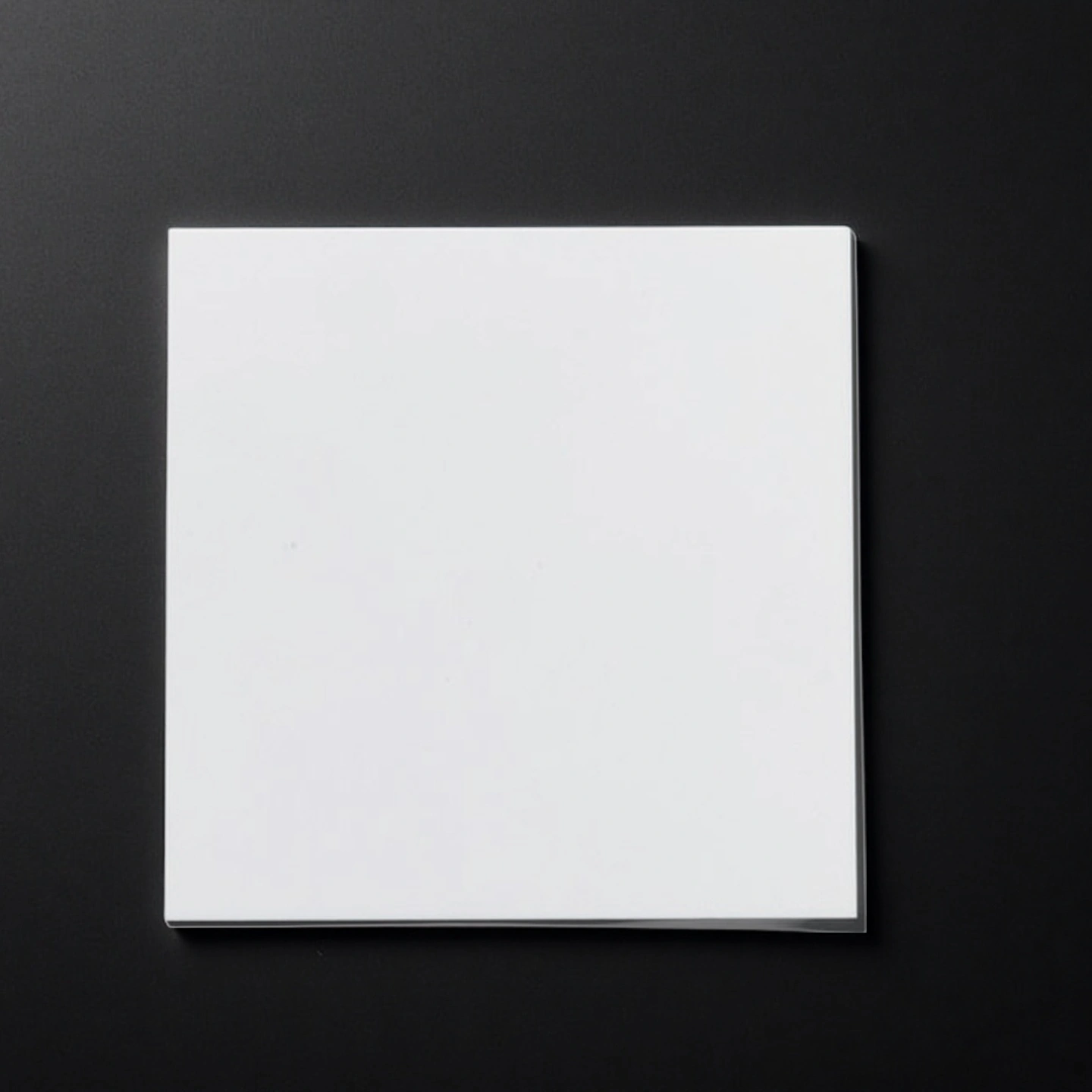

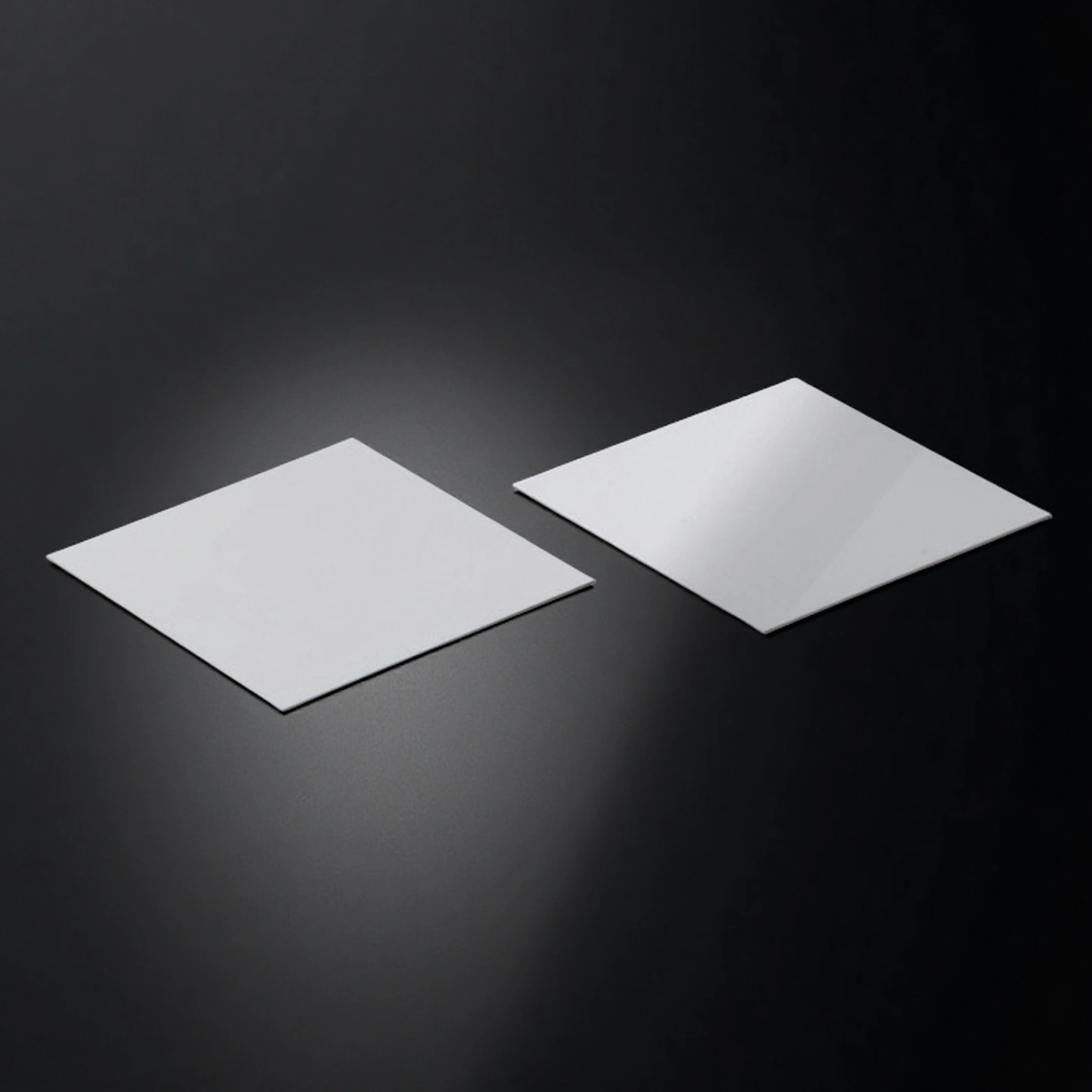

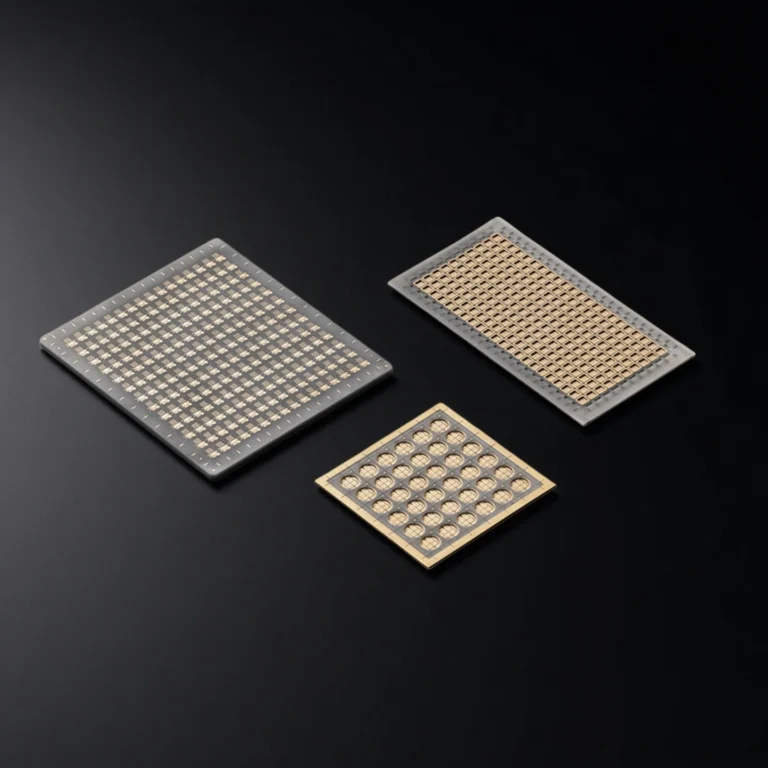

High Purity Alumina (HPA) ceramic substrates, composed of 96% to 99.99% aluminum oxide, are robust industrial ceramics known for exceptional mechanical, thermal, and electrical properties. These substrates are crucial in advanced electronic and industrial applications like aerospace, automotive, and medical devices.

