Ceramic Metal Melting Crucibles for Contamination Control and Clean Melts

Metal melting crucibles often fail under thermal cycling from cracking, hot-face erosion, and inclusion pickup—causing downtime, metal loss, and unstable melt quality.

ADCERAX engineers ceramic metal melting crucibles in alumina, silicon carbide, and zirconia to match your alloy chemistry and furnace heat profile, controlling ∆T-driven stress and crucible–melt interaction for cleaner, repeatable melts from 700–1800°C.

We engineer ceramic crucibles that last 2x longer and eliminate contamination.

Failures During Melting Crucible

Metal melting operations often stall when crucibles crack under thermal cycling, contaminate melts with erosion debris, or fail during runs. These events trigger emergency shutdowns, scrap valuable charge, and cause 2–4 hours of unplanned downtime. Standard refractory containers may fail within 10–20 cycles, while erosion-driven inclusions degrade product quality.

Reliable melting requires crucibles that tolerate repeated ambient-to-1600°C shocks, resist molten-metal/flux attack, and stay dimensionally stable under mechanical load.

Causes of Melting Crucible Failures

Most crucible failures stem from overlapping mechanisms rather than isolated events—thermal gradients, chemical reactions, and mechanical loads act simultaneously.

Diagnosing the primary failure mode enables targeted material selection and operational improvements.

Thermal shock from rapid heating

- Temperature gradients during startup generate tensile stresses exceeding ceramic strength, initiating cracks through the wall. This dominates when heating rates exceed 150-200°C/hour or when cold crucibles receive molten metal directly.

Molten metal penetration

- Liquid metals penetrate grain boundaries through capillary action, weakening cohesion and enabling spalling, particularly with aluminum and copper alloys.

Chemical erosion from flux attack

- Alkaline and fluoride-containing fluxes react with crucibles, dissolving the wall from the melt interface inward. Erosion accelerates above 1100°C, creating attack zones at the melt line.

Differential thermal expansion stress

- Constrained mounting systems generate interface stresses during heating. When expansion mismatch exceeds 2-3 × 10⁻⁶/°C, shear stresses initiate delamination or spalling.

Cyclic fatigue

- Each thermal cycle propagates microcracks at flaws and grain boundaries. Cumulative damage from 15-25 cycles causes sudden failure during normal operation.

Why Are Ceramic Materials Used for Metal Melting Crucible?

Ceramic in a melting crucible is not just a container material. It defines how heat flows into the charge, how the melt interacts with the vessel wall, and how failure initiates during thermal cycling. In precious-metal service, ceramic selection directly influences contamination risk and pour stability.

What Role Does Ceramic Play in Melting Crucible?

Dense, compatible ceramics reduce dissolution and particle shedding, lowering inclusions. Microcracks and grain pullout can become contamination sources.

Ceramics set the wall ∆T during ramps, charging, and cool-down. Thermal shock is driven by ∆T and edge/thickness stress—not peak temperature alone.

Ceramic chemistry and surface condition control wetting and adhesion. Erosion or flux roughens the hot face, increasing sticking and forcing harsher cleaning that speeds wear.

Different Ceramic Metal Melting Crucible Material Options

High-purity alumina (Al₂O₃) delivers low contamination risk with stable hot-face integrity and predictable dimensions.

SiC-based ceramics support fast cycling through high thermal shock tolerance and reduced temperature gradients.

Stabilized zirconia (ZrO₂) reduces adhesion in demanding melts while remaining chemically stable at high temperature.

How to Choose a Ceramic Crucible for Metal Melting?

A durable solution requires balancing thermal loading, chemistry, and geometry rather than optimizing one property in isolation. The framework below is designed to help engineers specify a ceramic metal melting crucible that remains stable across real operating variability.

Key Selection Parameters

Engineers must evaluate these interdependent factors:

Operating temperature range: Continuous vs. peak temperature matters; cycling near upper limits accelerates creep and grain-boundary weakening, especially at hot spots.

Atmosphere and fume chemistry: Oxidizing, reducing, inert, or vacuum conditions change surface reactions; flux fumes can be more damaging than the bulk melt.

