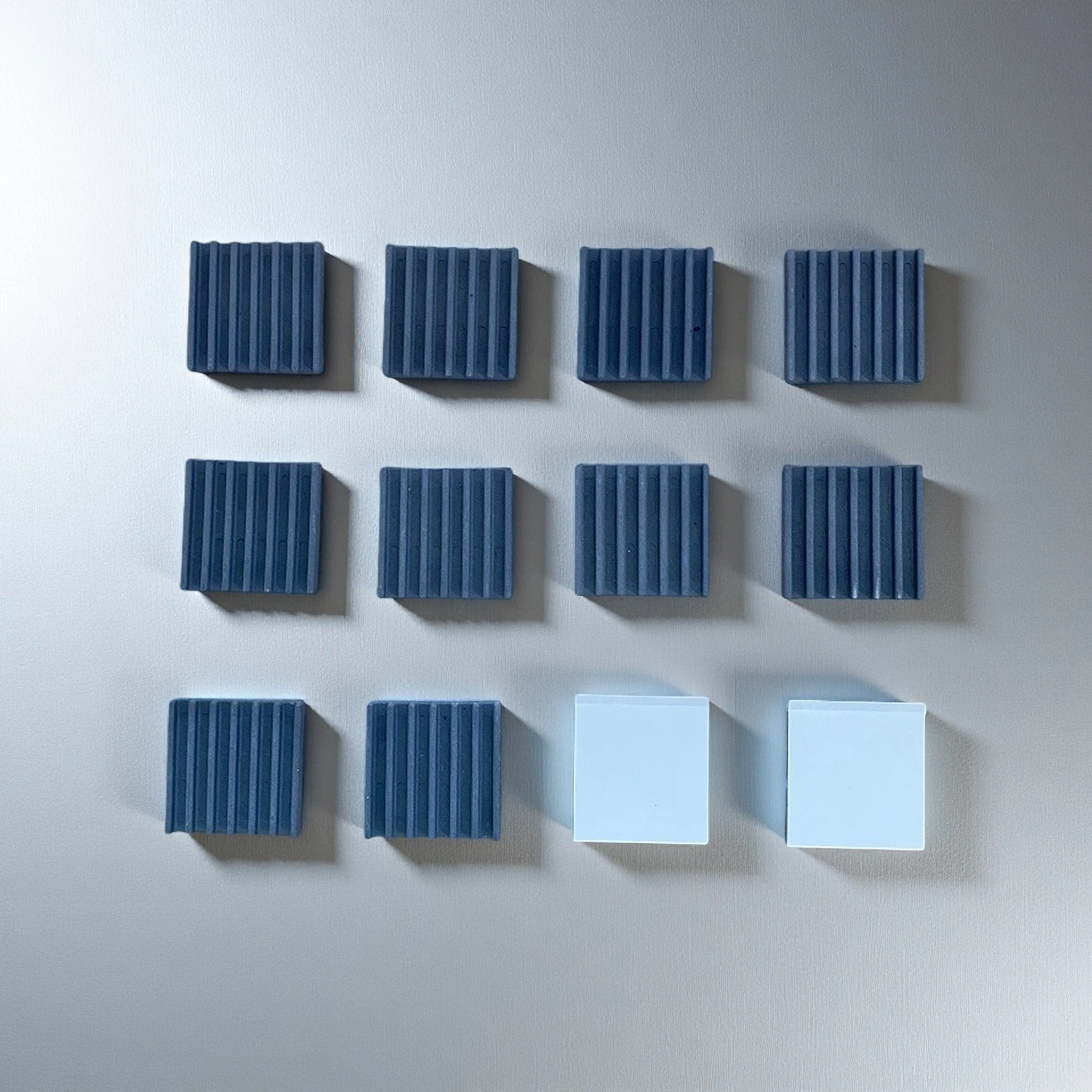

Packing

- Each heat sink is individually packed in anti-static foam

- Sealed and moisture-proof packaging