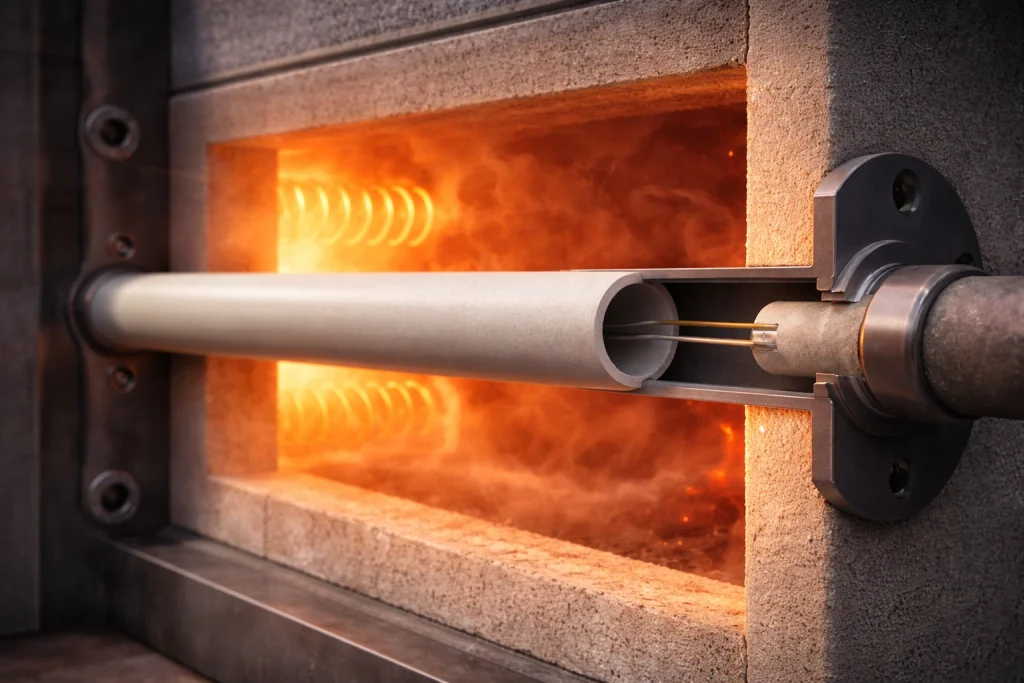

Ceramic Thermocouple Protection Tubes for Stable, Low-Drift Measurement

Ceramic thermocouple protection tubes are used in high-temperature furnaces and reactive process environments to protect the junction, reduce drift, and stabilize temperature feedback. Core advantages:

🛡️Junction isolation from furnace chemistry and deposits;

♨️High-temperature and thermal-cycling capability (alumina for 1700°C+ continuous service, SiC for severe cycling);

🧩Fit-up flexibility with custom lengths, closed-end tips, multi-bore designs, and flanged interfaces for repeatable installation.

Thermocouple Tube Failure Causes

Thermocouples in furnaces and reactors often fail early when the hot zone combines high heat, corrosive vapors, and frequent thermal cycling.

Metal sheaths can oxidize, scale, or carburize, which alters heat transfer and gradually shifts temperature readings. In reactive atmospheres, deposits and vapors can contaminate noble-metal thermocouple wires, increasing drift and accelerating calibration loss.

Fast transients—such as door-open events, purge changes, or aggressive ramp rates—can crack brittle protection parts when clearance, alignment, and mounting compliance are not controlled.

Why Thermocouple Tube Fails in Service?

In high-temperature service, thermocouples often drift before they fail. Reactive vapors and deposits can change junction conditions, while thermal cycling and constraint can crack the protection tube and shift alignment.

Thermal shock and temperature gradients

rapid insertion, door opening, and fast ramp cycles drive steep gradients across the tube wall, initiating cracks at the closed end or near support points.

Chemical attack and vapor transport

alkali vapors, glassy phases, fluxes, and process volatiles can react with the tube or migrate through micro-porosity, reaching the thermocouple junction.

Contamination-driven drift

at high temperature, small amounts of vapor exposure can change junction conditions and shift EMF output, especially in long-duration holds.

