An alumina ceramic open tube is a cylindrical component made from aluminum oxide (Al₂O₃), designed with both ends open to allow the passage of gases, liquids, or probes. These tubes are widely used in high-temperature, chemically aggressive, or electrically insulating environments due to alumina’s excellent thermal stability, corrosion resistance, and dielectric properties.

Benefits of Alumina Ceramic Tubes Open

-

Open-end flexibility: Both ends remain accessible for integration with flanges, seals, or connectors, allowing continuous gas flow and easy assembly.

-

Versatile fitting: Dual openings simplify alignment in tube furnaces, reactors, or flow-through systems where in/out connections are required.

-

Adaptable length configuration: Cut-to-size options ensure the open tube fits directly into experimental setups or industrial process lines.

-

Efficient replacement: Open geometry reduces downtime by enabling fast swap-out of worn liners or insulation sleeves.

-

Multi-purpose design: Can serve as liners, flow paths, or insulation channels, supporting diverse applications across laboratory and industrial environments.

Alumina Ceramic Open Tube Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

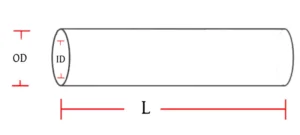

Alumina Ceramic Open Tube Size

Type 1: Al₂O₃ Tubes Open Both Ends

| Item No. | OD(mm) | ID(mm) | L(mm) | Purity(%) |

|---|---|---|---|---|

| TE-AT-20001 | 3 | 2 | 5-3000 | 99 |

| TE-AT-20002 | 3.5 | 2 | 5-3000 | 99 |

| TE-AT-20003 | 3.5 | 2.1 | 5-3000 | 99 |

| TE-AT-20004 | 3.5 | 2.2 | 5-3000 | 99 |

| TE-AT-20005 | 3.5 | 2.4 | 5-3000 | 99 |

| TE-AT-20006 | 3.5 | 2.5 | 5-3000 | 99 |

| TE-AT-20007 | 3.6 | 1.8 | 5-3000 | 99 |

| TE-AT-20008 | 3.7 | 2 | 5-3000 | 99 |

| TE-AT-20009 | 3.8 | 1.8 | 5-3000 | 99 |

| TE-AT-20010 | 4 | 2.0 | 5-3000 | 99 |

| TE-AT-20011 | 4 | 1.9 | 5-3000 | 99 |

| TE-AT-20012 | 4 | 2.4 | 5-3000 | 99 |

| TE-AT-20013 | 4 | 2.5 | 5-3000 | 99 |

| TE-AT-20014 | 4 | 2.8 | 5-3000 | 99 |

| TE-AT-20015 | 4 | 3 | 5-3000 | 99 |

| TE-AT-20016 | 4.1 | 1.7 | 5-3000 | 99 |

| TE-AT-20017 | 4.1 | 3.1 | 5-3000 | 99 |

| TE-AT-20018 | 4.2 | 2.4 | 5-3000 | 99 |

| TE-AT-20019 | 4.3 | 3 | 5-3000 | 99 |

| TE-AT-20020 | 4.4 | 3 | 5-3000 | 99 |

| TE-AT-20021 | 4.5 | 2 | 5-3000 | 99 |

| TE-AT-20022 | 4.5 | 3 | 5-3000 | 99 |

| TE-AT-20023 | 4.6 | 3.8 | 5-3000 | 99 |

| TE-AT-20024 | 4.7 | 3 | 5-3000 | 99 |

| TE-AT-20025 | 4.8 | 3 | 5-3000 | 99 |

| TE-AT-20026 | 4.8 | 3.3 | 5-3000 | 99 |

| TE-AT-20027 | 4.8 | 3.5 | 5-3000 | 99 |

| TE-AT-20028 | 4.8 | 3.8 | 5-3000 | 99 |

| TE-AT-20029 | 4.9 | 4.3 | 5-3000 | 99 |

| TE-AT-20030 | 5 | 3 | 5-3000 | 99 |

| TE-AT-20031 | 5 | 3.5 | 5-3000 | 99 |

| TE-AT-20032 | 5 | 4 | 5-3000 | 99 |

| TE-AT-20033 | 5.5 | 3 | 5-3000 | 99 |

| TE-AT-20034 | 5.5 | 4 | 5-3000 | 99 |

| TE-AT-20035 | 5.8 | 4.2 | 5-3000 | 99 |

| TE-AT-20036 | 6 | 2 | 5-3000 | 99 |

| TE-AT-20037 | 6 | 3 | 5-3000 | 99 |

| TE-AT-20038 | 6 | 3.5 | 5-3000 | 99 |

| TE-AT-20039 | 6 | 4.5 | 5-3000 | 99 |

| TE-AT-20040 | 6.3 | 3.2 | 5-3000 | 99 |

| TE-AT-20041 | 6.35 | 4 | 5-3000 | 99 |

| TE-AT-20042 | 6.35 | 4.5 | 5-3000 | 99 |

| TE-AT-20043 | 6.5 | 3 | 5-3000 | 99 |

| TE-AT-20044 | 6.7 | 3 | 5-3000 | 99 |

| TE-AT-20045 | 6.7 | 4 | 5-3000 | 99 |

| TE-AT-20046 | 7 | 3 | 5-3000 | 99 |

| TE-AT-20047 | 7 | 4 | 5-3000 | 99 |

| TE-AT-20048 | 7 | 4.5 | 5-3000 | 99 |

| TE-AT-20049 | 7 | 5 | 5-3000 | 99 |

| TE-AT-20050 | 7.5 | 2 | 5-3000 | 99 |

| TE-AT-20051 | 7.5 | 3 | 5-3000 | 99 |

| TE-AT-20052 | 7.5 | 4 | 5-3000 | 99 |

| TE-AT-20053 | 8 | 2 | 5-3000 | 99 |

| TE-AT-20054 | 8 | 2.5 | 5-3000 | 99 |

| TE-AT-20055 | 8 | 3 | 5-3000 | 99 |

| TE-AT-20056 | 8 | 3.5 | 5-3000 | 99 |

| TE-AT-20057 | 8 | 4 | 5-3000 | 99 |

| TE-AT-20058 | 8 | 5 | 5-3000 | 99 |

| TE-AT-20059 | 8.5 | 2 | 5-3000 | 99 |

| TE-AT-20060 | 8.5 | 5 | 5-3000 | 99 |

| TE-AT-20061 | 9 | 2 | 5-3000 | 99 |

| TE-AT-20062 | 9 | 2.5 | 5-3000 | 99 |

| TE-AT-20063 | 9 | 3 | 5-3000 | 99 |

| TE-AT-20064 | 9 | 3.5 | 5-3000 | 99 |

| TE-AT-20065 | 9 | 4 | 5-3000 | 99 |

| TE-AT-20066 | 9 | 5 | 5-3000 | 99 |

| TE-AT-20067 | 9 | 6 | 5-3000 | 99 |

| TE-AT-20068 | 9 | 7 | 5-3000 | 99 |

| TE-AT-20069 | 9.5 | 3 | 5-3000 | 99 |

| TE-AT-20070 | 9.5 | 3.5 | 5-3000 | 99 |

| TE-AT-20071 | 9.5 | 4.5 | 5-3000 | 99 |

| TE-AT-20072 | 9.5 | 5.5 | 5-3000 | 99 |

| TE-AT-20073 | 9.5 | 6 | 5-3000 | 99 |

| TE-AT-20074 | 9.5 | 7 | 5-3000 | 99 |

| TE-AT-20075 | 10 | 3.5 | 5-3000 | 99 |

| TE-AT-20076 | 10 | 4 | 5-3000 | 99 |

| TE-AT-20077 | 10 | 2 | 5-3000 | 99 |

| TE-AT-20078 | 10 | 2.5 | 5-3000 | 99 |

| TE-AT-20079 | 10 | 4.5 | 5-3000 | 99 |

| TE-AT-20080 | 10 | 5 | 5-3000 | 99 |

| TE-AT-20081 | 10 | 5.5 | 5-3000 | 99 |

| TE-AT-20082 | 10 | 6 | 5-3000 | 99 |

| TE-AT-20083 | 10 | 6.5 | 5-3000 | 99 |

| TE-AT-20084 | 10 | 7 | 5-3000 | 99 |

| TE-AT-20085 | 10 | 8 | 5-3000 | 99 |

| TE-AT-20086 | 11 | 3 | 5-3000 | 99 |

| TE-AT-20087 | 11 | 3.5 | 5-3000 | 99 |

| TE-AT-20088 | 11 | 4 | 5-3000 | 99 |

| TE-AT-20089 | 11 | 5 | 5-3000 | 99 |

| TE-AT-20090 | 11 | 7 | 5-3000 | 99 |

| TE-AT-20091 | 12 | 7 | 5-3000 | 99 |

| TE-AT-20092 | 12 | 8 | 5-3000 | 99 |

| TE-AT-20093 | 12 | 9 | 5-3000 | 99 |

| TE-AT-20094 | 12 | 10 | 5-3000 | 99 |

| TE-AT-20095 | 13 | 7 | 5-3000 | 99 |

| TE-AT-20096 | 13 | 8 | 5-3000 | 99 |

| TE-AT-20097 | 13 | 9 | 5-3000 | 99 |

| TE-AT-20098 | 13 | 10 | 5-3000 | 99 |

| TE-AT-20099 | 13 | 6 | 5-3000 | 99 |

| TE-AT-20100 | 14 | 3 | 5-3000 | 99 |

| TE-AT-20101 | 14 | 4 | 5-3000 | 99 |

| TE-AT-20102 | 14 | 6 | 5-3000 | 99 |

| TE-AT-20103 | 14 | 9 | 5-3000 | 99 |

| TE-AT-20104 | 14 | 10 | 5-3000 | 99 |

| TE-AT-20105 | 15 | 6 | 5-3000 | 99 |

| TE-AT-20106 | 15 | 7 | 5-3000 | 99 |

| TE-AT-20107 | 15 | 8 | 5-3000 | 99 |

| TE-AT-20108 | 15 | 9 | 5-3000 | 99 |

| TE-AT-20109 | 15 | 10 | 5-3000 | 99 |

| TE-AT-20110 | 15 | 11 | 5-3000 | 99 |

| TE-AT-20111 | 16 | 6 | 5-3000 | 99 |

| TE-AT-20112 | 16 | 8 | 5-3000 | 99 |

| TE-AT-20113 | 16 | 9 | 5-3000 | 99 |

| TE-AT-20114 | 16 | 10 | 5-3000 | 99 |

| TE-AT-20115 | 16 | 11 | 5-3000 | 99 |

| TE-AT-20116 | 16 | 12 | 5-3000 | 99 |

| TE-AT-20117 | 17 | 10 | 5-3000 | 99 |

| TE-AT-20118 | 17 | 11 | 5-3000 | 99 |

| TE-AT-20119 | 17 | 12 | 5-3000 | 99 |

| TE-AT-20120 | 17 | 13 | 5-3000 | 99 |

| TE-AT-20121 | 17 | 14 | 5-3000 | 99 |

| TE-AT-20122 | 18 | 10 | 5-3000 | 99 |

| TE-AT-20123 | 18 | 11 | 5-3000 | 99 |

| TE-AT-20124 | 18 | 12 | 5-3000 | 99 |

| TE-AT-20125 | 18 | 13 | 5-3000 | 99 |

| TE-AT-20126 | 18 | 14 | 5-3000 | 99 |

| TE-AT-20127 | 18 | 8.5 | 5-3000 | 99 |

| TE-AT-20128 | 19 | 9 | 5-3000 | 99 |

| TE-AT-20129 | 19 | 10 | 5-3000 | 99 |

| TE-AT-20130 | 19 | 11 | 5-3000 | 99 |

| TE-AT-20131 | 19 | 12 | 5-3000 | 99 |

| TE-AT-20132 | 19 | 13 | 5-3000 | 99 |

| TE-AT-20133 | 19 | 14 | 5-3000 | 99 |

| TE-AT-20134 | 19 | 15 | 5-3000 | 99 |

| TE-AT-20135 | 20 | 8 | 5-3000 | 99 |

| TE-AT-20136 | 20 | 10 | 5-3000 | 99 |

| TE-AT-20137 | 20 | 11 | 5-3000 | 99 |

| TE-AT-20138 | 20 | 14 | 5-3000 | 99 |

| TE-AT-20139 | 20 | 15 | 5-3000 | 99 |

| TE-AT-20140 | 20 | 16 | 5-3000 | 99 |

| TE-AT-20141 | 20 | 17 | 5-3000 | 99 |

| TE-AT-20142 | 21 | 3 | 5-3000 | 99 |

| TE-AT-20143 | 21 | 2.5 | 5-3000 | 99 |

| TE-AT-20144 | 21 | 10 | 5-3000 | 99 |

| TE-AT-20145 | 21 | 14 | 5-3000 | 99 |

| TE-AT-20146 | 21 | 16 | 5-3000 | 99 |

| TE-AT-20147 | 22 | 2.5 | 5-3000 | 99 |

| TE-AT-20148 | 22 | 16 | 5-3000 | 99 |

| TE-AT-20149 | 22 | 17 | 5-3000 | 99 |

| TE-AT-20150 | 22 | 19 | 5-3000 | 99 |

| TE-AT-20151 | 23 | 3.5 | 5-3000 | 99 |

| TE-AT-20152 | 23 | 12 | 5-3000 | 99 |

| TE-AT-20153 | 23 | 15 | 5-3000 | 99 |

| TE-AT-20154 | 23 | 16 | 5-3000 | 99 |

| TE-AT-20155 | 23 | 17 | 5-3000 | 99 |

| TE-AT-20156 | 23 | 18 | 5-3000 | 99 |

| TE-AT-20157 | 23 | 19 | 5-3000 | 99 |

| TE-AT-20158 | 24 | 5 | 5-3000 | 99 |

| TE-AT-20159 | 24 | 17 | 5-3000 | 99 |

| TE-AT-20160 | 24 | 18 | 5-3000 | 99 |

| TE-AT-20161 | 24 | 19 | 5-3000 | 99 |

| TE-AT-20162 | 24 | 14 | 5-3000 | 99 |

| TE-AT-20163 | 25 | 14 | 5-3000 | 99 |

| TE-AT-20164 | 25 | 15 | 5-3000 | 99 |

| TE-AT-20165 | 25 | 16 | 5-3000 | 99 |

| TE-AT-20166 | 25 | 17 | 5-3000 | 99 |

| TE-AT-20167 | 25 | 18 | 5-3000 | 99 |

| TE-AT-20168 | 25 | 19 | 5-3000 | 99 |

| TE-AT-20169 | 25 | 20 | 5-3000 | 99 |

| TE-AT-20170 | 25 | 21 | 5-3000 | 99 |

| TE-AT-20171 | 26 | 8 | 5-3000 | 99 |

| TE-AT-20172 | 26 | 14 | 5-3000 | 99 |

| TE-AT-20173 | 26 | 15 | 5-3000 | 99 |

| TE-AT-20174 | 26 | 16 | 5-3000 | 99 |

| TE-AT-20175 | 26 | 17 | 5-3000 | 99 |

| TE-AT-20176 | 26 | 18 | 5-3000 | 99 |

| TE-AT-20177 | 26 | 19 | 5-3000 | 99 |

| TE-AT-20178 | 26 | 20 | 5-3000 | 99 |

| TE-AT-20179 | 26 | 21 | 5-3000 | 99 |

| TE-AT-20180 | 27 | 21 | 5-3000 | 99 |

| TE-AT-20181 | 27 | 22 | 5-3000 | 99 |

| TE-AT-20182 | 28 | 19 | 5-3000 | 99 |

| TE-AT-20183 | 28 | 20 | 5-3000 | 99 |

