Ceramics Across EV System Requirements

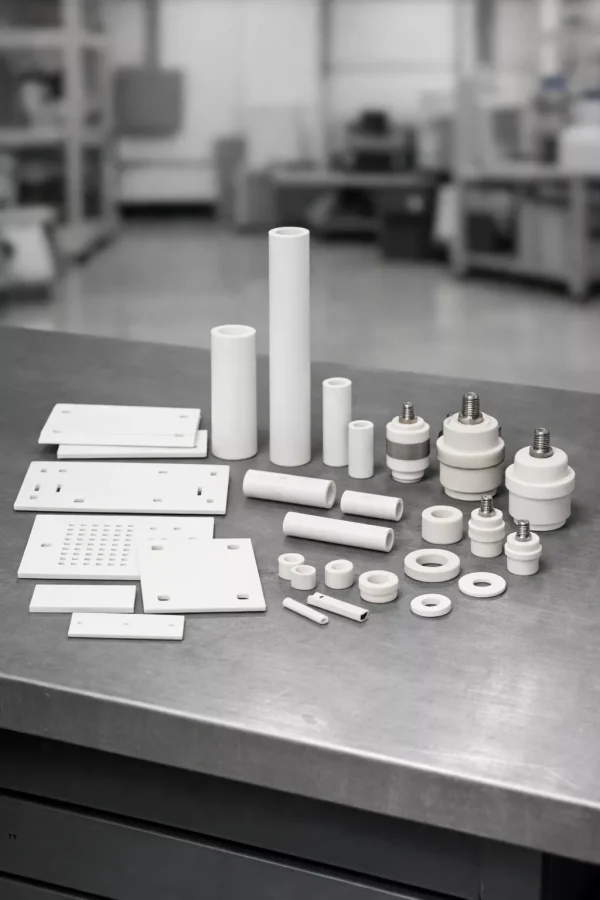

EV Industrial Ceramics are used in electric vehicle systems where insulation stability, structural strength, and thermal control must remain consistent under continuous electrical load.

As operating voltage increases and component spacing becomes tighter, electric vehicle ceramic components are widely applied in power electronics assemblies, high-voltage interfaces, and thermal transfer paths where metals and polymers lose reliability.

Material systems such as alumina, ZTA, boron nitride, and aluminum nitride are selected to provide electrical isolation, mechanical support, and controlled heat flow across different EV applications.

In electric vehicles, engineering ceramics for EV systems function as load-bearing and insulating components rather than secondary or auxiliary materials.

resists leakage at elevated voltage levels

remains stable against coolant and vapor contact

Supports insulation or controlled heating functions

supports load without deformation or creep

ADCERAX® Material Properties Supporting EV Ceramic Performance

Material behavior in EV Industrial Ceramics determines whether insulation, load support, and heat control remain stable throughout long operating cycles in electric vehicle systems.

Thermal Properties

| Material | Thermal Conductivity (W/m·K) | Max Continuous Service Temp (°C) | Thermal Expansion (10⁻⁶/K) | Test Conditions |

|---|---|---|---|---|

| Alumina (96–99.5%) | 24–30 | 1600 | 7.5–8.0 | Measured at 25–1000 °C, air |

| ZTA Ceramic | 18–22 | 1500 | 7.8–8.2 | Measured at 25–1000 °C, air |

| Boron Nitride (Hexagonal) | 25–60 (anisotropic) | 900 | 1.0–2.0 | Basal plane, inert atmosphere |

| Aluminum Nitride | 160–180 | 1400 | 4.5–5.3 | Measured at 25 °C, air |

Electrical Properties

| Material | Dielectric Strength (kV/mm) | Volume Resistivity (Ω·cm) | Dielectric Constant (1 MHz) | Test Conditions |

|---|---|---|---|---|

| Alumina | 12–15 | ≥10¹⁴ | 9.5–10.0 | 25 °C, dry condition |

| ZTA Ceramic | 10–13 | ≥10¹³ | 10.0–10.5 | 25 °C, dry condition |

| Boron Nitride | 3–4 | ≥10¹² | 3.5–4.0 | 25 °C, dry condition |

| Aluminum Nitride | 10–15 | ≥10¹³ | 8.5–9.0 | 25 °C, dry condition |

Chemical Stability

| Material | Acid Resistance | Alkali Resistance | Oxidation Behavior | Test Conditions |

|---|---|---|---|---|

| Alumina | Stable in most acids | Stable except strong alkali | Stable up to 1000 °C | Immersion tests, 25 °C |

| ZTA Ceramic | Stable in weak acids | Limited resistance | Stable up to 900 °C | Immersion tests, 25 °C |

| Boron Nitride | Inert to most chemicals | Reacts with strong alkali | Oxidizes above 850 °C | Static exposure tests |

| Aluminum Nitride | Hydrolysis sensitive | Limited alkali resistance | Oxidizes above 700 °C | Controlled humidity tests |

Mechanical Properties

| Material | Flexural Strength (MPa) | Fracture Toughness (MPa·m¹ᐟ²) | Elastic Modulus (GPa) | Test Conditions |

|---|---|---|---|---|

| Alumina | 300–380 | 3.5–4.0 | 320–380 | 3-point bending, RT |

| ZTA Ceramic | 600–800 | 5.5–7.0 | 300–330 | 3-point bending, RT |

| Boron Nitride | 30–50 | 2.0–2.5 | 30–40 | Machined specimen, RT |

| Aluminum Nitride | 320–360 | 3.0–3.5 | 310–330 | 3-point bending, RT |

Application Areas of EV Industrial Ceramics

In electric vehicle systems, EV industrial ceramics are applied according to how different materials address insulation performance, structural loading, and thermal control requirements within specific operating environments.

High Voltage Switching Assemblies

Alumina-based ceramic structures are widely used in EV high voltage switching systems where insulation stability and dimensional control directly affect electrical safety.

- Alumina ceramic maintains insulation integrity under repeated high-voltage switching cycles in relay assemblies.

- Metallized interfaces enable stable ceramic-to-metal sealing within compact high voltage enclosures.

- Dimensional stability supports consistent contact alignment during long-term EV operation.

Provides insulation stability for compact EV high voltage relay assemblies

Structural Support Interfaces

Zirconia Toughened Alumina materials are selected for EV components exposed to mechanical load and thermal fluctuation within constrained system layouts.

- ZTA ceramic substrate supports mechanical loading in EV assemblies requiring fracture resistance.

- Improved toughness reduces cracking risk under vibration and thermal cycling conditions.

- Structural consistency maintains alignment accuracy in power and control modules.

Supports load-bearing structures in EV power and control assemblies

Thermal Isolation Components

Boron nitride materials are applied in EV systems where controlled heat flow and electrical isolation must coexist in confined thermal environments.

- Boron nitride tube guides heat away from sensitive EV components without electrical conduction.

- Thermal stability maintains predictable performance under continuous temperature gradients.

- Chemical inertness supports long-term use near coolants and vapor exposure zones.

Manages localized heat while maintaining insulation in EV systems

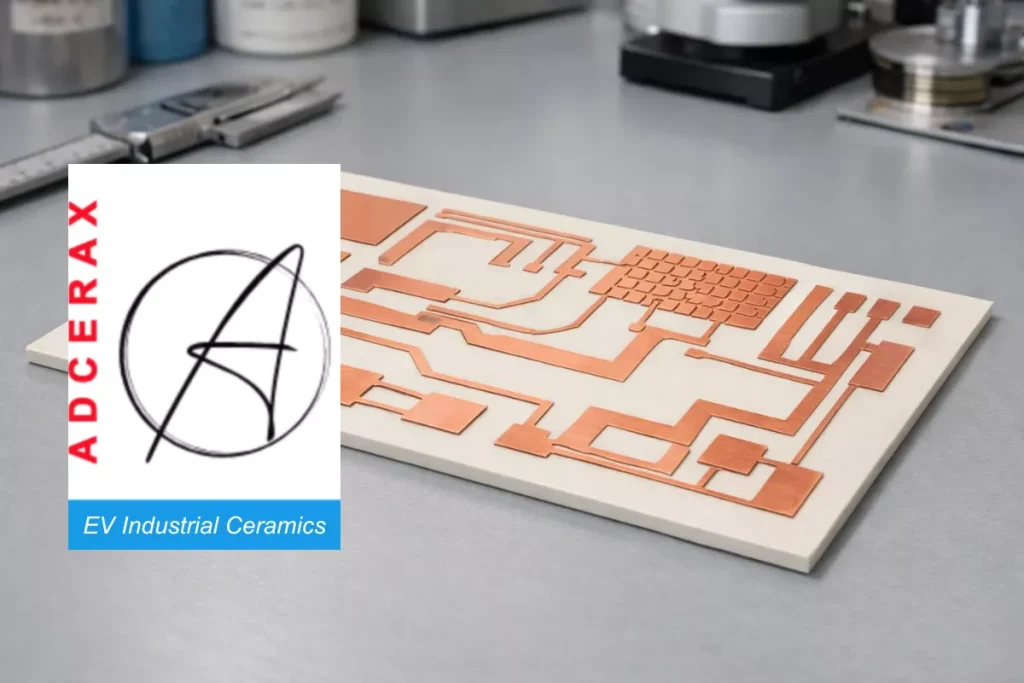

Power Module Heat Dissipation

Aluminum nitride substrates are specified in EV power electronics where heat dissipation efficiency directly influences module reliability.

- Aluminum nitride ceramic enables rapid heat transfer away from high-density power devices.

- Copper bonded layers support electrical connection and thermal spreading within compact modules.

- Thermal consistency improves service life across repeated power cycling conditions.

Enhances heat dissipation in EV power electronic modules

EV Ceramic Selection Aligned With System Requirements

EV Industrial Ceramics are specified according to insulation limits, mechanical loading, and thermal behavior within electric vehicle systems.

Engineering evaluation at the material and geometry level helps reduce qualification risk across power electronics and high-voltage assemblies.

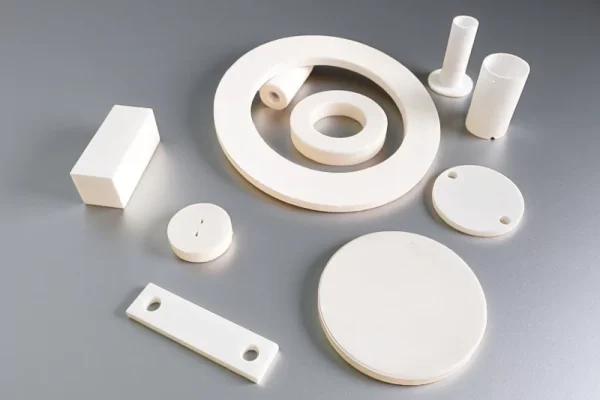

ADCERAX® Industrial Ceramic Categories for EV Applications

Material selection in EV Industrial Ceramics is guided by insulation demands, structural loading conditions, and thermal management requirements across different electric vehicle systems.

Aluminum Oxide

Alumina-based components are commonly used where electrical insulation and dimensional stability are required in EV assemblies.

- High voltage insulation reliability

- Metallization compatibility stability

- Consistent dimensional tolerance

ZTA

Zirconia Toughened Alumina materials are specified for EV components exposed to mechanical load and thermal variation.

- Improved fracture resistance

- Structural load stability

- Thermal shock tolerance

Boron Nitride

Boron nitride components are selected for EV environments requiring thermal control combined with electrical isolation.

- Controlled heat transfer paths

- Electrical insulation performance

- Chemical stability in service

Aluminum Nitride

Aluminum nitride substrates are applied in EV power electronics where heat dissipation and insulation must coexist.

- High thermal conductivity

- Electrical insulation integrity

- Power module integration

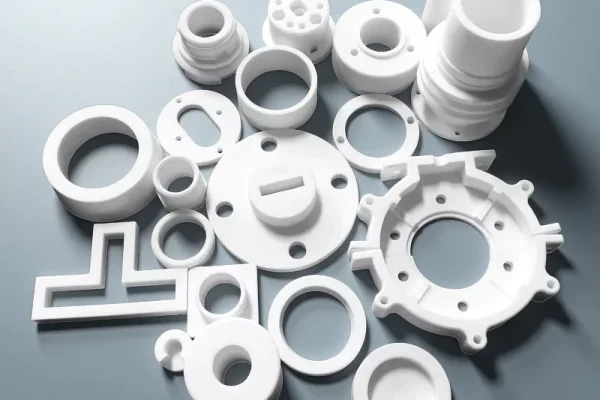

Integrated Manufacturing Services for EV Ceramic Components

ADCERAX® provides integrated manufacturing support for EV ceramic components used in high-voltage switching, structural support, thermal isolation, and power module assemblies across electric vehicle systems.

For electric vehicle industrial ceramics, manufacturing capability directly determines whether material performance can be realized at component level.

End-to-end control across forming, machining, joining, and surface preparation enables ceramic components to meet electrical, thermal, and mechanical requirements defined at application level.

align ceramic grade with electrical and thermal requirements

achieve near-net shapes with controlled shrinkage behavior

hold critical dimensions within ±0.02–0.05 mm range

apply uniform Mo-Mn layers for ceramic-metal joining

support brazing or copper bonding for EV assemblies

deliver defined roughness for sealing or contact interfaces

ADCERAX® Advanced Processing of EV Industrial Ceramics

Dimensional Control Machining

Precision machining enables complex ceramic geometries to meet tight dimensional and surface requirements within EV assemblies.

multi-axis ceramic machining centers, ≤0.02 mm tolerance

diamond tooling optimized for brittle ceramic cutting

Ra 0.4–0.8 μm on functional interfaces

Ceramic-to-Metal Interface Formation

Metallization processing creates reliable ceramic-to-metal interfaces required in EV high-voltage and power electronics applications.

Mo–Mn metallization with controlled layer thickness

hydrogen or controlled atmosphere furnaces up to 1500 °C

shear strength typically ≥120 MPa after brazing

Ceramic Bonded Assembly Integration

Bonding integration connects ceramic components with metal or copper structures for electrical and thermal functionality.

vacuum brazing furnaces below 10⁻⁴ Pa

copper bonding on AlN substrates up to 300 μm

low interface resistance for heat transfer efficiency

Custom Engineering for EV Ceramic Components

Custom ceramic components for EV programs are defined by application-specific electrical, thermal, and mechanical constraints rather than standard part catalogs.

For EV Industrial Ceramics, effective customization requires early alignment on material selection, geometry tolerance, and interface conditions across high-voltage, structural, and power electronics systems.

Engineering discussions initiated at the drawing or application stage help ensure ceramic components are manufacturable and compatible with EV system requirements.

ADCERAX® EV Industrial Ceramics Addressing Engineering Constraints in EV Systems

Industrial ceramic components provide stable dielectric strength that is inherently insensitive to temperature and aging. In EV engineering systems, insulation failure often occurs under coupled thermal and electrical stress rather than voltage alone. Ceramic materials for EV high voltage systems maintain predictable insulation behavior across long operating cycles.

Alumina-based industrial ceramic components combine electrical insulation with mechanical rigidity and dimensional stability. Relay housings require fixed insulation spacing under heat and vibration, which polymers and metals cannot maintain consistently. Engineering ceramics for EV systems preserve geometry and insulation integrity throughout service life.

Industrial ceramics offer a unique balance between electrical insulation and controlled thermal conductivity. Power electronics require heat dissipation without creating conductive paths. Ceramic components for EV power electronics satisfy both constraints within compact assemblies.

Rising EV system voltages reduce insulation margins and increase electric field intensity. Industrial ceramic materials exhibit high dielectric strength independent of humidity or aging mechanisms. This property allows ceramic materials for EV high voltage systems to support higher voltage architectures safely.

Thermal cycling introduces internal stress due to material expansion mismatch. Engineering ceramics for EV systems resist microcrack initiation through stable crystal structures and controlled grain boundaries. This supports long-term reliability in dynamic EV operating conditions.

Many EV components require both insulation and mechanical attachment to metal structures. Industrial ceramic components support metallization and brazing to form stable ceramic-to-metal interfaces. These interfaces maintain electrical isolation while tolerating thermal and mechanical loads.

Certain engineering ceramics exhibit high flexural strength and fracture toughness. In EV systems, this allows ceramic components to carry mechanical loads while remaining electrically insulating. Such dual functionality reduces part count and assembly complexity.

Compact EV architectures demand thinner insulation and tighter spacing. Industrial ceramic components provide high dielectric strength even at reduced thickness. This enables higher integration density without compromising electrical safety.

Metals can soften, oxidize, or creep under heat and electrical fields. Industrial ceramic components retain mechanical and electrical properties under combined thermal, electrical, and mechanical stress. This behavior aligns with long-life requirements in EV engineering systems.

EV environments introduce vibration from road and drivetrain dynamics. Properly engineered industrial ceramic components resist fatigue and crack propagation. This ensures stable performance in mobile EV systems.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.