Aluminum silicate fiber rope is a flexible high-temperature sealing and insulation rope made from alumina–silica (Al₂O₃–SiO₂) ceramic fibers. The fibers are spun into yarns and then twisted or braided into round or square sections, often with glass fiber or stainless-steel wire reinforcement to improve mechanical strength and durability.

Aluminum Silicate Fiber Rope Benefits

-

Stable high temperature sealing

The aluminum silicate fiber rope maintains compressibility and resilience in the 900–1100°C working range, making it suitable for furnace and boiler door gaskets that cycle between heating and cooling. -

Braided or twisted construction for mechanical strength

The rope can be supplied as twisted or tightly braided construction, providing better abrasion resistance at the sealing surface and reducing fiber shedding during repeated door movement. -

Reinforcement options for demanding applications

Aluminum silicate fiber rope can be reinforced with glass fiber for lighter duty up to medium temperatures, or with stainless steel wire for higher mechanical load and elevated temperature operation around burner blocks and slag lines. -

Flexible geometry for complex sealing paths

The rope is flexible enough to follow curved tracks, corners and irregular sealing grooves, which helps to retrofit existing furnaces without changing the metalwork of the door or frame. -

Compatible with typical refractory systems

The ceramic fiber rope is compatible with common refractory bricks, castables and ceramic fiber linings, reducing chemical interaction and helping maintain lining integrity during long campaigns.

Aluminum Silicate Ceramic Fiber Rope Properties

| Item | General Grade | Standard Grade | High Purity Grade | High Alumina Grade | Zirconia-Containing Grade |

| Classification Temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 |

| Service Temperature (°C) | <1000 | 1050 | 1100 | 1200 | 1350 |

| Color | White | Off-white | Off-white | Off-white | Off-white |

| Bulk Density (kg/m³) | 260–320 | 260–320 | 260–320 | 260–320 | 260–320 |

| Permanent Linear Shrinkage (%) (24 h holding; based on 128 kg/m³) | <2.5 (1000°C) | <2.5 (1050°C) | <2.5 (1100°C) | <2.5 (1100°C) | <2.5 (1350°C) |

| Thermal Conductivity (W/m·K) (bulk density 128 kg/m³) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) | 0.085 (400°C) |

| 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | 0.132 ( 800°C) | |

| 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | 0.180 (1000°C) | ||

| Tensile Strength (MPa) (bulk density 128 kg/m³) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Chemical Composition (wt%) | |||||

| Al₂O₃ | 44 | 46 | 47–49 | 52–55 | 39–40 |

| Al₂O₃ + SiO₂ | 96 | 97 | 99 | 99 | – |

| Al₂O₃ + SiO₂ + ZrO₂ | – | – | – | – | 99 |

| ZrO₂ | – | – | – | – | 15–17 |

| Fe₂O₃ | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na₂O + K₂O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

Aluminum Silicate Fiber Rope Specifications

| Type | Ceramic Fiber Round Braided Rope | Ceramic Fiber Square Braided Rope | Ceramic Fiber Yarn Twisted Rope | Ceramic Fiber Bulk Yarn Twisted Rope | Ceramic Fiber Tube Cover Rope | |||

| Item | AT-GSL-SC1001 (Glass Yarn Reinforced) | AT-GSL-SC2001 (Steel Wire Reinforced) | AT-GSL-SD1001 (Glass Yarn Reinforced) | AT-GSL-SD2001 (Steel Wire Reinforced) | AT-GSL-SE1001 (Glass Yarn Reinforced) | AT-GSL-SE2001 (Steel Wire Reinforced) | AT-GSL-SF1001 | AT-GSL-SG1001 |

| Operating Temp.(℃) | 650 | 1000 | 650 | 1000 | 650 | 1000 | 1000 | 1000 |

| Product Description | Ceramic fiber round braided rope and ceramic fiber square braided rope, also known as ceramic fiber packing or aluminum silicate packing, are composed of an inner core and an outer braided layer. The core is twisted from ceramic fiber yarns, while the outer layer is braided with ceramic fiber yarns reinforced with heat-resistant alloy wire or alkali-free glass fiber. | Ceramic fiber yarn twisted rope is produced by twisting multiple strands of ceramic fiber yarn reinforced with heat-resistant alloy wire or alkali-free glass fiber. | Ceramic fiber sliver twisted rope is made by twisting multiple ceramic fiber slivers (raw spinning fibers) on a rope-twisting machine. | Ceramic fiber tubular rope is a hollow braided rope made from ceramic fiber yarns reinforced with heat-resistant alloy wire or alkali-free glass fiber. | ||||

| Typical Applications | Sealing and insulation for industrial furnace doors, flues, and refractory brick expansion joints; sealing packings for industrial furnace burners, heat exchangers, high-temperature pipelines, and valves. | Commonly used in thermal insulation applications, including insulation wrapping for cables, cable trays, panels, and cable bridges; insulation covering for industrial furnace burners and heat exchangers; high-temperature wrapping for pipelines, valves, and flanges; and as wicking material for oil-burning equipment and decorative candle wicks. | Due to its loose structure, it is used only for insulation wrapping on equipment or pipelines. | Fire-resistant cable and high-temperature cable covering; high-temperature pipe wrapping and sleeving; and high-temperature gasket applications. | ||||

| Theoretical Bulk Density(kg/m3) | 550-700 | 550-700 | 500±30 | 380±30 | 300±50 | |||

| size (mm) | Diameter or Section: 6, 8, 10, 12, 14, 15, 16, 18, 20, 25, 30, 35, 40, 50mm; Length: 30-100m | Diameter: 20mm, Length: 100m | Diameter: 13, 19, 25, 38, 51, 63, 76, 102mm | |||||

| Moisture Content % | ≤2 | ≤1 | ||||||

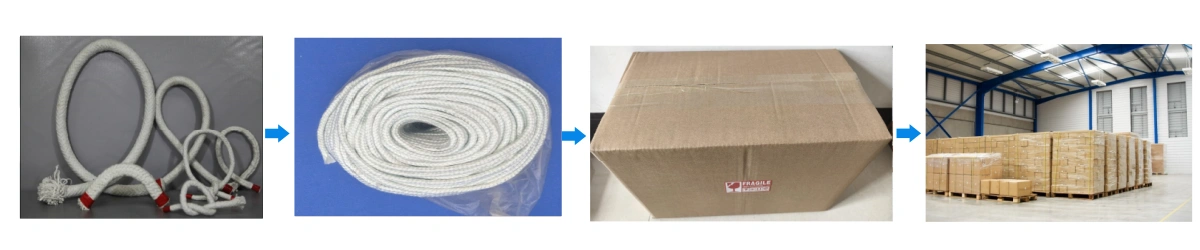

Aluminum Silicate Ceramic Fiber Rope Packaging

- Rope is typically supplied in coil or spool form, secured with ties to maintain shape and prevent tangling during handling.