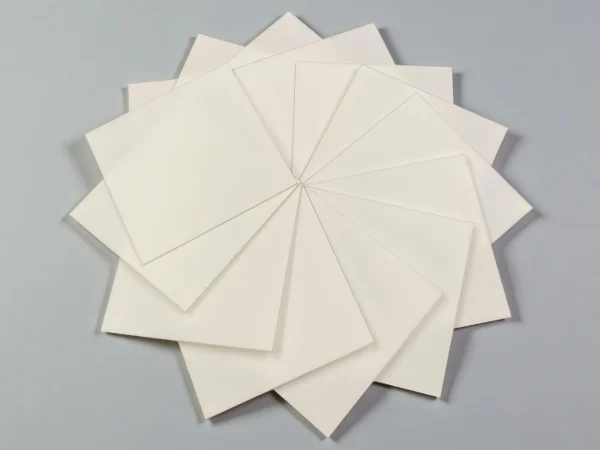

Customize Alumina /Al2O3 Substrate —96% to 99.7% Purity, Thin to Thick, Metallized & PCB Applications

ADCERAX supplies alumina ceramic substrates (Al₂O₃ substrates) for electronics, RF, LED, and lab applications. As a direct manufacturer in China, we offer 96%–99.6% purity options with polishing, metallization, and custom machining to support both prototypes and mass production.

With factory pricing, strict quality checks, and flexible supply, we ensure fast delivery worldwide. Products include alumina substrate PCBs, metallized copper Al₂O₃ substrates, and thin or thick film carriers, helping customers cut costs and improve reliability.

1730°C

Max Operating Temp

(99.7% Purity)

Tight Thickness & Flatness Control (Polishing, Drilling, Metallization)

Factory Direct Supply

What is Alumina Substrate?

Al2O3 Substrate Definition

Alumina substrate is a ceramic sheet made from Al₂O₃, used as an electrical insulator and mechanical carrier in electronic circuits and high-temperature devices. With stable dielectric constant, moderate thermal conductivity, and excellent chemical resistance, alumina ceramic substrates are widely applied in RF packaging, LED modules, and laboratory fixtures.

Alumina Substrate Thickness and Spec

Choosing the right high alumina substrate thickness helps balance performance and cost. ADCERAX offers all thickness ranges with tight tolerance control, making it easy to move from prototypes to mass production.

| Thickness Range | Typical Applications | Key Advantages |

|---|---|---|

| Thin Substrates (0.3–0.5 mm) | High-frequency circuits, lightweight PCB designs, R&D samples | Reduced weight, suitable for microwave & RF use, easy for prototyping |

| Standard Substrates (1–2 mm) | PCB-like carriers, LED modules, thick-film circuits | Most versatile, balances strength and processability, widely stocked |

| Thick Substrates (≥3 mm) | Power modules, heat spreaders, structural carriers, precision fixtures | High mechanical stability, excellent heat dissipation, reliable for high-power devices |

Alumina Substrate Properties & Benefits

🔌 High Dielectric Strength

Alumina sheet substrate provides stable insulation up to 15–22 kV/mm, ensuring reliable performance in RF circuits, LED packaging, and high-voltage power devices.

🌡️ Thermal Management

With thermal conductivity between 18–29 W/m·K, substrates enable efficient heat dissipation for LEDs, sensors, and microwave modules, extending device lifetime.

📏 Tight Tolerance Control

Precision flatness and thickness tolerance down to ±0.05 mm allow consistent circuit printing, laser drilling, and metallization, reducing defects in production.

⚙️ Versatile Processing Options

Available in thin (0.3–0.5 mm), standard (1–2 mm), and thick (≥3 mm) formats, alumina substrates support screen printing, sputtering, and custom metallized layers for diverse applications.

| Purity Level | Mechanical Properties | Thermal & Electrical Properties | Typical Applications | Key Advantages |

|---|---|---|---|---|

| 96% Al₂O₃ | Density: 3.6–3.75 g/cm³ Hardness: 8.8 Mohs Flexural Strength: 260 MPa Compressive Strength: 1910 MPa | Max Temp: 1450 °C Thermal Conductivity: ~22 W/m·K Dielectric Strength: 15 kV/mm Volume Resistivity: >10¹⁴ Ω·cm | Hybrid circuits, general insulators, low–medium power PCBs | Cost-effective, widely available, suitable for standard electronics |

| 99% Al₂O₃ | Density: 3.83 g/cm³ Hardness: 9 Mohs Flexural Strength: 300 MPa Compressive Strength: 2210 MPa | Max Temp: 1680 °C Thermal Conductivity: ~24 W/m·K Dielectric Strength: 19 kV/mm Volume Resistivity: >10¹⁴ Ω·cm | LED packaging, RF modules, power devices | Better dielectric stability, improved reliability for high-frequency circuits |

| 99.5% Al₂O₃ | Density: 3.9 g/cm³ Hardness: 9 Mohs Flexural Strength: 320 MPa Compressive Strength: 2300 MPa | Max Temp: 1700 °C Thermal Conductivity: ~27 W/m·K Dielectric Strength: 21 kV/mm Volume Resistivity: >10¹⁴ Ω·cm | High-performance circuits, optical components, precision electronics | Excellent strength and thermal performance, well-suited for advanced applications |

| 99.7% Al₂O₃ | Density: 3.94 g/cm³ Hardness: 9.1 Mohs Flexural Strength: 330 MPa Compressive Strength: 2300 MPa | Max Temp: 1730 °C Thermal Conductivity: ~29 W/m·K Dielectric Strength: 22 kV/mm Volume Resistivity: >10¹⁴ Ω·cm | Microwave circuits, sensors, precision instruments, research labs | Highest purity and consistency, low dielectric loss, ideal for demanding R&D and aerospace |

For RF or high-frequency designs, 99.5-99.7% alumina substrates deliver <X% lower loss than 96% grades.

Looking for the right alumina substrate grade or thickness for your project?

From 96% to 99.7% purity and from thin-film carriers to thick substrates, ADCERAX offers engineered solutions that match RF, LED, and power applications. Explore the categories below to find the substrate that fits your design.

Alumina(Al2O3) Ceramic Substrate Type

ADCERAX provides alumina ceramic substrates in 96%–99.7% purity with both standard sizes and custom machining options. From stock parts to special designs, we ensure stable quality and competitive pricing directly from our factory.