High Purity Alumina Substrates Benefits

- Material Purity: Formulated with Al₂O₃ purity levels up to 99.6%. This high purity minimizes dielectric loss and ensures stable chemical performance, preventing signal interference or corrosion in sensitive applications.

- Thermal Management: The material's thermal conductivity of over 24 W/m·K efficiently dissipates heat from active components like LEDs and power transistors. This process lowers operating temperatures, extending device lifespan and maintaining performance stability.

- Dimensional Stability: A low coefficient of thermal expansion (CTE) ensures the substrate remains dimensionally stable during temperature cycling. This stability is critical for maintaining the integrity of attached circuits and components, preventing stress-induced failures.

- Surface Quality: Available with as-fired, lapped, or diamond-polished surfaces reaching a smoothness of Ra < 0.1μm. A smooth surface is essential for thin-film deposition and high-frequency applications, reducing signal loss and improving circuit definition.

High Purity Alumina Substrates Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

High Purity Alumina Ceramic Substrates Specifications

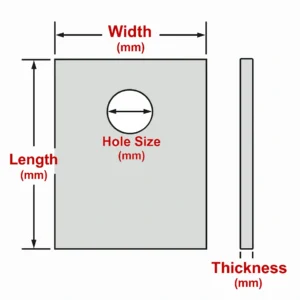

Type 1-96 Alumina Substrate Rectangular with Hole

| Item NO. | L* W*Thickness (mm) | Hole Dia (mm) |

| TE-J-1 | 10*2.4*2 | \ |

| TE-J-2 | 10*2.4*1.5 | \ |

| TE-J-3 | 10*15*0.6 | 4 |

| TE-J-4 | 10*16*1.5 | 3.5 |

| TE-J-5 | 10*20*1.6 | \ |

| TE-J-6 | 10*16*6 | \ |

| TE-J-7 | 10*10*2 | \ |

| TE-J-8 | 10*14*2 | \ |

| TE-J-9 | 10.4*18*1 | 3.8 |

| TE-J-10 | 10.6*17*1 | 3.8 |

| TE-J-11 | 11*11*1 | \ |

| TE-J-12 | 11*17*1 | \ |

| TE-J-13 | 11*7*1.5 | \ |

| TE-J-14 | 11*18*1 | 4 |

| TE-J-15 | 12*18.5*0.6 | 3.8 |

| TE-J-16 | 12*18*0.6 | 3.8 |

| TE-J-17 | 12*18.5*1 | \ |

| TE-J-18 | 12*18.5*0.6 | \ |

| TE-J-19 | 12.7*16.5*1.8 | 3.8 |

| TE-J-20 | 13*19*0.6 | \ |

| TE-J-21 | 14*18*3 | 3.4 |

| TE-J-22 | 14*19*2 | 3.5 |

| TE-J-23 | 14*20*1 | 3.2/3.5 |

| TE-J-24 | 14*20*0.6 | 3.2 |

| TE-J-25 | 14*20*1 | \ |

| TE-J-26 | 14*20*0.6 | \ |

| TE-J-27 | 14*20*2 | \ |

| TE-J-28 | 14*20*2 | 3.2 |

| TE-J-29 | 15*19.5*1 | 3.8 |

| TE-J-30 | 15*2*2.4 | \ |

| TE-J-31 | 16*21*2.5 | 3.5 |

| TE-J-32 | 16*22*0.6 | 3.3 |

| TE-J-33 | 16*22*0.6 | 4 |

| TE-J-34 | 16*22*0.6 | 3.7 |

| TE-J-35 | 16*46*1 | \ |

| TE-J-36 | 17*22*1 | 3.7 |

| TE-J-37 | 17*22*0.6 | 3.7 |

| TE-J-38 | 17*22*0.6 | \ |

| TE-J-39 | 17*22*1.5 | \ |