Melt and flux composition: Alloying elements and flux constituents can shift wetting and corrosion behavior; “same base metal” does not mean same crucible chemistry.

Cycle profile and ∆T: Fast ramp, cold charge additions, and rapid cool-down increase thermal shock load; quantify typical ∆T per cycle, not only setpoint.

Geometry constraints: Diameter-to-height ratio, wall thickness, and rim design drive stress distribution; thin walls reduce thermal lag but raise breakage risk.

Ceramic Metal Melting Crucible Material Comparison

The following materials are commonly specified, each with distinct performance profiles:

| Material | Strengths in This Application | Limitations to Consider | Best-Fit Operating Conditions | Engineering Notes |

|---|---|---|---|---|

| High-purity Alumina (≈99.5–99.8% Al₂O₃) | Low contamination risk; stable in many oxidizing/neutral melts; good dimensional control | Moderate thermal shock tolerance; can be attacked by aggressive fluxes | Medium–high temperature melting with controlled ramping; limited flux exposure | Use adequate wall thickness to manage handling stress; avoid cold-charge shock into hot crucible |

| Stabilized Zirconia (ZrO₂) | Improved interface behavior in some melts; strong chemical stability in select high-value melting | Dense/heavy; thermal gradients can be punishing if ramps are uncontrolled; grade dependent | High-purity melts where sticking/interaction dominates; disciplined thermal schedules | Confirm stabilization system vs. process temperature; design for uniform heating and controlled cool-down |

| SiC-based Ceramics | High thermal conductivity helps reduce gradients; strong thermal shock resistance for faster cycles | Oxidation behavior depends on atmosphere; surface layer changes can affect wetting | Fast cycling, frequent pours, high ∆T service with compatible atmosphere/flux | Consider protective strategies in oxidizing service; verify long-run surface behavior and cleaning method |

Typical Ceramic Crucible for Metal Melting

Engineers specify ceramic crucibles in forms determined by furnace type, capacity requirements, and material handling systems. The following configurations represent standard solutions adapted to common industrial melting scenarios.

alumina ceramic Metal melting crucible

For melting of non-ferrous metals and alloys where clean melt control and stable crucible geometry are required.

Silicon Carbide Metal melting crucible

For fast-cycle metal melting where rapid heat transfer helps reduce hot spots and thermal-shock cracking.

Zirconia ceramic Metal melting crucible

For high-temperature metal melting with strong thermal or chemical load, especially where repeated heat-up and cool-down occur.

Magnesia ceramic Metal melting crucible

For high-temperature metal melting where oxide ceramics require stronger chemical stability under aggressive melt/slag conditions.

Boron Nitride Metal melting crucible

For precision metal melting where non-wetting behavior is needed to ensure controlled melt release and reduced metal loss.

Yttrium Oxide Metal melting crucible

For ultra-clean metal melting where minimizing crucible–melt interaction and trace contamination is a priority.

Cylindrical Ceramic Metal Melting Crucible

Used in uniform-heating metal melting; straight walls improve alignment, stabilize melt circulation, and reduce hot-spot cracking risk.

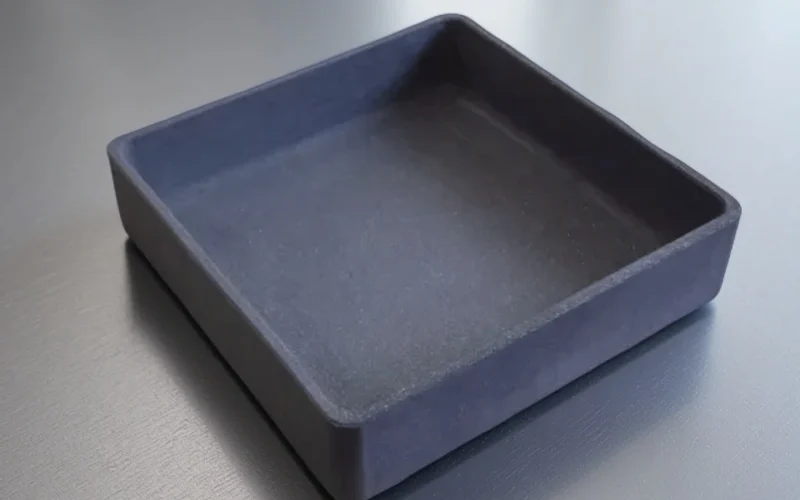

Rectangular Ceramic Metal Melting Crucible

Used in controlled heating applications; flat geometry improves heat isolation and limits direct flame exposure in oxidizing melt cycles.

Trapezoid Ceramic Metal Melting Crucible

Used in sealed mounted melting systems; stepped geometry improves positioning and reduces interface stress.

Conical Ceramic Metal Melting Crucible

Used in fixed-depth melting setups; tapered geometry improves repeatable seating and reduces clamp-induced stress in thermal cycling.

Ceramic Metal Melting Crucible with Spout

Used in controlled pouring melting operations; integrated spout enables stable melt transfer and reduces turbulence during discharge.

Semicircular Ceramic Metal Melting Crucible

Used in fixed-depth melting systems; curved profile improves seating stability and reduces stress concentration during thermal cycling.

Ceramic Metal Melting Crucible Operating Scenarios

These ceramic melting crucibles are used where thermal cycling, contamination risk, and downtime costs exceed conventional refractory limits. The scenarios below reflect typical operating contexts for advanced ceramics.

Aluminum alloy foundries

Operating at 700-780°C with 8-15 cycles per shift. Reaction-bonded SiC crucibles (20-50kg) prevent melt segregation while withstanding thermal shock.

Precious metal refining and jewelry manufacturing

Processing gold, silver, platinum at 1100-1800°C. High-purity alumina (99.7-99.8%, 50g-5kg) maintains karat accuracy and prevents discoloration. Integral pouring lips enable controlled metal transfer.

Copper and brass casting operations

Melting at 1100-1250°C with aggressive flux systems. Silicon carbide crucibles resist flux attack and provide efficient induction coupling. Wall thickness 8-12mm handles 10-30kg melts.

Investment casting foundries

Producing aerospace and medical superalloy components at 1400-1600°C. Zirconia-toughened alumina withstands automated handling while maintaining chemical inertness. Custom geometries fit vacuum chambers and bottom-pour systems.

Laboratory and R&D metal processing

Experimental alloy development with 50g-2kg capacities and frequent composition changes. Multiple standard sizes enable rapid changeover without contamination. Thin walls (2-4mm) minimize thermal mass.

Dental alloy manufacturing

Melting gold-platinum-palladium alloys at 1200-1400°C with strict tolerances. Small high-purity alumina crucibles (5-50g) prevent contamination and ensure batch traceability.

Failure Mode Analysis for Ceramic Metal Melting Crucible

Ceramic crucible failures in metal melting applications follow predictable patterns driven by thermal shock, chemical attack, or mechanical stress. Understanding these failure mechanisms enables material selection optimization and process adjustments that extend crucible service life and reduce downtime costs.

| Observable Symptom | Root Cause Mechanism | Design/Material Adjustment | Prevention Strategy | Notes |

|---|---|---|---|---|

| Rim chips or lip cracks after pouring | Edge tensile stress from handling + rapid cool-down; sharp corners concentrate stress | Add rim reinforcement; specify radiused lip; consider tougher grade | Control cool-down; avoid quenching; use proper tongs/support | Rim damage often precedes full-wall cracking |

| Hairline vertical cracks on sidewall | Thermal gradient stress from fast ramp or cold charge into hot crucible | Increase wall thickness modestly; shift to higher shock-tolerance material | Preheat charge; slow initial ramp; stabilize cycle profile | Track ∆T events, not only setpoint |

| Hot-face spalling and rough inner surface | Flux-driven chemical attack + microcrack growth; weakened grain boundaries | Select more compatible ceramic for flux chemistry; protect hot face via process control | Reduce flux exposure time; avoid over-fluxing; maintain dry charge/flux | Spall fragments become inclusions |

| Metal sticking and difficult pour release | Increased wetting from surface roughness, reaction products, or infiltrated metal | Consider zirconia/engineered oxide for interface; improve surface finish control | Limit aggressive scraping; use controlled cleaning; manage superheat | “Sticking” can signal early penetration damage |

| Localized erosion band or pit | Hot spot overheating from charge geometry or coil coupling; local creep/softening | Modify crucible geometry; consider SiC-based for thermal uniformity | Center charge; avoid bridging; maintain consistent fill level | Erosion bands often align with coil hot zone |

| Sudden breakage during lift/handling | Microcrack network + point loading; mechanical shock at elevated temperature | Increase mechanical robustness; revise support method; tighten handling controls | Use full-support tools; avoid side impact; define safe handling temperature | Handling is often the final trigger, not the root cause |

| “Clean melt” issues: unexpected inclusions | Spalling debris, flux reaction products, or prior-batch residue | Select low-reactivity material; define cleaning protocol; consider single-alloy dedicated crucibles | Avoid aggressive mechanical cleaning; implement inspection before reuse | Cross-contamination risk increases with reuse cycles |

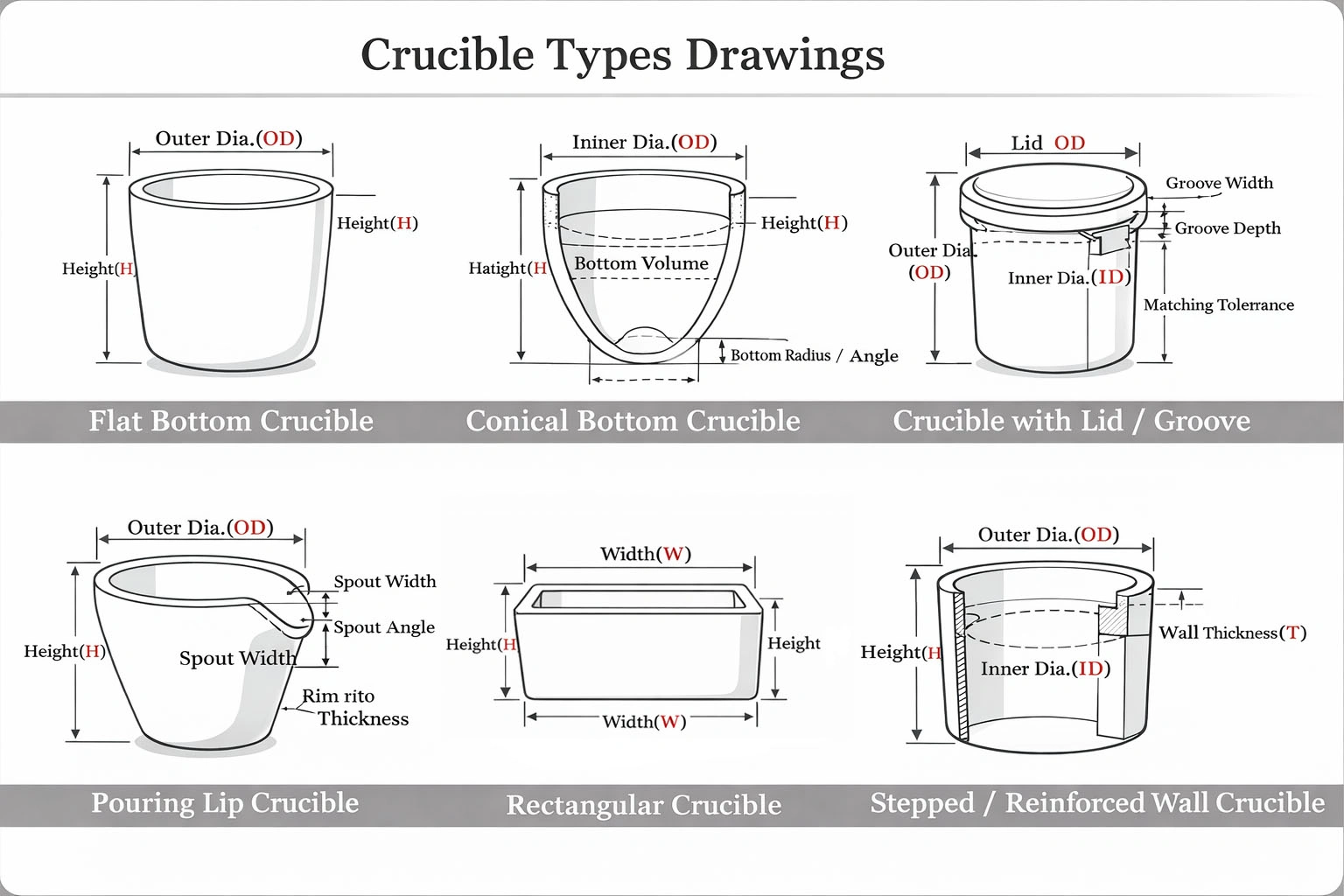

Ceramic Metal Melting Crucible Customization

Standard crucibles rarely match real melting conditions. ADCERAX supports custom ceramic melting crucibles engineered around your metal type, thermal cycle, and furnace interface to reduce cracking, contamination, and handling risk.

Why Custom Crucibles Are Specified ?

Melting temperatures or thermal ramp rates exceed standard design limits

Crucible geometry must match furnace holders, induction coils, or clamps

Melt cleanliness or wetting behavior is critical to yield

Repeated cracking occurs at rims, corners, or mounting interfaces

Pouring, transfer, or automation requires controlled geometry

What Can Be Customized?

Geometry & Structure

- Inner diameter / outer diameter / height

- Wall thickness zoning (reinforced rim or base)

- Cylindrical, conical, trapezoid, rectangular, or hybrid profiles

- Flat bottom, rounded bottom, or reinforced base

- Integrated spout, lip, or pouring edge (optional)

Material & Grade

- Alumina (Al₂O₃)

- Zirconia and ZTA

- Boron nitride (BN)

- Magnesia (MgO)

- Yttria-based ceramics (Y₂O₃)

Surface & Performance Tuning

- Hot-face finish to reduce wetting or erosion

- Edge rounding to limit stress concentration

- Density and microstructure tuning for contamination-sensitive melts

Custom Ceramic Metal Melting Crucible: What to Provide?

To evaluate a custom crucible, engineers typically provide:

Metal or alloy type

Operating temperature range and cycle profile

Furnace type and mounting method

Required melt capacity

Drawing, sketch, or reference sample

Quick Acceptance Checklist for Ceramic Metal Melting Crucible

Operating Environment

| Operating Environment |

|---|

| ☐ Maximum continuous operating temperature: ___ °C |

| ☐ Peak temperature during transients/superheat: ___ °C |

| ☐ Atmosphere defined (oxidizing / reducing / inert / vacuum) |

| ☐ Flux type and quantity documented (if used) |

| ☐ Charge condition controlled (dry / preheated / oily/painted scrap) |

Performance Requirements

| Performance Requirements |

|---|

| ☐ Contamination tolerance defined (acceptable inclusion level / purity requirement) |

| ☐ Thermal cycling frequency and typical ΔT per cycle established |

| ☐ Sticking risk assessed (metal/alloy and surface interaction history) |

| ☐ Cleaning and reuse method defined (scrape / burn-out / chemically compatible method) |

Design Parameters

| Design Parameters |

|---|

| ☐ Target capacity and fill height range defined |

| ☐ Wall thickness preference stated (response time vs robustness trade-off) |

| ☐ Rim/lip geometry requirement defined (radiused edge, reinforced rim if needed) |

| ☐ Coil clearance and installation constraints confirmed |

| ☐ Support method defined (base support vs side support; no point loading) |

Operational

| Operational |

|---|

| ☐ Ramp schedule defined for first heat and routine cycles |

| ☐ Cold charge addition rules established (mass, timing, preheat requirement) |

| ☐ Replacement indicators defined (crack length, spall %, erosion depth) |

Get in touch with us

Share your alloy type, temperature profile, atmosphere/flux conditions, and mounting constraints with our engineering team.

Visit the Ceramic Crucible page for standard specifications, or submit drawings for custom geometry and manufacturability review.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.