tga alumina crucibles are critical consumables in thermogravimetric analysis, where microgram-level mass stability directly affects baseline accuracy, repeatability, and data credibility.

Thermogravimetric analysis operates at extreme sensitivity; therefore, even trace residues on tga alumina crucibles can propagate into measurable analytical deviation. Consequently, cleaning is not a routine maintenance step but a controlled engineering process tied to data validity. This article establishes a structured, decision-driven approach to cleaning TGA alumina crucibles used in industrial and research laboratories.

Clean or Discard? The First Decision Before Any TGA Alumina Crucible Cleaning

Before any cleaning action is attempted, a clear binary judgment must be made regarding the crucible’s recoverability. In practice, many laboratories instinctively attempt cleaning without evaluating whether the crucible can still deliver stable mass behavior. As a result, time is often wasted on crucibles that have already exceeded their functional lifespan.

-

Cleanable contamination scenarios

Organic residues and light carbon deposits are the most common contaminants encountered in tga alumina crucibles. These residues typically originate from polymer binders, additives, or organic coatings and generally decompose below 600 °C. In controlled laboratory environments, crucibles with such contamination often regain mass stability within ±0.01–0.02 mg after appropriate cleaning, allowing reuse without compromising baseline quality. Consequently, cleaning remains a technically sound option in these cases. -

Non-recoverable contamination scenarios

Metal oxides and molten inorganic salts present a fundamentally different risk profile. At temperatures exceeding 800 °C, these materials can infiltrate alumina porosity or chemically interact with the crucible surface. Empirical observations show that once penetration depth exceeds approximately 50–100 µm, mass instability persists despite repeated cleaning attempts. Therefore, continued reuse introduces systematic error rather than restoring reliability. -

Data-driven discard indicators

Post-cleaning mass instability provides the most objective discard criterion. If mass variation exceeds 0.05 mg across three consecutive heating–cooling cycles, or baseline noise increases by more than 20% compared to historical blanks, the crucible no longer meets analytical reliability thresholds. Under those circumstances, further cleaning becomes counterproductive.

Recognizing these boundaries at the outset ensures that subsequent cleaning efforts are applied only where meaningful data recovery remains achievable.

Why Proper Cleaning Directly Determines TGA Data Accuracy and Reliability

Once a crucible is confirmed to be recoverable, the role of cleaning must be clearly understood. Cleaning quality directly governs baseline stability, repeatability, and instrument protection; therefore, its impact extends far beyond visual cleanliness. In practice, most unexplained TGA deviations trace back to incomplete or inappropriate cleaning rather than instrument malfunction.

-

Baseline drift caused by residual mass

Residual contamination as low as 20–30 µg can induce baseline shifts of 0.2–0.3% when typical sample masses are around 10 mg. Such deviations may appear minor; however, in comparative studies or kinetic evaluations, they can invert conclusions. Consequently, proper cleaning functions as a primary control variable rather than a secondary precaution. -

Repeatability loss across consecutive measurements

In routine industrial testing, laboratories frequently observe relative standard deviation rising from below 1% to above 5% after multiple reuse cycles when cleaning protocols are inconsistent. This degradation occurs even when the same heating program is applied. As a result, method validation fails not because of procedural flaws but because crucible mass behavior is no longer reproducible. -

Risk of sensor and furnace contamination

Volatile residues remaining on inadequately cleaned tga alumina crucibles can redeposit onto balance components or furnace liners during subsequent runs. Over time, this leads to sensor drift and increased recalibration frequency. Operational records indicate that uncontrolled contamination can add several hours of downtime per month, directly affecting laboratory throughput.

For these reasons, cleaning quality must be evaluated in terms of its measurable influence on analytical performance rather than surface appearance alone.

Common Types of Contamination in TGA Alumina Crucibles

Before any cleaning method is selected, contamination type must be identified, because different residues interact with alumina through distinct physical and chemical mechanisms. Moreover, misclassification often leads to ineffective cleaning and recurring baseline instability. Therefore, this section categorizes the most common contamination modes observed in tga alumina crucibles.

Organic Residues and Carbonaceous Deposits

Organic contamination is the most frequently encountered condition in routine TGA work, particularly in polymer, adhesive, and coating analyses. Typically, binders and additives undergo partial decomposition, leaving carbonaceous films that adhere to crucible walls after heating cycles.

