Ceramic Shaft Built for Wear, Corrosion and Long Service Life

ADCERAX is a ceramic shaft manufacturer, providing ceramic pump shaft and custom-to-drawing shaft components for wear- and corrosion-critical service. Material options include alumina, zirconia, silicon carbide, selected to stabilize fit and sealing performance where metal shafts pit, score, or drift—causing leakage, vibration, and frequent changeouts.

With fast engineering review, flexible small-batch sampling, and consistent grinding/lapping control, ADCERAX helps buyers validate quickly and scale to repeat production with reliable delivery.

What is a Ceramic Shaft?

A ceramic shaft is a precision shaft component made from technical ceramics—commonly alumina or zirconia—used to support rotation or alignment in corrosive, abrasive, or high-wear environments.

Compared with metal, it resists chemical attack and scoring, helping keep sealing surfaces and fit tolerances stable so pumps and drive assemblies run longer with fewer leaks and unplanned replacements.

Ceramic Shaft Characteristics & Guidance

Precision ceramic shafts deliver stable performance in wear, heat, and corrosive service. High hardness and low friction help maintain shaft geometry and sealing interfaces, while thermal and chemical resistance reduce deformation, scoring, and leakage in harsh operating conditions.

Ceramic Shaft Data Sheet

Alumina Ceramic Shaft

High-hardness shafts with reliable electrical insulation, keeping fit stable and reducing scoring that drives early seal leakage. A cost-effective choice for repeatable industrial shaft builds.

| Property | Unit | 99% Al₂O₃ | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

|---|---|---|---|---|---|---|---|---|

| Alumina content | % | 99 | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.88 | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Flexural strength | MPa | 360 | 379 | 312 | 313 | 314 | 315 | 320 |

| Hardness | GPa | 13.5 | 14.1 | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 30–35 | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | 200 | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1700 | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.2 | 8.4 | – | – | – | – | – |

| Melting point | °C | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 | ≈2050 |

Zirconia Ceramic Shaft

Tough, chip-resistant shafts that handle impact and assembly stress, protecting edges and alignment in compact, fit-critical mechanisms. Best when shock and handling risk are higher.

| Property | Specification |

| Maximum Working Temperature | 1500 °C continuous use |

| Density | 5.65 g/cm³ |

| Thermal Expansion Coefficient | 10.3 × 10⁻⁶/K (25–1000 °C) |

| Thermal Conductivity | 2.2 W/m·K at 1000 °C |

| Chemical Stability | 0.08% mass loss after 24 h acid/alkali exposure at 1200 °C |

| Flexural Strength | 900 MPa at room temperature |

| Fracture Toughness | 8 MPa·m½ |

| Hardness (Vickers) | 12 GPa |

| Elastic Modulus | 210 GPa |

Silicon Carbide Ceramic Shaft

Maximum abrasion and corrosion resistance for harsh wet-end duty, staying smooth in aggressive media to protect sealing interfaces and extend service intervals. Ideal for severe slurry/chemical wear.

| Property | Specification |

|---|---|

| Material System | RBSiC (80% SiC, 20% free Si) / SSiC (≥99% SiC) |

| Maximum Operating Temperature | ≤1380°C (RBSiC) / ≤1600°C (SSiC) |

| Bulk Density | 3.02 g/cm³ (RBSiC) / 3.10 g/cm³ (SSiC) |

| Open Porosity | <0.1% |

| Flexural Strength (20°C) | 250 MPa (RBSiC) / 380 MPa (SSiC) |

| Flexural Strength (1200°C) | 280 MPa (RBSiC) / 400 MPa (SSiC) |

| Compressive Strength | 1000–2200 MPa |

| Elastic Modulus | 330 GPa (RBSiC) / 420 GPa (SSiC) |

| Thermal Conductivity | 45 W/m·K (RBSiC) / 74 W/m·K (SSiC) |

| Thermal Expansion Coefficient | 4.1–4.5 ×10⁻⁶/K |

| Hardness | 2600–2800 kg/mm² |

How to Choose the Right Ceramic Shaft for Your Duty

⭐Typical temperature guidance

1. Alumina: up to ~1,000–1,500°C (dry/non-impact duty)

2. Zirconia: up to ~400–600°C (toughness-first builds)

3. Silicon Carbide: up to ~1,400–1,600°C (hot, abrasive, aggressive media)

⭐Corrosion & wear duty (quick wins)

1. Alumina: reliable general wear + insulation; strong value in most wet-end duty

2. Zirconia: better chip/impact tolerance when handling and assembly stress is higher

3. Silicon Carbide: strongest abrasion + chemical resistance for severe slurry/chemical service

⭐ High-speed vs low-speed selection

1. High-speed / seal-sensitive: prioritize surface stability—often SiC, or alumina for cost-focused wear duty

2. Low-speed / shock or handling risk: prioritize toughness—often zirconia to reduce chipping

3. If the main issue is leakage, prioritize sealing-zone finish and runout control, not only bulk strength

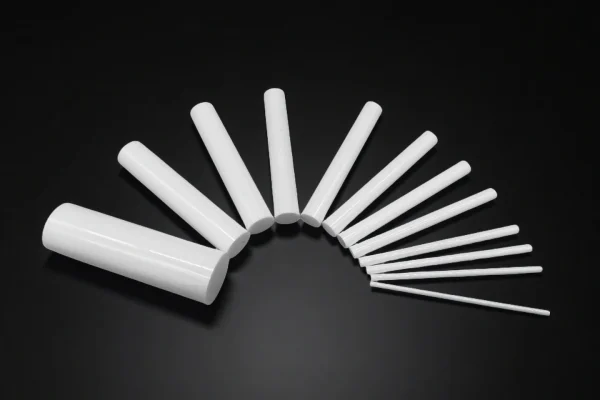

Ceramic Shaft Products & Types

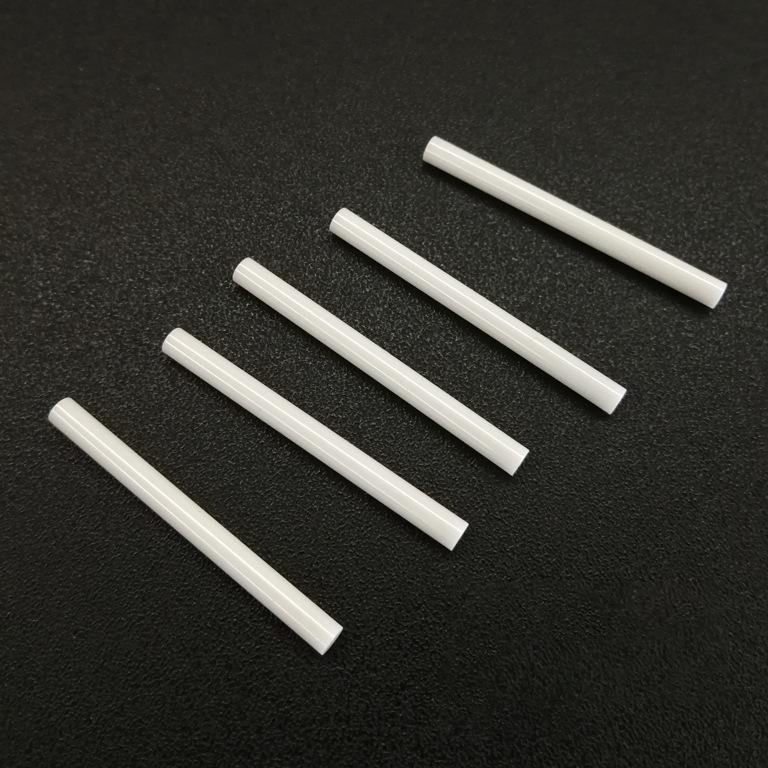

Precision machining ceramic shaft products include ceramic pump shafts, plunger shafts, motor shafts, shaft seals, and shaft-and-bushing assemblies. ADCERAX supplies alumina, zirconia, and silicon carbide options in standard sizes or custom-to-drawing builds to reduce wear, corrosion, leakage, and fit drift.

Alumina Ceramic Shaft

High-hardness, electrically insulating shafts that keep fit stable in abrasive duty—ideal for cost-effective wear control and dimensional repeatability.

zirconia ceramic shaft

Tough, chip-resistant shafts that tolerate impact and assembly stress—best for compact mechanisms where edge damage shortens life.

Silicon Carbide ceramic Shaft

Ultra wear- and corrosion-resistant shafts that stay smooth in aggressive media—built for severe service where seal life matters.

