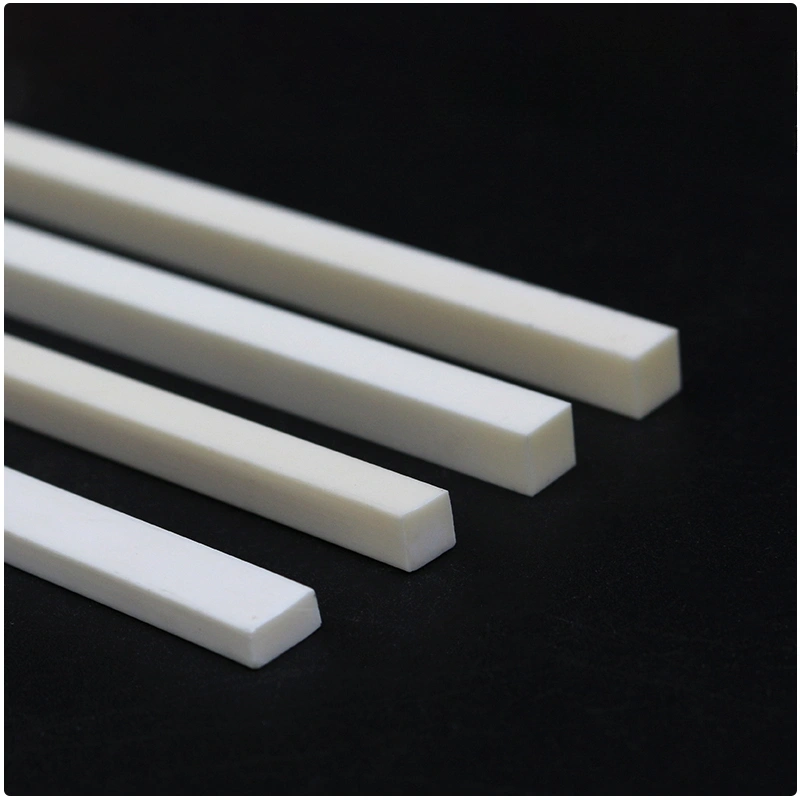

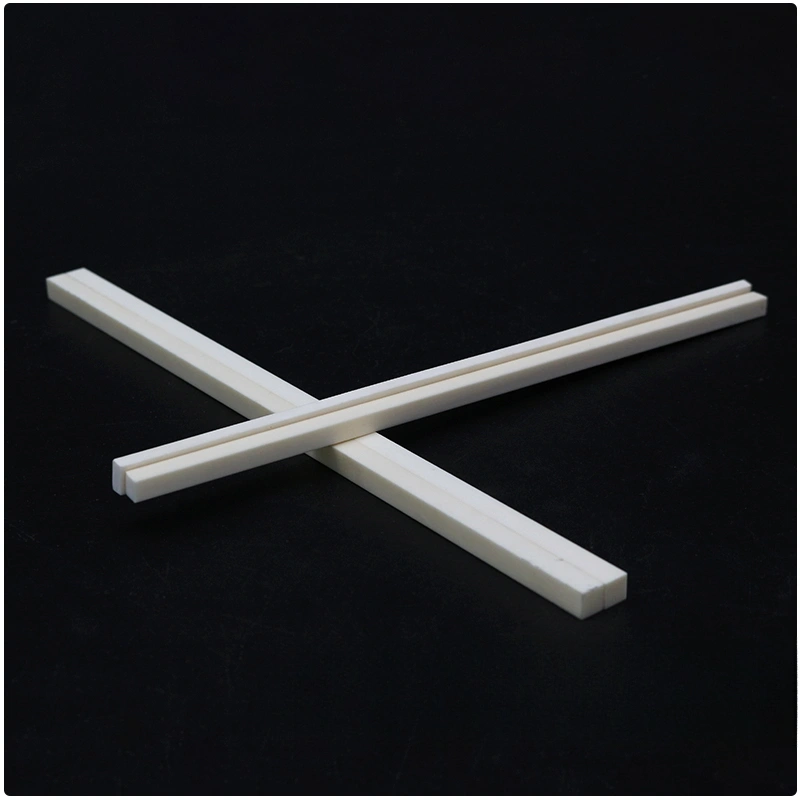

Alumina ceramic square rods are precision-engineered components made from aluminum oxide (Al₂O₃) with a square cross-section. They combine high hardness, thermal stability, chemical resistance, and electrical insulation properties, making them suitable for demanding industrial and laboratory environments.

Benefits of Square Alumina Rods

-

High hardness and wear resistance ensure durability in industrial use.

-

Stable insulation properties under high voltage and elevated temperatures.

-

Available in multiple purities to meet both standard and advanced applications.

-

Supports precision machining for non-standard cross-sections.

-

Maintains dimensional accuracy with ±0.2 mm tolerance.

Alumina Ceramic Square Rods Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Square Alumina Bar Specifications

| Item No. | Width (mm) | Height (mm) | Length (mm) |

| TE-AT-30036 | 2 | 1 | ≤2500 |

| TE-AT-30037 | 3 | 2 | ≤2500 |

| TE-AT-30038 | 4 | 2 | ≤2500 |

| TE-AT-30039 | 3 | 3 | ≤2500 |

| TE-AT-30040 | 6 | 4.5 | ≤2500 |

| TE-AT-30041 | 6 | 6 | ≤2500 |

| TE-AT-30042 | 7 | 6 | ≤2500 |

| TE-AT-30043 | 8 | 6 | ≤2500 |

| TE-AT-30044 | 8.5 | 6 | ≤2500 |

| TE-AT-30045 | 9 | 5 | ≤2500 |

| TE-AT-30046 | 9.5 | 7 | ≤2500 |

| TE-AT-30047 | 9.5 | 8 | ≤2500 |

| TE-AT-30048 | 10 | 6.5 | ≤2500 |

| TE-AT-30049 | 10 | 7.5 | ≤2500 |

| TE-AT-30050 | 11 | 8 | ≤2500 |

| TE-AT-30051 | 11 | 9.5 | ≤2500 |

| TE-AT-30052 | 13 | 7 | ≤2500 |

| TE-AT-30053 | 13 | 8.5 | ≤2500 |

| TE-AT-30054 | 14 | 9 | ≤2500 |

| TE-AT-30055 | 14 | 9.5 | ≤2500 |

| TE-AT-30056 | 15 | 8 | ≤2500 |

| TE-AT-30057 | 15 | 10 | ≤2500 |

| TE-AT-30058 | 16 | 12 | ≤2500 |

| TE-AT-30059 | 16 | 13.5 | ≤2500 |

| TE-AT-30060 | 17 | 14 | ≤2500 |

| TE-AT-30061 | 17 | 15.5 | ≤2500 |

| TE-AT-30062 | 18 | 13 | ≤2500 |

| TE-AT-30063 | 18 | 15.5 | ≤2500 |

| TE-AT-30064 | 19 | 16 | ≤2500 |

| TE-AT-30065 | 20 | 15 | ≤2500 |

| TE-AT-30066 | 20 | 17 | ≤2500 |

| TE-AT-30067 | 21 | 16 | ≤2500 |

| TE-AT-30068 | 21 | 18.5 | ≤2500 |

| TE-AT-30069 | 23 | 9 | ≤2500 |

| TE-AT-30070 | 23 | 12.5 | ≤2500 |

| TE-AT-30071 | 23 | 18 | ≤2500 |

*Note: The table above shows only some standard specifications. For more specifications, please refer to the complete product catalogue or contact us for customization.

Square Alumina Rods Packaging:

- Standard Export Protection

Alumina ceramic square rods are wrapped with foam and cushioning film, then packed in strong cartons or wooden crates. - Safe Transport

All packages are palletized and strapped for stability, ensuring safe delivery by sea or air. - Customized Options

Moisture-proof bags, vacuum sealing, and individual labelling can be provided on request.