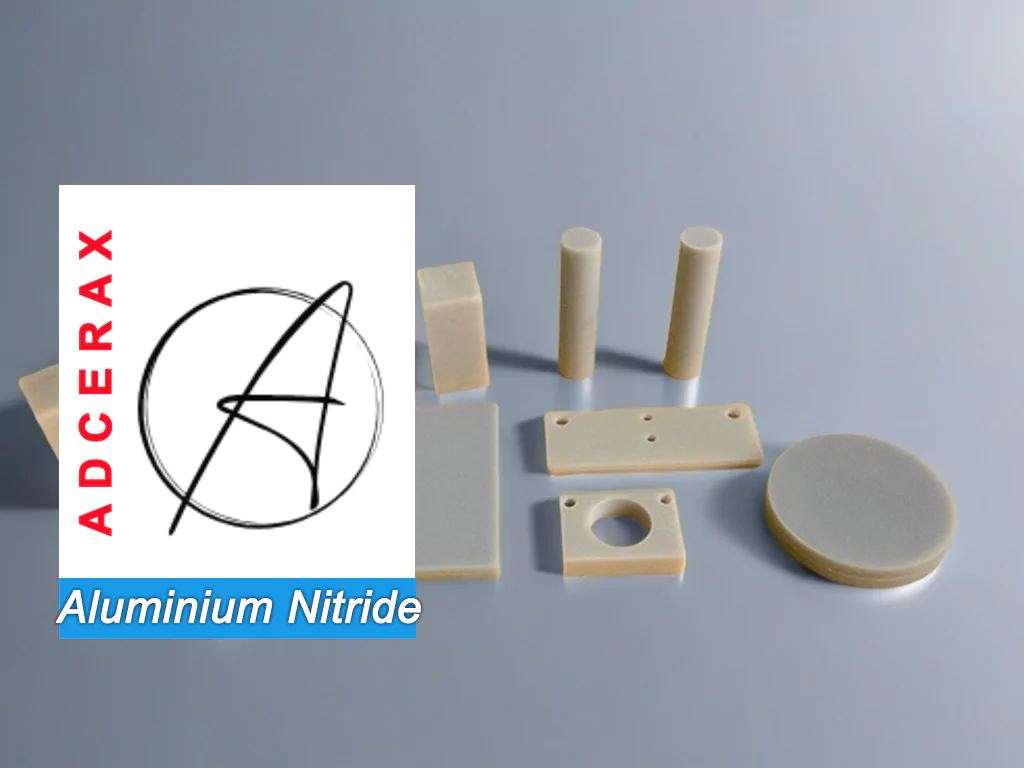

Aluminum Nitride Plate for IGBT, SiC/GaN Devices, LED Packaging and RF Assemblies

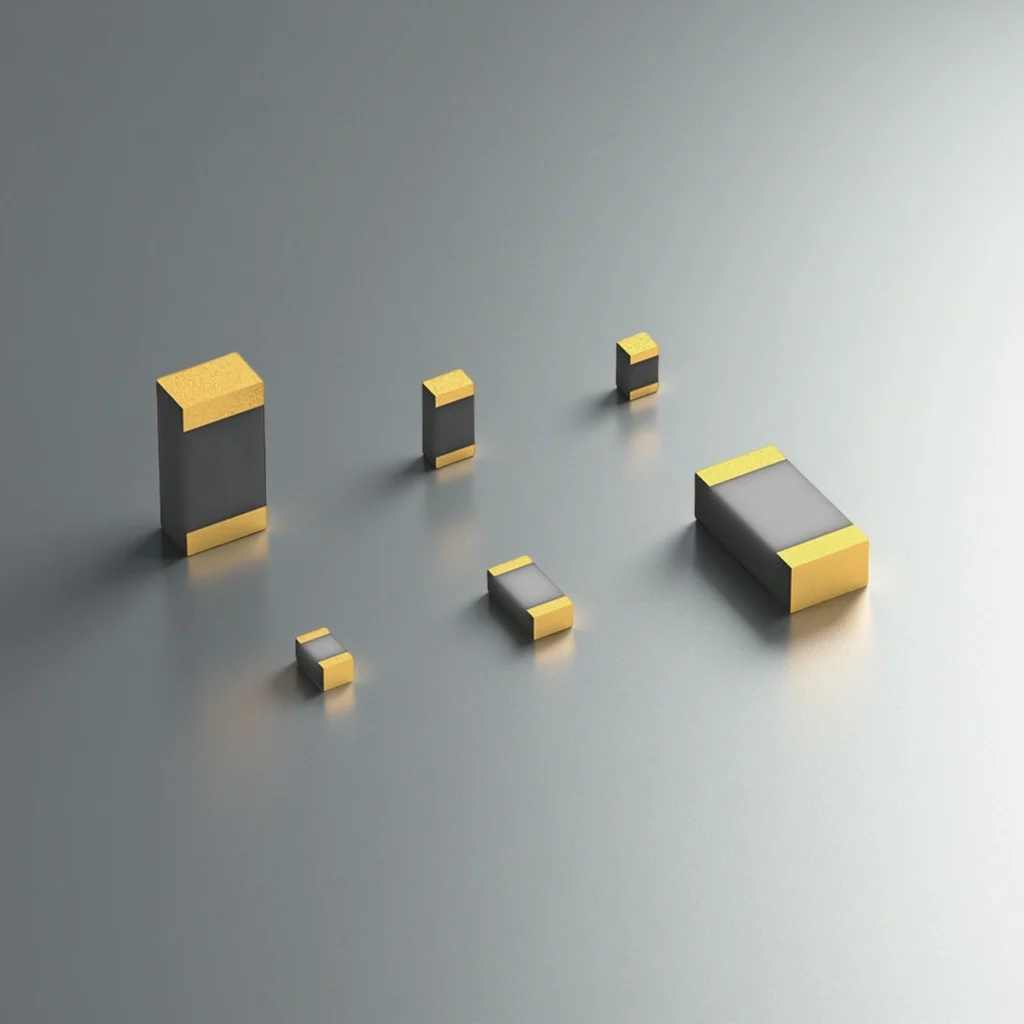

As a dedicated manufacturer of high-performance aln ceramic components, ADCERAX supplies aluminum nitride plates engineered for efficient heat spreading and electrical insulation in IGBT modules, SiC/GaN power devices, LED assemblies and RF systems. Our product range includes bare aluminum nitride plates, polished AlN ceramic plates and custom-machined AlN plates with defined thickness, flatness and dimensional tolerances. With in-house machining, drawing support and flexible small-to-large batch capability, we deliver aluminum nitride plates that fit directly into module housings, heat spreaders and high-power device packages.

👉 Send your required size, tolerance and application details—ADCERAX supplies the aluminum nitride plates engineered to keep your high-power modules running stable and cool.

