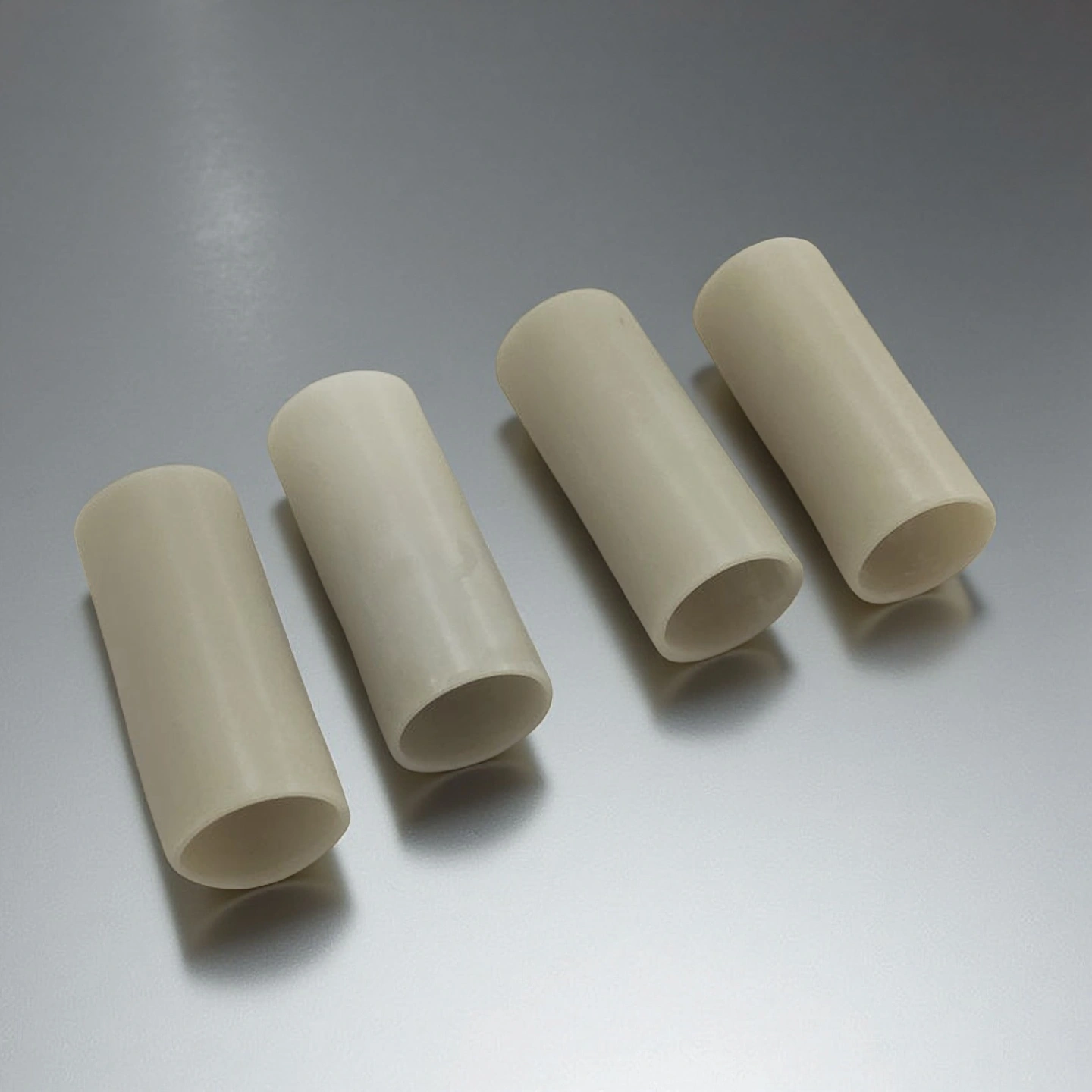

Aluminum nitride tube is a ceramic tube made from aluminum nitride (AlN), designed for applications where high thermal conductivity and electrical insulation are required at the same time. Compared with common ceramic tubes such as alumina or quartz, an aluminum nitride tube can transfer heat much faster while still acting as an electrical insulator and keeping a relatively low thermal expansion close to silicon.

Aluminum Nitride Tube Benefits

-

High heat transfer efficiency: Aluminum nitride tube offers thermal conductivity typically in the 170–220 W/m·K range, which helps remove heat quickly from furnace zones, thermocouple sheaths and power modules.

-

Electrical insulation at elevated temperature: AlN tube maintains high volume resistivity and dielectric strength, making it suitable where high voltage and high temperature appear in the same assembly.

-

Low thermal expansion for stable alignment: The coefficient of thermal expansion around 4.5–5.6×10⁻⁶/K reduces thermal stress between aluminum nitride tubes and silicon or metal components in repeated heating cycles.

-

Thermal shock resistance in fast cycling: Typical AlN ceramics can tolerate temperature jumps on the order of 300–400 °C, which supports rapid ramp-up or emergency cooling in many furnace and process conditions.

-

Suitability for aggressive atmospheres: Aluminum nitride tubes remain stable in many inert and certain process gases, including hydrogen and carbon dioxide, within their specified temperature limits.

Aluminum Nitride Ceramic Tube Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

Aluminium Nitride Tube Specifications

| Aluminum Nitride Tube | ||||

| Item No. | Outer Diameter(mm) | Inner Diameter(mm) | Thickness(mm) | Length(mm) |

| AT-ALN-G1001 | 5 | 3 | 1.0 | ≤100 |

| AT-ALN-G1002 | 8 | 4 | 2.0 | |

| AT-ALN-G1003 | 10 | 6 | 2.0 | |

| AT-ALN-G1004 | 12 | 7 | 2.5 | |

| AT-ALN-G1005 | 15 | 10 | 2.5 | |

| AT-ALN-G1006 | 20 | 14 | 3.0 | |

| AT-ALN-G1007 | 30 | 24 | 3.0 | ≤300 |

| AT-ALN-G1008 | 50 | 46 | 2.0 | |

| AT-ALN-G1009 | 55 | 49 | 3.0 | |

| AT-ALN-G1010 | 65 | 57 | 4.0 | |

| AT-ALN-G1011 | 70 | 60 | 5.0 | |

| AT-ALN-G1012 | 80 | 67 | 6.5 | |

| AT-ALN-G1013 | 90 | 82 | 4.0 | |

| AT-ALN-G1014 | 100 | 92 | 4.0 | |

| AT-ALN-G1015 | 150 | 139 | 5.5 | |

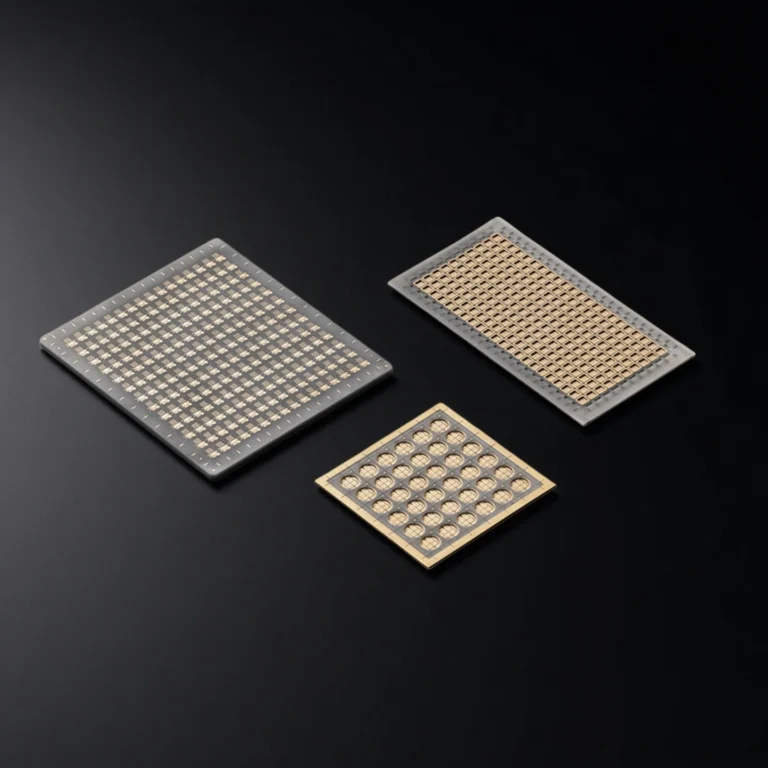

AlN ceramic tube Packaging

- Each aluminum nitride tube is wrapped with soft cushioning material to protect the ceramic from vibration and point impact.