ADCERAX is a China-based manufacturer with over 20 years of experience in high-purity Magnesium Oxide (MgO) ceramics. We supply crucibles, tubes, rods, plates, insulators, and refractory parts, all engineered for extreme temperature, electrical insulation, and molten-metal resistance.

With in-house forming, machining, and inspection, we deliver both standard and custom MgO components that ensure precision, purity, and durability. Our ceramics help clients solve heat shock, corrosion, and insulation failures, improving system reliability and service life.

99.9% Purity

High-purity MgO ceramics

Stable against corrosion & wear

Excellent dielectric strength

Safe for heaters and sensors

Magnesium Oxide Ceramic (MgO) is an advanced inorganic material formed by sintering high-purity magnesium oxide powder into a dense crystalline structure. It combines high thermal stability, electrical insulation, and corrosion resistance, making it one of the most reliable materials for high-temperature and electrical insulation applications.

Yes. Magnesium oxide (MgO) is a true ceramic, produced by sintering rather than melting or polymerization. It is a non-metallic, inorganic compound with ionic bonding and a crystalline structure, giving it the classic ceramic traits — hardness, brittleness, and high thermal resistance.

As crucibles, tubes, or insulators, MgO ceramics maintain stability, purity, and dielectric strength under molten metal contact or rapid heating, outperforming metals and plastics in harsh environments.

Unlike alloys that creep or polymers that deform, MgO preserves geometry and insulation at extreme temperatures — reducing maintenance and extending equipment life.

In short, magnesium oxide ceramic is a high-purity refractory insulator used where metals and polymers fail.

| Property | Metals | Magnesium Oxide (Ceramic) | Metal Ceramic (Cermet) | Polymers |

| Atomic bonding | Metallic | Ionic / Covalent | Mixed (Metallic/Ionic) | Covalent |

| Electrical behavior | Conductive | Insulating (high dielectric) | Conductive to Insulating | Insulating |

| Thermal stability | Medium | Very high (>1800 °C) | High | Low (<300 °C) |

| Corrosion resistance | Moderate | Excellent (chemical inertness) | Good to Excellent | Poor |

| Mechanical behavior | Ductile | Hard & brittle | Hard & Tough | Flexible |

| Manufacturing method | Melt & cast | Powder press & sinter | Powder metallurgy (sintering, hot pressing) | Mold & cure |

This structural distinction explains why MgO is categorized purely as a ceramic.

Magnesium oxide ceramics combine exceptional thermal stability, high electrical insulation, and chemical resistance for use in extreme environments.Their dense microstructure and purity ensure reliable performance above 1800 °C, making MgO ideal for furnace components, heaters, and insulating parts.

With high density, fine grain structure, and smooth surface finish, magnesium oxide ceramics offer exceptional dimensional stability and minimal porosity, ensuring precision and cleanliness in high-temperature and electrical applications.

| Property | Typical Value / Range | Description |

|---|---|---|

| Density | 3.52–3.56 g/cm³ | High density ensures mechanical strength and thermal shock resistance. |

| Purity | 99%–99.9% MgO | High-purity MgO minimizes contamination and improves dielectric reliability. |

| Color | White or off-white | High-purity MgO appears whiter; trace impurities may cause a light cream tint. |

| Surface Roughness | Ra 0.5–1.6 μm | Fine polishing provides smoother surfaces for better sealing or coating adhesion. |

Featuring excellent heat resistance, thermal conductivity, and low thermal expansion, MgO ceramics perform reliably above 1800 °C, providing stable insulation and structural integrity in furnaces and heating systems.

| Property | Typical Value / Range | Description |

|---|---|---|

| Maximum Operating Temperature | 1800–2000 °C | Maintains mechanical and dimensional stability under extreme heat. |

| Thermal Conductivity | 30–60 W/m·K (at 25 °C) | Transfers heat efficiently while retaining electrical insulation. |

| Thermal Expansion Coefficient (CTE) | 12–13 × 10⁻⁶ /K (20–1000 °C) | Compatible with refractory metals and other ceramics to reduce cracking risk. |

| Thermal Shock Resistance | Excellent | Withstands rapid temperature changes in furnace and heater applications. |

Combining high dielectric strength and outstanding insulation resistance, magnesium oxide ceramics prevent electrical leakage and maintain consistent performance in heaters, sensors, and high-voltage assemblies.

| Property | Typical Value / Range | Description |

|---|---|---|

| Dielectric Strength | >10 kV/mm | Provides excellent insulation for high-voltage components and heaters. |

| Volume Resistivity | >10¹⁴ Ω·cm (at 25 °C) | Ensures low leakage current and stable insulation performance. |

| Dielectric Constant (εr) | 9.6 – 10.2 | Offers consistent electrical response across temperature ranges. |

| Loss Tangent (tan δ) | ≤ 0.0005 | Low energy loss under AC conditions, ideal for power and sensor systems. |

With strong compressive strength, hardness, and resistance to wear, MgO ceramics maintain mechanical integrity under load and vibration, delivering long-term durability in demanding industrial environments.

| Property | Typical Value / Range | Description |

|---|---|---|

| Flexural Strength | 120–150 MPa | Provides rigidity and resistance to mechanical stress. |

| Compressive Strength | 700–1000 MPa | Withstands heavy static loads and structural pressure. |

| Hardness (Mohs) | 5–6 | Sufficient hardness for wear and erosion resistance. |

| Elastic Modulus (Young’s Modulus) | 250–280 GPa | Maintains stiffness and dimensional accuracy at high temperatures. |

Chemically inert and corrosion-resistant, magnesium oxide ceramics remain stable in contact with molten metals and reactive gases, extending component life in metallurgical, chemical, and vacuum systems.

| Property | Typical Value / Range | Description |

|---|---|---|

| Chemical Stability | Excellent | Resistant to most acids and alkalis; unaffected by oxidation. |

| Corrosion Resistance | Excellent vs molten metals | Ideal for crucibles and furnace linings in Ni, Pb, and U melts. |

| Water Solubility | Insoluble | Remains stable in humid or vapor environments when properly sintered. |

| Reactivity | Low | Chemically inert to most gases and metals under operating conditions. |