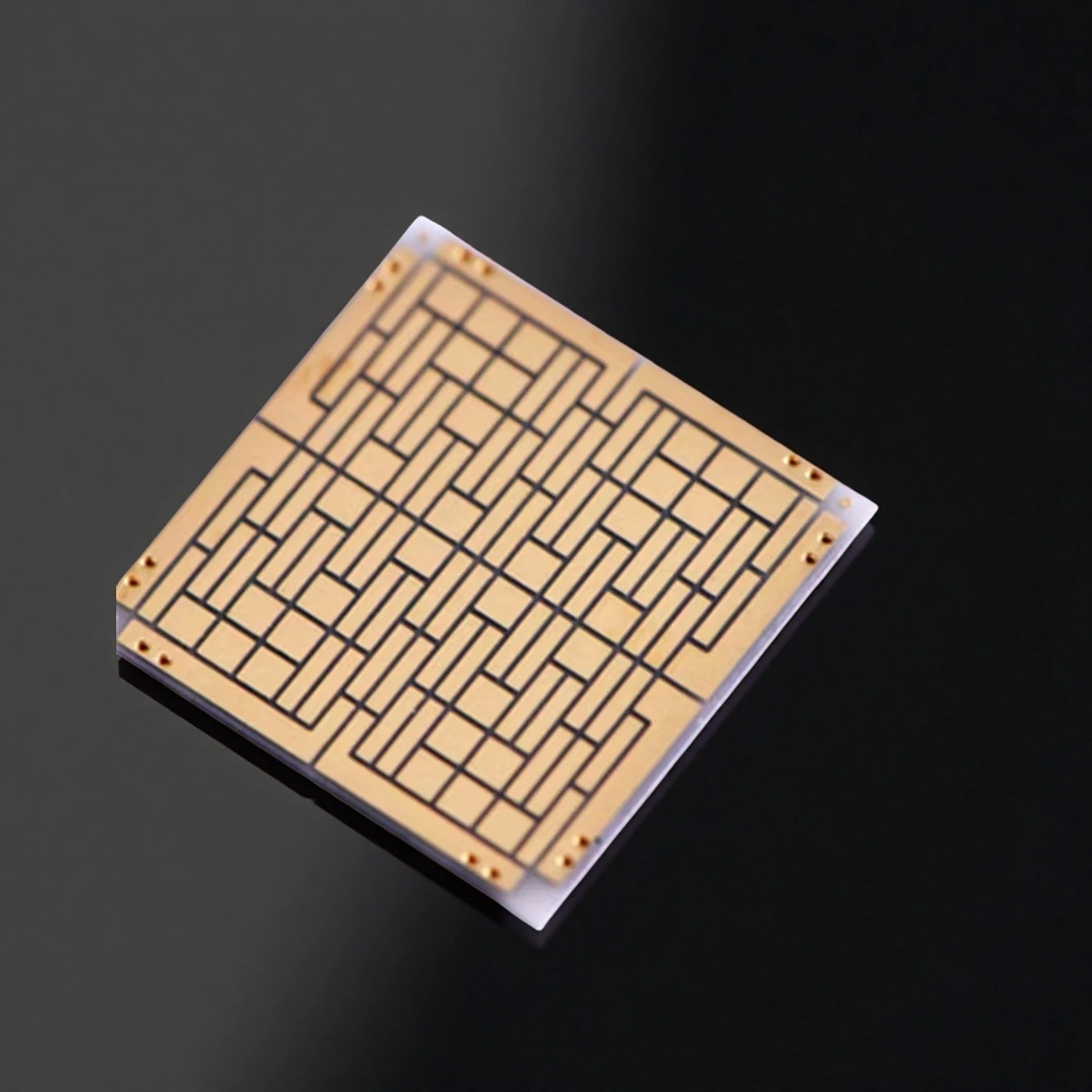

metalized alumina substrate

Metalized alumina substrates provide excellent thermal conductivity, mechanical strength, and reliable low-resistance circuit connections. They are widely used in power electronic modules, LED packaging, laser devices, and sensor bases.

High Purity alumina substrate

High-purity alumina substrates (99.6%–99.9%) deliver outstanding insulation, flatness, and stable thermal expansion for precision use. They are commonly applied in semiconductor packaging, microelectronics, vacuum devices, and high-power laser systems.

Black alumina ceramic substrate

Black alumina ceramic substrates combine high mechanical strength with anti-reflective properties to minimize optical interference. They are suitable for optical instruments, infrared detection, and electronic components operating in harsh environments.

Explore Our Alumina Substrate Solutions

From RF circuits and LED packaging to power devices and sensors, our Al2O3 ceramic substrates are engineered for performance and reliability.

Alumina Ceramic Substrate Applications

Alumina (Al2O3)ceramic substrates are essential in electronics, RF circuits, LED packaging, and research labs. They combine dielectric stability, heat dissipation, and precision machining, making them reliable for both industrial production and advanced R&D.

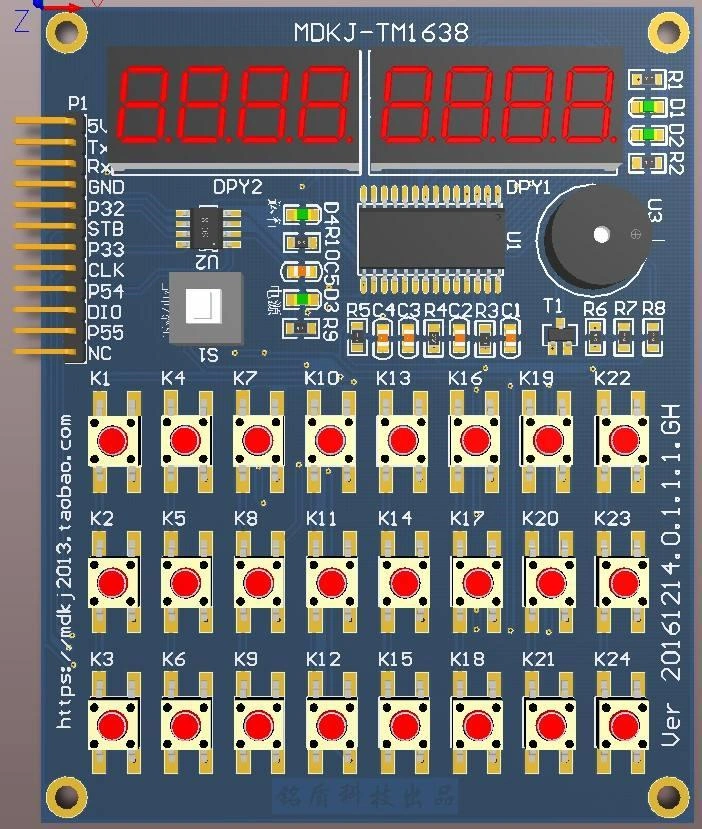

🔌Electronics & PCB Prototyping

Pain Points: Organic laminates (e.g., FR4) warp under heat, poor dielectric stability causes circuit failures, and inconsistent thickness leads to rework in prototyping.

Our Solution: ADCERAX alumina PCB substrates provide ±0.05 mm thickness tolerance, dielectric strength up to 22 kV/mm, and long-term stability, reducing prototyping errors by 20–30% and ensuring smooth transition to mass production.

📡 RF & Microwave Packaging

Pain Points: High-frequency circuits often suffer from signal degradation, high insertion loss, and unstable dielectric performance, especially in 5G and radar modules.

Our Solution: ADCERAX RF alumina substrates maintain a dielectric constant of 9.4–9.9 and low loss tangent (0.0001–0.0004), ensuring minimal signal loss and stable GHz-range performance. Thin substrates (0.3–0.5 mm) with metallization support compact RF integration.

💡 LED & Power Devices

Pain Points: High-power LEDs and power modules face overheating, reduced efficiency, and shortened device lifetime when using low thermal conductivity carriers.

Our Solution: With thermal conductivity up to 29 W/m·K, ADCERAX LED substrate alumina efficiently dissipates heat, extending chip lifetime by up to 30%. Options include 1–2 mm substrates for mid-power LED packaging and ≥3 mm heat spreaders for high-current devices.

🔬 Laboratory & R&D

Pain Points: Researchers need small-batch, high-purity substrates for experiments, but often face long lead times, inconsistent quality, and lack of customization.

Our Solution: ADCERAX provides thin and nanoporous alumina substrates tailored for sensors, membranes, and advanced testing. With fast prototyping support and factory-direct supply, labs can accelerate research and scale results into industrial application.

customize alumina ceramic substrates supplier

From prototypes to mass production, ADCERAX provides tailor-made alumina ceramic substrates—flexible in size, purity, and machining—to match your application. Lead time for custom prototype: approx. 7-25days; mass orders: 3-10 weeks

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX as Your Alumina Ceramic Substrate Manufacturers?

ADCERAX is a trusted alumina ceramic substrate factory in China, delivering factory-direct pricing, fast lead times, and full customization. With strict tolerance control and reliable global shipping, we make sourcing Al2O3 substrate simple, consistent, and worry-free.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Alumina Ceramic Substrate Factory-ADCERAX

ADCERAX is a professional China alumina substrate manufacturer and supplier that offers high-performance components with tight tolerances (±0.1mm) and custom geometries. Using advanced forming methods and CNC machining, we deliver precision-engineered solutions for electronics, chemical, and high-temperature applications.

- 99.7% high-purity alumina for stable performance

- Custom parts based on your drawings or samples

- Fast prototyping (7–15 days) & flexible MOQ

- ISO-compliant quality control & inspection reports

- Direct engineering support from design to delivery

Alumina Substrate Etching and Machining

This section outlines our core machining strengths, from material grades and tolerance control to advanced forming and finishing methods. We deliver customized alumina ceramic substrates solutions to meet diverse industrial needs with precision and reliability.

| Technical Capabilities Overview | |

|---|---|

| Material Grades | 96%, 99%, 99.5%, 99.7% Al₂O₃ – high purity for demanding applications |

| Tolerances | Up to ±0.1mm – suitable for precision assemblies |

| Forming Methods | Dry pressing, isostatic pressing, extrusion, casting, injection molding |

| Processing | CNC machining, fine grinding, polishing |

| Surface Finish | Polished / Unglazed / Glazed |

| Customization | Drawings, CAD files, or samples accepted for custom parts |

Alumina Substrate Quality & Certifications

FAQ

It combines stable dielectric constant (~9.6), low loss tangent, moderate thermal conductivity, and strong mechanical strength with high-temperature capability and dimensional stability.

Thin substrates (0.3–0.5 mm) are ideal for lightweight circuits and prototyping, while standard substrates (1–2 mm) fit PCB carriers and LED boards. For high-power devices and heat spreaders, thick substrates (≥3 mm) provide stability and efficient heat dissipation.

Alumina maintains dielectric and mechanical stability at high temperatures where FR-4 softens; it also offers better heat spreading and lower RF loss for many high-frequency designs.

To provide an accurate quotation, please share substrate dimensions, purity level, thickness, surface treatment (polished, metallized, etc.), and order quantity. Our team will respond within 24 hours with a detailed quote.

Yes. We offer bonded copper Al₂O₃ substrates with specified metallization thickness, solder-finish, and mask/via details to match assembly needs.

We support LTCC substrate alumina programs and can discuss anodic alumina substrate (AAO) or alumina substrate membrane for R&D.

Common techniques include laser etching, wet chemical etching, and plasma etching. Each method is selected based on design complexity, required resolution, and production scale.

Yes. ADCERAX supports custom alumina substrate etching based on drawings or prototypes, with tolerance control up to ±0.05 mm. Both small R&D batches and mass production orders can be fulfilled with stable quality and fast delivery.

Sapphire is single crystal and more scratch-resistant. Use particle-free solvents and non-abrasive methods; avoid HF unless your thin-film stack requires it and controls are in place.

Wipe with IPA or acetone in a clean tray, then DI water rinse and nitrogen blow-dry. Avoid abrasive cloths; handle with gloves to prevent fingerprints that affect metallization or printing.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Ready to Partner with ADCERAX?

Whether you need a standard alumina substrate or a complex customized Al2O3 substrate, our team is ready to assist. Get in touch today to discuss your requirements.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours