-

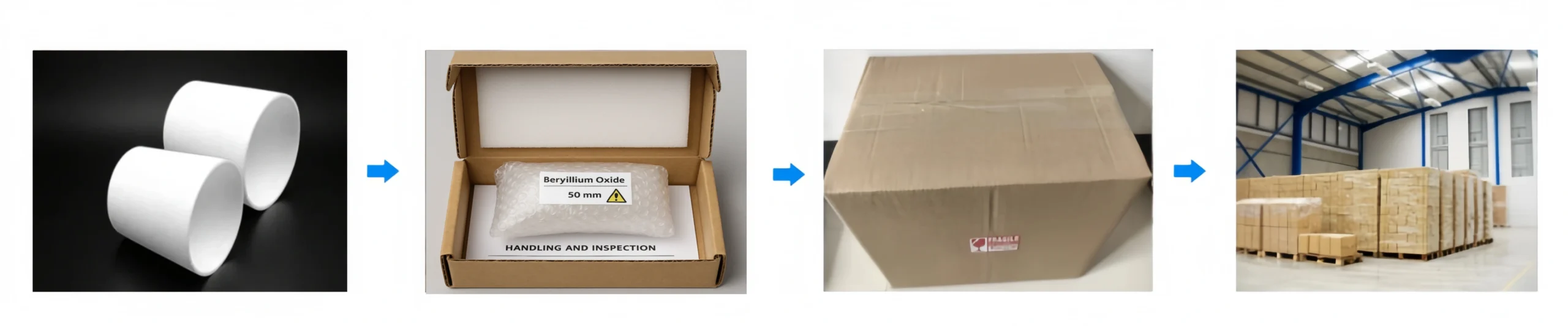

Install

1. Inspection before use

a. Unpack in a clean area; verify that the protective seal and label are intact.

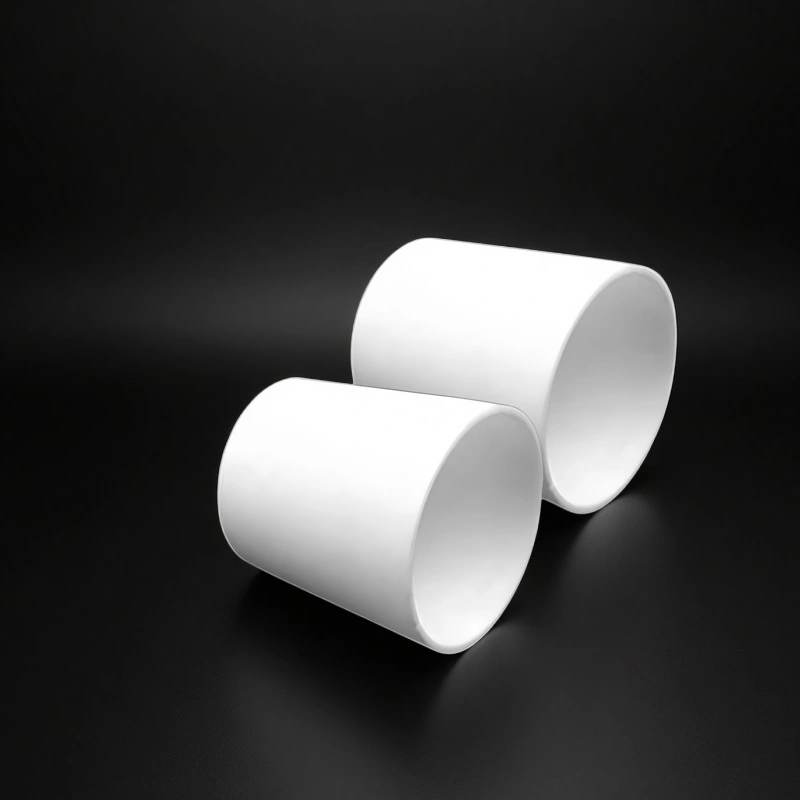

b. Check the crucible surface and edges for chips or cracks using visual and tactile inspection.

c. Confirm that the BeO hazard symbol and lot traceability number are clearly visible for documentation.

2. Fixture alignment

a. Place the crucible gently into the furnace support or holder, ensuring even contact at all points.

b. Avoid point loading—use graphite or ceramic pads if needed to distribute thermal stress.

c. When using lids or covers, ensure uniform seating and allow venting through a micro-hole or port to prevent pressure buildup.

3. Pre-heating protocol

a. Ramp temperature slowly (3–5 °C/min) for the first heat cycle to remove residual moisture.

b. Maintain a low-temperature hold (100–150 °C for 1–2 h) before raising to operating temperature.

c. Avoid direct flame or localized radiant heat on a cold crucible to prevent thermal shock.

-

Use

1. Operating conditions

a. Recommended temperature: up to 1,700–1,800 °C in vacuum or inert gas atmospheres (Ar, N₂).

b. Avoid long exposure to oxidizing environments above 1,000 °C, as this can affect surface color and integrity.

c. Ensure all heating and cooling cycles remain within specified ramp rates to prevent stress cracks.

2. Atmosphere control

a. For inert processes, confirm oxygen < 0.1 % and maintain constant flow to minimize BeO oxidation.

b. For vacuum melting, perform a pre-purge to remove residual moisture and volatiles before heating.

3. Handling during operation

a. Always use ceramic or graphite tongs with padded grips.

b. Do not introduce wet tools or liquids into a hot crucible—this may cause steam spallation.

c. Keep workspace ventilated and designate a closed furnace zone for BeO use to comply with HSE standards.

-

Store

1. Packaging retention

a. Store the crucible in its original sealed bag or bubble wrap until installation.

b. Retain the handling sheet and inspection record inside the box for traceability.

2. Environmental conditions

a. Store at room temperature (15–30 °C) in a dry, dust-free, vibration-free environment.

b. Avoid stacking heavy items on top; use a dedicated shelf or cabinet for BeO products.

3. Storage duration

a. Under proper conditions, BeO crucibles maintain mechanical and dielectric integrity for 5+ years.

b. Before reuse after long-term storage, perform a visual and weight check for contamination or microcracks.

-

Clean

1. Routine cleaning (after each cycle)

a. Allow the crucible to cool below 80 °C before handling.

b. Wipe interior and exterior gently with lint-free wipes or soft brushes; avoid abrasive contact.

c. Rinse using ultrapure water or high-purity ethanol, then dry at 100 °C for 1 h.

2. Deep cleaning (for residues)

a. Soak in weak acid (e.g., dilute HCl 0.1 M) for metal oxide residues; rinse thoroughly.

b. For organic contamination, use a low-temperature air bake at 400–500 °C to burn off residues.

c. Never use ultrasonic baths or high-pressure jets—risk of microfracture.

3. Inspection after cleaning

a. Check for surface pitting, glaze loss, or discoloration.

b. Any visible damage requires decommissioning and replacement to prevent contamination or failure.

-

Cautions

1. Safety precautions

a. BeO dust is hazardous if inhaled. Never grind, sand, or machine the crucible.

b. Handle only fully sintered pieces; avoid impact, scratching, or drilling.

c. Always wear protective gloves, goggles, and dust masks when cleaning or installing.

2. HSE compliance

a. Maintain local exhaust ventilation (LEV) near the working area.

b. Dispose of damaged crucibles through licensed hazardous waste facilities.

c. Include BeO crucible identification in your laboratory HSE register.

3. Common misuse & corrective actions

a. Rapid heating/quenching → cracking → reduce ramp rate; use gradual preheat and cool-down.

b. Chemical corrosion from flux residues → review compatibility chart; apply liner if necessary.

c. Impact during loading → edge chipping → use padded supports and non-metallic tongs.