| TE-AT-20184 | 28 | 21 | 5-3000 | 99 |

| TE-AT-20185 | 28 | 22 | 5-3000 | 99 |

| TE-AT-20186 | 28 | 23 | 5-3000 | 99 |

| TE-AT-20187 | 28 | 23.5 | 5-3000 | 99 |

| TE-AT-20188 | 28 | 24 | 5-3000 | 99 |

| TE-AT-20189 | 28 | 25 | 5-3000 | 99 |

| TE-AT-20190 | 29 | 23 | 5-3000 | 99 |

| TE-AT-20191 | 29 | 24 | 5-3000 | 99 |

| TE-AT-20192 | 29 | 25 | 5-3000 | 99 |

| TE-AT-20193 | 30 | 15 | 5-3000 | 99 |

| TE-AT-20194 | 30 | 20 | 5-3000 | 99 |

| TE-AT-20195 | 30 | 21 | 5-3000 | 99 |

| TE-AT-20196 | 30 | 22 | 5-3000 | 99 |

| TE-AT-20197 | 30 | 24 | 5-3000 | 99 |

| TE-AT-20198 | 30 | 26 | 5-3000 | 99 |

| TE-AT-20199 | 31 | 23 | 5-3000 | 99 |

| TE-AT-20200 | 31 | 25 | 5-3000 | 99 |

| TE-AT-20201 | 31 | 26 | 5-3000 | 99 |

| TE-AT-20202 | 31 | 27 | 5-3000 | 99 |

| TE-AT-20203 | 32 | 26 | 5-3000 | 99 |

| TE-AT-20204 | 32 | 27 | 5-3000 | 99 |

| TE-AT-20205 | 33 | 28 | 5-3000 | 99 |

| TE-AT-20206 | 34 | 18 | 5-3000 | 99 |

| TE-AT-20207 | 34 | 22 | 5-3000 | 99 |

| TE-AT-20208 | 34 | 23 | 5-3000 | 99 |

| TE-AT-20209 | 34 | 30 | 5-3000 | 99 |

| TE-AT-20210 | 35 | 27 | 5-3000 | 99 |

| TE-AT-20211 | 35 | 29.5 | 5-3000 | 99 |

| TE-AT-20212 | 36 | 30 | 5-3000 | 99 |

| TE-AT-20213 | 36 | 31 | 5-3000 | 99 |

| TE-AT-20214 | 37 | 29 | 5-3000 | 99 |

| TE-AT-20215 | 37 | 31.5 | 5-3000 | 99 |

| TE-AT-20216 | 37 | 32 | 5-3000 | 99 |

| TE-AT-20217 | 38 | 31 | 5-3000 | 99 |

| TE-AT-20218 | 45 | 38.5 | 5-3000 | 99 |

| TE-AT-20219 | 46 | 38.5 | 5-3000 | 99 |

| TE-AT-20220 | 60 | 30 | 5-3000 | 99 |

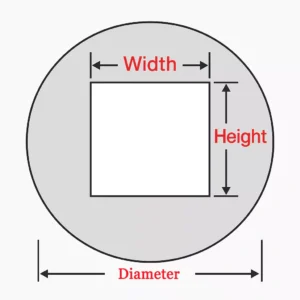

| Item No. | Diameter(mm) | Width (mm) | Height (mm) | Length (mm) |

| TE-AT-50026 | 2 | 1.3 | 0.9 | ≤2000 |

| TE-AT-50027 | 10 | 2 | 1 | ≤2000 |

| TE-AT-50028 | 15 | 4 | 3 | ≤2000 |

| TE-AT-50029 | 20 | 3.5 | 3.5 | ≤2000 |

| TE-AT-50030 | 24 | 7 | 6 | ≤2000 |

| TE-AT-50031 | 25.5 | 7.5 | 5 | ≤2000 |

| TE-AT-50032 | 29 | 6 | 4.5 | ≤2000 |

| TE-AT-50033 | 30 | 10 | 8 | ≤2000 |

| TE-AT-50034 | 35 | 10 | 7.5 | ≤2000 |

| TE-AT-50035 | 37.5 | 11 | 11 | ≤2000 |

| TE-AT-50036 | 40 | 9.5 | 7 | ≤2000 |

Alumina Ceramic Open Pipe Packaging

- Each tube is individually wrapped in anti-static foam and packed in reinforced cartons.