| TE-J-40 | 17*22*1 | \ |

| TE-J-41 | 17*37.1*1 | \ |

| TE-J-85 | 22*30*2 | \ |

| TE-J-86 | 22*28*1 | 3.4 |

| TE-J-87 | 22*28*0.6 | 3.4 |

| TE-J-88 | 22*28*1 | \ |

| TE-J-89 | 22*28*0.6 | \ |

| TE-J-90 | 22*25*1 | 3.6 |

| TE-J-91 | 22*25*0.6 | 3.1 |

| TE-J-92 | 22*25*1 | 3.1 |

| TE-J-93 | 22*22*0.6 | 3 |

| TE-J-94 | 22*35*1 | \ |

| TE-J-95 | 22*35*1.5 | 3.5 |

| TE-J-96 | 23*34*1 | 3.2 |

| TE-J-97 | 24*30*1 | \ |

| TE-J-98 | 24*35.5*1 | \ |

| TE-J-99 | 24*40*0.6 | \ |

| TE-J-100 | 24*60*1 | \ |

| TE-J-101 | 24*70*0.6 | \ |

| TE-J-102 | 24*72*1 | \ |

| TE-J-103 | 24*90*0.6 | \ |

| TE-J-104 | 24*95*1 | \ |

| TE-J-105 | 24*125*1 | \ |

| TE-J-106 | 24*104*1 | \ |

| TE-J-107 | 25*34*0.6 | \ |

| TE-J-108 | 25*40*1 | \ |

| TE-J-109 | 25*40*0.6 | \ |

| TE-J-110 | 25*110*0.6 | \ |

| TE-J-111 | 26*30*1 | 3.2 |

| TE-J-112 | 26*31*1 | 3.5 |

| TE-J-113 | 26*35*1 | \ |

| TE-J-114 | 27*60*0.6 | \ |

| TE-J-115 | 27*90*0.6 | \ |

| TE-J-116 | 27*48*1 | 5 |

| TE-J-117 | 27.5*4.2*2.5 | \ |

| TE-J-118 | 28*40*1 | \ |

| TE-J-119 | 28*42*0.6 | \ |

| TE-J-120 | 28*44*0.6 | 6 |

| TE-J-121 | 28*64*1 | \ |

| TE-J-122 | 28*72*1 | \ |

| TE-J-123 | 29*33*1.3 | \ |

| TE-J-124 | 30*38*1 | 3.5 |

| TE-J-125 | 30*40*1 | 3.5 |

| TE-J-126 | 30*43*0.6 | 4.5 |

| TE-J-127 | 32*50*1 | \ |

| TE-J-128 | 32*60*1 | \ |

| TE-J-129 | 33*53*1.3 | \ |

| TE-J-130 | 33*73*1.3 | \ |

| TE-J-131 | 33.6*51.4*0.8 | 5 |

| TE-J-132 | 33.6*51.4*2 | 5 |

| TE-J-133 | 34*64*0.6 | \ |

| TE-J-134 | 34*39*0.6 | \ |

| TE-J-135 | 35*48*1 | 5.5 |

| TE-J-136 | 35*68*1 | \ |

| TE-J-137 | 35*45*1 | \ |

| TE-J-138 | 35*85*0.6 | \ |

| TE-J-139 | 38*38*0.6 | \ |

| TE-J-140 | 38*50*0.6 | \ |

| TE-J-141 | 35*35*20 | \ |

| TE-J-142 | 38.5*41*1 | \ |

| TE-J-143 | 39*91*0.6 | \ |

| TE-J-144 | 40*30*1 | 3.5 |

| TE-J-145 | 40*56*1 | \ |

| TE-J-146 | 40*43*0.6 | \ |

| TE-J-147 | 40*105*0.635 | \ |

| TE-J-148 | 40*140*0.6 | \ |

| TE-J-149 | 40*150*1 | \ |

| TE-J-150 | 40*260*1 | \ |

| TE-J-151 | 44*16*1 | \ |

| TE-J-152 | 44*28*0.6 | 6 |

| TE-J-153 | 50*50*1 | \ |

| TE-J-154 | 50*50*3 | \ |

| TE-J-155 | 55*18*2 | \ |

| TE-J-156 | 75*18*2 | \ |

| TE-J-157 | 100*100*1 | \ |

| TE-J-158 | 100*100*2 | \ |

| TE-J-159 | 100*100*3 | \ |

| TE-J-160 | 120*160*2 | \ |

| TE-J-161 | 120*160*3 | \ |

| TE-J-162 | 120*160*4 | \ |

| TE-J-163 | 120*160*6 | \ |

| TE-J-164 | 160*160*1 | \ |

| TE-J-165 | 160*160*0.6 | \ |

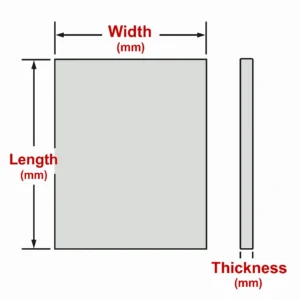