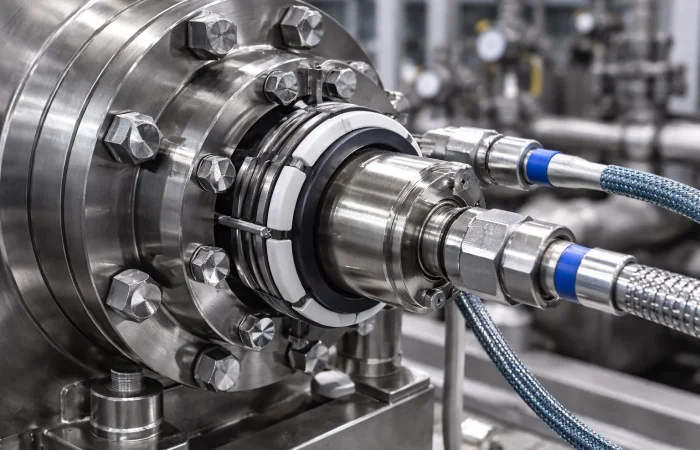

ceramic pump shaft

Wear- and corrosion-resistant shafts for pump wet ends—keeping rotation smooth, sealing stable, and service life longer in harsh media.

ceramic plunger shaft

High-strength ceramic shafts for reciprocating duty—maintaining tight fit and low wear under pressure, impact, and abrasive contact.

ceramic motor shaft

Dimensionally stable ceramic shafts for precision drive systems—supporting smooth rotation, electrical insulation, and long-term alignment accuracy.