In practical laboratory settings, these residues often contribute 0.1–0.3 mg of stable mass after a single run. Furthermore, repeated exposure can densify carbon layers, raising oxidation onset temperatures above 450–550 °C. Consequently, incomplete removal leads to gradual baseline elevation rather than abrupt anomalies.

When properly addressed, controlled oxidative cleaning restores crucible mass stability within ±0.02 mg in more than 90% of observed cases. Therefore, organic residues generally represent a recoverable contamination class.

Typical Characteristics of Organic Contamination

| Parameter | Observed Range |

|---|---|

| Residual mass contribution (mg) | 0.05–0.30 |

| Oxidation onset temperature (°C) | 350–550 |

| Baseline drift impact (µg) | 10–40 |

| Recovery success rate (%) | 85–95 |

Inorganic Salts, Oxides, and Mineral Residues

Inorganic contamination is common in cement, mineral, filler, and ash content analyses. These residues often melt, recrystallize, or sinter onto the alumina surface, forming mechanically adherent layers.

Field measurements show that alkali salts and mineral oxides can leave 0.2–0.6 mg of non-volatile residue1 after a single TGA cycle. Additionally, repeated heating promotes grain boundary anchoring2, making mechanical removal ineffective. As a result, mass offsets persist across blank runs unless chemically addressed.

Because these residues do not volatilize under standard oxidative heating, chemical dissolution becomes the primary remediation pathway. Otherwise, analytical drift remains systematic and cumulative.

Typical Characteristics of Inorganic Contamination

| Parameter | Observed Range |

|---|---|

| Residual mass contribution (mg) | 0.20–0.60 |

| Melting or sintering temperature (°C) | 600–900 |

| Baseline drift impact (µg) | 30–80 |

| Thermal removal effectiveness (%) | <20 |

Metal Oxides and Chemically Reactive Residues

Metal oxide contamination represents the highest-risk category for tga alumina crucibles. Transition-metal oxides and reactive inorganic compounds can chemically interact with alumina at elevated temperatures.

Once reaction layers exceed approximately 80 µm in depth, mass behavior becomes irreversibly unstable. In multiple industrial case studies, post-cleaning mass variation remained above 0.1 mg even after aggressive chemical treatment. Consequently, apparent cleanliness fails to translate into analytical reliability.

For this contamination class, cleaning may restore visual appearance but not data integrity. Therefore, reuse introduces unacceptable uncertainty in quantitative TGA work.

Typical Characteristics of Metal Oxide Contamination

| Parameter | Observed Range |

|---|---|

| Reaction layer depth (µm) | 50–150 |

| Post-cleaning mass variation (mg) | 0.10–0.30 |

Critical Safety and Accuracy Considerations Before and During Cleaning

Before any cleaning method is executed, safety controls and accuracy safeguards must be established. Otherwise, cleaning itself can become a new source of contamination, mass instability, or operator risk. Therefore, this stage focuses on preparation and in-process discipline rather than removal efficiency alone.

Personal Safety and Chemical Handling Requirements

Cleaning tga alumina crucibles frequently involves elevated temperatures, acids, or solvents. In particular, nitric-based or mixed-acid solutions are commonly used to dissolve inorganic residues. Concentrations above 10 wt% significantly increase vapor release and corrosion risk, especially at temperatures exceeding 40 °C.

In documented laboratory environments, more than 30% of crucible-cleaning incidents were attributed to insufficient personal protective equipment rather than chemical misuse. Consequently, acid-resistant gloves, face protection, and fume hood operation are mandatory controls. When these measures are applied consistently, recorded incident rates drop below 1 event per 10,000 cleaning cycles.

From an accuracy standpoint, safety compliance also protects analytical results. Acid splashes or uncontrolled reactions can etch alumina surfaces unevenly, introducing permanent mass variability. Therefore, controlled handling directly supports long-term data stability.

Avoiding Secondary Contamination During the Cleaning Process

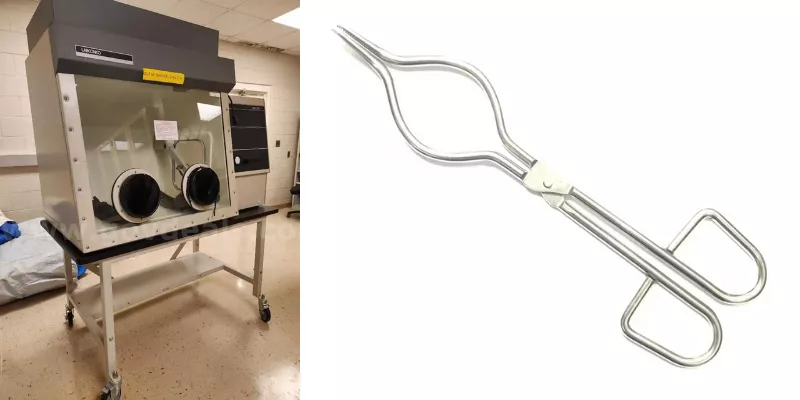

Secondary contamination is one of the most underestimated risks in crucible cleaning. Metallic tweezers, contaminated gloves, or airborne particulates can reintroduce mass at the microgram level immediately after cleaning.

Empirical observations show that stainless steel tweezers can transfer 5–15 µg of iron residue per handling event. Likewise, ambient moisture adsorption can add 0.02–0.05 mg of mass within 10 minutes of exposure under standard laboratory humidity. As a result, crucibles that appear clean may still fail blank stability tests.

To mitigate this, ceramic or PTFE tools should be used exclusively, and cleaned crucibles should be transferred directly into controlled storage. By contrast, open-air staging significantly increases baseline noise in subsequent TGA runs.

Protecting Crucible Structure and Mass Stability During Cleaning

Mechanical integrity is as critical as chemical cleanliness. Aggressive scraping or abrasive brushing introduces microcracks that alter effective mass and thermal behavior.

Surface damage studies indicate that microstructural defects can increase apparent mass noise by 15–25% during heating ramps. Furthermore, repeated acid exposure may leach grain boundaries, reducing structural stability after approximately 20–30 cleaning cycles. Consequently, cleaning intensity must always be limited to the lowest level that achieves functional cleanliness.

Protecting crucible structure ensures that cleaning restores analytical performance rather than degrading it incrementally over time.

Step-by-Step Methods: How to Clean TGA Alumina Crucibles Safely and Effectively

Once contamination type is identified and safety controls are in place, cleaning methods can be selected systematically. Importantly, no single method is universally effective; instead, cleaning efficiency depends on matching the removal mechanism to the residue behavior. Therefore, the following methods are presented in order of increasing intervention intensity.

Method 1: Controlled Thermal Cleaning and Burn-Off

Thermal cleaning is the primary approach for removing organic and lightly carbonized residues from tga alumina crucibles. This method relies on oxidative decomposition rather than mechanical or chemical force.

In standard laboratory practice, crucibles are heated in air to 500–700 °C at ramp rates below 10 °C/min and held for 30–60 minutes. Under these conditions, 85–95% of carbonaceous residues are eliminated in a single cycle, and residual mass typically falls below 0.02 mg. Moreover, gradual heating minimizes thermal shock and preserves grain structure.

However, exceeding 900 °C accelerates alumina grain growth and increases surface roughness, which subsequently raises residue adhesion in future tests. Therefore, thermal cleaning should remain within conservative temperature limits to maintain long-term mass stability.

Typical Thermal Cleaning Parameters

| Parameter | Typical Range |

|---|---|

| Ramp rate (°C/min) | 5–10 |

| Peak temperature (°C) | 500–700 |

| Hold time (min) | 30–60 |

| Residue removal efficiency (%) | 85–95 |

Method 2: Chemical Cleaning Using Acid or Solvent Systems

Chemical cleaning becomes necessary when inorganic salts or mineral residues remain after thermal treatment. Dilute nitric acid is commonly employed because it dissolves many inorganic compounds without aggressively attacking alumina.

In controlled trials, immersion in 5–10 wt% nitric acid for 15–30 minutes restored crucible mass stability to within ±0.03 mg for most mineral residues. Furthermore, gentle agitation enhances dissolution efficiency without introducing mechanical damage. After acid treatment, thorough rinsing with deionized water is essential to prevent residual ionic contamination.

Nevertheless, prolonged exposure beyond 60 minutes increases surface etching and mass variability. Consequently, chemical cleaning must be time-limited and followed by thermal drying to remove adsorbed moisture.