170–200 W/m·K

Stable thermal conduction for power modules and LED/UV assemblies

Controlled machining for thickness, flatness and dimensional accuracy

What Are Aluminum Nitride Plates

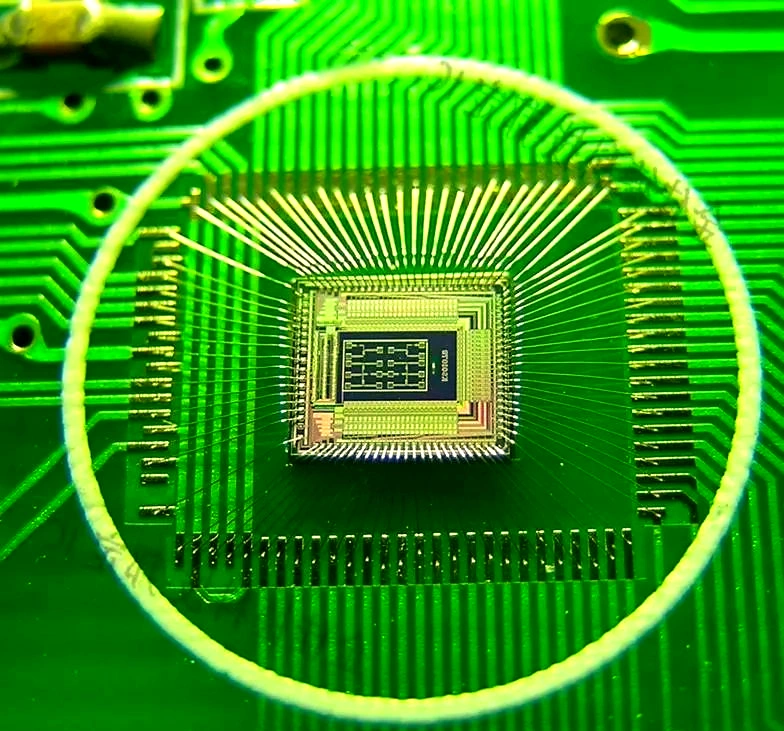

An aluminum nitride plate is a flat, high-thermal-conductivity AlN ceramic component used as both a heat-spreading layer and an electrically insulating structural base in high-power electronic and optoelectronic assemblies. It provides a thermally efficient path from semiconductor junctions to heat sinks while maintaining stable dielectric strength, controlled thermal expansion and low warpage, making it suitable for IGBT modules, SiC/GaN devices, LED packages, RF power amplifiers and industrial power systems.

Aluminum Nitride Plate Functions

A heat-spreading base under power semiconductor chips, LED chips or RF devices.

An insulating plate between live circuits and metal housings or heat sinks.

A stable ceramic plate for thermal management in compact modules.

Key Material Properties of Aluminum Nitride Ceramic Plate

Aluminum nitride plate is selected because its material properties are balanced around heat, insulation and mechanical stability. A typical aln plate offers the following performance parameters and functional advantages that support reliable use in power, LED and RF assemblies.

Aluminum Nitride Plate Properties Sheet

| Property Sort | Property Content | Unit | ALN-170 | ALN-200 | ALN-230 |

Basic | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

- This chart displays the typical properties of aluminum nitride (AlN) materials used in our standard products. Please note: Customized parts may have adjusted characteristics depending on production methods, with specific parameters determined by the stabilizer type and formula chosen for your application.

Advantages of AlN Plate

The AlN ceramic plate can reach a thermal conductivity much higher than alumina, so it removes heat more quickly from IGBT, SiC, GaN and LED chips.

The aluminum nitride ceramic plate provides high dielectric strength and low dielectric loss, which helps designers keep creepage and clearance distances under control.

The coefficient of thermal expansion of AlN is close to that of silicon and SiC, so the aluminum nitride plate helps reduce thermal stress and solder fatigue.

The AlN plate is rigid enough to support chips, wires and bonding pads without excessive bending during assembly and operation.

An aluminum nitride ceramic plate can work at elevated temperatures where polymer or metal-insulated boards are not suitable.

The aluminum nitride plate offers a uniform surface for metallization and bonding, ensuring stable chip attachment.

