With over 20 years of expertise in advanced ceramics manufacturing, ADCERAX specializes in producing high-purity Beryllium Oxide (BeO) ceramics. Our engineering team supports both standard and custom BeO substrates, plates, rods, tubes, and crucibles, ensuring precise tolerances and consistent performance even under extreme conditions.

🤝Partner with ADCERAX — your experienced BeO ceramic manufacturer delivering precision, purity, and performance. Request a quote today to explore customized BeO solutions for your project.

≥97% Purity

High-purity BeO ceramics

Heat & electrical insulation

Thermal Conductivity

Ultra-efficient heat transfer

Beryllium oxide ceramic (BeO) is a high-performance advanced ceramic material valued for its extraordinary thermal conductivity, excellent electrical insulation, and high mechanical strength. It belongs to the class of functional ceramics used where efficient heat dissipation and electrical isolation must coexist — such as in power electronics, RF systems, aerospace hardware, and medical instruments.

Beryllium ceramics are made from ultra-fine BeO powders (≥97 % purity) that are sintered into dense, homogeneous bodies through controlled high-temperature processing (≈1750–1850 °C).

During sintering, microstructural uniformity and grain boundary control are critical — they determine thermal conduction pathways, dielectric integrity, and mechanical reliability.

Additives are rarely used because even trace impurities can degrade BeO’s conductivity or increase dielectric losses, so these ceramics are typically fabricated with high-purity feedstocks and vacuum sintering atmospheres.

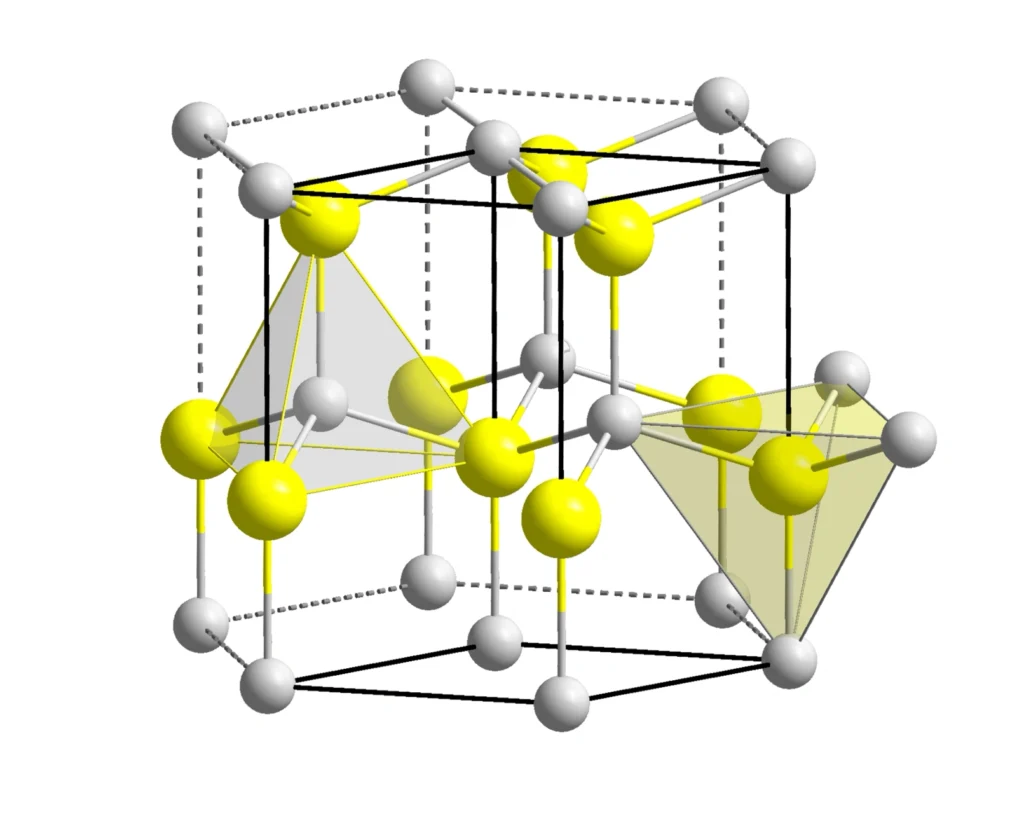

Beryllium oxide (BeO) has a hexagonal wurtzite crystal structure, which is similar to zinc oxide (ZnO).

