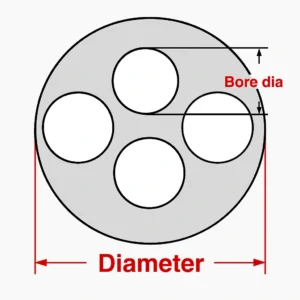

A 4-bore alumina tube is a high-temperature ceramic tube made from high-purity aluminum oxide (typically ≥95% Al₂O₃) that contains four parallel internal channels (bores) running along its length. These bores are evenly spaced and isolated from each other, allowing the tube to be used for multiple functions simultaneously.

Alumina Four Bores Tube Benefits

- High thermal resistance: Stable performance up to 1700°C

- Excellent electrical insulation: Volume resistivity >10⁶ Ω·cm

- Multi-channel design: 4 evenly spaced bores for gas or wire separation

- Dimensional precision: Tolerance up to ±0.2mm for ID/OD

- High chemical inertness: Resistant to most acids and alkalis

- Dense microstructure: Low porosity, high mechanical strength

Properties for Alumina Four Bores Tube

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Specifications of 4 Bores Alumina Tube

| SKU | Dia.(mm) | Bore Dia(mm) | L(mm) | Purity Available |

| TE-AT-138 | 1.5 | 0.3 | L≤2500 | Al₂O₃95% Al₂O₃99% Al₂O₃99.5% |

| TE-AT-139 | 2 | 0.4 | L≤2500 | |

| TE-AT-140 | 2.5 | 0.6 | L≤2500 | |

| TE-AT-141 | 3 | 0.8 | L≤2500 | |

| TE-AT-142 | 3.5 | 0.8 | L≤2500 | |

| TE-AT-143 | 3.5 | 1 | L≤2500 | |

| TE-AT-144 | 4 | 1 | L≤2500 | |

| TE-AT-145 | 4 | 1.3 | L≤2500 | |

| TE-AT-146 | 4.5 | 1.2 | L≤2500 | |

| TE-AT-147 | 5 | 1.2 | L≤2500 | |

| TE-AT-148 | 5.5 | 1.3 | L≤2500 | |

| TE-AT-149 | 6 | 1.3 | L≤2500 | |

| TE-AT-150 | 6.5 | 1.4 | L≤2500 | |

| TE-AT-151 | 8 | 2.0 | L≤2500 | |

| TE-AT-152 | 8.5 | 2.2 | L≤2500 | |

| TE-AT-153 | 10 | 3.0 | L≤2500 | |

| TE-AT-154 | 12 | 3.9 | L≤2500 | |

| TE-AT-155 | 14 | 3.9 | L≤2500 | |

| TE-AT-156 | 16 | 4.0 | L≤2500 |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

Alumina Four Bores Tube Packaging:

Each tube is individually wrapped in anti-static foam and packed in a rigid cardboard box.