An alumina ceramic slice is a thin, flat component manufactured from high-purity alumina (Al₂O₃), typically in the range of 96–99.7%. It is designed for use as an insulating, wear-resistant, and dimensionally stable layer in assemblies that require precise thickness, electrical isolation, or thermal stability.

Alumina Ceramic Slice Benefits

- Assembly consistency: Defined thickness and bow keep clamping force and creepage distances stable, reducing rework in power modules and fixtures.

- Damage-minimized edges: Controlled micro-chipping and optional edge radius prevent point-stress initiation and handling scratches.

- Traceable geometry: Laser ID, lot marks and datum fiducials enable repeatable set-ups and faster QA correlation.

- Process-ready finish: Selectable Ra for thermal interface pastes, bonding films or dry contact surfaces; polished faces reduce particulate risk.

- Balanced material choice: 96% Al₂O₃ provides dielectric strength and wear resistance at a competitive cost; higher-purity variants are available when contamination risk is critical.

Alumina Ceramic Slice Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

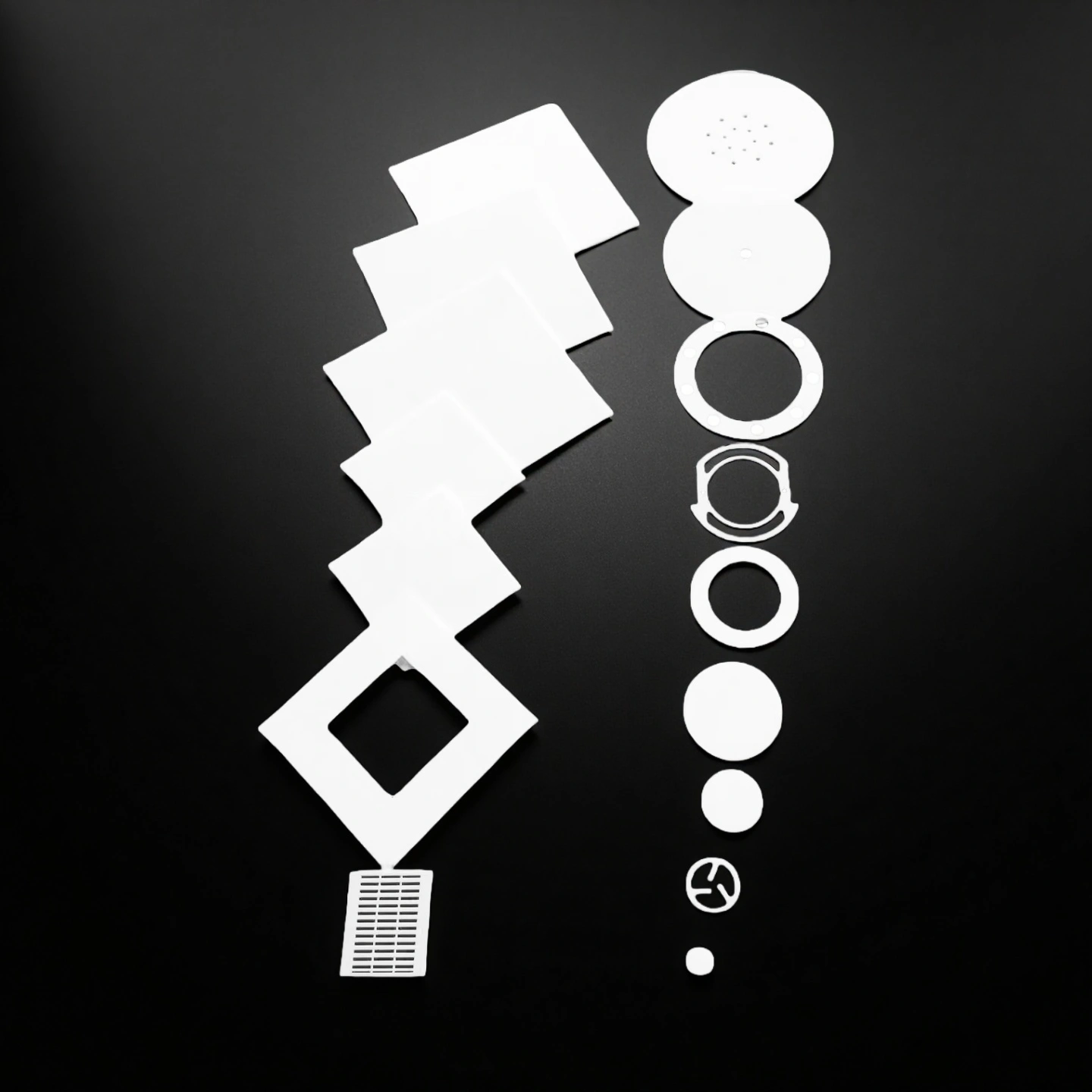

Alumina Ceramic Slice Specifications

Type 1: Round Alumina Ceramic Slice

| Round Alumina Ceramic Slice | ||

| Item No. | Diameter(mm) | Thick(mm) |

| AT-DIS001 | 25 | 1.5 |

| AT-DIS002 | 32 | 2 |

| AT-DIS003 | 38 | 2 |

| AT-D-42-2 | 42 | 2 |

| AT-DIS004 | 51 | 2 |

| AT-DIS005 | 64 | 3 |

| AT-DIS006 | 76 | 3 |

| AT-D-82-6 | 82 | 6 |

| AT-DIS007 | 89 | 4 |

| AT-DIS008 | 102 | 4 |

| AT-DIS009 | 127 | 5 |

| AT-DIS010 | 152 | 5 |