Mechanical stress and constraint

tight fits, misalignment, or differential expansion between tube and mounting hardware create bending stress and edge chipping.

Creep/softening of non-ceramic supports

metal holders or thin shields can deform at temperature and force the tube into contact with the load or hot-face.

Why Are Ceramic Materials Used for Thermocouple Protection Tubes?

High-temperature failure is rarely “temperature only.” In furnaces and reactors, reactive vapors, deposits, and thermal cycling attack the sheath and contaminate the junction, which drives drift and unstable feedback. Ceramic tubes are used to place a dense, insulating barrier between the atmosphere and the hot junction.

What ceramics address in hot-zone measurement ?

maintains insulation when conductive films form

reduces reactions and deposits at the junction

prevents cracks from constraint and expansion

Different Ceramic Thermocouple Protection Tube Material Options

Stable electrical insulation and chemical neutrality in many oxidizing/neutral furnace atmospheres.

Higher thermal conductivity and robustness for harsh handling and faster thermal profiles

Toughness and thermal-shock resistance for cycling- and vibration-dominated installations.

How to Choose a Ceramic Thermocouple Protection Tube?

Thermocouple ceramic tubes are used to isolate the junction from furnace chemistry and handling while staying stable at high temperature. Unlike general sensor protection tubes that focus on abrasion or corrosion, thermocouple tubes prioritize contamination control and drift reduction.

Key Selection Parameters

In furnaces and reactors, thermocouple protection tubes are function-critical components that directly influence measurement stability and service life.

Material selection, tube geometry, and mounting conditions determine resistance to heat, atmosphere attack, drift, and thermal shock.

peak temperature, soak duration, ramp rate, and the number of cycles per week.

oxidizing, neutral, vacuum, or mixed; identify vapors (alkali, borates, silica, metal fumes) that can drive drift or tube reaction.

insulation needs, risk of conductive deposits, and cold-end creepage/clearance expectations for signal stability.

OD/ID targets, closed-end thickness, immersion length, straightness, and any dual-bore/insulator needs inside the sheath.

how the tube is supported (cantilever vs guided), clamp compliance, allowance for thermal expansion, and required clearance to avoid binding.

Thermocouple Protection Tube Material Comparison

| Material | Strength | Limitations | Best-fit Conditions | Notes |

|---|---|---|---|---|

| High-purity Alumina (Al₂O₃) | High-temp rigidity; electrical insulation | Can crack with thermal shock; dislikes constraint | Furnaces where drift/contamination control matters (oxidizing/neutral) | Use stable fit, controlled insertion, and clearance |

| Silicon Carbide (SiC) | High thermal conductivity; good toughness | Atmosphere/drift sensitivity must be checked | Robust handling and fast thermal profiles where chemistry allows | Use when vapor-driven drift is not the main risk |

| Silicon Nitride (Si₃N₄) | High fracture toughness; strong thermal-shock resistance | Oxidizing/hot-gas chemistry must be verified; cost higher | Severe thermal cycling, vibration, and mechanically demanding installs | Prioritize clearance and compliant mounting to avoid point loads |

| Zirconia (ZrO₂) | Low thermal conductivity; good hot stability | Lower thermal shock margin; cost higher | When heat loss reduction and junction shielding matter | Keep clearance; avoid tight clamping and fast insertion |

Typical Ceramic Tube Builds for Thermocouple Protection

Thermocouple protection tubes are selected by balancing material and configuration. Material affects insulation, contamination control, corrosion resistance, and response, while tube form (open/closed end, multi-bore, flange/thread) controls junction exposure and installation repeatability.

