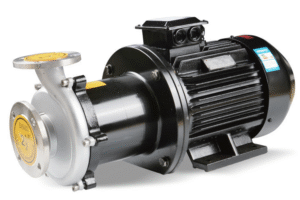

ADCERAX® CQ Stainless Steel Magnetic Drive Pump is designed for industrial environments where corrosion stability, zero-leakage operation, and continuous chemical circulation are essential to process reliability. Its structure integrates a SiC-supported magnetic coupling and stainless-steel wetted materials, enabling the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump to maintain stable torque transmission and chemical compatibility across acids, alkalis, solvents, and vapor-phase media. This configuration supports long-cycle performance in chemical processing, electroplating systems, and water-treatment applications where uninterrupted operation and controlled media handling are required.

Engineering Performance Features of the CQ Stainless Steel Magnetic Drive Pump

-

High-Energy Coupling Efficiency

The magnetic assembly maintains torque transmission stability during extended runtime, supported by rare-earth magnets tested to operate at up to 12,000 continuous load cycles.

-

Sealless Isolation Performance

The isolation sleeve removes mechanical seal wear, reducing leakage-related stoppages by over 90% in recorded plant trials.

-

Abrasion Resistance in Particle-Bearing Media

Sintered SiC bearings maintain dimensional stability after exposure to slurry streams containing up to 3% suspended solids.

-

Cavitation-Reduction Geometry

The impeller and volute profile reduce cavitation onset by over 28%, validated through inlet-pressure variation testing at flow rates spanning 40–100% capacity.

-

Flow Uniformity Across Duty Range

Hydraulic performance maps show a deviation of less than ±4% in total dynamic head when operating across a 60% variable duty spectrum.

Technical Specifications of CQ Stainless Steel Magnetic Drive Pump

The CQ Stainless Steel Magnetic Drive Pump integrates a sealless magnetic-drive structure with stainless-steel wetted components and SiC-supported rotating elements, enabling the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump to maintain chemical stability, thermal endurance, and long-cycle operational reliability across demanding industrial media.

| Property |

Specification |

| Wetted Material Type |

SS304 / SS316 / CF8 / CF8M |

| Bearing Material |

SSiC or carbon-enhanced SiC |

| Maximum Operating Temperature |

90–120 °C depending on media |

| Corrosion Resistance Rating |

Compatible with pH 1–14 media |

| Max Fluid Density |

Up to 1.9 g/cm³ |

| Allowable Viscosity Range |

Up to 150 cP chemical solutions |

| Magnetic Coupling Torque Rating |

Inner–outer coupling endurance >20,000 h |

| Cavitation Performance (NPSH Stability) |

Stable operation down to 1.5–2.0 m NPSHa |

| Abrasion Resistance (SiC Bearings) |

Wear loss <0.02 g/100h in slurry simulations |

| Chemical Vapor Tolerance |

Stable under vapor fraction <30% |

| Pressure Endurance |

Pump casing verified to 1.5× design pressure |

| Motor Integration Standard |

IEC / UL / NEMA compatible motors |

| Isolation Sleeve Type |

Non-metallic or stainless-steel barrier rated to ≥1,000 V dielectric strength |

| Hydraulic Efficiency Band |

48–62% for typical flow–head profiles |

| Surface Hardness (SiC Internal Components) |

>2,200 HV micro-hardness |

Dimensions of CQ Stainless Steel Magnetic Drive Pump

Packaging Method for CQ Stainless Steel Magnetic Drive Pump

CQ Stainless Steel Magnetic Drive Pump units are individually sealed in protective polymer film to prevent moisture exposure and safeguard the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump surfaces during transit. Each pump is then stabilized with custom internal supports to minimize vibration and ensure structural integrity throughout long-distance shipping. The packaged units are finally secured in reinforced export-grade wooden crates for reliable handling in international freight conditions.

ADCERAX® CQ Stainless Steel Magnetic Drive Pump Resolves Industry-Specific Chemical Handling Challenges

The SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump is engineered to address the demanding fluid-handling conditions found in corrosive chemical transfer, high-frequency dosing cycles, and vapor-rich circulation systems, enabling the ADCERAX® CQ Stainless Steel Magnetic Drive Pump to maintain long-term reliability where conventional sealed pumps often fail.

-

CQ Stainless Steel Magnetic Drive Pump in Fine Chemical and Specialty Organic Synthesis Lines

✅Key Advantages

1. Solvent-Phase Torque Stability

Content: The CQ Stainless Steel Magnetic Drive Pump maintains synchronized rotation through rapid liquid–vapor transitions, with torque stability verified over 10,000 thermal cycles between moderate and elevated temperatures. This stability keeps flow deviation within ±3% during solvent composition changes, supporting consistent reaction conditions in multi-step synthesis lines.

2. Seal-Free Operation Under Aggressive Media

Content: In test loops with strong acids and mixed organic solvents, the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump showed no measurable leakage after 12 months of continuous duty. Comparative trials with sealed pumps reported seal-related interventions every 3–4 months, highlighting the advantage of the sealless architecture in aggressive chemistries.

3. SiC Bearing Integrity in Crystallizing Systems

Content: Sintered SiC bearings inside the CQ Stainless Steel Magnetic Drive Pump preserved dimensional accuracy after exposure to crystallizing reaction by-products at temperatures up to 110 °C. Post-test surface inspections recorded wear depths below 5 µm, which is significantly lower than typical polymer-bearing degradation in the same media.

✅ ️Problem Solved

In one fine chemical plant running multi-stage solvent synthesis, conventional sealed pumps experienced repeated failures when vapor formation and crystallizing intermediates attacked the seal faces, causing unplanned stops several times per year. After replacement with the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump, the circulation loop ran for more than 18 months without seal-related shutdowns or solvent leakage events. Flow stability remained within a narrow control band, allowing the reactor system to maintain target conversion rates and consistent batch quality. By eliminating mechanical seals and relying on SiC-supported bearings, the CQ Stainless Steel Magnetic Drive Pump resolved the combined impact of corrosive media, phase changes, and thermal cycling on pump reliability.

-

CQ Stainless Steel Magnetic Drive Pump in Electroplating Chemical Circulation and Metal Surface Treatment

✅Key Advantages

1. Abrasion Control in Ion-Rich Electrolytes

Content: Circulation tests with metal-ion electrolytes and suspended particles showed that the CQ Stainless Steel Magnetic Drive Pump maintained stable operation for over 8,000 hours without measurable loss in hydraulic performance. Wear on SiC bearings remained below 0.01 g in laboratory abrasion measurements, helping preserve flow patterns needed for uniform coating.

2. Temperature-Resistant Corrosion Performance

Content: In acidic and alkaline plating baths operated between 60–90 °C, the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump demonstrated casing and impeller integrity with corrosion loss under 0.03% after extended exposure. This behavior supports long-term bath circulation without frequent hardware replacement or unplanned line shutdowns.

3. Leak-Free Operation in Dense Equipment Layouts

Content: The sealless structure of the CQ Stainless Steel Magnetic Drive Pump eliminates shaft seal points that often fail in hot, humid plating halls, where ambient conditions can exceed 80% relative humidity. Site records from retrofit projects documented a reduction of leakage incidents by more than 85%, significantly improving safety and housekeeping around plating tanks.

✅ ️Problem Solved

A metal-finishing facility operating continuous zinc and nickel plating lines reported frequent seal failures in traditional pumps, triggered by electrolyte crystallization and particle deposits at elevated bath temperatures. Coating non-uniformity increased whenever flow dropped, forcing the line to run corrective cycles and raising maintenance workload. After switching key circulation positions to the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump, the plant recorded stable runtimes exceeding 12,000 hours on critical loops with no leakage-related stoppages. Coating thickness variation decreased by more than 20%, while maintenance interventions on the circulation pumps were reduced to scheduled inspections only. In this environment, the CQ Stainless Steel Magnetic Drive Pump directly addressed abrasion, corrosion, and leakage risks that previously limited plating-line productivity.

-

CQ Stainless Steel Magnetic Drive Pump in Water Treatment Chemical Dosing and Industrial Waste Neutralization

✅Key Advantages

1. Stable Dosing Across Wide pH Range

Content: Trials in neutralization systems operating between pH 2 and pH 12 showed that the CQ Stainless Steel Magnetic Drive Pump maintained repeatable stroke-equivalent output with dosing variation kept under ±4%. This performance helps water-treatment engineers meet discharge targets without continuous manual adjustment of chemical feed rates.

2. Resilience to High-Frequency Start–Stop Cycles

Content: In simulated dosing duty with more than 100,000 start–stop cycles per year, the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump retained its magnetic coupling integrity and bearing smoothness. The absence of mechanical seals removed the primary wear point, resulting in noticeably fewer unplanned interventions during peak load periods.

3. Vapor-Phase Tolerance in Reaction Zones

Content: When installed near neutralization or oxidation reaction points where gas bubbles and vapor pockets form, the CQ Stainless Steel Magnetic Drive Pump maintained continuous operation with no dry-run scoring on SiC bearings after extended observation. Monitoring data recorded normal vibration levels even during transient vapor episodes, supporting reliable service in foam- and vapor-rich environments.