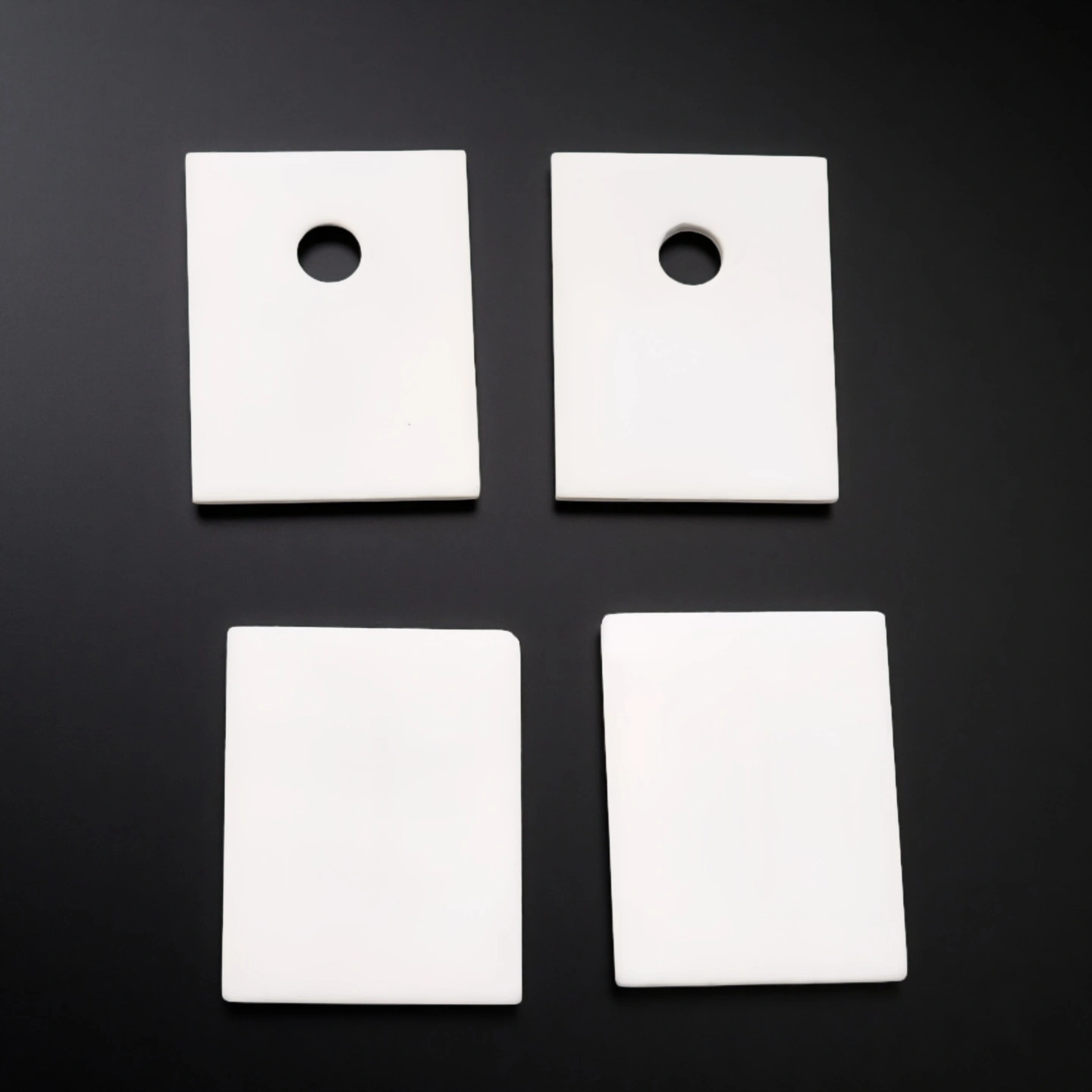

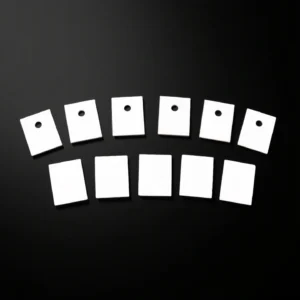

Type 2: Square Alumina Ceramic Slice

| Square Alumina Ceramic Plate | |||

| Item No. | Length | Width | Thickness |

| AT-P-220-220-5 | 220mm | 220mm | 5mm |

| AT-P-216-102-5 | 216mm | 102mm | 5mm |

| AT-P-208-110-5 | 208mm | 110mm | 5mm |

| AT-P-152-152-5 | 152mm | 152mm | 5mm |

| AT-P-150-80-4 | 150mm | 80mm | 4mm |

| AT-P-107-53-4 | 107mm | 53mm | 4mm |

| AT-P-102-76-6 | 102mm | 76mm | 6mm |

| AT-P-102-25-6 | 102mm | 25mm | 6mm |

| AT-P-90-65-6 | 90mm | 65mm | 6mm |

| AT-P-90-45-4 | 90mm | 45mm | 4mm |

| AT-P-60-40-4 | 60mm | 40mm | 4mm |

| AT-P-60-10-5 | 60mm | 10mm | 5mm |

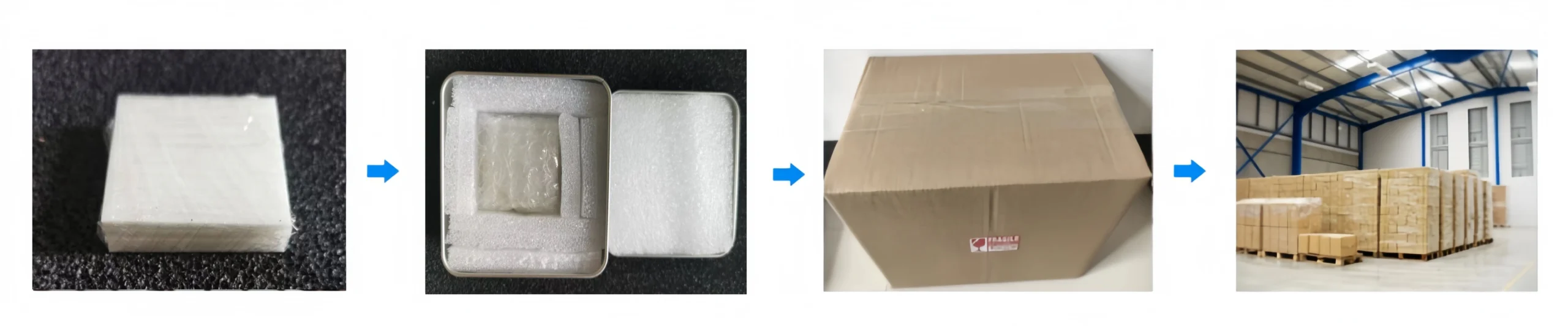

Alumina Ceramic Slice Packaging

- Clean-pack: interleaf + protective stackers to limit abrasion.