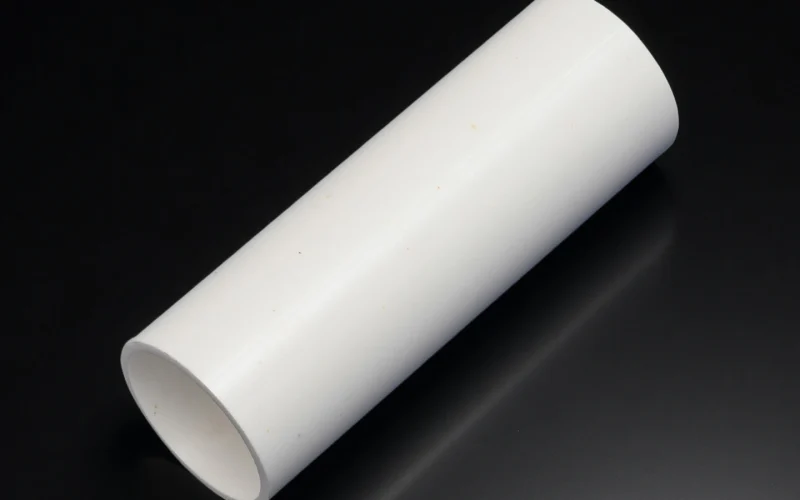

alumina thermocouple protection tube

High electrical insulation and chemical stability for low drift protection.

Thermocouple Zirconia Ceramic Tube

High toughness and thermal-shock resistance for cycling stability.

silicon carbide thermocouple protection tube

High thermal conductivity and strength for fast, reliable response.

silicon nitride thermocouple protection tube

High electrical insulation and chemical stability for low drift protection.

