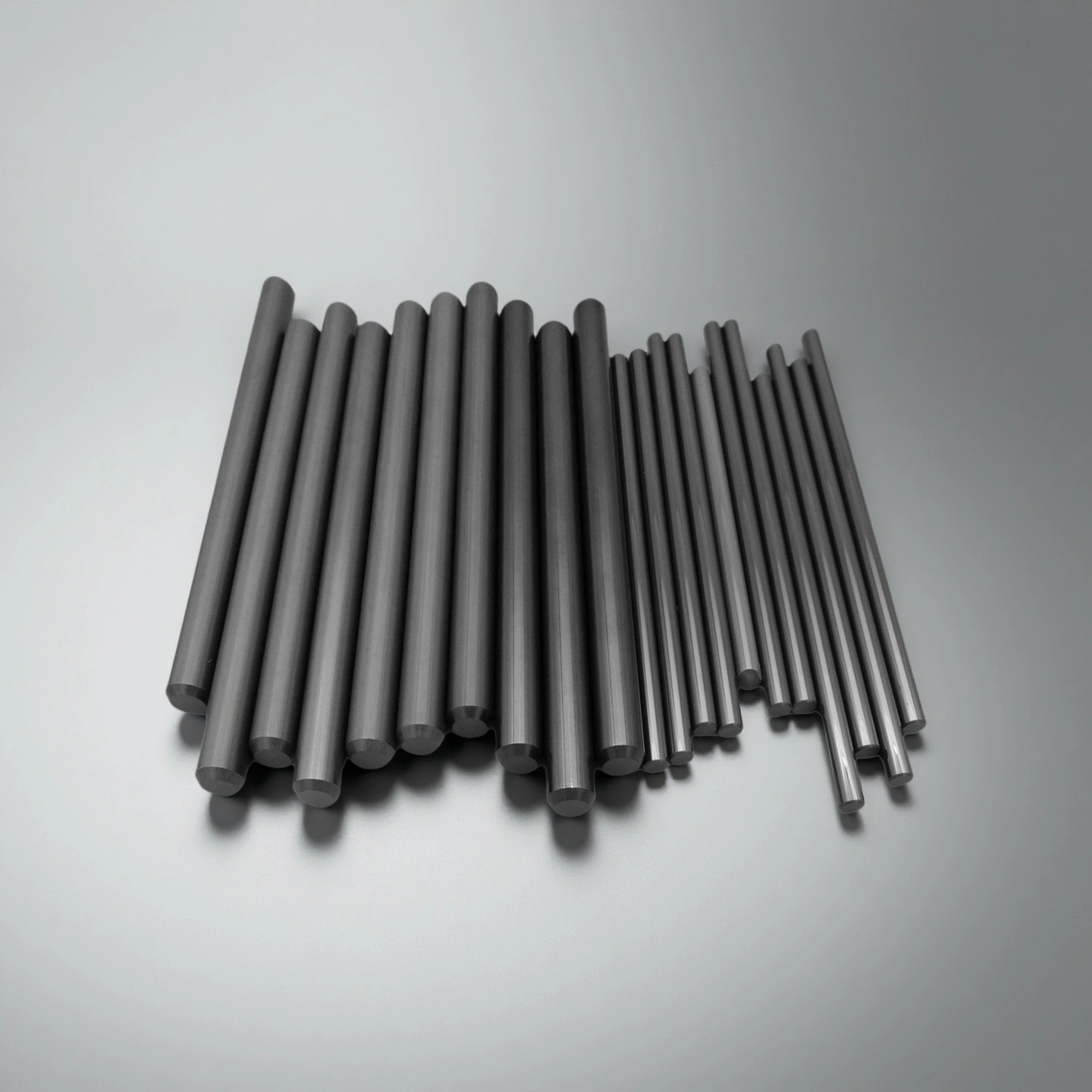

Silicon nitride plunger is a precision Si₃N₄ ceramic piston rod used in high-pressure pumps, metering pumps and filling equipment, designed with polished working surfaces, tight clearance control and custom shoulders to match OEM pump heads and packing systems.

Silicon Nitride Plunger Benefits

-

Extended service life in high-pressure duty

In many pump applications, silicon nitride plungers show service life roughly 7–12 times longer than metal plungers under comparable conditions, reducing change-out frequency and packing damage. -

Tight clearance and leakage control

Precision grinding allows plunger–bushing gaps to be set in the order of a few micrometres, supporting stable volumetric efficiency and controlled leakage in high-pressure pump heads. -

Polished surface for seal and packing stability

The working surface of the silicon nitride plunger can be finished to about Ra 0.1 μm, limiting friction peaks and helping elastomer, PTFE or composite packings maintain sealing performance over large cycle counts. -

Wear and corrosion behaviour suited to demanding media

The high hardness and chemical stability of Si₃N₄ ceramics make the plunger suitable for water, salt solutions, many chemicals, epoxy resin and other fluids where metal plungers are prone to wear tracks and corrosion. -

Strength retention at elevated temperature

Silicon nitride maintains significant mechanical strength up to around 1000–1200 °C, so the plunger can tolerate heat generated in the pump head without sudden loss of integrity when operated within design limits.

Silicon Nitride Ceramic Plunger Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Silicon Nitride Plunger Specifications

| Silicon Nitride Plunger | |||

| Item No. | Diameter (mm) | Length (mm) | Purity (mm) |

| AT-SIC-ZS001 | 2 | 20 | 85-99 |

| AT-SIC-ZS002 | 2 | 50 | 85-99 |

| AT-SIC-ZS003 | 3 | 50 | 85-99 |

| AT-SIC-ZS004 | 4 | 50 | 85-99 |

| AT-SIC-ZS005 | 5 | 50 | 85-99 |

| AT-SIC-ZS006 | 6 | 60 | 85-99 |

| AT-SIC-ZS007 | 6.75 | 50 | 85-99 |

| AT-SIC-ZS008 | 7.5 | 100 | 85-99 |

| AT-SIC-ZS009 | 8 | 30 | 85-99 |

| AT-SIC-ZS010 | 10 | 40 | 85-99 |

| AT-SIC-ZS011 | 12 | 10 | 85-99 |

| AT-SIC-ZS012 | 12 | 40 | 85-99 |

| AT-SIC-ZS013 | 15 | 10 | 85-99 |

| AT-SIC-ZS014 | 15 | 40 | 85-99 |

| AT-SIC-ZS015 | 20 | 80 | 85-99 |

| AT-SIC-ZS016 | 20 | 40 | 85-99 |

| AT-SIC-ZS017 | 25 | 50 | 85-99 |

| AT-SIC-ZS018 | 30 | 80 | 85-99 |

| AT-SIC-ZS019 | 2-80 | 20-200 | 85-99 |

Si3N4 ceramic plunger Packing

- Each silicon nitride plunger is individually wrapped in soft protective material to prevent contact damage and micro-chipping.