An alumina tube closed at one end is a high-temperature ceramic component made from aluminum oxide (Al₂O₃), with one end sealed and the other open. The closed end allows the tube to contain gases, liquids, or solid samples without leakage. It also protects internal components (like sensors or wires) from direct exposure to harsh environments, making it ideal for controlled atmosphere experiments or industrial heating systems.

Advantages of Alumina Tubes Closed One End

- High thermal resistance: Suitable for continuous use up to 1700°C(≥99.5%)

- Closed-end design: Ideal for gas-tight applications and sample containment

- High-purity alumina: Ensures chemical inertness and minimal contamination

- Electrical insulation: Suitable for thermocouple and sensor protection

- Dimensional precision: Tolerance control up to ±0.05mm - 5mm

Alumina Tubes Closed One End Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

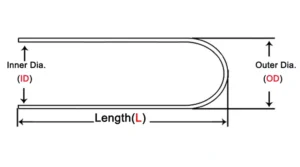

Specifications of Alumina Tubes Closed One End

| Item No. | Outer Dia(mm) | Inner Dia(mm) | Length(mm) | Purity(%) |

| TE-AT-10001 | 3 | 1 | 20-2000 | 99 |

| TE-AT-10002 | 3 | 1.5 | 20-2000 | 99 |

| TE-AT-10003 | 3 | 2 | 20-2000 | 99 |

| TE-AT-10004 | 3.2 | 0.8 | 20-2000 | 99 |

| TE-AT-10005 | 3.2 | 0.9 | 20-2000 | 99 |

| TE-AT-10006 | 3.5 | 1.3 | 20-2000 | 99 |

| TE-AT-10007 | 3.5 | 2 | 20-2000 | 99 |

| TE-AT-10008 | 3.5 | 2.1 | 20-2000 | 99 |

| TE-AT-10009 | 3.5 | 2.2 | 20-2000 | 99 |

| TE-AT-10010 | 3.5 | 2.4 | 20-2000 | 99 |

| TE-AT-10011 | 3.5 | 2.5 | 20-2000 | 99 |

| TE-AT-10012 | 3.6 | 0.4 | 20-2000 | 99 |

| TE-AT-10013 | 3.6 | 0.9 | 20-2000 | 99 |

| TE-AT-10014 | 3.6 | 1.8 | 20-2000 | 99 |

| TE-AT-10015 | 3.7 | 0.7 | 20-2000 | 99 |

| TE-AT-10016 | 3.7 | 2 | 20-2000 | 99 |

| TE-AT-10017 | 3.8 | 1.1 | 20-2000 | 99 |

| TE-AT-10018 | 3.8 | 1.8 | 20-2000 | 99 |

| TE-AT-10019 | 4 | 0.6 | 20-2000 | 99 |

| TE-AT-10020 | 4 | 0.5 | 20-2000 | 99 |

| TE-AT-10021 | 4 | 2.0 | 20-2000 | 99 |

| TE-AT-10022 | 4 | 1.9 | 20-2000 | 99 |

| TE-AT-10023 | 4 | 2.4 | 20-2000 | 99 |

| TE-AT-10024 | 4 | 2.5 | 20-2000 | 99 |

| TE-AT-10025 | 4 | 2.8 | 20-2000 | 99 |

| TE-AT-10026 | 4 | 3 | 20-2000 | 99 |

| TE-AT-10027 | 4.1 | 1.7 | 20-2000 | 99 |

| TE-AT-10028 | 4.1 | 3.1 | 20-2000 | 99 |

| TE-AT-10029 | 4.2 | 1.2 | 20-2000 | 99 |

| TE-AT-10030 | 4.2 | 2.4 | 20-2000 | 99 |

| TE-AT-10031 | 4.3 | 3 | 20-2000 | 99 |

| TE-AT-10032 | 4.4 | 3 | 20-2000 | 99 |

| TE-AT-10033 | 4.5 | 1.5 | 20-2000 | 99 |

| TE-AT-10034 | 4.5 | 2 | 20-2000 | 99 |

| TE-AT-10035 | 4.5 | 3 | 20-2000 | 99 |

| TE-AT-10036 | 4.6 | 3.8 | 20-2000 | 99 |

| TE-AT-10037 | 4.7 | 3 | 20-2000 | 99 |

| TE-AT-10038 | 4.8 | 0.6 | 20-2000 | 99 |

| TE-AT-10039 | 4.8 | 3 | 20-2000 | 99 |

| TE-AT-10040 | 4.8 | 3.3 | 20-2000 | 99 |

| TE-AT-10041 | 4.8 | 3.5 | 20-2000 | 99 |

| TE-AT-10042 | 4.8 | 3.8 | 20-2000 | 99 |

| TE-AT-10043 | 4.9 | 4.3 | 20-2000 | 99 |

| TE-AT-10044 | 5 | 3 | 20-2000 | 99 |

| TE-AT-10045 | 5 | 3.5 | 20-2000 | 99 |

| TE-AT-10046 | 5 | 4 | 20-2000 | 99 |

| TE-AT-10047 | 5.5 | 3 | 20-2000 | 99 |

| TE-AT-10048 | 5.5 | 4 | 20-2000 | 99 |

| TE-AT-10049 | 5.8 | 4.2 | 20-2000 | 99 |

| TE-AT-10050 | 6 | 1.5 | 20-2000 | 99 |

| TE-AT-10051 | 6 | 2 | 20-2000 | 99 |

| TE-AT-10052 | 6 | 3 | 20-2000 | 99 |

| TE-AT-10053 | 6 | 3.5 | 20-2000 | 99 |

| TE-AT-10054 | 6 | 4.5 | 20-2000 | 99 |

| TE-AT-10055 | 6.3 | 3.2 | 20-2000 | 99 |

| TE-AT-10056 | 6.35 | 4 | 20-2000 | 99 |

| TE-AT-10057 | 6.35 | 4.5 | 20-2000 | 99 |

| TE-AT-10058 | 6.5 | 3 | 20-2000 | 99 |

| TE-AT-10059 | 6.7 | 3 | 20-2000 | 99 |

| TE-AT-10060 | 6.7 | 4 | 20-2000 | 99 |

| TE-AT-10061 | 7 | 3 | 20-2000 | 99 |

| TE-AT-10062 | 7 | 4 | 20-2000 | 99 |

| TE-AT-10063 | 7 | 4.5 | 20-2000 | 99 |

| TE-AT-10064 | 7 | 5 | 20-2000 | 99 |

| TE-AT-10065 | 7.5 | 2 | 20-2000 | 99 |

| TE-AT-10066 | 7.5 | 3 | 20-2000 | 99 |

| TE-AT-10067 | 7.5 | 4 | 20-2000 | 99 |

| TE-AT-10068 | 8 | 1 | 20-2000 | 99 |

| TE-AT-10069 | 8 | 2 | 20-2000 | 99 |

| TE-AT-10070 | 8 | 2.5 | 20-2000 | 99 |

| TE-AT-10071 | 8 | 3 | 20-2000 | 99 |

| TE-AT-10072 | 8 | 3.5 | 20-2000 | 99 |

| TE-AT-10073 | 8 | 4 | 20-2000 | 99 |

| TE-AT-10074 | 8 | 5 | 20-2000 | 99 |

| TE-AT-10075 | 8.5 | 2 | 20-2000 | 99 |

| TE-AT-10076 | 8.5 | 5 | 20-2000 | 99 |

| TE-AT-10077 | 9 | 2 | 20-2000 | 99 |

| TE-AT-10078 | 9 | 2.5 | 20-2000 | 99 |

| TE-AT-10079 | 9 | 3 | 20-2000 | 99 |

| TE-AT-10080 | 9 | 3.5 | 20-2000 | 99 |

| TE-AT-10081 | 9 | 4 | 20-2000 | 99 |

| TE-AT-10082 | 9 | 5 | 20-2000 | 99 |

| TE-AT-10083 | 9 | 6 | 20-2000 | 99 |

| TE-AT-10084 | 9 | 7 | 20-2000 | 99 |

| TE-AT-10085 | 9.5 | 3 | 20-2000 | 99 |

| TE-AT-10086 | 9.5 | 3.5 | 20-2000 | 99 |

| TE-AT-10087 | 9.5 | 4.5 | 20-2000 | 99 |

| TE-AT-10088 | 9.5 | 5.5 | 20-2000 | 99 |

| TE-AT-10089 | 9.5 | 6 | 20-2000 | 99 |

| TE-AT-10090 | 9.5 | 7 | 20-2000 | 99 |

| TE-AT-10091 | 10 | 1 | 20-2000 | 99 |

| TE-AT-10092 | 10 | 3.5 | 20-2000 | 99 |

| TE-AT-10093 | 10 | 4 | 20-2000 | 99 |

| TE-AT-10094 | 10 | 2 | 20-2000 | 99 |

| TE-AT-10095 | 10 | 2.5 | 20-2000 | 99 |

| TE-AT-10096 | 10 | 4.5 | 20-2000 | 99 |

| TE-AT-10097 | 10 | 5 | 20-2000 | 99 |

| TE-AT-10098 | 10 | 5.5 | 20-2000 | 99 |

| TE-AT-10099 | 10 | 6 | 20-2000 | 99 |

| TE-AT-10100 | 10 | 6.5 | 20-2000 | 99 |

| TE-AT-10101 | 10 | 7 | 20-2000 | 99 |

| TE-AT-10102 | 10 | 8 | 20-2000 | 99 |

| TE-AT-10103 | 11 | 1 | 20-2000 | 99 |

| TE-AT-10104 | 11 | 3 | 20-2000 | 99 |

| TE-AT-10105 | 11 | 3.5 | 20-2000 | 99 |

| TE-AT-10106 | 11 | 4 | 20-2000 | 99 |

| TE-AT-10107 | 11 | 5 | 20-2000 | 99 |

| TE-AT-10108 | 11 | 7 | 20-2000 | 99 |

| TE-AT-10109 | 12 | 7 | 20-2000 | 99 |

| TE-AT-10110 | 12 | 8 | 20-2000 | 99 |

| TE-AT-10111 | 12 | 9 | 20-2000 | 99 |

| TE-AT-10112 | 12 | 10 | 20-2000 | 99 |

| TE-AT-10113 | 13 | 7 | 20-2000 | 99 |

| TE-AT-10114 | 13 | 8 | 20-2000 | 99 |

| TE-AT-10115 | 13 | 9 | 20-2000 | 99 |

| TE-AT-10116 | 13 | 10 | 20-2000 | 99 |

| TE-AT-10117 | 13 | 6 | 20-2000 | 99 |

| TE-AT-10118 | 14 | 3 | 20-2000 | 99 |

| TE-AT-10119 | 14 | 4 | 20-2000 | 99 |

| TE-AT-10120 | 14 | 6 | 20-2000 | 99 |

| TE-AT-10121 | 14 | 9 | 20-2000 | 99 |

| TE-AT-10122 | 14 | 10 | 20-2000 | 99 |

| TE-AT-10123 | 15 | 6 | 20-2000 | 99 |

| TE-AT-10124 | 15 | 7 | 20-2000 | 99 |

| TE-AT-10125 | 15 | 8 | 20-2000 | 99 |

| TE-AT-10126 | 15 | 9 | 20-2000 | 99 |

| TE-AT-10127 | 15 | 10 | 20-2000 | 99 |

| TE-AT-10128 | 15 | 11 | 20-2000 | 99 |

| TE-AT-10129 | 16 | 6 | 20-2000 | 99 |

| TE-AT-10130 | 16 | 8 | 20-2000 | 99 |

| TE-AT-10131 | 16 | 9 | 20-2000 | 99 |

| TE-AT-10132 | 16 | 10 | 20-2000 | 99 |

| TE-AT-10133 | 16 | 11 | 20-2000 | 99 |

| TE-AT-10134 | 16 | 12 | 20-2000 | 99 |

| TE-AT-10135 | 17 | 1 | 20-2000 | 99 |

| TE-AT-10136 | 17 | 10 | 20-2000 | 99 |

| TE-AT-10137 | 17 | 11 | 20-2000 | 99 |

| TE-AT-10138 | 17 | 12 | 20-2000 | 99 |

| TE-AT-10139 | 17 | 13 | 20-2000 | 99 |

| TE-AT-10140 | 17 | 14 | 20-2000 | 99 |

| TE-AT-10141 | 18 | 10 | 20-2000 | 99 |

| TE-AT-10142 | 18 | 11 | 20-2000 | 99 |

| TE-AT-10143 | 18 | 12 | 20-2000 | 99 |

| TE-AT-10144 | 18 | 13 | 20-2000 | 99 |

| TE-AT-10145 | 18 | 14 | 20-2000 | 99 |

| TE-AT-10146 | 18 | 8.5 | 20-2000 | 99 |

| TE-AT-10147 | 19 | 1 | 20-2000 | 99 |

| TE-AT-10148 | 19 | 9 | 20-2000 | 99 |

| TE-AT-10149 | 19 | 10 | 20-2000 | 99 |

| TE-AT-10150 | 19 | 11 | 20-2000 | 99 |

| TE-AT-10151 | 19 | 12 | 20-2000 | 99 |

| TE-AT-10152 | 19 | 13 | 20-2000 | 99 |

| TE-AT-10153 | 19 | 14 | 20-2000 | 99 |

| TE-AT-10154 | 19 | 15 | 20-2000 | 99 |

| TE-AT-10155 | 20 | 8 | 20-2000 | 99 |

| TE-AT-10156 | 20 | 10 | 20-2000 | 99 |

| TE-AT-10157 | 20 | 11 | 20-2000 | 99 |

| TE-AT-10158 | 20 | 14 | 20-2000 | 99 |

| TE-AT-10159 | 20 | 15 | 20-2000 | 99 |

| TE-AT-10160 | 20 | 16 | 20-2000 | 99 |

| TE-AT-10161 | 20 | 17 | 20-2000 | 99 |

| TE-AT-10162 | 21 | 3 | 20-2000 | 99 |

| TE-AT-10163 | 21 | 2.5 | 20-2000 | 99 |

| TE-AT-10164 | 21 | 10 | 20-2000 | 99 |

| TE-AT-10165 | 21 | 14 | 20-2000 | 99 |

| TE-AT-10166 | 21 | 16 | 20-2000 | 99 |

| TE-AT-10167 | 22 | 2.5 | 20-2000 | 99 |

| TE-AT-10168 | 22 | 16 | 20-2000 | 99 |

| TE-AT-10169 | 22 | 17 | 20-2000 | 99 |

| TE-AT-10170 | 22 | 19 | 20-2000 | 99 |

| TE-AT-10171 | 23 | 3.5 | 20-2000 | 99 |

| TE-AT-10172 | 23 | 12 | 20-2000 | 99 |

| TE-AT-10173 | 23 | 15 | 20-2000 | 99 |

| TE-AT-10174 | 23 | 16 | 20-2000 | 99 |

| TE-AT-10175 | 23 | 17 | 20-2000 | 99 |

| TE-AT-10176 | 23 | 18 | 20-2000 | 99 |

| TE-AT-10177 | 23 | 19 | 20-2000 | 99 |

| TE-AT-10178 | 24 | 5 | 20-2000 | 99 |

| TE-AT-10179 | 24 | 17 | 20-2000 | 99 |

| TE-AT-10180 | 24 | 18 | 20-2000 | 99 |

| TE-AT-10181 | 24 | 19 | 20-2000 | 99 |

| TE-AT-10182 | 24 | 14 | 20-2000 | 99 |

| TE-AT-10183 | 25 | 14 | 20-2000 | 99 |

| TE-AT-10184 | 25 | 15 | 20-2000 | 99 |

| TE-AT-10185 | 25 | 16 | 20-2000 | 99 |

| TE-AT-10186 | 25 | 17 | 20-2000 | 99 |

| TE-AT-10187 | 25 | 18 | 20-2000 | 99 |

| TE-AT-10188 | 25 | 19 | 20-2000 | 99 |

| TE-AT-10189 | 25 | 20 | 20-2000 | 99 |

| TE-AT-10190 | 25 | 21 | 20-2000 | 99 |

| TE-AT-10191 | 26 | 8 | 20-2000 | 99 |

| TE-AT-10192 | 26 | 14 | 20-2000 | 99 |

| TE-AT-10193 | 26 | 15 | 20-2000 | 99 |

| TE-AT-10194 | 26 | 16 | 20-2000 | 99 |

| TE-AT-10195 | 26 | 17 | 20-2000 | 99 |

| TE-AT-10196 | 26 | 18 | 20-2000 | 99 |

| TE-AT-10197 | 26 | 19 | 20-2000 | 99 |

| TE-AT-10198 | 26 | 20 | 20-2000 | 99 |

| TE-AT-10199 | 26 | 21 | 20-2000 | 99 |

| TE-AT-10200 | 27 | 21 | 20-2000 | 99 |

| TE-AT-10201 | 27 | 22 | 20-2000 | 99 |

| TE-AT-10202 | 28 | 19 | 20-2000 | 99 |

| TE-AT-10203 | 28 | 20 | 20-2000 | 99 |

| TE-AT-10204 | 28 | 21 | 20-2000 | 99 |

| TE-AT-10205 | 28 | 22 | 20-2000 | 99 |

| TE-AT-10206 | 28 | 23 | 20-2000 | 99 |

| TE-AT-10207 | 28 | 23.5 | 20-2000 | 99 |

| TE-AT-10208 | 28 | 24 | 20-2000 | 99 |

| TE-AT-10209 | 28 | 25 | 20-2000 | 99 |

| TE-AT-10210 | 29 | 23 | 20-2000 | 99 |

| TE-AT-10211 | 29 | 24 | 20-2000 | 99 |

| TE-AT-10212 | 29 | 25 | 20-2000 | 99 |

| TE-AT-10213 | 30 | 15 | 20-2000 | 99 |

| TE-AT-10214 | 30 | 20 | 20-2000 | 99 |

| TE-AT-10215 | 30 | 21 | 20-2000 | 99 |

| TE-AT-10216 | 30 | 22 | 20-2000 | 99 |

| TE-AT-10217 | 30 | 24 | 20-2000 | 99 |

| TE-AT-10218 | 30 | 26 | 20-2000 | 99 |

| TE-AT-10219 | 31 | 23 | 20-2000 | 99 |

| TE-AT-10220 | 31 | 25 | 20-2000 | 99 |

| TE-AT-10221 | 31 | 26 | 20-2000 | 99 |

| TE-AT-10222 | 31 | 27 | 20-2000 | 99 |

| TE-AT-10223 | 32 | 26 | 20-2000 | 99 |

| TE-AT-10224 | 32 | 27 | 20-2000 | 99 |

| TE-AT-10225 | 33 | 28 | 20-2000 | 99 |

| TE-AT-10226 | 34 | 18 | 20-2000 | 99 |

| TE-AT-10227 | 34 | 22 | 20-2000 | 99 |

| TE-AT-10228 | 34 | 23 | 20-2000 | 99 |

| TE-AT-10229 | 34 | 30 | 20-2000 | 99 |

| TE-AT-10230 | 35 | 27 | 20-2000 | 99 |

| TE-AT-10231 | 35 | 29.5 | 20-2000 | 99 |

| TE-AT-10232 | 36 | 30 | 20-2000 | 99 |

| TE-AT-10233 | 36 | 31 | 20-2000 | 99 |

| TE-AT-10234 | 37 | 29 | 20-2000 | 99 |

| TE-AT-10235 | 37 | 31.5 | 20-2000 | 99 |

| TE-AT-10236 | 37 | 32 | 20-2000 | 99 |

| TE-AT-10237 | 38 | 31 | 20-2000 | 99 |

| TE-AT-10238 | 45 | 38.5 | 20-2000 | 99 |

| TE-AT-10239 | 46 | 38.5 | 20-2000 | 99 |

| TE-AT-10240 | 60 | 30 | 20-1000 | 99 |

![]() Download Alumina Tube Closed One End More Size

Download Alumina Tube Closed One End More Size

Alumina Tube Closed One End Packing

- Each tube is individually wrapped in foam-lined protective sleeves