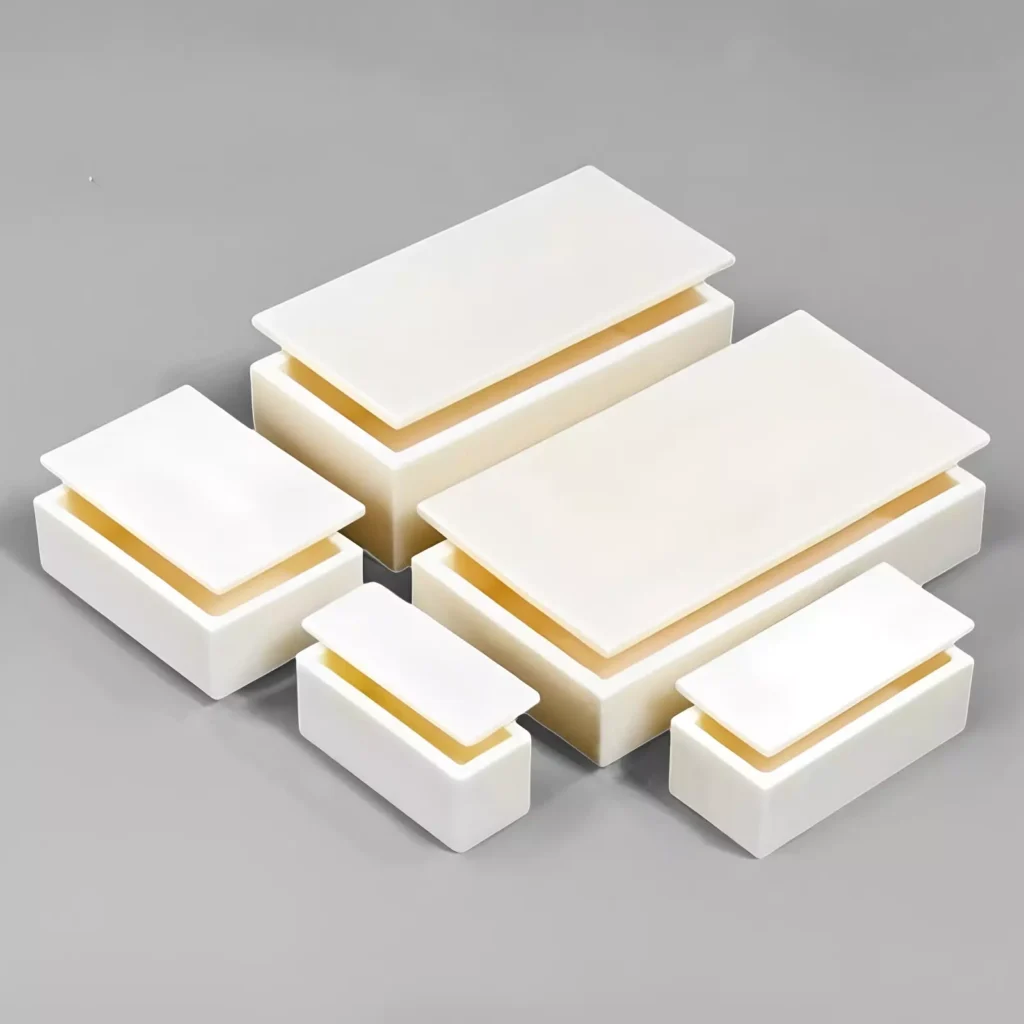

ADCERAX supplies magnesium oxide (MgO) ceramics for high-temperature, electrical, and chemical use. Our crucibles, rods, tubes, and plates feature high insulation, corrosion resistance, and stability under extreme heat. Each part is made from high-purity MgO for long life and reliable performance.

MgO crucibles provide exceptional thermal stability, corrosion resistance, and strength under extreme heat and reactive environments.

MgO rods provide excellent insulation, rigidity, and chemical stability for use in high-temperature and vacuum environments.

High-purity magnesium oxide tubes provide superior insulation, thermal stability, and corrosion resistance in demanding electrical and heating systems.

High-purity magnesium oxide plates deliver excellent thermal insulation, corrosion resistance, and dimensional stability for furnace and electrical systems.

Every ADCERAX MgO ceramic delivers proven reliability — less maintenance, longer uptime, and exceptional stability in the world’s toughest thermal and electrical environments.

Challenges: Traditional refractories (e.g., alumina) corrode severely in aggressive molten metals, leading to material contamination, reduced purity, and compromised performance. Their structural instability at extreme temperatures also impacts efficiency and safety.

Challenges: Traditional refractories (e.g., alumina) corrode severely in aggressive molten metals, leading to material contamination, reduced purity, and compromised performance. Their structural instability at extreme temperatures also impacts efficiency and safety.

Challenges: Many conventional refractory materials fail at extreme temperatures, suffering from thermal shock, creep, and chemical degradation. This leads to frequent replacements, costly downtime, and compromised process stability and energy efficiency.

Challenges: Many conventional refractory materials fail at extreme temperatures, suffering from thermal shock, creep, and chemical degradation. This leads to frequent replacements, costly downtime, and compromised process stability and energy efficiency.

Challenges: Many conventional electrical insulators degrade at high temperatures, losing dielectric strength or suffering thermal breakdown. This compromises device reliability, leads to electrical leakage, and shortens the lifespan of critical electronic and sensor components.

Challenges: Many conventional electrical insulators degrade at high temperatures, losing dielectric strength or suffering thermal breakdown. This compromises device reliability, leads to electrical leakage, and shortens the lifespan of critical electronic and sensor components.

Challenges: Many materials used in R&D lack the required purity, thermal stability, or chemical inertness for precise experiments. Contamination, material degradation at high temperatures, or unwanted reactions can compromise experimental results and limit the scope of research.

Challenges: Many materials used in R&D lack the required purity, thermal stability, or chemical inertness for precise experiments. Contamination, material degradation at high temperatures, or unwanted reactions can compromise experimental results and limit the scope of research.ADCERAX is a professional magnesium oxide (MgO) ceramics manufacturer, specializing in high-purity components with complex geometries, tight tolerances, and exceptional insulation and thermal stability.Custom magnesium oxide ceramics are produced according to your drawings or samples and typically delivered within 3–7 weeks with full quality assurance.

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

ADCERAX is a trusted magnesia ceramic manufacturer in China, providing high-purity MgO components for electrical, thermal, and chemical applications worldwide. We offer both standard and customized MgO ceramics, ensuring exceptional insulation, stability, and cost efficiency for global OEM and industrial clients.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

ADCERAX integrates design, machining, quality control, and logistics into a seamless manufacturing workflow. Our one-stop approach for magnesium oxide (MgO) ceramic ensures stable performance, high precision, and faster delivery from prototype to batch production.

ADCERAX specializes in the production of high-purity magnesium oxide ceramics, combining advanced forming and sintering technology with precision CNC machining and strict quality control. Each MgO component is engineered for excellent insulation, thermal stability, and chemical resistance, ensuring long-term reliability in high-temperature, vacuum, and electrical insulation applications.

| Manufacturing Capabilities Overview | |||

|---|---|---|---|

| Capability Item | Typical Value / Description | ||

| Material Grades | High-purity MgO ceramics (≥ 99%) with excellent insulation, density, and corrosion resistance. | ||

| Dimension Range | Custom parts from small tubes to large crucibles, machined to ±0.05–0.2 mm tolerance. | ||

| Forming Methods | CIP / isostatic pressing, CNC machining, and precision sintering for stable microstructure. | ||

| Processing | Controlled sintering up to 1800 °C ensures full density and long-term thermal stability. | ||

| Surface Finish | Polished MgO surfaces reach Ra < 0.3 μm, providing smooth sealing and low contamination. | ||

Magnesium oxide (MgO) ceramics have an ionic crystal structure, giving them excellent electrical insulation, high thermal conductivity, and superior heat resistance up to about 1800 °C.

In contrast, alumina (Al₂O₃) ceramics possess a covalent-ionic structure with higher hardness and mechanical strength, but lower thermal conductivity than MgO.

As a result, MgO ceramics are preferred for high-temperature insulation and crucibles, while Al₂O₃ is widely used for wear-resistant and structural components.

Magnesium oxide is considered a ceramic material because it’s a non-metallic solid that remains stable under extreme heat. When sintered, it becomes hard, dense, and electrically insulating, which are the key traits of ceramics.

These properties make MgO ceramics widely used in heaters, insulators, and laboratory equipment where metals or plastics cannot perform.

MgO Ceramics are typically manufactured by sintering high-purity magnesium oxide powder at high temperatures. Different sintering techniques and post-processing methods can be employed to achieve desired microstructures and properties.The following table shows the specific process:

| Step | Process Description | Process Parameters/Conditions | Key Considerations |

|---|---|---|---|

| 1. Raw Material Preparation | Select high-purity magnesium oxide (MgO) raw material, typically with a purity ≥ 99%. Small amounts of stabilizers (such as Y2O3 or CaO) can be added. | Purity: ≥ 99%; Particle size: 0.1-5 µm (ball milling required) | Avoid introducing impurities (such as Fe2O3, SiO2) to prevent degradation of ceramic properties. |

| 2. Forming | Mix MgO powder with binder and solvent, then form. Common methods include dry pressing, isostatic pressing, or slip casting. | Dry pressing pressure: 100-300 MPa; Isostatic pressing pressure: 150-400 MPa | Control the uniformity of the green density to avoid cracking during sintering. |

| 3. Binder Burnout | Remove organic binders and moisture at low temperature (400-600°C). | Heating rate: 1-5°C/min; Holding time: 2-4 hours | Slow heating is necessary to prevent cracking. Use vacuum or inert atmosphere (e.g., nitrogen) to prevent MgO decomposition. |

| 4. High-Temperature Sintering | Densify at high temperature (1600-2000°C), typically using vacuum sintering or protective atmosphere sintering (e.g., argon). | Sintering temperature: 1600-2000°C; Holding time: 1-4 hours | Strictly control the oxygen partial pressure (low oxygen environment inhibits MgO volatilization) to prevent abnormal grain growth and increased brittleness. |

| 5. Cooling | Slowly cool to room temperature after sintering, controlling the cooling rate (≤ 5°C/min) to avoid thermal stress cracking. | Cooling rate: ≤ 5°C/min | Rapid cooling may cause microcracks, affecting mechanical strength. |

| 6. Post-Processing | Optional steps: surface polishing, coating, or precision machining to improve dimensional accuracy and corrosion resistance. | Surface roughness: Ra ≤ 0.1 µm | Use diamond tools during machining to avoid metal contamination. |

| 7. Property Testing | Measure key properties such as density, flexural strength, thermal conductivity, and dielectric constant. | Density: ≥ 3.58 g/cm³; Flexural strength: ≥ 150 MPa | Use Archimedes' method for density measurement and three-point bending test for strength measurement, ensuring they meet application requirements (e.g., refractory materials or electronic components). |

Supplementary Information

MgO Ceramics are available in various forms, including tubes, rods, plates, crucibles, and custom shapes to meet specific application requirements.

Of course they can be customized.Adcerax has decades of experience in magnesium oxide ceramics for industries like semiconductors and electronics. With advanced facilities and skilled experts, we can meet your specific needs, including complex designs and strict tolerances.

MgO Ceramics offer advantages such as superior thermal performance at high temperatures, excellent electrical insulation properties, and resistance to chemical attack in harsh environments. They are also relatively cost-effective compared to some other high-performance ceramics.The following table shows the performance comparison of other materials:

| Ceramic Type | Magnesium Oxide Ceramic | Aluminum Oxide Ceramic | Zirconium Oxide Ceramic | Silicon Nitride Ceramic | Silicon Carbide Ceramic |

|---|---|---|---|---|---|

| Melting Point (°C) | approx. 2800 | approx. 2050 | approx. 2700 | approx. 1900 | approx. 2800 |

| Mohs Hardness (Moh's) | 5-6 | 9 | 9.2 | 9 - 9.5 | 9.5 |

| Density (g/cm³) | 3.52-3.56 | 3.6-3.98 | 5.6 - 6.02 | 2.6 - 3.2 | 3.2 - 3.4 |

| Coefficient of Thermal Expansion (× 10⁻⁶ / °C) | 13*10⁻⁶ | 7-8 | 10-12 | 2.5 - 3.0 | 4.0 - 4.5 |

| Insulation | Good insulation at high temperatures, room-temperature specific resistance > 10¹⁴Ω·cm, and the resistivity drops sharply with increasing temperature | Good | Ionic conduction at high temperatures, pure ZrO₂ is insulating, and the | Good | Semiconductor |

| Chemical Stability | Strong resistance to corrosion of alkaline metal solutions, easy to hydrate in humid air | Acid- and alkali- resistant | Resistant to corrosion of acidic and neutral substances | High-temperature resistant, corrosion-resistant | High-temperature resistant, corrosion-resistant |

| Thermal Conductivity (W/m·K) | approx. 50 | approx. 24 | approx. 2-3 | approx. 10 - 15 | approx. 100 - 120 |

| Thermal Shock Resistance | Ordinary | Ordinary | Good | Good | Good |

| Application Areas | Smelting crucibles, radar domes, infrared windows, etc. | Cutting tools, molds, electronic ceramics, etc. | Engine components, sensors, fuel cell diaphragms, etc. | High-temperature engines, cutting tools, etc. | Bearings, gas turbine blades, chemical linings, etc. |

| Cost | Medium | Low | High | High | High |

Yes — magnesia ceramics are among the most eco-friendly advanced ceramics.

Made from natural magnesium oxide (MgO), they are non-toxic, stable, and free of harmful emissions during production or use.

Their excellent durability allows multiple thermal cycles without degradation, reducing waste and extending component lifespan.

After service, MgO ceramics can be recycled or reprocessed, and their inert nature ensures no contamination to air, water, or soil.

For industries seeking both high performance and sustainability, magnesia ceramics provide a long-term, responsible material choice.

Yes — ADCERAX provides magnesia ceramic for sale specifically engineered for laboratory and analytical applications.

Our high-purity magnesium oxide ceramics deliver excellent thermal insulation, chemical inertness, and dimensional stability, making them ideal for crucibles, tubes, and plates used in high-temperature testing, melting, and analysis.

Both standard sizes and custom lab components are available, ensuring compatibility with diverse experimental systems.

You can purchase magnesia ceramics directly from ADCERAX, one of the trusted China magnesia ceramics suppliers with over 20 years of manufacturing expertise.

We specialize in high-purity MgO ceramics including crucibles, tubes, rods, and insulation parts — all engineered for superior heat resistance, chemical stability, and precision machining.

As a factory-direct supplier, ADCERAX provides competitive pricing, bulk order support, and full customization to meet the needs of industrial users and laboratories worldwide.

To get a quote, simply send ADCERAX your drawing, quantity, and material requirements.

Our team will prepare a custom magnesia ceramics quotation within 24 hours.

We provide standard and custom MgO parts with factory-direct pricing for both small and bulk orders.

The magnesium oxide ceramics market is expanding steadily, driven by rising demand for high-temperature and corrosion-resistant materials.

Key industries such as metallurgy, electronics, and energy are increasingly replacing metals and polymers with MgO ceramics for greater reliability and efficiency.

Global market size is projected to grow at around 5–7% CAGR, supported by industrial upgrades and clean-energy investments.

Manufacturers like ADCERAX lead with custom magnesium oxide ceramics, meeting global OEM demand for precision, purity, and long service life.

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

Contact ADCERAX for design support, sample validation, and global delivery.

info@adcerax.com

+(86) 0731-74427743 | WhatsApp: +(86) 19311583352

Within 24 hours

WhatsApp us

The more details you provide, the faster we can respond.

*We respond within 24 hours. All inquiries are confidential.

The more details you provide, the faster we can quote.

*We respond within 24 hours. All inquiries are confidential.