This structure consists of each beryllium atom tetrahedrally coordinated by four oxygen atoms, and vice versa. The tight ionic–covalent bonding within this lattice gives BeO its extraordinary thermal conductivity, high melting point, and excellent dielectric strength.

Beryllium Oxide (BeO) Ceramics combine high thermal conductivity with excellent electrical insulation and mechanical reliability. Their superior purity and stability make them ideal for demanding applications in power electronics, RF modules, aerospace, and high-temperature systems.

Beryllium Oxide (BeO) Ceramics combine high density, hardness, and structural stability. Their fine-grained structure and low porosity ensure dimensional accuracy, strength, and reliability under high temperature and stress.

| Property | Typical Value / Range | Description |

|---|---|---|

| Density | 2.85–3.02 g/cm³ | High density ensures structural integrity and dimensional stability under mechanical or thermal stress. |

| Purity | ≥99.5% BeO | High-purity BeO provides consistent mechanical performance and chemical inertness. |

| Color | White to light gray | Color tone indicates BeO purity; slight cream tint may appear from minimal trace oxides. |

| Surface Roughness | Ra 0.4–1.0 μm (polished) | Fine polishing produces smooth surfaces for precision sealing and metallization. |

| Crystal Structure | Hexagonal wurtzite (HCP) | Stable crystalline lattice ensures phonon mobility and contributes to high thermal conductivity. |

| Hardness (Hv) | 1100–1200 kg/mm² | Excellent hardness provides superior wear and abrasion resistance. |

| Porosity | <0.1% | Near-zero porosity enhances mechanical strength and long-term material reliability. |

Beryllium Oxide (BeO) Ceramics offer high thermal conductivity, low expansion, and strong thermal shock resistance, ensuring stable heat management in demanding applications.

| Property | Typical Value / Range | Description |

|---|---|---|

| Thermal Conductivity | 200–250 W/m·K | Exceptional thermal conduction enables efficient heat dissipation in high-power assemblies. |

| Specific Heat Capacity | 1.0–1.2 J/g·K | Provides effective heat buffering and temperature stability during rapid thermal cycling. |

| Thermal Expansion Coefficient (CTE) | 8.0–8.5 ×10⁻⁶ /K | Closely matches metals and semiconductors, minimizing thermal stress in composite structures. |

| Thermal Shock Resistance | Excellent | Retains mechanical integrity under sudden temperature changes or repeated heat cycling. |

| Maximum Operating Temperature | Up to 1800 °C (inert or vacuum atmosphere) | Maintains crystal stability and thermal reliability under extreme service conditions. |

| Heat Dissipation Efficiency | Superior | Transfers localized heat uniformly, preventing hot spots in compact device designs. |

Beryllium Oxide (BeO) Ceramics offer high electrical insulation and stable dielectric performance. Their low loss and high resistivity suit RF, microwave, and high-voltage applications.

| Property | Typical Value / Range | Description |

|---|---|---|

| Electrical Resistivity | >10¹³ Ω·cm | Provides excellent insulation, preventing current leakage in high-voltage systems. |

| Dielectric Constant (εr) | 6.5–7.5 | Maintains impedance stability for RF and microwave applications. |

| Dielectric Strength | 9–12 kV/mm | Withstands high electric fields without breakdown or discharge. |

| Dielectric Loss (tan δ) | ≤3×10⁻³ | Ensures low signal loss and high efficiency at high frequencies. |

| Insulation Resistance | >10¹² Ω | Guarantees electrical separation between conductive elements in compact assemblies. |

| Volume Resistivity (at 25 °C) | >10¹⁴ Ω·cm | Stable resistivity across temperature range ensures consistent dielectric performance. |