Type 2-96 Alumina Substrate Rectangular

| Item | Length(mm) | Width(mm) | Thickness(mm) | Purity(%) |

| TE-J-169 | 10 | 10 | 0.25 | 96-99.8% |

| TE-J-170 | 10 | 10 | 0.5 | 96-99.8% |

| TE-J-171 | 10 | 10 | 0.635 | 96-99.8% |

| TE-J-172 | 10 | 10 | 1 | 96-99.8% |

| TE-J-173 | 20 | 20 | 1 | 96-99.8% |

| TE-J-174 | 20 | 20 | 2 | 96-99.8% |

| TE-J-175 | 25 | 25 | 1 | 96-99.8% |

| TE-J-176 | 30 | 30 | 0.635 | 96-99.8% |

| TE-J-177 | 30 | 30 | 1 | 96-99.8% |

| TE-J-178 | 30 | 30 | 2 | 96-99.8% |

| TE-J-179 | 35 | 35 | 1 | 96-99.8% |

| TE-J-180 | 40 | 40 | 1 | 96-99.8% |

| TE-J-181 | 40 | 40 | 5 | 96-99.8% |

| TE-J-182 | 50 | 50 | 0.5 | 96-99.8% |

| TE-J-183 | 50 | 50 | 0.635 | 96-99.8% |

| TE-J-184 | 50 | 50 | 1.5 | 96-99.8% |

| TE-J-185 | 50 | 50 | 5 | 96-99.8% |

| TE-J-191 | 60 | 60 | 1 | 96-99.8% |

| TE-J-192 | 65 | 74 | 0.2 | 96-99.8% |

| TE-J-193 | 65 | 74 | 0.28 | 96-99.8% |

| TE-J-194 | 70 | 70 | 2 | 96-99.8% |

| TE-J-195 | 70 | 70 | 3 | 96-99.8% |

| TE-J-196 | 76.2 | 76.2 | 0.75 | 96-99.8% |

| TE-J-197 | 80 | 80 | 3 | 96-99.8% |

| TE-J-198 | 80 | 80 | 5 | 96-99.8% |

| TE-J-199 | 80 | 110 | 5 | 96-99.8% |

| TE-J-200 | 84 | 84 | 0.8 | 96-99.8% |

| TE-J-201 | 100 | 100 | 0.5 | 96-99.8% |

| TE-J-202 | 100 | 100 | 0.635 | 96-99.8% |

| TE-J-203 | 100 | 100 | 1.2 | 96-99.8% |

| TE-J-204 | 100 | 100 | 1.5 | 96-99.8% |

| TE-J-205 | 100 | 100 | 2.2 | 96-99.8% |

| TE-J-206 | 100 | 100 | 2.5 | 96-99.8% |

| TE-J-207 | 100 | 100 | 3.5 | 96-99.8% |

| TE-J-208 | 100 | 100 | 0.25 | 96-99.8% |

| TE-J-209 | 100 | 100 | 1.055 | 96-99.8% |

| TE-J-210 | 100 | 100 | 0.25 | 96-99.8% |

| TE-J-211 | 100 | 100 | 0.35 | 96-99.8% |

| TE-J-212 | 100 | 100 | 0.5 | 96-99.8% |

| TE-J-213 | 100 | 100 | 0.6 | 96-99.8% |

| TE-J-214 | 100 | 100 | 0.7 | 96-99.8% |

| TE-J-215 | 100 | 100 | 1.5 | 96-99.8% |

| TE-J-216 | 100 | 100 | 2.335 | 96-99.8% |

| TE-J-217 | 100 | 100 | 2.5 | 96-99.8% |

| TE-J-218 | 100 | 100 | 3.2 | 96-99.8% |

| TE-J-219 | 100 | 100 | 3.5 | 96-99.8% |

| TE-J-220 | 100 | 100 | 4 | 96-99.8% |

| TE-J-221 | 100 | 100 | 5 | 96-99.8% |

| TE-J-227 | 109 | 109 | 1 | 96-99.8% |

| TE-J-228 | 110 | 110 | 5 | 96-99.8% |

| TE-J-229 | 114 | 114 | 1 | 96-99.8% |

| TE-J-230 | 114 | 114 | 0.38 | 96-99.8% |

| TE-J-231 | 114 | 114 | 0.5 | 96-99.8% |

| TE-J-232 | 114 | 114 | 0.65 | 96-99.8% |

| TE-J-233 | 115 | 115 | 0.12 | 96-99.8% |

| TE-J-234 | 115 | 115 | 0.125 | 96-99.8% |

| TE-J-235 | 120 | 120 | 0.25 | 96-99.8% |

| TE-J-236 | 120 | 120 | 0.38 | 96-99.8% |

| TE-J-237 | 120 | 120 | 0.5 | 96-99.8% |

| TE-J-238 | 120 | 120 | 0.635 | 96-99.8% |

| TE-J-239 | 120 | 120 | 0.8 | 96-99.8% |

| TE-J-240 | 120 | 120 | 0.25 | 96-99.8% |

| TE-J-241 | 120 | 120 | 1 | 96-99.8% |

| TE-J-242 | 120 | 120 | 3 | 96-99.8% |

| TE-J-243 | 125 | 125 | 2 | 96-99.8% |

| TE-J-244 | 127 | 127 | 1 | 96-99.8% |

| TE-J-245 | 127 | 127 | 1.5 | 96-99.8% |

| TE-J-246 | 138 | 190 | 0.25 | 96-99.8% |

| TE-J-247 | 138 | 190 | 0.38 | 96-99.8% |

| TE-J-248 | 138 | 190 | 0.32 | 96-99.8% |

| TE-J-249 | 138 | 190 | 0.5 | 96-99.8% |

| TE-J-250 | 138 | 190 | 0.8 | 96-99.8% |

| TE-J-251 | 138 | 190 | 0.65 | 96-99.8% |

| TE-J-252 | 138 | 190 | 1 | 96-99.8% |

| TE-J-253 | 138 | 190 | 0.38 | 96-99.8% |

| TE-J-254 | 138 | 190 | 0.5 | 96-99.8% |

| TE-J-255 | 138 | 190 | 0.635 | 96-99.8% |

| TE-J-256 | 138 | 190 | 1 | 96-99.8% |

| TE-J-257 | 150 | 150 | 1.8 | 96-99.8% |

| TE-J-258 | 150 | 150 | 1 | 96-99.8% |

| TE-J-259 | 150 | 150 | 1.5 | 96-99.8% |

| TE-J-260 | 150 | 150 | 2 | 96-99.8% |

| TE-J-261 | 150 | 150 | 3 | 96-99.8% |

| TE-J-262 | 150 | 150 | 5 | 96-99.8% |

| TE-J-263 | 150 | 150 | 8 | 96-99.8% |

| TE-J-264 | 152 | 152 | 0.635 | 96-99.8% |

| TE-J-265 | 160 | 170 | 2.5 | 96-99.8% |

| TE-J-266 | 180 | 180 | 2 | 96-99.8% |

| TE-J-267 | 180 | 180 | 3 | 96-99.8% |

| TE-J-268 | 180 | 180 | 5 | 96-99.8% |

| TE-J-269 | 200 | 200 | 2 | 96-99.8% |

| TE-J-270 | 200 | 200 | 3 | 96-99.8% |

| TE-J-271 | 200 | 200 | 5 | 96-99.8% |

| TE-J-272 | 220 | 220 | 2 | 96-99.8% |

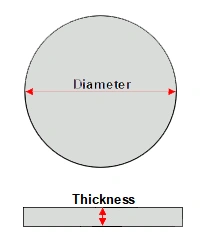

Type 3-96 Alumina Substrate Round

| Item | Diameter(mm) | Thickness(mm) | Purity(%) |

| TE-AD-002 | 3.5 | 1 | 96-99.8% |

| TE-AD-003 | 5 | 1 | 96-99.8% |

| TE-AD-004 | 6 | 0.25 | 96-99.8% |

| TE-AD-005 | 6 | 0.5 | 96-99.8% |

| TE-AD-006 | 6 | 0.635 | 96-99.8% |

| TE-AD-007 | 6 | 1 | 96-99.8% |

| TE-AD-008 | 8 | 0.25 | 96-99.8% |

| TE-AD-009 | 8 | 0.5 | 96-99.8% |

| TE-AD-010 | 8 | 0.635 | 96-99.8% |

| TE-AD-011 | 8 | 1 | 96-99.8% |

| TE-AD-012 | 10 | 0.25 | 96-99.8% |

| TE-AD-013 | 10 | 0.38 | 96-99.8% |

| TE-AD-014 | 10 | 0.5 | 96-99.8% |

| TE-AD-015 | 10 | 0.635 | 96-99.8% |

| TE-AD-016 | 10 | 1 | 96-99.8% |

| TE-AD-017 | 12 | 0.25 | 96-99.8% |

| TE-AD-018 | 12 | 0.5 | 96-99.8% |

| TE-AD-019 | 12 | 0.635 | 96-99.8% |

| TE-AD-020 | 12 | 1 | 96-99.8% |

| TE-AD-021 | 16 | 0.25 | 96-99.8% |

| TE-AD-022 | 16 | 0.5 | 96-99.8% |

| TE-AD-023 | 16 | 0.635 | 96-99.8% |

| TE-AD-024 | 16 | 1 | 96-99.8% |

| TE-AD-025 | 18 | 0.5 | 96-99.8% |

| TE-AD-026 | 18 | 0.635 | 96-99.8% |

| TE-AD-027 | 18 | 1 | 96-99.8% |

| TE-AD-028 | 20 | 0.25 | 96-99.8% |

| TE-AD-029 | 20 | 0.5 | 96-99.8% |

| TE-AD-030 | 20 | 0.635 | 96-99.8% |

| TE-AD-031 | 20 | 1 | 96-99.8% |

| TE-AD-032 | 25 | 0.5 | 96-99.8% |

| TE-AD-033 | 25 | 0.65 | 96-99.8% |

| TE-AD-034 | 25 | 1 | 96-99.8% |

| TE-AD-035 | 30 | 0.5 | 96-99.8% |

| TE-AD-036 | 30 | 0.635 | 96-99.8% |

| TE-AD-037 | 30 | 1 | 96-99.8% |

| TE-AD-038 | 33 | 1 | 96-99.8% |

| TE-AD-039 | 35 | 1 | 96-99.8% |

| TE-AD-040 | 35 | 2 | 96-99.8% |

| TE-AD-041 | 36 | 4 | 96-99.8% |

| TE-AD-042 | 40 | 1 | 96-99.8% |

| TE-AD-043 | 40 | 1.5 | 96-99.8% |

| TE-AD-044 | 42 | 2 | 96-99.8% |

| TE-AD-045 | 50 | 0.5 | 96-99.8% |

| TE-AD-046 | 50 | 0.635 | 96-99.8% |

| TE-AD-047 | 50 | 1 | 96-99.8% |

| TE-AD-048 | 50 | 2 | 96-99.8% |

| TE-AD-049 | 55 | 0.5 | 96-99.8% |

| TE-AD-050 | 60 | 10 | 96-99.8% |

| TE-AD-051 | 65 | 0.5 | 96-99.8% |

| TE-AD-052 | 75 | 1 | 96-99.8% |

| TE-AD-053 | 82 | 6 | 96-99.8% |

| TE-AD-054 | 89 | 5.5 | 96-99.8% |

| TE-AD-055 | 100 | 0.5 | 96-99.8% |

| TE-AD-056 | 100 | 0.635 | 96-99.8% |

| TE-AD-057 | 100 | 1 | 96-99.8% |

| TE-AD-058 | 101.6 | 0.5 | 96-99.8% |

| TE-AD-059 | 101.6 | 1 | 96-99.8% |

| TE-AD-060 | 120 | 2 | 96-99.8% |

| TE-AD-061 | 125 | 6 | 96-99.8% |

Type 4: Alumina ceramic substrate for thin film circuit

| Specification Dimensions | Alumina Ceramic Substrate | |||

|---|---|---|---|---|

| As-fired Wafer | Fine Ground Wafer | Polished Wafer | ||

| Outline Dimensions | Max (mm) | 101.6×101.6 | 101.6×101.6 | 101.6×101.6 |

| Typical (mm) | 50.8×50.8, 76.2×76.2, 101.6×101.6 | 50.8×50.8, 76.2×76.2, 101.6×101.6 | 50.8×50.8, 76.2×76.2, 101.6×101.6 | |

| Tolerance (mm) | Standard Grade: ≤±0.8%, but absolute value ≥±0.1; Precision Grade: ≤±0.5%, but absolute value ≥±0.05; |

Standard Grade: ≤±0.5%, but absolute value ≥±0.08; Precision Grade: ≤±0.2%, but absolute value ≥±0.05; |

Standard Grade: ≤±0.5%, but absolute value ≥±0.08; Precision Grade: ≤±0.2%, but absolute value ≥±0.05; |

|

| Substrate Thickness | Thickness Range (mm) | 0.15~2.5 | 0.15~2.5 | 0.15~2.5 |

| Typical (mm) | 0.150, 0.254, 0.381, 0.508 | 0.150, 0.254, 0.381, 0.508 | 0.150, 0.254, 0.381, 0.508 | |

| Tolerance (mm) | Standard Grade: ≤±10.0%, but absolute value ≥±0.05; Precision Grade: ≤±5.0%, but absolute value ≥±0.02; |

Standard Grade: ≤±5.0%, but absolute value ≥±0.04; Precision Grade: ≤±1.0%, but absolute value ≥±0.02; |

Standard Grade: ≤±5.0%, but absolute value ≥±0.04; Precision Grade: ≤±1.0%, but absolute value ≥±0.02; |

|

| Laser Drilling | Min (mm, recommended 0.8-1.5 times substrate thickness) | Φ0.08 | Φ0.08 | Φ0.08 |

| Laser Drilled Hole Front/Back Aperture Difference | ≤20% | ≤20% | ≤20% | |

| Minimum Hole Pitch (mm, recommended 3 times hole diameter or more) | ≥0.25 | ≥0.25 | ≥0.25 | |

| Warp | mm/mm | 0.005/mm | 0.003/mm | 0.002/mm |

Type 5: 996 Alumina Substrates size

| 996 Alumina Substrates | ||

| Item No. | Thickness(mm) | Length *Width(mm) |

| AT-AO-J1001 | 0.15 | 50.8×50.8 |

| AT-AO-J1002 | 0.254 | |

| AT-AO-J1003 | 0.381 | |

| AT-AO-J1004 | 0.508 | |

| AT-AO-J1005 | 0.635 | |

| AT-AO-J1006 | 1.0 | |

| AT-AO-J1007 | 2.0 | |

| AT-AO-J1008 | 2.5 | |

| AT-AO-J1009 | 0.15 | 76.2×76.2 |

| AT-AO-J1010 | 0.254 | |

| AT-AO-J1011 | 0.381 | |

| AT-AO-J1012 | 0.508 | |

| AT-AO-J1013 | 0.635 | |

| AT-AO-J1014 | 1.0 | |

| AT-AO-J1015 | 2.0 | |

| AT-AO-J1016 | 2.5 | |

| AT-AO-J1017 | 0.15 | 101.6×101.6 |

| AT-AO-J1018 | 0.254 | |

| AT-AO-J1019 | 0.381 | |

| AT-AO-J1020 | 0.508 | |

| AT-AO-J1021 | 0.635 | |

| AT-AO-J1022 | 1.0 | |

| AT-AO-J1023 | 2.0 | |

| AT-AO-J1024 | 2.5 | |

| AT-AO-J1025 | 0.15 | 114.3×114.3 |

| AT-AO-J1026 | 0.254 | |

| AT-AO-J1027 | 0.381 | |

| AT-AO-J1028 | 0.508 | |

| AT-AO-J1029 | 0.635 | |

| AT-AO-J1030 | 1.0 | |

| AT-AO-J1031 | 2.0 | |

| AT-AO-J1032 | 2.5 | |

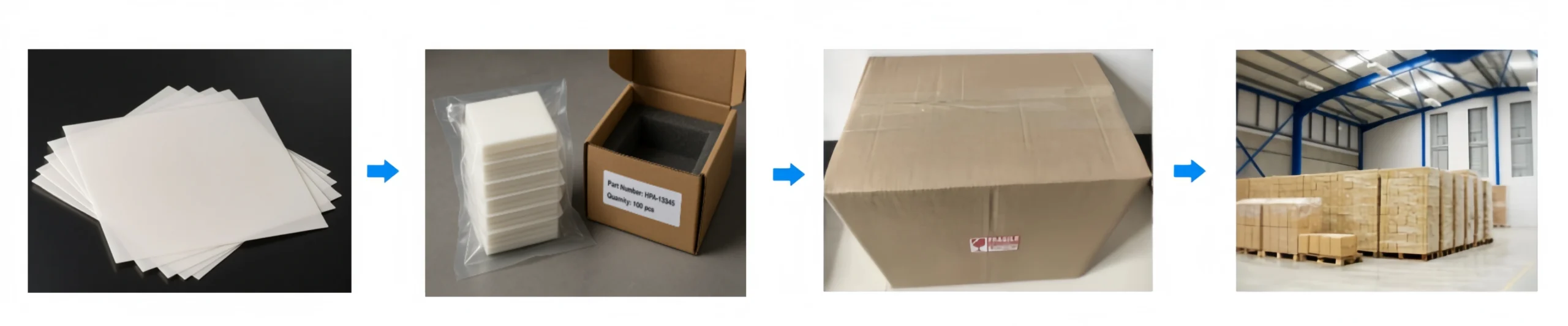

High Purity Alumina Substrates Packaging

- Substrates are separated by soft, lint-free paper.

- Stacked and vacuum-sealed in cleanroom-grade PE bags.