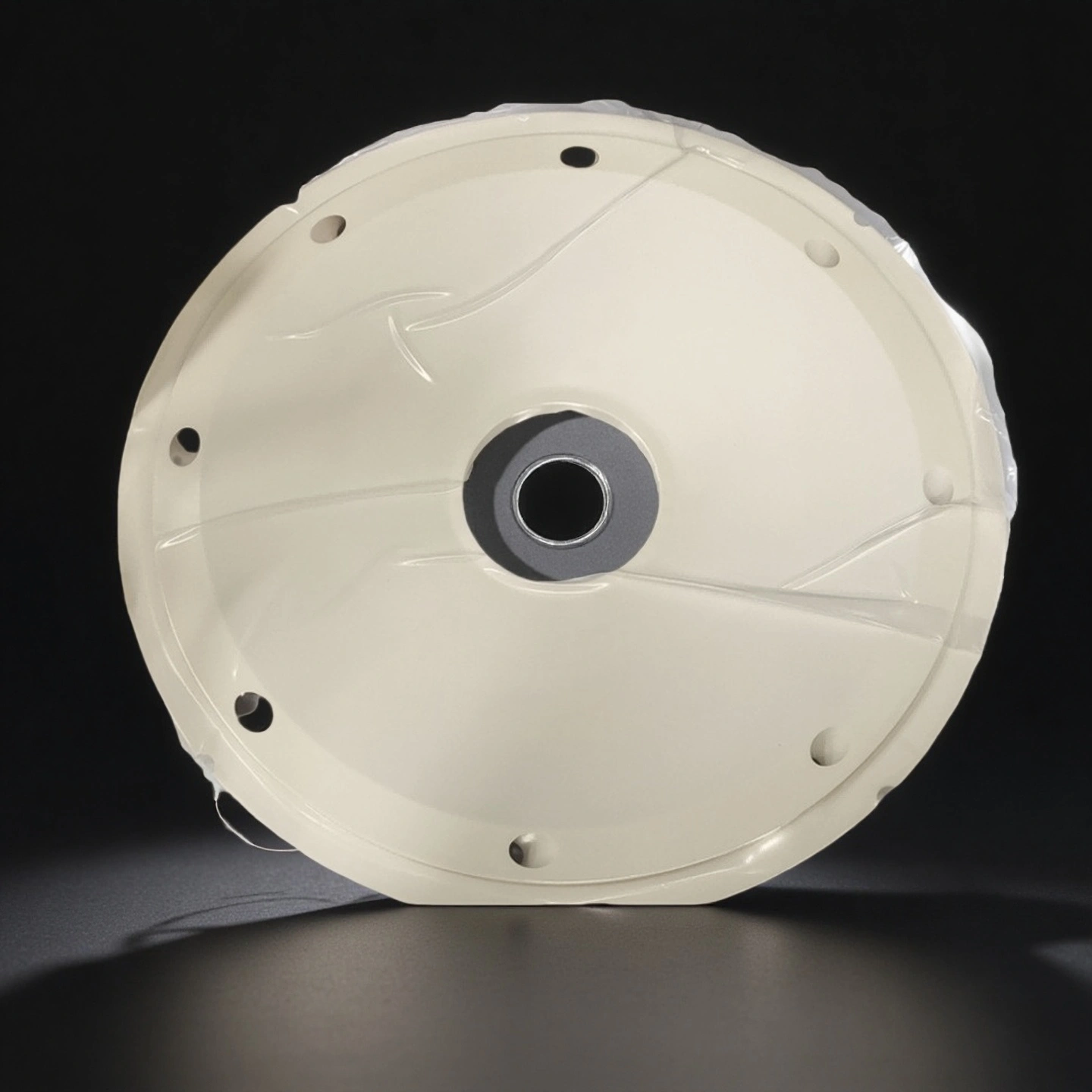

An alumina wafer carrier is a high-purity ceramic fixture—made from 99.7–99.9% alumina—designed to hold and support silicon, sapphire, and compound semiconductor wafers during processes such as diffusion, oxidation, wet cleaning, RIE and CMP. Its stable, inert structure protects wafers from deformation, particle contamination and metallic impurities while maintaining flatness through high-temperature and chemical environments.

Alumina Wafer Carrier Benefits

-

Designed for high temperature wafer processing

Alumina wafer carriers tolerate furnace and diffusion steps up to roughly 1700–1750 °C, allowing repeated thermal cycling without the softening or deformation seen in many polymer-based carriers. -

Flatness and stability for polishing and lapping

Polished alumina polishing plates and carrier plates are specified with flatness down to the micrometer and even sub-micrometer level across large diameters, supporting uniform material removal in CMP and lapping. -

Low contamination for higher wafer yield

Industry studies show that particulate contamination can contribute to more than 60% of wafer yield loss, so robust, low-particle carriers are critical; high purity alumina carriers reduce organic outgassing compared with polymer boxes and contribute less micro-debris than many metal fixtures. -

Chemically resistant in aggressive chemistries

Alumina carrier plates withstand common wet cleaning chemistries and CMP slurries used in wafer cleaning and polishing processes, where they are exposed to oxidizers and abrasive suspensions over long periods. -

Flexible geometries for different tools

Commercial alumina polishing plates and carrier plates are available as discs, rings and complex grooved forms up to several hundred millimeters in diameter, making it practical to match the fixture design to the diffusion furnace, CMP tool or cleaning bench.

Alumina Ceramic Wafer Carrier Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Wafer Carrier Specifications

| Item No. | Outer Dia(mm) | Height(mm) | Purity(%) |

| AT-BDT-B001 | 240 | 15 | 99.5 |

| AT-BDT-B002 | 240 | 25 | 99.6 |

| AT-BDT-B003 | 245 | 25 | 99.6 |

| AT-BDT-B004 | 263 | 25 | 99.6 |

| AT-BDT-B005 | 300 | 20 | 99.6 |

| AT-BDT-B006 | 310 | 20 | 99.6 |

| AT-BDT-B007 | 350 | 15 | 99.5 |

| AT-BDT-B008 | 355 | 16 | 99.6 |

| AT-BDT-B009 | 360 | 16 | 99.6 |

| AT-BDT-B010 | 400 | 15 | 99 |

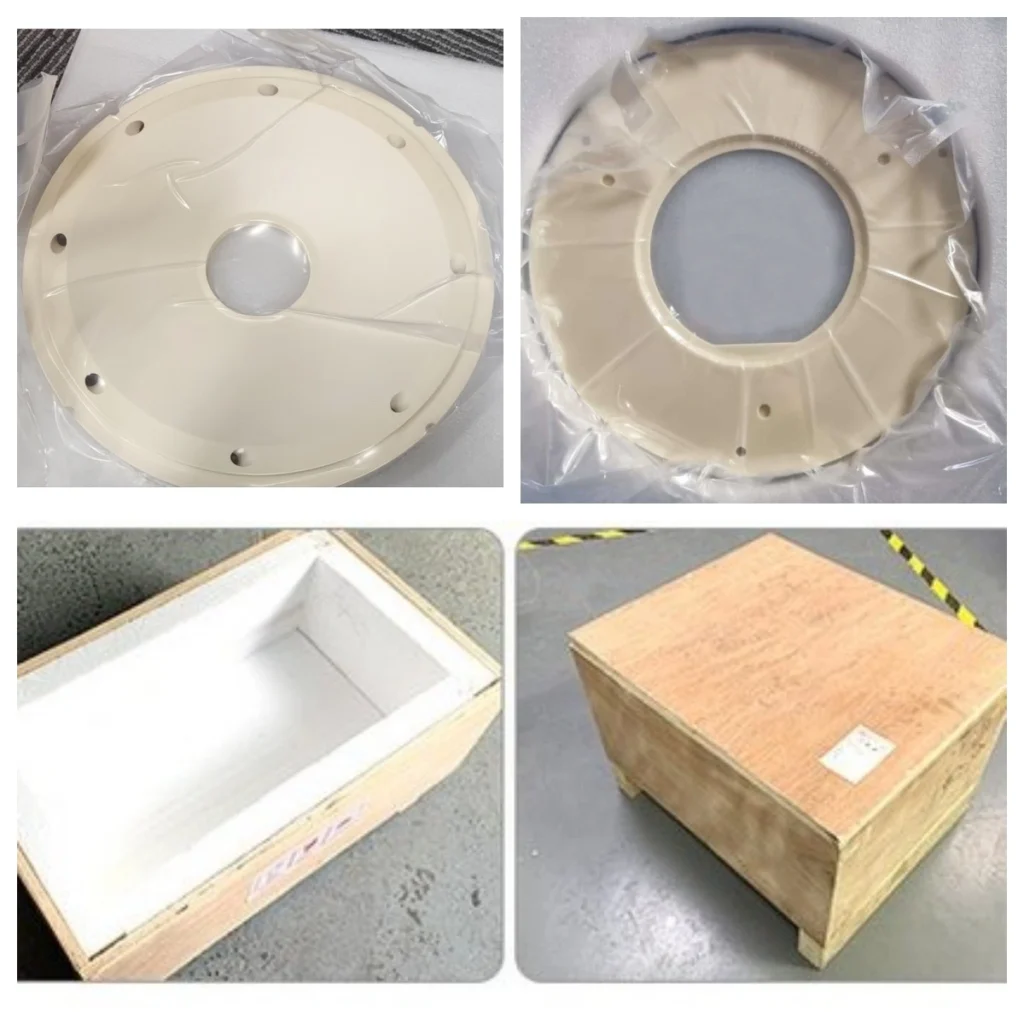

Alumina Ceramic Wafer Carrier Packaging

- Carriers are first wrapped in clean, lint-free protective material to limit particle generation during transport, consistent with practices used for ceramic and polished wafer plates.