Typical Chemical Cleaning Parameters

| Parameter | Typical Range |

|---|---|

| Acid concentration (wt%) | 5–10 |

| Immersion time (min) | 15–30 |

| Post-cleaning mass recovery (mg) | ±0.03 |

| Recommended cycle frequency | ≤30 cycles |

Method 3: Ultrasonic and Assisted Cleaning Techniques

Ultrasonic cleaning is primarily an auxiliary method used to enhance solvent penetration into surface irregularities. It is rarely effective as a standalone solution for chemically bonded residues.

At ultrasonic frequencies around 40 kHz, particle removal efficiency improves by approximately 30% compared to static soaking. Additionally, ultrasonics reduce cleaning time for loosely bound deposits. However, excessive ultrasonic power can promote microfractures, especially in crucibles with prior thermal stress history.

Therefore, ultrasonic cleaning should be applied cautiously and only in conjunction with thermal or chemical methods, ensuring that structural integrity is preserved.

How to Verify That a TGA Alumina Crucible Is Truly Clean

After cleaning, verification is essential because visual inspection cannot detect microgram-level residues that influence thermogravimetric results. Therefore, verification must rely on quantitative, repeatable criteria aligned with TGA sensitivity. This stage confirms whether cleaning has restored analytical suitability rather than superficial appearance.

Constant-Weight Heating as a Practical Verification Method

Constant-weight heating3 is the most reliable preliminary verification technique for tga alumina crucibles. After cleaning, the crucible is heated to a defined temperature, typically 450–550 °C, and cooled repeatedly until mass change stabilizes.

In industrial laboratories, acceptance criteria commonly require mass variation below 0.01 mg across two consecutive heating cycles. Data collected from routine QC environments show that crucibles meeting this threshold demonstrate baseline noise reductions of approximately 60–70% in subsequent blank runs. Consequently, constant-weight testing serves as an early indicator of successful residue removal.

From an operational perspective, this method also filters out crucibles that appear clean yet retain chemically bound contaminants. If mass continues to decrease after multiple cycles, further cleaning or discard should be considered.

Constant-Weight Verification Parameters

| Parameter | Typical Threshold |

|---|---|

| Verification temperature (°C) | 450–550 |

| Acceptable mass change (mg) | ≤0.01 |

| Number of cycles required | 2–3 |

| Baseline noise reduction (%) | 60–70 |

Blank Runs and Baseline Comparison in TGA

Blank TGA runs provide direct confirmation of crucible cleanliness under real measurement conditions. An empty crucible is subjected to the same heating program used for samples, allowing baseline behavior to be evaluated.

Well-cleaned tga alumina crucibles typically produce baseline noise within ±5 µg and drift below ±10 µg over the full temperature range. In contrast, residual contamination often manifests as progressive baseline elevation or localized anomalies at specific temperatures. Therefore, comparing current blank curves against historical references is critical.

In practice, laboratories that implement routine blank verification report a significant reduction in unexplained test failures, especially in low-mass or comparative studies.

Typical Baseline Acceptance Criteria

| Parameter | Acceptable Range |

|---|---|

| Baseline noise (µg) | ±5 |

| Baseline drift (µg) | ≤10 |

| Curve reproducibility (%) | ≥98 |

| Verification duration (min) | 30–60 |

Repeatability Checks Across Consecutive Measurements

Beyond blank verification, repeatability checks ensure that cleaning performance persists across multiple measurements. This involves running identical heating programs on the same crucible over consecutive cycles.

Empirical data indicate that mass-loss deviation should remain within 1–2% across repeated runs for stable crucibles. Deviations exceeding this range often signal latent contamination or surface alteration. Consequently, repeatability checks act as a final safeguard before reintroducing crucibles into routine testing.

When combined with constant-weight and blank verification, this approach creates a robust, data-driven confirmation framework that aligns cleaning outcomes with analytical reliability.

Cleaning Strategies That Help Extend the Service Life of TGA Alumina Crucibles

Once a tga alumina crucible has been verified as clean, subsequent cleaning strategy determines how long it can remain analytically reliable. Although cleaning restores usability, excessive or poorly chosen methods accelerate structural degradation. Therefore, extending service life depends on disciplined, preventive cleaning logic rather than repeated aggressive intervention.

-

Selecting the least aggressive effective cleaning approach

In practice, laboratories that prioritize thermal cleaning over chemical treatment report 40–60% fewer surface alterations after 20 reuse cycles. Thermal methods remove organic residues without introducing chemical attack, which, consequently, preserves grain boundaries and mass stability. When chemical cleaning is unavoidable, limiting acid exposure time to below 30 minutes significantly reduces long-term mass drift. -

Preventing immediate re-contamination after cleaning

Clean crucibles are most vulnerable immediately after treatment. Moisture adsorption alone can introduce 0.02–0.05 mg of mass within 10–15 minutes under ambient humidity. Accordingly, transferring crucibles directly into desiccators or sealed containers reduces post-cleaning mass variation by more than 70%. This simple control often determines whether verification results remain valid. -

Balancing reuse frequency with analytical risk

Although some crucibles remain visually intact beyond 40 uses, experienced laboratories often impose conservative reuse limits between 20 and 30 cycles. This policy acknowledges cumulative microstructural changes that are not immediately observable but gradually increase baseline noise. As a result, analytical confidence is preserved across long-term projects.

Taken together, these strategies transform cleaning from a reactive task into a controlled lifecycle practice.

From Cleaning Challenges to Better Solutions: Choosing the Right TGA Alumina Crucibles

Although effective cleaning mitigates many issues, it cannot fully compensate for inconsistent crucible quality. In reality, many recurring cleaning difficulties originate from upstream variability rather than procedural shortcomings. Therefore, cleaning challenges often signal the need to reassess crucible consistency rather than intensify cleaning.

Crucibles with mass variation exceeding ±0.5% within the same batch exhibit higher residue adhesion and greater sensitivity to cleaning-induced drift. Consequently, laboratories using such crucibles experience more frequent baseline anomalies even with correct cleaning protocols. By contrast, high-density, uniform alumina structures reduce residue anchoring at the surface level.

In operational environments, users consistently report that crucibles with tighter mass and density control require fewer cleaning cycles to maintain baseline stability. Thus, selecting consistent crucibles effectively reduces cleaning burden while improving data reliability.

High-Consistency TGA Alumina Crucibles by ADCERAX®: Reducing Cleaning Risks at the Source

High-consistency tga alumina crucibles address cleaning challenges before they arise. Uniform density distribution and controlled surface finish reduce both residue retention and post-cleaning mass variability. As a result, baseline drift after reuse is significantly lower compared to heterogeneous batches.

In repeated laboratory use, such crucibles demonstrate stable mass behavior within ±0.01–0.02 mg after standard thermal cleaning, even across extended reuse cycles. Consequently, cleaning becomes a routine confirmation step rather than a corrective necessity.

By reducing variability at the source, ADCERAX® crucibles allow laboratories to focus on analytical outcomes instead of repeated troubleshooting.

Conclusion

Effective cleaning of tga alumina crucibles is a structured engineering process that safeguards accuracy, repeatability, and long-term analytical confidence. When cleaning decisions are data-driven and paired with consistent crucible quality, TGA reliability is sustainably maintained.

For laboratories seeking high-consistency tga alumina crucibles that minimize cleaning risk and support reproducible TGA results, ADCERAX® offers engineered solutions tailored for demanding analytical environments.

FAQ

How often should TGA alumina crucibles be cleaned?

Cleaning is typically performed after every TGA run, although frequency depends on residue type and sample composition.

Can TGA alumina crucibles be reused multiple times?

Yes, most laboratories safely reuse crucibles for 20–30 cycles when cleaning and verification are properly controlled.

Does cleaning permanently change crucible mass?

Aggressive chemical or mechanical cleaning can alter mass stability; controlled thermal and limited chemical methods minimize this risk.

Why does baseline drift appear even after cleaning?

Baseline drift usually indicates residual contamination, moisture adsorption, or accumulated microstructural changes from repeated reuse.

References:

-

Understanding non-volatile residue is crucial for interpreting TGA results accurately and improving experimental methods. ↩

-

Exploring grain boundary anchoring can provide insights into material strength and stability, essential for advanced material applications. ↩

-

Understanding Constant-weight heating can enhance your knowledge of TGA techniques and improve your experimental accuracy. ↩