Alumina lining brick is a dense, wear-resistant ceramic tile made from high-alumina (Al₂O₃) material, engineered to protect equipment surfaces that face long-term sliding or impact abrasion. It is installed inside ball mills, chutes, cyclones, hoppers, and transfer points to extend service life, stabilize product quality, and reduce maintenance downtime.

Alumina Lining Brick Advantages

- Media & energy efficiency: low surface roughness reduces media loss and lowers kWh/t in fine grinding lines.

- Geometry that fits: rectangular, trapezoid, and curved tiles minimize grout lines and misalignment, improving flow and cleaning.

- Clean grinding: inert alumina surface helps limit iron pick-up versus steel liners in color-sensitive powders.

- Impact-matched selections: thickness and shape variants for feed and lifter zones to mitigate high-impact wear.

Alumina Lining Brick Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Ceramic Lining Brick Specifications

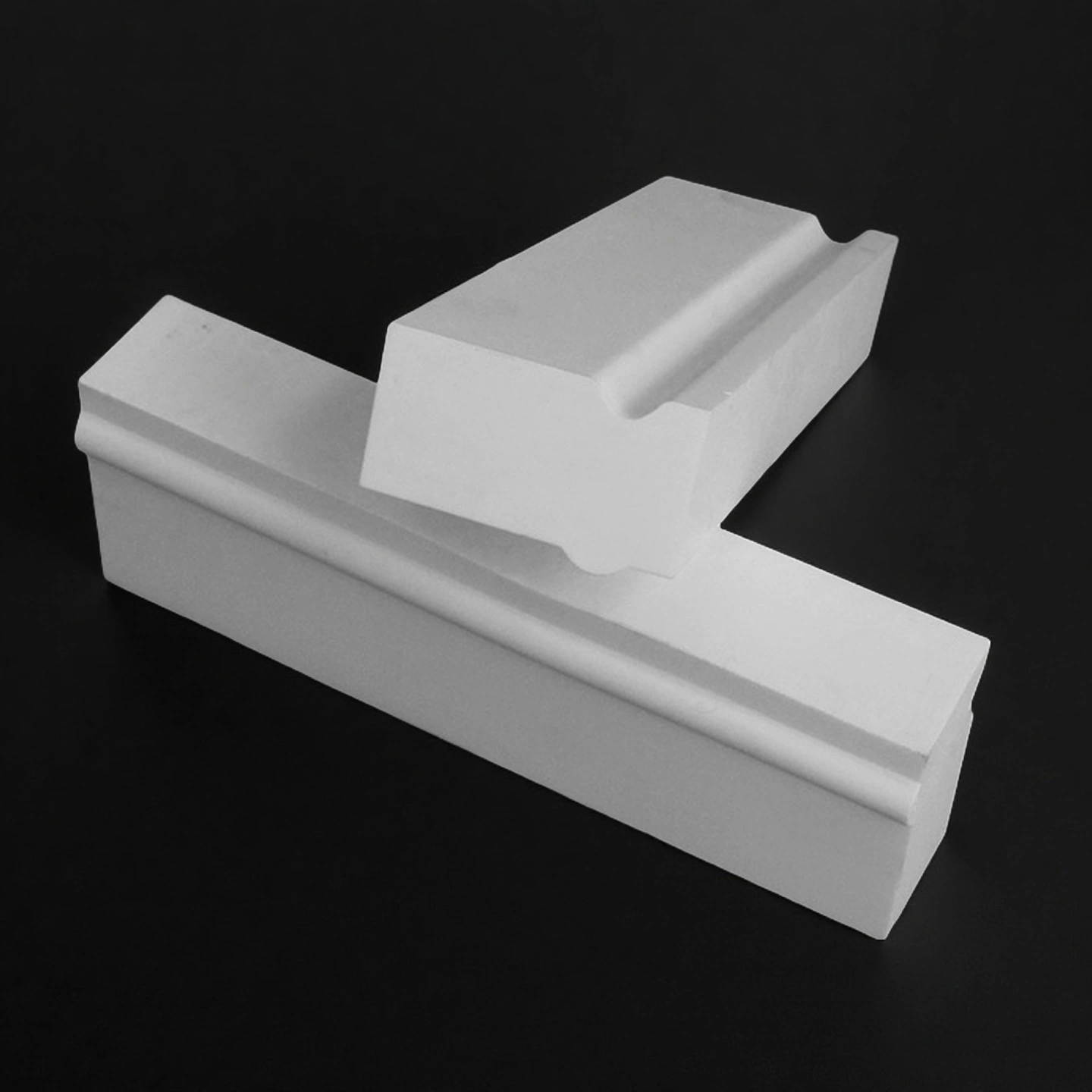

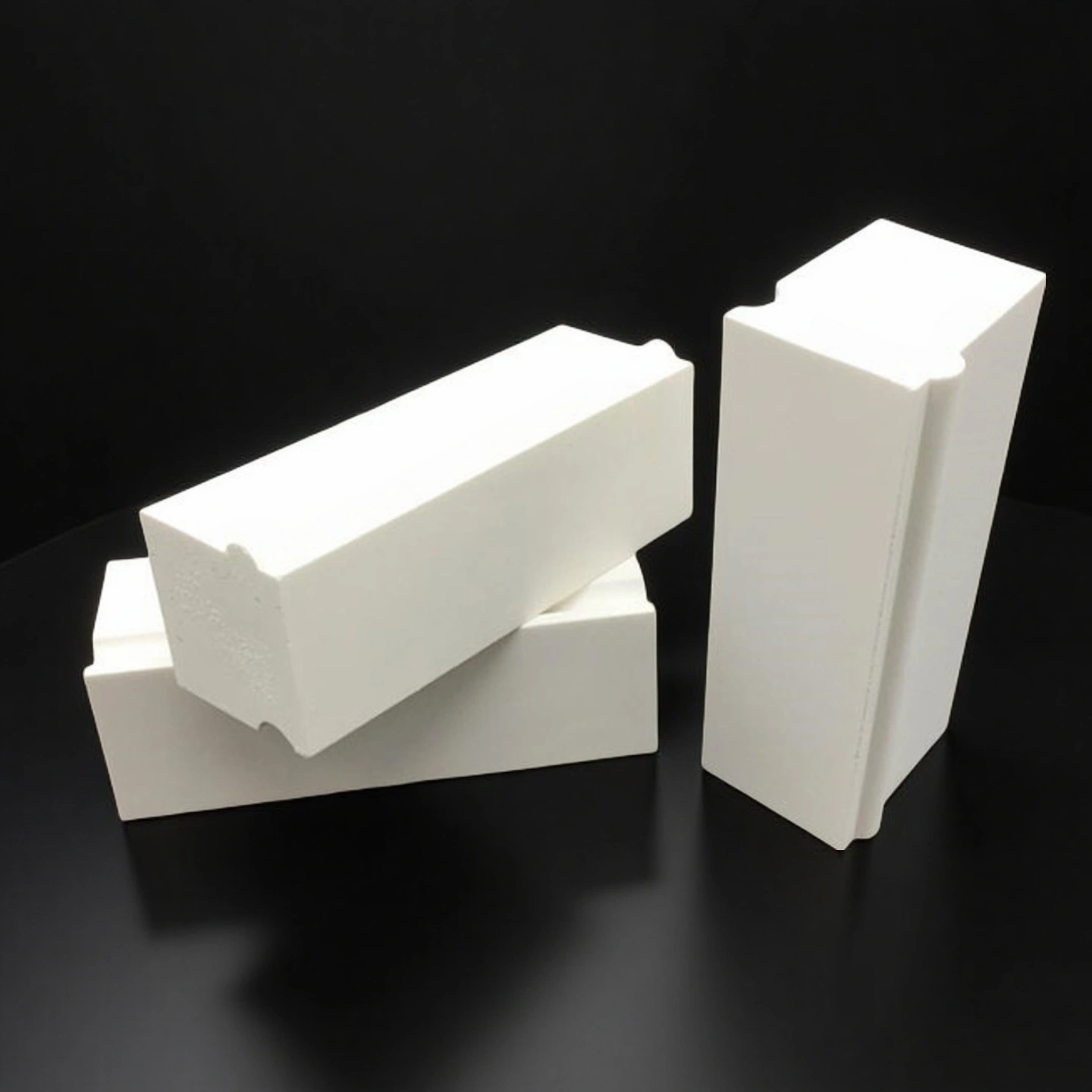

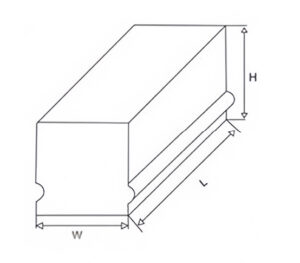

Type 1: Alumina Lining Brick

| Alumina Lining Brick | |||

| Item No. | Height(mm) | Width(mm) | Length(mm) |

| AT-YHL-CZ001 | 35 | 50 | 150 |

| AT-YHL-CZ002 | 40 | 50 | 150 |

| AT-YHL-CZ003 | 50 | 50 | 150 |

| AT-YHL-CZ004 | 60 | 50 | 150 |

| AT-YHL-CZ005 | 70 | 50 | 150 |

| AT-YHL-CZ006 | 90 | 50 | 150 |

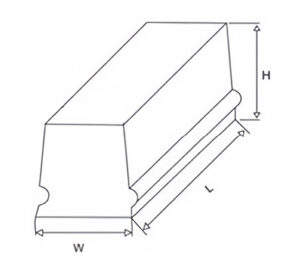

Type 2: Tapered Alumina Lining Brick

| Tapered Alumina Lining Brick | |||

| Item No. | Height(mm) | Width(mm) | Length(mm) |

| AT-YHL-CZ007 | 35 | 45/50 | 150 |

| AT-YHL-CZ008 | 40 | 45/50 | 150 |

| AT-YHL-CZ009 | 50 | 45/50 | 150 |

| AT-YHL-CZ010 | 60 | 45/50 | 150 |

| AT-YHL-CZ011 | 70 | 45/50 | 150 |

| AT-YHL-CZ012 | 90 | 45/50 | 150 |

Type 3: Card slot alumina lining brick

| Alumina Lining Board Card Slot | |||

| Item No. | Length (mm) | Width (mm) | Thickness (mm) |

| AT-YHL-KC001 | 25 | 25 | 25 |

| AT-YHL-KC002 | 50 | 30 | 5 |

| AT-YHL-KC003 | 50 | 30 | 8 |

| AT-YHL-KC004 | 50 | 30 | 10 |

| AT-YHL-KC005 | 60 | 40 | 10 |

| AT-YHL-KC006 | 70 | 50 | 15 |

| AT-YHL-KC007 | 80 | 60 | 20 |

| AT-YHL-KC008 | 90 | 60 | 30 |

| AT-YHL-KC009 | 150 | 100 | 20 |

| AT-YHL-KC010 | 150 | 100 | 30 |

Type 4: Dovetail alumina lining brick

| Dovetail Shaped Alumina Lining Board | |||

| Item No. | Length (mm) | Width (mm) | Thickness (mm) |

| AT-YHL-YW001 | 25 | 25 | 15 |

| AT-YHL-YW002 | 50 | 30 | 10 |

| AT-YHL-YW003 | 50 | 30 | 15 |

| AT-YHL-YW004 | 60 | 40 | 10 |

| AT-YHL-YW005 | 70 | 50 | 10 |

| AT-YHL-YW006 | 80 | 60 | 10 |

| AT-YHL-YW007 | 90 | 70 | 10 |

| AT-YHL-YW008 | 100 | 60 | 10 |

| AT-YHL-YW009 | 100 | 60 | 12 |

| AT-YHL-YW010 | 110 | 70 | 15 |

| AT-YHL-YW011 | 120 | 90 | 10 |

| AT-YHL-YW012 | 130 | 110 | 10 |

| AT-YHL-YW013 | 140 | 120 | 20 |

| AT-YHL-YW014 | 150 | 130 | 20 |

Type 5: Alumina lining brick for pipe

| Alumina lining plate for pipe | |||

| Item No. | Length(mm) | Width(mm) | Thickness(mm) |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

| AT-YHL-CB044 | 50 | 25/24 | 7 |

Alumina Lining Bricks Packaging

- Individually shrink-wrapped & packed with foam layer protection Bundled by row, stacked on fumigated wooden/steel pallets