Boron Nitride Plates | High-Temperature Insulation and Molten Metal Handling

ADCERAX is a dedicated boron nitride plate manufacturer with more than 20 years of experience, specializing in hot-pressed BN plates for high-temperature insulation, molten metal contact parts, vacuum furnace fixtures, thermal tooling, and electrical isolation components. We focus on controllable density, thickness, and dimensional accuracy to ensure stable performance under demanding industrial environments.

We offer both standard BN plate inventory and custom-made BN parts based on drawings or samples, providing flexible small-batch and project-based production to support diverse industrial applications.

🤝 Send your drawing or required size to receive a fast technical review and tailored BN plate solution.

What is a Boron Nitride Plate?

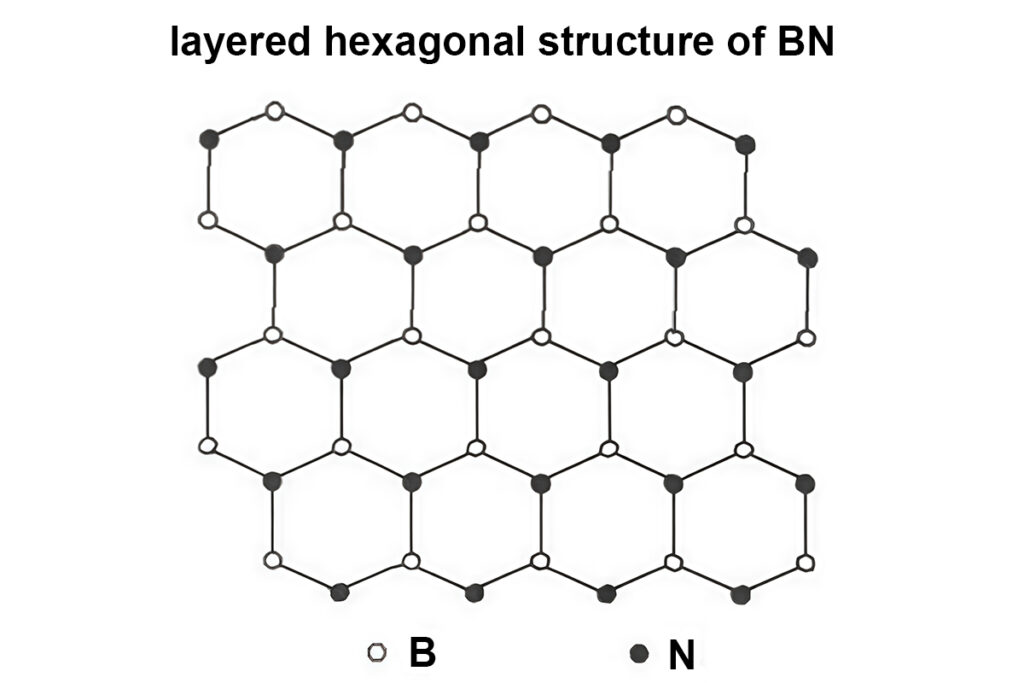

Boron nitride plate is a flat component made primarily from hot-pressed hexagonal boron nitride sheet material. This ceramic is often described as “white graphite” because its layered structure gives it high thermal conductivity in-plane while remaining an excellent electrical insulator.

Hot-pressed h-BN can be machined with conventional carbide tools into plates, blocks, and boron nitride ceramic sheet formats. These parts keep their mechanical stability and insulation function at elevated temperatures in vacuum, inert gas, or controlled atmospheres.

Boron Nitride Sheets Properties

Boron nitride (BN) plates offer high thermal stability, chemical inertness, and strong electrical insulation performance. Their layered crystal structure supports effective thermal spreading, low thermal expansion, and reliable non-wetting behavior when in contact with molten metals.

| Property | Unit | Pyrolytic Boron Nitride (PBN) | Hot-Pressed Boron Nitride (HPBN) | Description / Application Focus |

|---|---|---|---|---|

| Purity | % | 99.99 | 99.5 | High-purity BN ensures chemical stability and oxidation resistance under extreme temperatures. |

| Density | g/cm³ | 2.15–2.19 | 1.96–2.00 | Low density with high structural integrity; ideal for lightweight thermal and vacuum components. |

| Thermal Conductivity | W/m·K | 60 (A-direction) | 55 | Excellent heat transfer for high-temperature insulation and thermal management applications. |

| Dielectric Strength | kV/mm | 55 | 76 | Superior electrical insulation and high dielectric constant for electronic and vacuum environments. |

| Maximum Working Temperature | °C | 1000 (air) / 2300 (vacuum) | 900 (air) / 1850 (vacuum) | Maintains mechanical strength and stability in both oxidizing and vacuum atmospheres. |

| Bending Strength | MPa | 173 (A-direction) | 310 | Excellent mechanical reliability and resistance to cracking after repeated thermal cycling. |

| Thermal Expansion Coefficient | /°C | 6×10⁻⁷ | 1.8×10⁻⁶ | Low thermal expansion provides outstanding dimensional stability and thermal shock resistance. |

| Compressive Strength | MPa | 154 (A-direction) | 120 | High compressive strength supports long service life in demanding structural applications. |

Key values vary by BN grade (HPBN vs PBN) and working atmosphere; contact ADCERAX for grade selection.

Boron Nitride Sheet Function

BN sheets act as thermal spreaders or thermal buffers to stabilize temperature gradients, reduce hot-spot formation, and maintain process uniformity in heated or insulated zones.

The material provides high resistance and dielectric strength, enabling safe spacing, component separation, and fixture insulation within high-temperature or powered assemblies.

BN sheets form a non-wetting and low-sticking contact surface between components, tools, or molten non-ferrous metals to minimize residue build-up and ease cleaning.

BN sheets can serve as shims, spacers, or precision interface layers in mechanical fixtures, helping maintain controlled tolerances under thermal cycling.

China Boron Nitride Plate Products

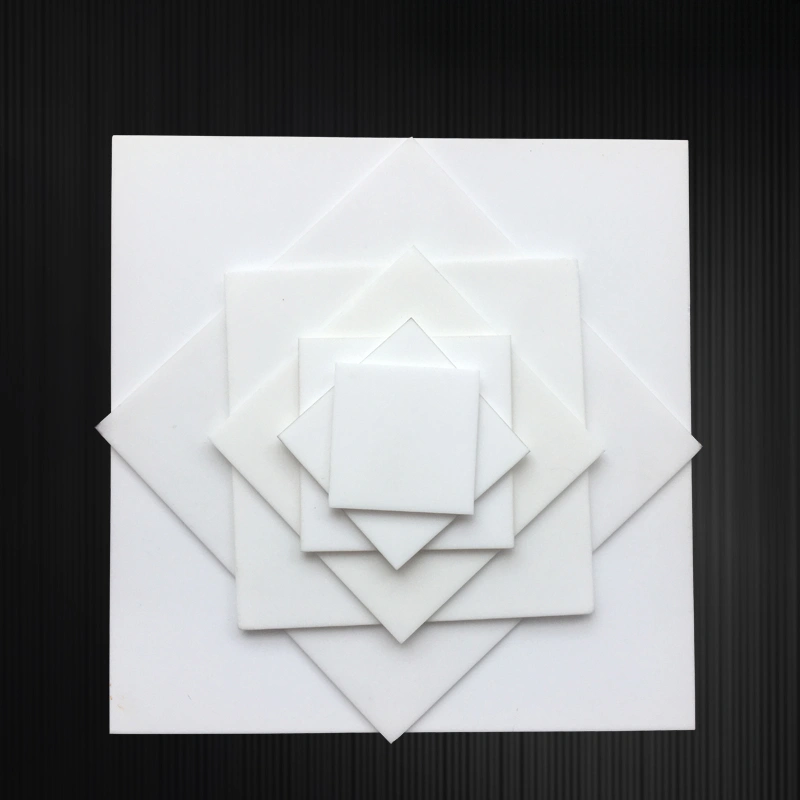

ADCERAX supplies hot-pressed boron nitride plates and sheets in multiple grades, thickness options, and machining sizes. Standard BN plate formats are available, and custom dimensions can be produced according to drawings or samples.

High purity bn plates are used as high-temperature insulation panels, non-wetting contact surfaces, furnace fixture components, and thermal barrier liners in molten metal processing, vacuum systems, and precision heating equipment.

- Resistant to sticking and chemical attack by molten metals

- Stable geometry under high heat and thermal cycling

- Machinable to customized dimensions and thickness

Hexagonal BN sheets provide clean-release surfaces, thermal insulation, and stable performance under repeated heating cycles, used in high-temperature furnace panels, diffusion barriers, and non-wetting contact layers.

- Non-wetting to molten metals and reactive materials

- Stable thickness and flatness at elevated temperature

- Available in custom-cut sizes and thickness ranges

BN insulation gaskets deliver electrical insulation, thermal resistance, and low-friction contact surfaces, suitable for sealing, spacing, and heat-isolating interfaces in thermal processing equipment and vacuum chambers.

- No reaction or sticking to molten alloys during operation

- Maintains stable shape under repeated thermal cycling

- Custom profiles and precise hole patterns available

💡 Stable at High Heat. Precise in Every Detail — That’s ADCERAX BN Plates.

When conventional ceramic plates deform, stick to molten metals, or fail under thermal cycling, ADCERAX boron nitride plates remain dimensionally reliable, non-wetting, and easy to machine — helping you reduce downtime, improve fixture lifespan, and maintain consistent process quality.

Boron Nitride (BN) Plate Applications

Boron Nitride (BN) ceramics are widely used in semiconductor processing, precision machinery, metallurgy, and laboratory equipment. They serve essential roles in components such as insulating rings, tubes, plates, and spacers supporting high-temperature operations, vacuum systems, and precision instruments across multiple industrial fields.

Thermal Furnaces & Vacuum Heat-Treatment Systems

💥Problem:

Some insulating ceramic materials provide insulation but insufficient heat spread and precision machining, causing stress concentration at mounting points.

🧩ADCERAX Solution:

✅ Low thermal expansion + thermal shock resistance

✅ Stable dimensions during repeated cycling

✅ Custom-machined fit to existing equipment

Laboratory & Materials Research Systems

💥Problem:

Lab testing requires repeatable thermal cycling & stable platform flatness, but common refractory plates deform or crack after multiple experiments.

🧩ADCERAX Solution:

✅ Small-batch custom machining tailored to testing devices

✅ Smooth surfaces with controlled flatness for repeated loading

✅ Stable dielectric strength under thermal cycling

Molten Metal Handling & Casting (Al, Mg, Cu Alloys)

💥Problem:

Traditional ceramic plates and coated metal plates experience metal wetting, sticking, and chemical adhesion, increasing cleaning time and contaminating melt purity.

🧩ADCERAX Solution:

✅ Natural non-wetting to Al / Mg melt

✅ Stable in 800–1100°C molten metal environments

✅ Reduced oxidation and residue accumulation

Power Electronics & Electrical Isolation Components

💥Problem:

Some insulating ceramic materials provide insulation but insufficient heat spread and precision machining, causing stress concentration at mounting points.

🧩ADCERAX Solution:

✅ Electrical insulation + moderate thermal conductivity

✅ Machinable features (slots, tapped holes, recesses, cavities)

✅ Stable thin-plate installation

Custom Boron Nitride (BN) Plate Manufacturer

ADCERAX is a boron nitride plate manufacturer in China, providing standard and custom-machined BN plates based on drawings or samples. We support multiple grades, thickness ranges, and precise sizing with stable batch consistency and typical delivery within 3–9 weeks.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX – Advanced Boron Nitride (BN) Plate Supplier

ADCERAX is a boron nitride plate manufacturer and supplier from China, providing factory-direct production, stable material quality, and accurate machining to specification. With advanced hot-pressing, precision finishing, and custom fabrication capability, we deliver consistent performance and reliable dimensional control for every BN sheet.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates BN plate forming, precision machining, material grading, and quality inspection into a unified manufacturing process. We supply both standard-size and custom-machined boron nitride plates for thermal insulation, molten-metal contact surfaces, and high-temperature fixture components — from sample development to volume production.

-

Precision Machining & Dimensional Control

Each BN plate can be machined to tight tolerances, flatness, and surface finish requirements. This supports accurate fitment in high-temperature assemblies, clean-release surfaces, and long-term size stability under thermal cycling. -

Batch Consistency & Material Verification

Every batch is inspected for density, purity level, microstructure uniformity, and moisture control. Our hot-pressed processing ensures predictable performance, stable insulation behavior, and reduced failure risk in demanding thermal processes. -

Customization & Engineering Support

We provide custom BN plate solutions based on drawings or samples, supporting non-standard sizes, thickness ranges, hole patterns, or stepped geometry. ADCERAX engineers assist with material grade selection and production feasibility, ensuring practical results and reliable global delivery.

ADCERAX specializes in producing hot-pressed boron nitride (BN) plates with stable density, controlled moisture content, and precision machining capability. Each plate is processed for reliable thermal insulation, smooth non-wetting surfaces, and dimensional stability under continuous high-temperature operation. As a professional BN plate manufacturer, ADCERAX ensures consistent batch quality, machinable structures, and long-term performance — ideal for molten-metal contact surfaces, furnace insulation boards, thermal barrier liners, and precision fixture components.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | Hot-pressed boron nitride (BN) with controlled density, low moisture absorption, and uniform microstructure. Available in multiple BN grades (e.g., HPBN, HBN) to match insulation, non-wetting, and high-temperature performance needs. | ||

| Precision Machining | CNC machining, milling, and surface lapping available to achieve tight tolerance plates in thickness, length, and width. Machinable into stepped, slotted, hole-patterned, or profile-cut components while maintaining structural stability. | ||

| Forming & Shaping | Produced through hot-press forming for large or small plate sections. Supports custom thickness ranges, non-standard dimensions, protective edges, and special-shape plate designs based on drawings or samples. | ||

| Flatness & Dimensional Control | Optimized forming conditions minimize internal stress, porosity, and warpage, providing consistent flatness and thickness stability under high-temperature use. Suitable for furnace panels, fixture boards, and thermal barrier liners requiring precision fit. | ||

| Surface Finishing | Smooth, non-wetting surfaces available for molten metal contact and clean-release applications. Optional fine-finish machining provides improved edge quality and installation readiness depending on end-use requirements. | ||

FAQ

No. A cubic boron nitride plate belongs to the family of superhard abrasive materials. It is related to the products used in a cubic boron nitride plated metal wheel for grinding. The boron nitride plates on this page are hot-pressed hexagonal BN components designed for insulation, thermal management, and molten metal handling, not for abrasive wheels.

For an accurate quotation on BN plates or boron nitride sheets, please provide:

Application description and working atmosphere

Maximum operating temperature and thermal cycling pattern

Plate dimensions, thickness, and required tolerances

Quantity for samples and expected batch volumes

Any specific inspection or documentation requirements

In contact with molten aluminum and other non-ferrous melts, boron nitride plate surfaces show low wettability. This reduces build-up, helps maintain clean metal flow, and can extend fixture life compared with many conventional refractories. Service life still depends on temperature, flow speed, and mechanical loading, so ADCERAX can recommend plate thickness and support strategy based on your process.

Compared with alumina, boron nitride sheet material offers higher in-plane thermal conductivity and much better non-wetting behavior with many molten metals, but is generally softer and requires careful handling. Compared with graphite, BN maintains electrical insulation and resists oxidation better at moderate temperatures, making it suitable where both insulation and cleanliness are critical.

es. BN plates can be CNC-machined into stepped blocks, rings, bushings, channels, hole patterns, or fixture interfaces according to drawings or samples. The material supports drilling, milling, slotting, and surface trimming with stable accuracy, making it suitable for customized furnace panels, thermal barrier parts, and non-wetting contact components.

Hot-pressed BN plates are made from sintered h-BN powder blocks and are widely used as machinable structural parts in furnaces and casting lines. A pyrolytic boron nitride plate or pyrolytic boron nitride sheet is grown by chemical vapor deposition and is usually chosen for very specialized vacuum or semiconductor environments. ADCERAX focuses on hot-pressed BN plates and boron nitride sheets for industrial applications.

Choose hot-pressed BN plates when you need structural insulation components, machinable geometries, threaded or stepped features, mounting holes, or large-area furnace panels. Hot-pressed BN offers stable density, good mechanical integrity, and ease of CNC shaping, making it suitable for molten-metal contact surfaces, thermal barrier boards, and fixture plates.

Choose pyrolytic boron nitride (PBN) sheet when ultra-high purity, extremely low porosity, and atomically smooth surfaces are required—especially in semiconductor, crystal growth, evaporation sources, and precise thermal control environments. PBN is deposited chemically and provides near-perfect uniform microstructure ideal for contamination-sensitive applications.

You can source boron nitride plate for sale directly from ADCERAX, where material selection, machining feasibility, thickness options, and drawings can be reviewed by engineers before ordering.

Yes. ADCERAX is a professional boron nitride plate manufacturer in China, and we can ship BN plate orders worldwide, including the United States, Europe, Japan, South Korea, and other industrial markets. All shipments follow export-grade packing, dimensional inspection, and required commercial documentation to ensure smooth and safe customs clearance.

You can purchase machinable boron nitride plates for molten aluminium handling directly from ADCERAX, a BN plate manufacturer with over 20 years of production experience. We supply hot-pressed BN plates and custom-machined BN components designed for aluminium casting, launder systems, melt filtration, crucible lining, and metal contact fixtures.

h-BN (hexagonal boron nitride) plates and Si₃N₄ (silicon nitride) plates are both advanced ceramic materials, but they serve different application needs due to their structure, thermal behavior, and mechanical properties.

• h-BN Plate (Hexagonal Boron Nitride)

h-BN plates have a layered graphite-like structure, giving them excellent machinability, chemical inertness, high-temperature stability, non-wetting behavior with molten metals, and electrical insulation. They are widely used in aluminum casting systems, crucible liners, diffusion fixtures, vacuum tooling, thermal insulation boards, and semiconductor process parts.

✅ Key traits: machinable, non-wetting, thermally stable, electrically insulating

• Si₃N₄ Plate (Silicon Nitride)

Si₃N₄ plates are high-strength, tough, and wear-resistant structural ceramics with strong resistance to thermal shock, bending load, and mechanical stress. They are used in bearings, wear components, mechanical spacers, nozzles, and high-load industrial assemblies.

✅ Key traits: high strength, impact & wear resistance, structural reliability

In simple selection terms:

Choose h-BN plates when machinability, molten metal contact, electrical insulation, or high-temperature non-wetting is required.

Choose Si₃N₄ plates when mechanical strength, impact resistance, durability, and high-load structural stability are critical.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours