Alumina TLC plates are thin-layer chromatography (TLC) plates coated with high-purity alumina (Al₂O₃) instead of the more common silica gel. They are widely used in analytical and preparative chemistry when compounds of interest—such as amines, alkaloids, steroids, or other basic and weakly polar molecules—do not separate well on silica.

Alumina TLC Plate Benefits

- Stable selectivity for basic analytes: reduces tailing vs. silica when separating amines, steroids, alkaloids.

- Flexible backings: glass for rigidity and scanning, aluminum/polyester for cutting and field use.

- Repeatable Rf: controlled layer thickness and particle size support method transfer and lot-to-lot consistency.

- Fast readout: UV254 indicator option for immediate visualization under UV lamps.

- Prep & analytical choices: thin layers for sharp bands, thick layers for higher loading and scraping.

Alumina TLC Plate Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina TLC Plate Specifications

| Alumina TLC Plates | ||||||

| Item No. | Type | Model | Particle Size | Coating Thickness | Dimensions | Quantity/Box |

| AT-AGF254-1 | Neutral alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 25×75mm | 80 pieces |

| AT-AGF254-2 | Neutral alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 25×100mm | 80 pieces |

| AT-AGF254-3 | Neutral alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 50×200mm | 20 pieces |

| AT-AGF254-4 | Neutral alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 100×200mm | 10 pieces |

| AT-AGF254-5 | Neutral alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 200×200mm | 20 pieces |

| AT-AGF254-6 | Alkaline alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 25×75mm | 80 pieces |

| AT-AGF254-7 | Alkaline alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 25×100mm | 80 pieces |

| AT-AGF254-8 | Alkaline alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 50×200mm | 20 pieces |

| AT-AGF254-9 | Alkaline alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 100×200mm | 10 pieces |

| AT-AGF254-10 | Alkaline alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 200×200mm | 20 pieces |

| AT-AGF254-11 | Acidic alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 25×75mm | 80 pieces |

| AT-AGF254-12 | Acidic alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 25×100mm | 80 pieces |

| AT-AGF254-13 | Acidic alumina tlc plates | AGF254 | 10-40um | 0.2 ± 0.03mm | 200×200mm | 30 pieces |

| AT-AGF254-14 | Neutral Alumina Preparative Plate | AGF254 | 10-40um | 0.35 ± 0.03mm | 200×200mm | 20 pieces |

| AT-AGF254-15 | Neutral Alumina Preparative Plate | AGF254 | 10-40um | 0.5 ± 0.05mm | 200×200mm | 20 pieces |

| AT-AGF254-16 | Basic Alumina Preparative Plate | AGF254 | 10-40um | 0.35 ± 0.03mm | 200×200mm | 20 pieces |

| AT-AGF254-17 | Basic Alumina Preparative Plate | AGF254 | 10-40um | 0.5 ± 0.05mm | 200×200mm | 20 pieces |

| AT-AGF254-18 | Acidic Alumina Preparative Plate | AGF254 | 10-40um | 0.5mm | 200×200mm | 20 pieces |

| AT-AGF254-19 | Acidic Alumina Preparative Plate | AGF254 | 10-40um | 1mm | 200×200mm | 20 pieces |

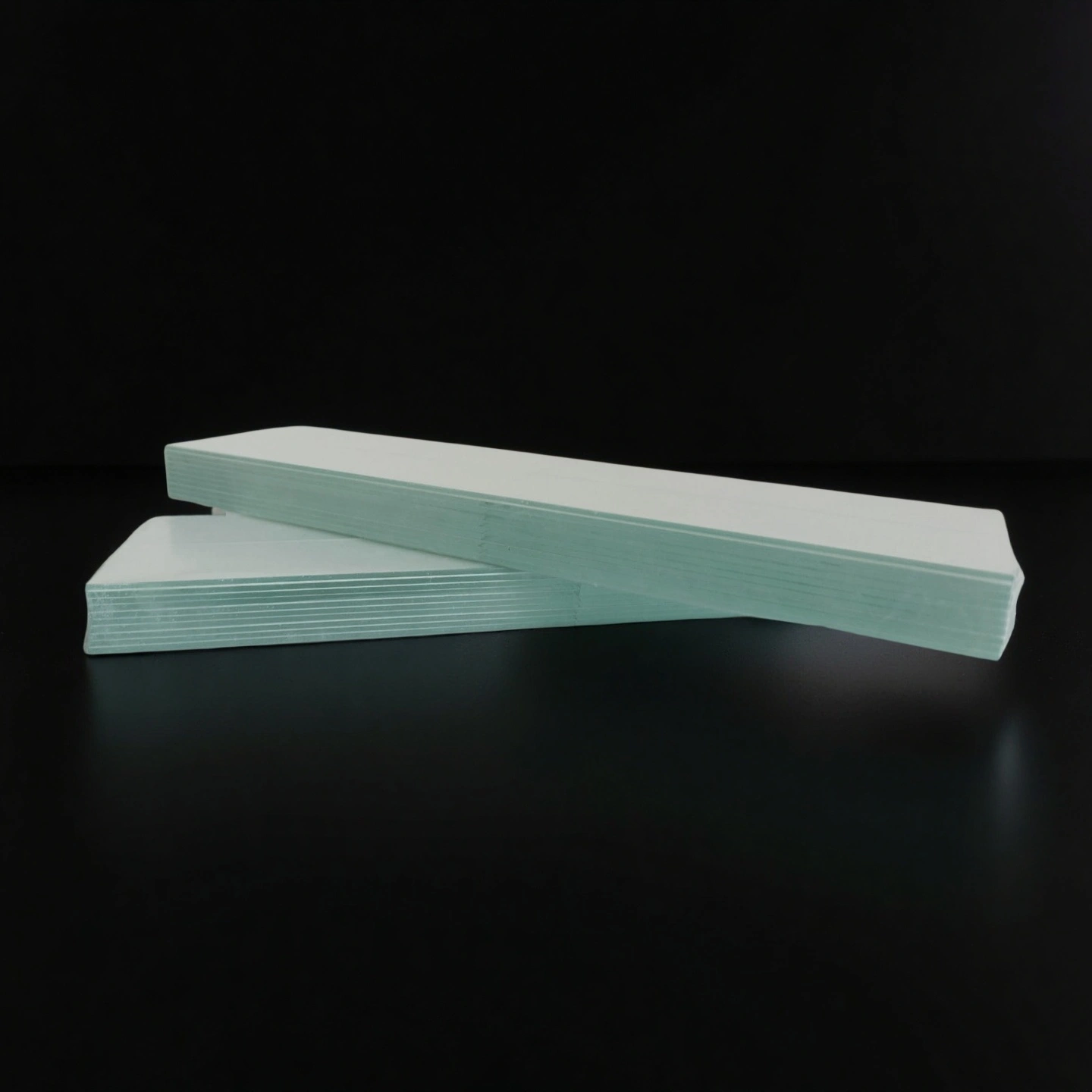

Alumina TLC Plates Packaging

- Inner: sealed packs with desiccant (10–25 plates per pack depending on size/backing).

- Outer: impact-protected cartons with corner guards for glass-backed plates.