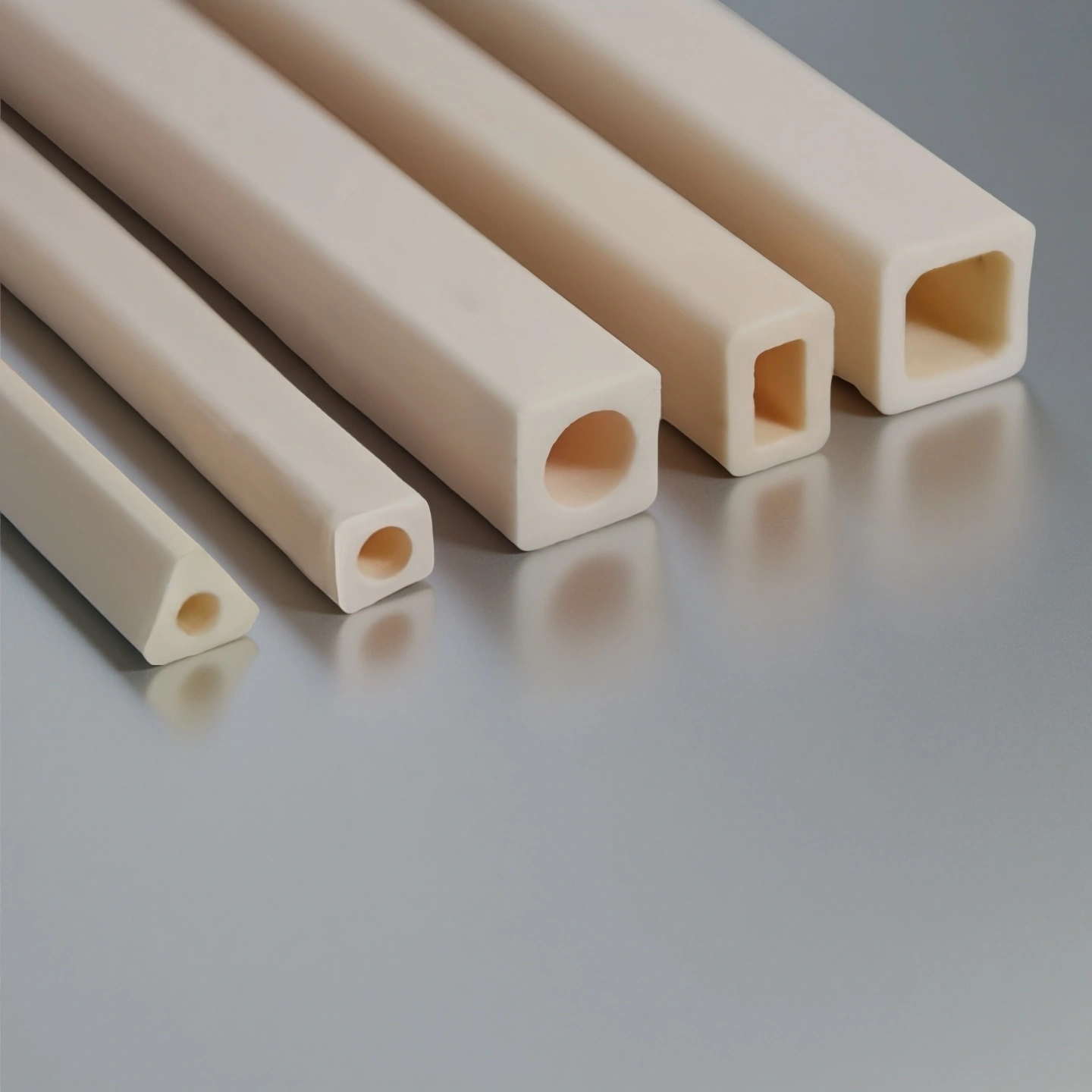

Square ceramic thermocouple protection tubes

For constrained mounts and fixed-orientation requirements. Square profile prevents rotation and improves alignment.

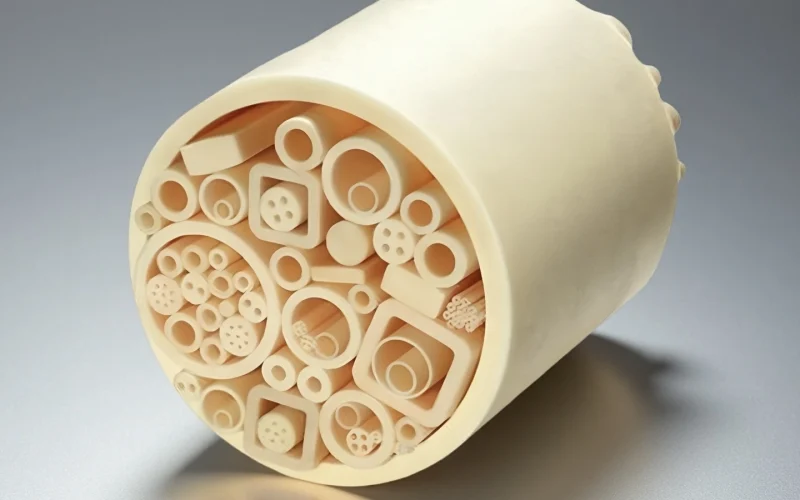

Multi-Bore Ceramic thermocouple protection tubes

For multi-element probes and drift-sensitive control loops. Separated bores improve insulation and reduce cross-talk.

ceramic thermocouple protection tubes, Open Both Ends

For guided furnace installs and frequent probe replacement. Open-through design enables fast insertion and easy maintenance.

ceramic thermocouple protection tubes, One End Closed

For corrosive atmospheres and drift-sensitive temperature control. Closed tip isolates the hot junction to reduce contamination exposure.

ceramic thermocouple protection tube with threaded

For threaded ports requiring adjustable insertion depth. Threaded mounting locks position with repeatable adjustment.

ceramic thermocouple protection tube with flange

For wall penetrations needing fixed depth and sealing. Flange mounting stabilizes position and supports sealing.

Ceramic Thermocouple Protection Tubes Applications

Ceramic thermocouple protection tubes are specified where high temperature, aggressive atmospheres, or thermal cycling would degrade metal sheaths and destabilize temperature measurement.

High-Temperature Furnaces

1.Continuous/batch furnaces in controlled atmospheres

2.Limits scale buildup and measurement drift

3.Common in heat treatment, sintering, and kilns

Chemical Reactors & Process Vessels

1. Reactive gas service with corrosive vapors

2. Isolates the junction from chemical attack

3. Maintains stable readings in long soaks

Metallurgical & Foundry Operations

1. High thermal gradients and intermittent exposure

2. Thermal shock, abrasion, and slag resistance

3. Often paired with closed-end or thick-wall tube designs

Power, Energy & Thermal Systems

1. Boilers, reformers, and high-temperature test rigs

2. Stable insulation and protection under thermal cycling

3. Suitable for long insertion lengths and guided mounting

Failure Modes and Mitigation for Ceramic Thermocouple Tubes

Most protection-tube issues are driven by thermal gradients, atmosphere attack, and mounting constraints. Use the table below to match visible symptoms to likely causes and practical design adjustments.