Beryllium Oxide (BeO) Ceramics exhibit excellent chemical stability and corrosion resistance. They remain inert in most environments, ensuring reliability in high-temperature and chemically aggressive conditions.

| Property | Typical Characteristic | Description |

|---|---|---|

| Chemical Stability | Excellent | Highly inert to most acids, alkalis, and molten metals at room temperature. |

| Corrosion Resistance | Outstanding | Resists oxidation, moisture, and chemical attack in harsh industrial environments. |

| Reactivity | Low | Stable under vacuum or inert gas; reacts only with fluorine or concentrated acids at high temperatures. |

| Solubility in Water | Insoluble | Maintains integrity and performance in humid or aqueous environments. |

| Oxidation Resistance | High | Stable up to 1800 °C in oxidizing atmospheres without surface degradation. |

| Toxicity Precaution | Handle with care | BeO dust is hazardous during machining; finished ceramics are fully safe when intact. |

ADCERAX manufactures beryllium oxide (BeO) ceramics with high thermal conductivity, insulation, and strength. Our crucibles, rods, and substrates ensure reliable performance and durability in high-power, high-temperature systems.

BeO crucibles offer exceptional thermal conductivity, stability, and resistance to reactive environments.

BeO rods offer high thermal conductivity, insulation, and strength for high-temperature and vacuum use.

BeO substrates deliver superior thermal conductivity, electrical insulation, and dimensional stability forelectronic systems.

Every ADCERAX BeO ceramic ensures superior heat transfer, electrical insulation, and structural integrity — built for precision, performance, and reliability in the toughest environments.

Application: In power modules, amplifiers, and RF transmitters, heat dissipation and insulation must coexist. BeO substrates and insulators deliver both — providing metal-like thermal conductivity and excellent dielectric strength for long-life circuit protection.

Application: In power modules, amplifiers, and RF transmitters, heat dissipation and insulation must coexist. BeO substrates and insulators deliver both — providing metal-like thermal conductivity and excellent dielectric strength for long-life circuit protection.🧩 Why engineers choose BeO:

Rapid heat spreading minimizes chip burnout and failure rates.

Reliable insulation ensures stable high-voltage operation.

Available in metallized or custom-machined forms for direct assembly.

💬 Looking for thermally conductive substrates or BeO insulators for power control modules? Contact ADCERAX for design support and fast prototyping.

🧩 Core benefits:

Maintains optical precision under rapid heating and cooling.

Low dielectric loss improves signal fidelity in high-frequency systems.

Compatible with metallization and active brazing processes.

⚙️ Custom BeO reflectors and laser bases are available upon request — optimized for your wavelength, geometry, and mounting design.

🧩 Advantages in production:

No contamination during repeated heating cycles.

Maintains shape and strength up to 1800 °C.

Extends service life, reducing replacement and downtime costs.

🔬 Request a quote for BeO crucibles or rods built to your dimensions and test requirements.

Their non-magnetic and vacuum-stable nature makes them perfect for sensitive measurement and imaging systems.

🧩 Key features:

Biocompatible and stable under continuous load.

Excellent heat dissipation maintains accuracy and safety.

Clean, non-contaminating surfaces suitable for vacuum chambers.

💡 Custom BeO components for medical and analytical instruments are available — engineered for precision and repeatability.

ADCERAX provides custom-engineered BeO ceramic components tailored to your exact design and performance needs. We support precision machining, fine surface finishing, and tight dimensional tolerance control, ensuring reliable fit and function in complex assemblies. Whether you require unique geometries, metallized surfaces, or prototype-to-production runs, our engineering team delivers fast, accurate, and consistent results for high-performance applications.

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX is a trusted beryllium oxide ceramic manufacturer in China, supplying high-purity BeO components for thermal, electrical, and structural applications worldwide. We provide both standard and customized BeO ceramics, delivering superior heat conductivity, insulation, and stability for global OEMs and high-tech industries.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates material design, precision machining, quality inspection, and export logistics into a seamless workflow. Our one-stop service for beryllium oxide (BeO) ceramics ensures high purity, consistent quality, and reliable delivery — from prototype to mass production.

ADCERAX specializes in producing high-purity beryllium oxide ceramics, combining advanced powder processing, isostatic pressing, and high-temperature sintering with precision CNC machining.Each BeO component is engineered for maximum thermal conductivity, mechanical integrity, and dielectric reliability, ensuring consistent performance under extreme heat and power conditions.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | High-pure BeO ceramics (≥99%) offering outstanding thermal transfer, electrical insulation, and microstructural stability. | ||

| Dimension Range | Custom machined rods, crucibles, and substrates from miniature to large format, with tolerances down to ±0.05 mm. | ||

| Forming Methods | Isostatic pressing, precision CNC machining, and controlled atmosphere sintering for dense, defect-free microstructures. | ||

| Processing | Sintered under high-temperature vacuum conditions for full densification and superior heat dissipation efficiency. | ||

| Surface Finish | Polished BeO surfaces achieve high smoothness and cleanliness for metallization or vacuum sealing applications. | ||

BeO is available in various forms, including:

BeO is typically manufactured by:

Beryllium oxide (BeO) is not a universally used material in all ceramic insulators. While it has excellent properties, its use is limited to specialized applications.Such as

1,High-power RF and microwave electronics: Amplifiers, circuits

2,High-voltage electronics: Insulators, power supplies

3,Laser systems: Laser tubes, heat sinks

4,Semiconductor manufacturing equipment: Critical components

BeO is chosen for its superior performance, but its use is limited due to cost and toxicity, requiring strict safety measures.

Yes, beryllia is considered toxic in powder form if inhaled. When machining or handling BeO, it is crucial to follow strict safety protocols:

Beryllium oxide (BeO) stands out among advanced ceramics for its exceptional thermal conductivity, electrical insulation, and mechanical stability — a rare combination not found in most oxide ceramics.

The table below compares BeO with other commonly used materials in high-performance applications:

| Property | Beryllium Oxide (BeO) | Alumina (Al₂O₃) | Aluminum Nitride (AlN) | Zirconia (ZrO₂) |

|---|---|---|---|---|

| Thermal Conductivity | ★★★★★ Extremely high — ideal for heat dissipation | ★★ Moderate | ★★★★ High but lower than BeO | ★ Low |

| Electrical Insulation | ★★★★★ Excellent | ★★★★ Good | ★★★ Good | ★★★ Good |

| Mechanical Strength | ★★★★ High with low density | ★★★ Moderate | ★★★ Moderate | ★★★★★ Very high but heavy |

| Thermal Shock Resistance | ★★★★ Excellent | ★★★ Moderate | ★★★★ Good | ★★★ Moderate |

| Maximum Service Temperature | Up to ~1800 °C | Up to ~1600 °C | Up to ~1500 °C | Up to ~1000 °C |

| Typical Applications | Power electronics, RF modules, aerospace, nuclear systems | Insulators, substrates, crucibles | LED packages, semiconductor devices | Mechanical wear parts, bearings |

BeO ceramics uniquely deliver metal-like thermal performance with full electrical insulation, making them indispensable in high-power, high-frequency, and heat-intensive applications that other ceramics cannot match.

Beryllium oxide maintains stable performance above 1000 °C, providing efficient heat dissipation and dimensional integrity in continuous thermal cycling.

Yes. ADCERAX supports custom geometries, surface finishes, metallization, and tolerance designs, from prototype development to volume production.

Yes. Beryllium oxide (BeO) ceramics can be metallized and hermetically joined to various metals using specialized coating and brazing processes.

Because of its high thermal conductivity and strong dielectric insulation, BeO serves as an excellent base for power electronic packages, RF modules, and vacuum components where both electrical isolation and heat transfer are required.

Please provide drawings or samples, detailed dimensions (ID/OD/length), tolerance requirements, surface finish, and target quantity for accurate pricing and feasibility evaluation.

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact ADCERAX for design support, sample validation, and global delivery.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours

WhatsApp us

The more details you provide, the faster we can respond.

*We respond within 24 hours. All inquiries are confidential.

The more details you provide, the faster we can quote.

*We respond within 24 hours. All inquiries are confidential.