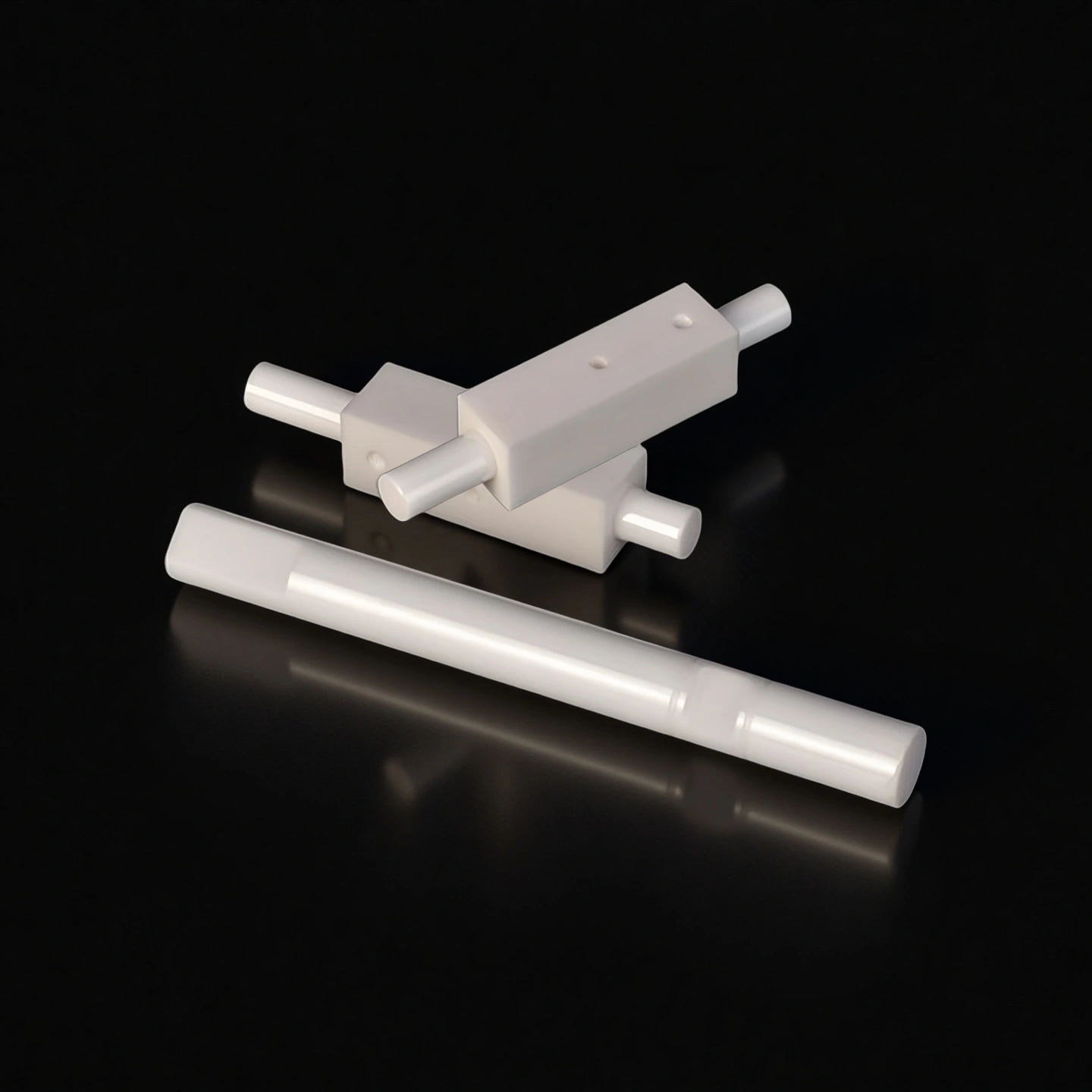

ceramic shaft seal

Hard, smooth ceramic sealing surfaces that reduce scoring and leakage—helping seals run cooler, last longer, and stay reliable in demanding service.

Ceramic Shafts — Reduce Wear, Leakage, and Fit Drift in Critical Assemblies.

Ceramic Shaft Applications

Ceramic shafts are used in pump wet ends, mechanical seal interfaces, drive/motor assemblies, and shaft-and-bushing systems to control wear, corrosion, heat stress, and fit drift at critical interfaces.

Pump & Fluid Handling Systems

💠Where ceramic shafts are used

Ceramic pump shafts are commonly used in chemical pumps, dosing pumps, water pumps, and magnetic drive pumps. Their hardness and corrosion resistance help protect sealing zones, reduce scoring, and keep clearances stable—extending service intervals in abrasive or chemically aggressive media.

💠Why choose ceramic shaft for pump: longer seal life, lower leakage risk, reduced maintenance.

Shaft Seals & Mechanical Seal Interfaces

💠Where ceramic shaft are used

Ceramic mechanical shaft seals are widely applied as wear surfaces in mechanical seal systems. Their smooth, hard surfaces reduce seal face damage and heat buildup, helping seals run cooler and more consistently in demanding duty.

💠Why choose ceramic shaft seal: reduced leakage, longer seal runtime, cleaner contact surfaces.

Motor & Drive Components

💠Where ceramic motor shaft are used

Ceramic motor shafts and drive shafts are used where electrical insulation, corrosion resistance, or dimensional stability is required. They help maintain alignment and smooth rotation in compact drive systems exposed to moisture, chemicals, or frequent washdown.

💠Why choose ceramic shaft for motor: insulation, vibration control, alignment stability.

Plunger, Piston, and Reciprocating Assemblies

💠Where ceramic plunger shaft are used

In ceramic plunger pumps and reciprocating mechanisms, ceramic shafts resist wear and surface damage under repeated contact, pressure, and impact. This helps maintain tight fit and consistent motion where metal shafts quickly polish or gall.

💠Why choose ceramic plunger shaft: stable motion, reduced wear debris, predictable service life.

Customize Ceramic Shaft Supplier

ADCERAX custom ceramic shafts are made to your drawing and fit requirements in alumina, zirconia, or silicon carbide. Share key dimensions, tolerances, surface finish, and quantity for a fast review. Typical custom lead time is 2–9 weeks, depending on complexity.

Customization Options

Define the duty first—media, corrosion, abrasion, temperature, speed, and load. Proper material selection helps the ceramic shaft resist scoring and chemical attack while keeping fit stable.

Share your key fit zones—OD/length/steps and how the shaft locates in the housing, bushing, or seal. Controlled geometry improves alignment, reduces runout, and simplifies replacement.

Focus on the contact behavior—rotation, sliding points, particles, and lubrication. A well-specified ceramic shaft slows clearance growth and protects sealing and bearing interfaces.

Specify where finish matters—bearing diameters, sealing zones, and end faces—plus acceptance criteria. Proper grinding/lapping and inspection improve repeatability and reduce assembly variation.

Customization Process

Share your drawing or key dimensions (OD/ID/length), quantity, tolerance targets, surface finish needs, and duty conditions.

We confirm material selection, fit intent, and critical zones (sealing/bearing surfaces) with you before production.

We manufacture ceramic shafts to spec, then inspect key dimensions and functional surfaces for batch repeatability.