Aluminum Nitride Plate Product from ADCERAX

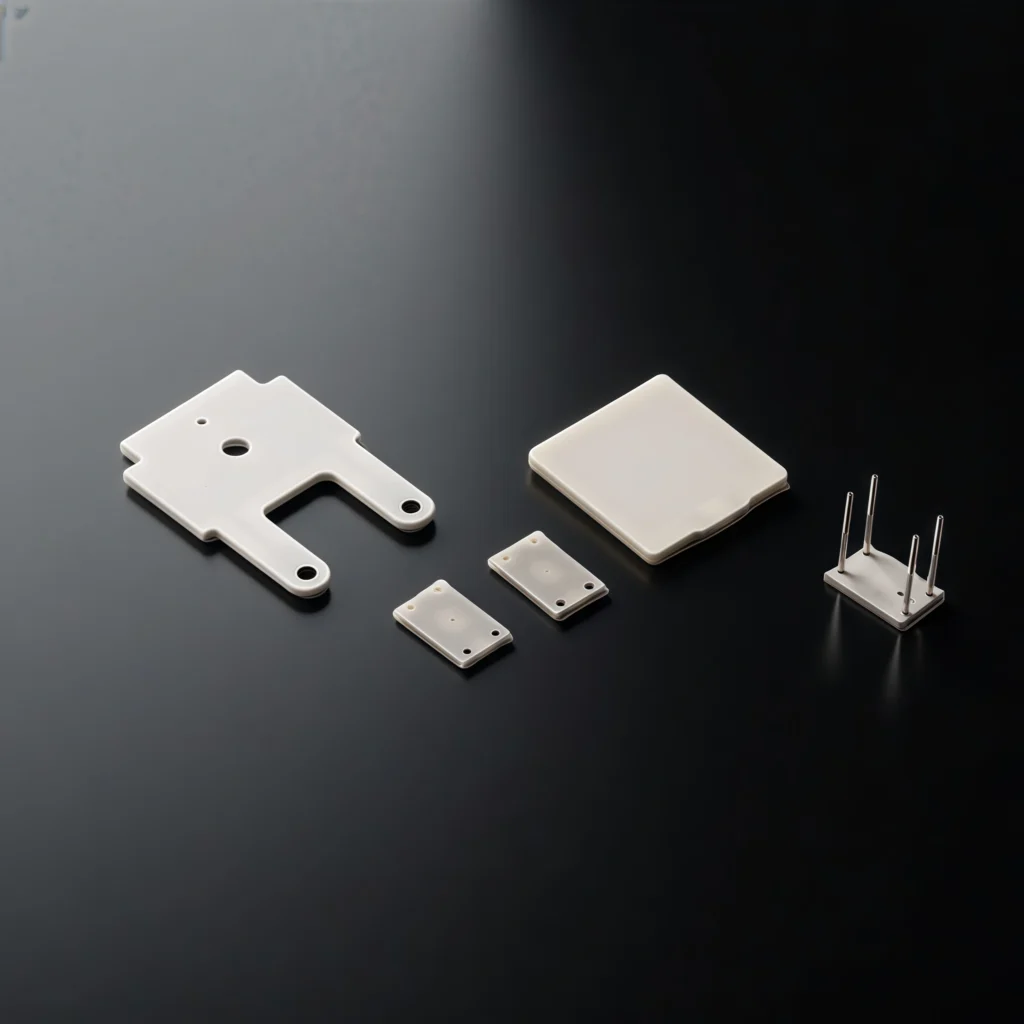

ADCERAX provides aluminum nitride plates in multiple configurations, covering bare AlN sheets, heating plates, hot-pressed AlN disks, metallized heat-spreader bridges, electrostatic chuck plates and thin AlN heater sheets. Each format supports specific mounting layouts and thermal paths, and can be produced in standard sizes or fully customized outlines according to drawings and project requirements.

AlN Heat-Spreader Plate functions as a metalized ceramic part that routes heat from power, LED/UV and RF components while maintaining electrical isolation in compact modules.

- Provides stable metalized pads for secure die attach and wire-bond paths.

- Creates low-resistance thermal links to manage localized heat in dense layouts.

- Supports custom pad shapes and outlines for diverse device footprints.

Aluminum Nitride Heater Sheet serves as a thin ceramic heater for localized temperature control and rapid thermal steps in LED modules, analytical devices and semiconductor tools.

- Supports flexible electrode layouts for targeted heating areas.

- Maintains consistent thickness for repeatable thermal profiles.

- Fits compact assemblies where space-efficient heating is required.

Aln sheets act as thermally conductive and electrically insulating bases for power modules, LED and UV LED chips, RF components and precision sensor packages.

- Supports direct device placement without pre-metallization.

- Allows precise pad and footprint definition in early layout stages.

- Maintains consistent thickness and outline across small to mid-scale builds.

AlN Ceramic Electrostatic Chuck provides a stable clamping surface for wafer positioning and thermal control in semiconductor processes requiring uniform heat transfer.

- Enables uniform wafer contact for consistent thermal distribution.

- Supports custom electrode patterns to match different wafer sizes and process needs.

- Maintains stable flatness and outline for repeatable handling across production cycles.

Aln heating plates function as compact ceramic heaters for equipment preheating, localized temperature control and stable thermal steps in precision tools.

- Supports rapid temperature rise with stable ceramic geometry.

- Compatible with custom electrode layouts for diverse heating zones.

- Maintains consistent thickness and outline for repeatable thermal profiles.

Hot pressed aln plates act as stable ceramic bases for power, LED, RF and sensing components requiring a clean surface before metallization.

- Provides a uniform pressed surface suited for direct device placement or later metallization.

- Offers consistent thickness control for structured mounting in power and LED packages.

- Supports custom outlines and pad areas for diverse electronic layouts.

💡Build better modules with an AlN plate engineered for your application.

ADCERAX provides AlN plates tailored for stable thermal paths and clean electrical isolation across demanding modules. Share your drawing to receive application-ready parts and a reliable lead time.

