Custom Precision Ceramics Solutions for Industrial Equipment & Engineering Applications

ADCERAX is a China precision ceramic manufacturer supplying engineered alumina, zirconia, silicon nitride, silicon carbide and other advanced ceramic parts for industrial equipment builders. We produce rings, shafts, plungers, tubes, plates, nozzles and other custom precision ceramic components with tight-tolerance machining.

For design engineers, we offer a clear path from small-batch samples to stable repeat supply, so you validate a design once and rely on consistent ceramics for years. Fast technical feedback, drawing support and predictable lead times help you cut iterations, lower qualification risk and keep projects on schedule.

What Are Precision Ceramics?

Precision Ceramics Definition

Precision ceramics are advanced technical ceramic materials that are formed, sintered and then accurately machined so every part meets tight dimensional tolerances and consistent surface quality.

Why Engineers Choose Precision Ceramics?

Compared with standard technical ceramics or metal parts, precision ceramics offer the following key advantages in industrial equipment:

Precision ceramics resist wear and corrosion far better than metals or plastics, so plungers, seats, bushings and liners run longer with fewer replacements and less downtime.

Low thermal expansion and high stiffness help precision ceramic parts keep clearances and sealing gaps within tolerance, even at elevated temperature or under continuous load.

Ceramic components do not rust and shed very few particles, protecting fluids, samples and sensors from metallic contamination in lab and process systems.

Once a design is qualified, controlled forming, sintering and grinding deliver repeatable dimensions batch after batch, reducing re-qualification work and simplifying sourcing.

Precision Ceramics Properties

Precision ceramics offer high hardness and wear resistance, excellent chemical and thermal stability, low thermal expansion, strong electrical insulation and tight dimensional tolerances over time. These properties make precision ceramics suitable for long-life, tight-tolerance components in pumps, valves, analytical instruments and automated machinery.

Mechanical strength and wear resistance

- High hardness and compressive strength help precision ceramic parts survive abrasion, sliding contact and point loads.

- Suitable for plungers, seats, bushings and liners that run for long cycles in slurry, powder or chemical media.

Electrical insulation and dielectric behavior

- Materials such as alumina and aluminum nitride provide strong dielectric strength and volume resistivity for insulating tubes, spacers and housings.

- Stable insulation over a wide temperature range supports sensors, heaters and high-voltage assemblies.

Chemical resistance and cleanliness

- Precision ceramics are inert to many acids, alkalis and solvents, so wetted parts do not corrode or leach metals.

- Low contamination and low outgassing make them suitable for analytical instruments and clean process lines.

Thermal stability at elevated temperatures

- Low creep and good hot strength allow precision ceramics to keep shape and function at temperatures where many metals soften.

- Low thermal expansion reduces distortion and helps maintain sealing gaps and alignments through heat-up and cool-down.

Precision Ceramic Products

Our precision ceramics portfolio includes rings, sleeves, shafts, tubes, plates and laboratory ware. Below are examples of other precision ceramics used in lab and R&D setups.

Agate mortar and pestle is used in laboratories and R&D labs for fine grinding small batches of powders, mixing additives and preparing uniform test samples where controlled particle size and low cross-contamination are important.

- Inner surface and pestle head are smoothly finished for efficient grinding and easy cleaning between samples.

- Offered in multiple cup diameters with matching pestles to suit different sample volumes and bench layouts.

- Stable bowl geometry and reasonably thick wall design help the set sit firmly on the worktop and reduce spillage during operation.

Glass mortar and pestle is used in laboratories to gently grind powders, dissolve reagents and mix small liquid–solid suspensions, where operators need to visually monitor the mixture through a clear bowl and control particle size for routine analyses.

- Smooth inner surface and rounded pestle head help achieve fine grinding while keeping residues easy to rinse off between samples.

- Transparent bowl allows technicians to see the mixing process clearly and judge dispersion, sediment and color changes in real time.

- Offered in multiple capacities with matched pestles and a stable flat base, making it easy to choose the right size for different sample volumes and bench setups.

⭐️ Reliable Precision Ceramic Components for Demanding Industrial Equipment

ADCERAX helps equipment builders convert designs into precision ceramic components with consistent dimensions and predictable lead times. Share your drawings and key requirements, and our team will review, optimise and quote a solution you can qualify once and rely on for ongoing production.

Precision Ceramic Applications

Precision ceramics are used across chemical processing, lab analysis, new energy lines and automation systems wherever long-life wear, sealing and insulation components are required.

Precision Ceramics for Chemical & Process Equipment

🔹Applications

- Wear and corrosion protection for dosing pumps, chemical injection systems and process valves.

- Stable internals for flow meters, sampling devices and analyzers.

- Ceramic plungers, seats and nozzles designed to handle aggressive media.

Precision Ceramics for Pumps, Valves & Fluid Handling

🔹Applications

- Seal rings, bushings and thrust elements to reduce leakage and extend overhaul intervals.

- Valve balls and seats that retain tight shutoff after long exposure to slurry or chemicals.

- Components that maintain clearances and precision ceramic parallel surfaces at operating temperature.

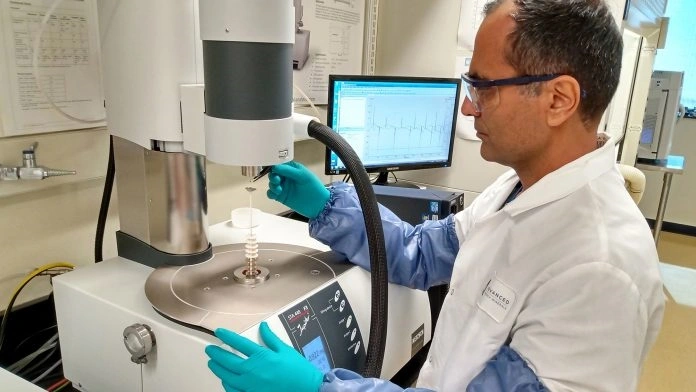

Precision Ceramics for Analytical & Laboratory Instruments

🔹Applications

- Crucibles, boats and fixtures for thermal analysis and materials testing.

- Insulating supports for high-temperature furnaces and kilns.

- Precision tubes and plates that minimize contamination and background signal.

Precision Ceramics for New Energy & Battery Materials Equipment

🔹Applications

- Wear liners and grinding elements for slurry preparation and dispersion.

- Flow components for electrolyte handling and chemical dosing.

- Fixtures and carriers used in drying, calcination and sintering processes.

Precision Ceramics for Mechanical Automation & Motion Components

🔹Applications

- Guide elements, positioning stops and wear strips in automated machinery.

- Precision bushings and bearings where lubrication is limited.

- Components that maintain tolerances over long cycles and temperature variations.

Custom precision ceramics Supplier

We specialize in custom precision ceramic parts based on customer drawings, samples or application requirements. Rings, plungers, tubes, plates, nozzles and other complex geometries can be tailored in size, wall thickness, holes, grooves and surface finish to match your operating conditions. Custom precision ceramic components typically require 3–9 weeks depending on design complexity, machining tolerances and inspection scope.

Customization Options

Extra-large / Extra-small diameters, non-standard thicknesses, and ultra-long / ultra-short lengths.

Provide higher - level dimensional accuracy and concentricity control than the standard.

Flanges, steps, threads, drilling holes, grooves, etc.

Adjust the material according to the application requirements.

Polish and grind the surface to achieve a specific surface roughness.

Customization Process

Send us your drawing, CAD file, or physical sample with material grade, dimensions, tolerances, and quantity. Our engineers will evaluate the design and provide a detailed quotation with lead time and pricing.

Once the quote is approved, we proceed with sample prototyping (1–50 pcs) if needed, for testing and validation.

After sample approval or direct confirmation, we begin batch manufacturing using CNC machining, sintering, and polishing. All parts undergo dimensional checks, material purity testing, and surface finish inspection.

Finished products are securely packed and shipped via DHL/FedEx/UPS or your preferred method. We support global delivery with full documentation.

Why Choose ADCERAX as Your precision ceramic Manufacturer?

ADCERAX is a precision ceramic manufacturer in China supplying industrial users with both custom and standard parts made in-house. Consistent tolerances, responsive engineering and export experience keep your precision ceramic sourcing simple and dependable.

Competitive pricing with strict quality control from raw material sourcing to final delivery

Professional team providing comprehensive technical support and collaborative design

Small batch orders to large-scale production with complex geometries and tight tolerances

24-hour response and 24-hour dispatch for standard items, 3-7 weeks for custom orders.

China Precision Ceramic Factory-ADCERAX

ADCERAX has been engaged in advanced ceramics for over 20 years and has developed more than 2,000 types of precision ceramic parts across alumina, zirconia, silicon nitride, silicon carbide, aluminum nitride and related materials.

We supply both custom and standard precision ceramic components for a wide range of equipment designs, exporting to more than 50 countries and supporting industrial users and OEMs that rely on stable wear, sealing and structural ceramic parts.

Precision Ceramic Machining

Precision ceramics behave as hard, brittle engineering materials during cutting, so successful machining depends on rigid fixturing, suitable diamond tooling and controlled cutting loads. The goal is to achieve clean, repeatable features without introducing microcracks or distortion that could shorten service life.

Tooling and Machine Setup

💡Machine choice

- Use rigid CNC lathes, mills and dedicated grinding machines with good spindle condition and stable fixturing.

- Precision surface and cylindrical grinders are preferred whenever tight tolerances or fine surface finish are required.

💡Tooling selection

- Choose sharp diamond or CBN tools with positive rake and polished cutting edges to reduce cutting forces.

- Use stable tool holders with minimal overhang to limit chatter and vibration when machining precision ceramics.

💡Cutting conditions

- Start with light depths of cut and moderate feed rates; increase gradually while monitoring edge quality.

- Apply coolant or mist where needed to manage heat, but avoid thermal shock and keep chips and grinding swarf clear of the cutting zone.

Process Recommendations

💡Turning and grooving

- Use smooth tool entry and exit, avoiding plunging directly into sharp internal corners.

- Leave small corner radii at groove bottoms and shoulders to reduce stress concentration and improve edge strength.

💡Milling and pocketing

- Prefer climb milling with light radial engagement to minimise edge chipping along slot and pocket walls.

- Ramp or helix into pockets instead of full-width plunging to reduce shock on the cutting edge.

💡Drilling and threading

- Use peck drilling with controlled chip removal to reduce the risk of cracks at the hole exit.

- For threads, consider thread milling or carefully controlled tapping with generous run-out and deburring of starts.

💡Grinding and lapping

- Finish critical surfaces by precision grinding and, where required, lapping to reach the specified surface finish and flatness.

- Dress grinding wheels regularly to keep them sharp and to maintain predictable stock-removal rates.

Tips-for-Machining (DFM)

💡Avoid knife-edge features

- Keep minimum wall thickness and land widths above agreed limits; extremely sharp fins and thin edges are prone to chipping during machining and in service.

💡Use radii and chamfers wisely

- Add small corner radii or chamfers wherever possible to reduce stress concentrations and improve edge robustness, especially around slots, pockets and windows.

💡Separate critical and non-critical tolerances

- Tighten tolerances only where function requires it and relax non-critical dimensions; this reduces machining time, scrap risk and inspection cost.

💡Plan fixturing surfaces

- Include flat reference pads or clamping areas so the precision ceramic part can be held securely without stressing functional sections or delicate edges.

ADCERAX Precision Ceramic Machining Capabilities

ADCERAX combines engineering support, drawing optimisation and CNC machining assets dedicated to precision ceramics. We turn fired blanks into rings, tubes, plates, plungers and other custom parts with stable quality for demanding industrial and laboratory equipment.

| Capability Category | Equipment / Specification | Engineering Value Provided |

|---|---|---|

| Precision CNC Machining | Vertical and horizontal CNC machining centres for precision ceramics | Stable dimensions and clean edges on rings, tubes, plates, plungers and complex custom shapes |

| Fine Grinding & Surface Finish | Surface grinders, diamond wheels, lapping fixtures | Controlled flatness, parallelism and surface quality on sealing, bearing and locating faces |

| Hole, Slot & Thread Machining | CNC drilling, tapping, thread milling and small-diameter tooling | Accurate holes, grooves and threads for spacers, connectors and hardware interfaces |

| Prototype & Small-Batch Runs | Flexible fixture systems and quick-change tooling | Fast turnaround for samples and low-volume custom precision ceramic parts |

| Metrology & Inspection | CMM, optical measurement systems, gauges and dedicated inspection jigs | Consistent tolerances and documented quality for repeat production and multi-batch programs |

Precision Ceramics Quality & Certifications

Our precision ceramics are produced under certified quality systems with material traceability and documented inspection, supporting OEM audits and long-term supply programs

ADCERAX Precision Ceramic Machining Capabilities

ADCERAX combines engineering support, drawing optimisation and CNC machining assets dedicated to precision ceramics. We turn fired blanks into rings, tubes, plates, plungers and other custom parts with stable quality for demanding industrial and laboratory equipment.

| Capability Category | Equipment / Specification | Engineering Value Provided |

|---|---|---|

| Precision CNC Machining | Vertical and horizontal CNC machining centres for precision ceramics | Stable dimensions and clean edges on rings, tubes, plates, plungers and complex custom shapes |

| Fine Grinding & Surface Finish | Surface grinders, diamond wheels, lapping fixtures | Controlled flatness, parallelism and surface quality on sealing, bearing and locating faces |

| Hole, Slot & Thread Machining | CNC drilling, tapping, thread milling and small-diameter tooling | Accurate holes, grooves and threads for spacers, connectors and hardware interfaces |

| Prototype & Small-Batch Runs | Flexible fixture systems and quick-change tooling | Fast turnaround for samples and low-volume custom precision ceramic parts |

| Metrology & Inspection | CMM, optical measurement systems, gauges and dedicated inspection jigs | Consistent tolerances and documented quality for repeat production and multi-batch programs |

FAQs About Precision Ceramics

Precision ceramics are technical ceramics that have been taken several steps further in terms of dimensional control and consistency. They differ from standard technical ceramics in that:

Tolerances are tighter and repeatable – key diameters, flatness and parallelism are ground and lapped to precise limits rather than left as-fired.

Features are fully engineered – grooves, threads, slots and sealing faces are designed and machined for specific assemblies, not just generic shapes.

Process control is stricter – forming, sintering, machining and inspection are all tied to documented routes so each batch behaves the same in service.

In short, standard technical ceramics provide the material performance, while precision ceramics add the dimensional accuracy and consistency needed for critical industrial components.

We supply rings, sleeves, bushings, plungers, shafts, tubes, plates, discs, nozzles, liners and custom-shaped precision machined ceramics for industrial and laboratory equipment.

Yes. Our precision ceramic machining team works directly from your 2D/3D drawings or verified samples, reviewing tolerances and features to ensure the design can be manufactured repeatably.

We need drawings, material or application description, tolerance and surface-finish targets, annual usage, batch sizes and any special inspection or documentation requirements.

Yes. We regularly provide prototype and small-batch runs so you can validate designs and test performance before committing to full-scale production.

Our engineers can suggest radii, wall thickness, datum schemes and tolerance splits that make the part easier to machine, more robust in service and more economical to produce.

Ceramics are hard and brittle, so we use diamond tooling, lighter cuts, stable fixturing and grinding/lapping instead of heavy conventional cutting, focusing on avoiding microcracks and edge chipping.

1. Wear and sealing components in pumps and valves

Precision ceramics are widely used as seal rings, valve seats, bushings and plungers in chemical, dosing and slurry pumps, as well as control valves. Their wear and corrosion resistance keeps leakage and clearances stable over long service intervals.

2. Flow-control elements and nozzles

In dosing, spraying, coating and jet systems, precision ceramic nozzles, orifices and restrictors help maintain consistent flow rates and spray patterns. Dimensional stability under pressure and temperature changes improves process repeatability.

3. Insulating tubes, spacers and housings

Where electrical insulation or thermal isolation is critical, precision ceramic tubes, sleeves, stand-offs and housings are used around heaters, sensors, electrodes and feedthroughs. They provide reliable dielectric strength and low thermal expansion.

4. Wear-resistant plates, discs and liners

Mixers, mills, classifiers, chutes and hoppers often use precision ceramic plates, discs and liner tiles in high-wear zones. These parts protect steel structures from abrasion and chemical attack, extending equipment life and reducing downtime.

5. Positioning, guiding and motion components

In automation and motion systems, precision ceramic guides, stops, bushings and support elements keep positioning accuracy and clearances stable over many cycles, especially where lubrication is limited or temperatures fluctuate.

6. Fixtures, supports and carriers for high-temperature processes

Precision ceramic fixtures, pins, supports and carriers hold parts in place during drying, calcination, sintering or thermal treatment. Their dimensional stability at elevated temperatures helps maintain geometry and process consistency.

Yes. ADCERAX is a China-based precision ceramic manufacturer exporting regularly to industrial users in the US, Canada, Germany, the UK, France and other mature manufacturing markets. We are familiar with export packing, customs documentation and common Incoterms, and communicate in English for drawings, RFQs and technical reviews, so overseas customers can source precision ceramic parts from China with predictable lead times and low logistics risk.

Sometimes, but not always. In simple cases a precision ceramic ring, sleeve or plate can drop into an existing metal design with only minor adjustments. However, ceramics are hard and brittle with different thermal expansion and mounting needs, so many parts work better with small redesigns (fillets, clearances, support surfaces, fixing method). The safest approach is to share your current metal drawing and operating conditions so we can confirm where a direct swap is feasible and where geometry changes are needed for a reliable conversion to precision ceramics.

ADCERAX is a china precision ceramic factory providing standard rings, sleeves, tubes, plates, nozzles and other parts, as well as precision machined ceramics made to customer drawings. You can send us your requirements, drawings or BOM, and we will respond with factory-direct pricing and lead times tailored to your order.

Get in touch with us

We believe that Adcerax will become your best partner!

Please fill in your contact information in the form or call us.

*Our team will answer your inquiries within 24 hours.

*Your information will be kept strictly confidential.

info@adcerax.com

Telephone: +(86) 0731-74427743

WhatsApp: +(86) 19311583352

Within 24 hours