| Symptom | Likely cause | Design / material adjustment | Notes |

|---|---|---|---|

| Hot-end cracking (axial or star cracks) | Thermal shock from fast ramps, door-open events, or cold purge | Increase clearance and add compliant support; consider a more shock-tolerant material/geometry | Avoid rigid clamping near the hot zone |

| Chipping at mouth or support point | Mechanical contact, vibration, misalignment during insertion | Add chamfer/lead-in; improve alignment; use wear-resistant contact region if unavoidable | Many cracks initiate from edge damage |

| Rapid drift / unstable readings | Vapor/deposit contamination of the junction; leakage paths from conductive deposits | Use high-purity alumina for insulation; add sealing/purge control; keep junction isolated from deposits | Drift is often contamination-driven, not sensor failure |

| Surface glazing, pitting, or erosion | Atmosphere chemistry attack, particulate impingement, or slag exposure | Switch to a chemistry-appropriate ceramic (often SiC in harsher exposure); add baffles/shields | Confirm atmosphere species, not only temperature |

| Tube bending or sag over time | Over-temperature soak, long unsupported span, creep under load | Increase wall thickness; shorten unsupported length; add guided support | Treat hot-end temperature as the design limit |

| Premature fracture at mounting interface | Constraint from tight fit, hard set-screws, or thermal expansion mismatch | Use compliant collars; define cold-end clearance; avoid point loading | Mounting design often dominates reliability |

| Seal leakage at wall penetration | Gasket mismatch, flange distortion, or thermal cycling loosening | Use stable sealing stack; control flange flatness; verify thermal expansion allowances | Leaks often appear after cycling, not at install |

| Internal wire shorting (multi-bore) | Deposit bridging, damaged bores, or wire movement under vibration | Specify correct bore spacing; secure wires; keep deposits out via sealing/purge | Improves signal stability in multi-element probes |

Custom Thermocouple Protection Tubes Options

In hot-zone temperature measurement, customization is typically driven by thermal gradients, atmosphere exposure, and mounting constraints, rather than appearance or nominal size.The following options are commonly adjusted to control failure modes such as cracking, drift, or unstable insertion depth.

Custom Options Matrix

| Custom Parameter | Typical Range / Form | Why It Matters in This Application |

|---|---|---|

| Closed-End Thickness | ~1.5–3 mm (typical) | Balances response time and mechanical strength at the hot tip; overly thin ends crack under cycling, overly thick ends slow response. |

| Multi-Bore Configuration | 2-bore / 4-bore / 6-bore | Separates thermocouple wires, improves insulation, and reduces cross-talk or contamination between elements. |

| Flange or Threaded Interface | Designed to match furnace wall or reactor nozzle | Enables repeatable insertion depth, reliable sealing, and controlled axial positioning under thermal expansion. |

| Overall Length & Immersion Depth | Set by hot-zone location | Determines whether the junction sits fully inside the stable temperature zone rather than boundary or gradient regions. |

Installation & Fit-Up Notes

Clearance and mounting compliance are as important as material choice; tight clamping often drives early cracking during ramps.

Closed-end geometry should be matched to ramp rate and cycling severity, not only maximum temperature.

Interface features (flange/thread) are primarily measurement-control features, not mechanical conveniences.

Ceramic Thermocouple Tubes Quick Acceptance Checklist

Thermal & Environment

| Thermal & Environment |

|---|

| ☐ Maximum hot-end temperature |

| ☐ Atmosphere type and corrosive vapors |

| ☐ Thermal cycling severity |

Geometry & Installation

| Geometry & Installation |

|---|

| ☐ Tube form selection |

| ☐ Mounting interface |

| ☐ Clearance and alignment |

Measurement & Stability

| Measurement & Stability |

|---|

| ☐ Drift and contamination control |

| ☐ Signal stability requirements |

| ☐ Noble-metal thermocouple protection |

Dimensions & Quality

| Dimensions & Quality |

|---|

| ☐ OD / ID / overall length |

| ☐ Abrasion or slag exposure |

| ☐ Inspection scope and traceability |

Get in touch with us

Share your temperature profile, atmosphere, and mounting constraints to narrow material and geometry. For dimensions and tolerances, see the parent page: Ceramic Tubes.

Send a drawing or failed part for fit-up and failure review.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.