Typical Applications of AlN Ceramic Plate

Aluminum nitride ceramic plates are applied in high-power electronics, LED and UV-LED assemblies, RF and microwave devices, and optical or photonic modules where efficient heat spreading, dimensional stability and reliable electrical insulation are essential for compact and thermally demanding designs.

🔌Power Electronics

🧩ADCERAX Solution: ADCERAX provides 170–200 W/m·K AlN plates with controlled warpage, tight machining tolerance and optional metallization, ensuring reliable mounting, thermal uniformity and repeatability across batches.

🔹Case Study: A power-module manufacturer in Germany faced overheating problems in an EV inverter project, where alumina substrates caused junction temperatures to exceed safe operating limits. ADCERAX supplied 0.635-mm aluminum nitride plates with 180 W/m·K thermal conductivity and controlled warpage below 0.25%. After switching to ADCERAX AlN plates, the customer recorded a junction-temperature reduction of 18–22°C and achieved the required power-cycling lifetime without redesigning the module footprint.

📶RF /Microwave & 5G Components

🧩 ADCERAX Solution: ADCERAX delivers thin, flat AlN plates with strong thermal uniformity and customizable cavities or pad layouts to maintain optical stability and extend LED operational lifetime.

🔹Case Study: A U.S.-based UV-curing equipment company experienced rapid output decay in a compact UV module due to insufficient heat dissipation. ADCERAX delivered customized 0.4-mm AlN plates with optimized flatness for uniform chip mounting. Thermal imaging tests showed a surface-temperature reduction of 14°C, leading to a measurable improvement in wavelength stability and a 28% increase in LED operational lifetime.

💡LED /UV LED Packaging

🧩ADCERAX Solution: ADCERAX supplies high-purity AlN plates with stable dielectric properties and precise machining for accurate outlines, pad geometry and defect-free mounting areas.

🔹Case Study: A Japanese RF module supplier reported performance drift in a GaN PA module due to substrate heating. ADCERAX supplied high-purity AlN plates with controlled flatness and improved thermal uniformity. After adopting the new substrate, the customer documented a 12% improvement in gain stability and significantly reduced thermal-induced frequency drift during high-power operation.

⚙️Photonics & Optoelectronic Packaging

🧩ADCERAX Solution: ADCERAX provides tight-tolerance AlN plates with low thermal expansion and clean, flat surfaces suitable for bonding, coating and precision mounting.

🔹Case Study: A Canadian photonics company faced alignment drift in a compact laser module where the existing substrate warped during bonding. ADCERAX delivered tight-tolerance AlN plates with improved flatness control, reducing displacement during assembly. The final system demonstrated stable optical alignment over extended thermal cycling, cutting alignment-related rejects by more than 40%.

Custom Aluminum Nitride Plates Supplier

We provide custom aluminum nitride ceramic plates manufactured according to customer drawings, samples or target outlines. Dimensions, thickness levels, hole patterns, cutouts and surface conditions can be produced to match specific assembly layouts. Custom AlN substrates typically require 3–9 weeks depending on layout complexity and machining needs.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – aluminum nitride (AlN) Plate manufacturers

ADCERAX is a aluminum nitride plate manufacturer in China producing AlN plates in standard and custom formats for diverse module layouts. As an aluminum nitride plate wholesaler, we focus on consistent plate quality, precise machining control and flexible customization suitable for both sampling and volume production.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX provides integrated manufacturing for aluminum nitride plates, covering forming, sintering and CNC machining in a streamlined workflow. We produce bare AlN plates, polished sheets and custom-cut plate geometries according to drawings or sample requirements. Prototype and volume orders are both supported.

-

Precision Machining & Dimensional Control:

Aluminum nitride plates are machined with controlled thickness, flatness and outline accuracy. CNC processing ensures clean edges, consistent surfaces and tight tolerances suitable for direct integration into customer assemblies. -

Batch Consistency & Production Reliability

Each batch of AlN plates is inspected for geometry repeatability and uniform material density. Stable forming and sintering processes help maintain predictable plate behavior across multiple production runs. -

Customization Based on Drawings

We provide drawing-based customization for outline dimensions, thickness levels, holes, slots, cutouts and surface finishes. Custom aluminum nitride plates can be produced to match specific mounting envelopes or assembly layouts with engineering support throughout fabrication.