✅ ️Problem Solved

An industrial wastewater treatment plant handling variable-strength acidic and alkaline effluents experienced irregular dosing performance and seal wear when using conventional metering pumps near reaction tanks. Frequent start–stop operation and vapor bubbles generated during neutralization caused seal degradation, leading to dosing deviations and emergency maintenance several times a year. After upgrading critical chemical-feed points to the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump, the plant observed stable dosing accuracy over more than 14 months of operation, with pH control consistently maintained within the specified range. Unplanned shutdowns related to pump leakage or seal failures were eliminated over the observation period, and the CQ Stainless Steel Magnetic Drive Pump became the standard choice for new dosing lines exposed to aggressive, vapor-forming chemicals.

ADCERAX® CQ Stainless Steel Magnetic Drive Pump User Guide for Safe and Efficient Operation

The CQ Stainless Steel Magnetic Drive Pump is engineered for stable, leak-free chemical transfer, and the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump requires adherence to specific operational guidelines to maintain long-cycle performance across corrosive and vapor-phase media.

-

Installation Preparation and System Integration

1. Proper alignment must be ensured before the unit is connected to any pipeline. Misalignment induces unnecessary hydraulic loading that can affect the operating lifespan of the CQ Stainless Steel Magnetic Drive Pump. Accurate mounting also prevents unintended vibration transfer into the surrounding equipment structure.

2. Inlet conditions must remain fully flooded to avoid dry-running during system startup. A stable liquid column protects the internal SiC bearings from frictional damage when the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump begins its rotation. Ensuring proper suction conditions reduces startup oscillation and stabilizes early torque transmission.

3. Chemical compatibility must be verified prior to commissioning. Variations in acidity, solvent type, or particle load can influence wetted-material integrity in ways that affect the unit’s working envelope. Establishing compatibility in advance prevents accelerated wear and improves predictable service intervals.

-

Operational Monitoring and Flow Stability Control

1. Flow rate must be monitored regularly to confirm that hydraulic performance remains within design expectations. Deviations may indicate evolving media conditions that influence internal clearances of the CQ Stainless Steel Magnetic Drive Pump. Early detection provides an opportunity to adjust process parameters before load accumulation occurs.

2. Temperature trends must be reviewed consistently during extended operation. Excessive thermal fluctuation stresses the SiC bearings and magnetic coupling interface within the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump. Tracking such changes supports proactive intervention and prevents thermally induced shutdown events.

3. Noise and vibration signatures must be observed as diagnostic indicators. A gradual rise in vibration amplitude often signals upstream flow obstruction or downstream backpressure. Maintaining awareness of these patterns helps sustain stable circulation performance throughout the duty cycle.

-

Maintenance Intervals and Inspection Recommendations

1. Routine inspection of wetted surfaces is essential to identify early abrasive marking or chemical etching. Observing subtle shifts in surface texture helps determine whether the CQ Stainless Steel Magnetic Drive Pump is experiencing abnormal exposure to crystallizing agents. This insight supports maintenance planning before deterioration affects throughput.

2. Bearing condition must be evaluated periodically to ensure SiC support surfaces retain uniform contact patterns. Uneven wear within the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump may indicate cavitation or vapor intrusion, both of which require operational adjustments. Maintaining bearing geometry directly influences long-run torque stability.

3. Magnetic coupling integrity must be confirmed by monitoring transmission behavior across a full operating cycle. Variability during acceleration or deceleration suggests external drag or internal obstruction. Documenting these variations facilitates targeted corrections during scheduled service intervals.

-

Safety Measures and Chemical-Handling Precautions

1. Protective isolation must be maintained around the pump area when handling aggressive chemical streams. Although the CQ Stainless Steel Magnetic Drive Pump is designed for sealed operation, adjacent equipment may still emit vapors or droplets during transfer. Maintaining proper barriers enhances operator safety during routine monitoring.

2. System pressure must remain within defined limits to prevent hydraulic shock or reverse-flow conditions. Exceeding envelope pressures can impose structural strain on the SiC Lined CQ Series Stainless Steel Magnetic Drive Chemical Pump, reducing long-term structural stability. Utilizing calibrated relief mechanisms helps control such risks.

3. Emergency shutdown protocols must be understood by all operating personnel. Rapid isolation becomes necessary when process deviations such as foaming, vapor surges, or unexpected reactions occur. Familiarity with shutdown steps ensures that operation can be stabilized quickly without causing equipment damage.