Shafts are protected, labeled, and shipped with complete export-ready documents for smooth delivery.

ADCERAX: Factory-Direct Ceramic Shaft Supplier in China

ADCERAX is a China-based ceramic shaft manufacturer with factory-direct engineering support and controlled production for consistent fit and surface quality. Fast drawing review, flexible small-batch sampling, and batch inspection help reduce risk and keep repeat-order supply reliable.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX Ceramic Shaft Factory & Exporter

ADCERAX specializes in export-ready ceramic shaft manufacturing from China, backed by 20+ years of advanced ceramics experience and proven process control. We produce shafts in alumina, zirconia, silicon carbide, and silicon nitride for harsh-duty service.

Standard options support fast replacement, and custom-to-drawing builds are available for fit-critical designs. With batch inspection, traceable records, and export-ready packing, ADCERAX helps buyers keep supply stable, reduce scrap, and maintain predictable maintenance cycles.

Ceramic Shaft Manufacturing Process

Controlled powder selection and mixing to support stable sintering and repeatability.

Pre-sinter features such as holes, slots, or reliefs to reduce post-fire machining load.

Finish OD/steps and fit-critical zones;define sealing/bearing surfaces and required surface finish.

Near-net shaping based on shaft geometry to build uniform density before firing.

Firing to develop hardness, strength, and corrosion resistance with shrinkage.

Dimensional and surface checks for batch consistency, then protective packing for export delivery.

FAQs About Ceramic Shaft

| Factor / Item | Ceramic Shaft | Metal Shaft |

|---|---|---|

| Wear resistance | Very high; surface stays hard and smooth in abrasive duty | Moderate; surfaces polish, score, and wear faster under particles |

| Corrosion resistance | Excellent in many acids, alkalis, and aggressive media (material-dependent) | Prone to rust, pitting, and chemical attack without coatings or alloys |

| Dimensional stability | Low thermal expansion; clearances change more slowly over time | More prone to distortion and clearance drift from heat and load |

| Sealing & leakage control | Stable, smooth sealing zones; longer seal life and lower leakage risk | Seal areas damage more easily, leading to higher leakage risk over time |

| Electrical insulation | Naturally insulating; can combine structural and insulation functions | Conductive; requires sleeves or coatings when insulation is needed |

| Service life & maintenance | Longer, more predictable life in harsh duty; fewer replacements | More frequent replacement and maintenance in corrosive or abrasive duty |

| Initial part cost | Higher piece price but often lower life-cycle cost | Lower upfront cost but higher total cost where wear/corrosion are severe |

| Machinability / rework | Needs dedicated ceramic machining; finished parts are difficult to rework | Easily machined and modified with standard metalworking processes |

Ceramic shafts are worth choosing over metal when corrosion, abrasion, or leakage are the main failure drivers, because they keep surface finish and fit much more stable in harsh media. Even with a higher unit price, they usually deliver longer service life, fewer seal problems, and lower total cost than metal shafts in demanding duty.

- Alumina is a cost-effective wear and insulation choice for many duties.

- Zirconia is tougher and more chip-resistant under impact/handling.

- Silicon carbide is preferred for severe abrasion plus chemical attack where you want maximum surface durability.

A drawing is best. If not, send OD/ID/length, step details, tolerance targets, surface finish needs, duty conditions (media/temp/speed), and quantity. This is enough to confirm feasibility and quote accurately.

Yes. Custom-to-drawing production is supported for fit-critical shafts, including stepped geometries and functional surfaces. We review the critical zones first to prevent mis-specs.

Yes. Stepped shafts and fit features are supported. The best path depends on geometry—some features are planned early, then finished by grinding/lapping to achieve final fit.

Yes, depending on hole size, location, and tolerance. Holes and features are typically planned to reduce crack risk and improve repeatability. Share the hole spec and whether it is through or blind.

Leakage control depends on stable fit, correct surface finish at the seal zone, and alignment/runout control. Specify the sealing interface clearly and avoid mixing “unknown finish” with high-sensitivity seals.

Yes. Ceramic shafts are frequently paired with bushings/sleeves to control wear and clearance growth. If you share the bushing material and lubrication conditions, we can advise on pairing priorities.

Yes. Small-batch sampling is supported to validate fit and life before repeat production. This is common for new designs or replacement conversions from metal.

Why choose ceramic shaft instead of metal shaft

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.