ADCERAX specializes in producing aluminum nitride plates through controlled forming, high-temperature sintering and precision CNC machining. Our process maintains consistent plate thickness, flatness and outline accuracy to support stable integration into customer assemblies. Each batch is inspected for geometry repeatability and surface uniformity, ensuring low-defect, clean ceramic plates suitable for both prototype and volume builds. These manufacturing strengths allow us to deliver aluminum nitride plates with reliable dimensional control, smooth surfaces and flexible customization based on customer drawings.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | Aluminum nitride plate material produced with controlled powder processing and stable sintering to achieve uniform density, clean surfaces and consistent ceramic integrity suitable for precision machining. | ||

| Precision Machining | CNC and laser machining used to deliver stable plate thickness, clean edges and outline tolerances typically held within ±0.05–0.10 mm for customer-defined geometries. | ||

| Forming & Shaping | Supports custom plate formats including rectangles, squares and non-standard outlines, with optional holes, slots, cutouts and surface conditioning according to drawings. | ||

| Flatness & Dimensional Control | Stabilized sintering ensures low warpage and predictable flatness across batches, with uniform dimensions maintained for repeatable assembly alignment. | ||

| Inspection & Quality Control | Full inspection of thickness, flatness, edge condition and surface integrity to ensure consistent plate geometry and readiness for downstream machining or assembly. | ||

FAQs About Aluminum Nitride Plate

The thickness of the aluminum nitride plate is selected by balancing thermal resistance, isolation voltage and mechanical strength. Thinner AlN plates can reduce thermal resistance between the chip and heat sink, while thicker plates increase mechanical strength and the breakdown voltage of the insulation. When you send your drawing or module outline, ADCERAX can suggest a thickness range that matches your power level and assembly method.

Yes. ADCERAX supplies custom aluminum nitride plates based on customer drawings or samples. Length, width, thickness, drilling, slots, edge chamfers and surface finishing can all be specified. The AlN ceramic plate is produced and inspected according to the agreed tolerances so that it fits directly into the existing module or packaging design.

An aluminum nitride plate has higher thermal conductivity than an alumina plate, so it transfers heat away from the chip more efficiently for the same thickness and footprint. Compared with BeO plates, an AlN ceramic plate provides strong thermal performance without the handling and environmental concerns associated with beryllium-containing materials. Because of this, many new power modules replace alumina or BeO plates with aluminum nitride plates in order to upgrade power density and simplify material management.

In many cases, the same metallization systems used on other ceramic plates can be adapted to aluminum nitride plates, but the exact process parameters may change. If you plan to metallize or pattern the AlN ceramic plate yourself, ADCERAX can supply aluminum nitride plates with a surface roughness suitable for your process or provide pre-metallized options on request.

For a fast and accurate quotation, it is helpful to provide: plate dimensions, thickness, tolerance requirements, surface condition, machining details (holes, slots, chamfers), expected quantity, intended application and any special inspection requirements. With these details, ADCERAX can evaluate the most suitable aluminum nitride plate process route and give a clear lead time and price range.

Most aluminum nitride plates are supplied from 0.25 mm to 3 mm thick, with custom thicknesses available depending on forming and machining limits.

Typical outline tolerances fall within ±0.05–0.10 mm depending on plate size and machining complexity. Smaller features may require tighter CNC control after sintering.

Yes. Aluminum nitride plates can be machined with custom holes, slots, cavities and non-standard outlines using CNC, laser or diamond tooling. Both through-features and partial-depth cuts can be produced, and tolerances are defined according to plate thickness and feature size. Drawings or 3D models are reviewed for feasibility before machining to ensure the final geometry matches the intended assembly layout.

Aluminum nitride plates go through a structured inspection workflow before packaging and shipment.

The process typically includes:

• Dimensional Verification

Thickness measurement across multiple points

Flatness check based on plate size and tolerance requirements

Outline and hole-pattern verification against drawings or CAD data

• Machined-Edge Evaluation

Inspection of edge smoothness after CNC/laser machining

Confirmation of chamfers (if specified)

Detection of edge chipping or micro-crack formation

• Surface Integrity Review

Visual inspection under proper lighting

Check for stains, pits, grain pull-out and machining marks

Confirmation that surfaces meet bonding or metallization readiness

Yes. AlN plates are compatible with soldering, die-attach materials and high-temperature adhesives when the surface is prepared appropriately.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours