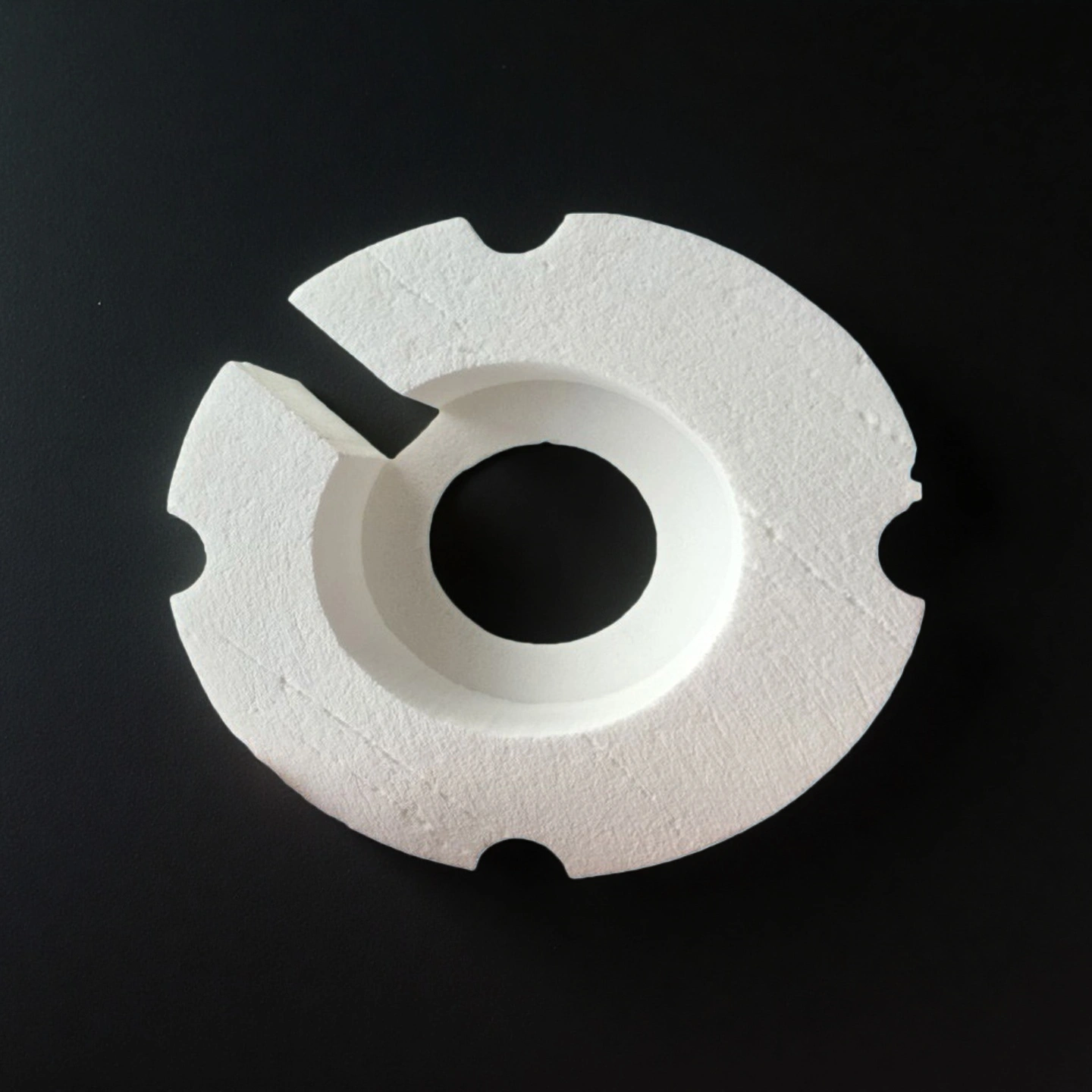

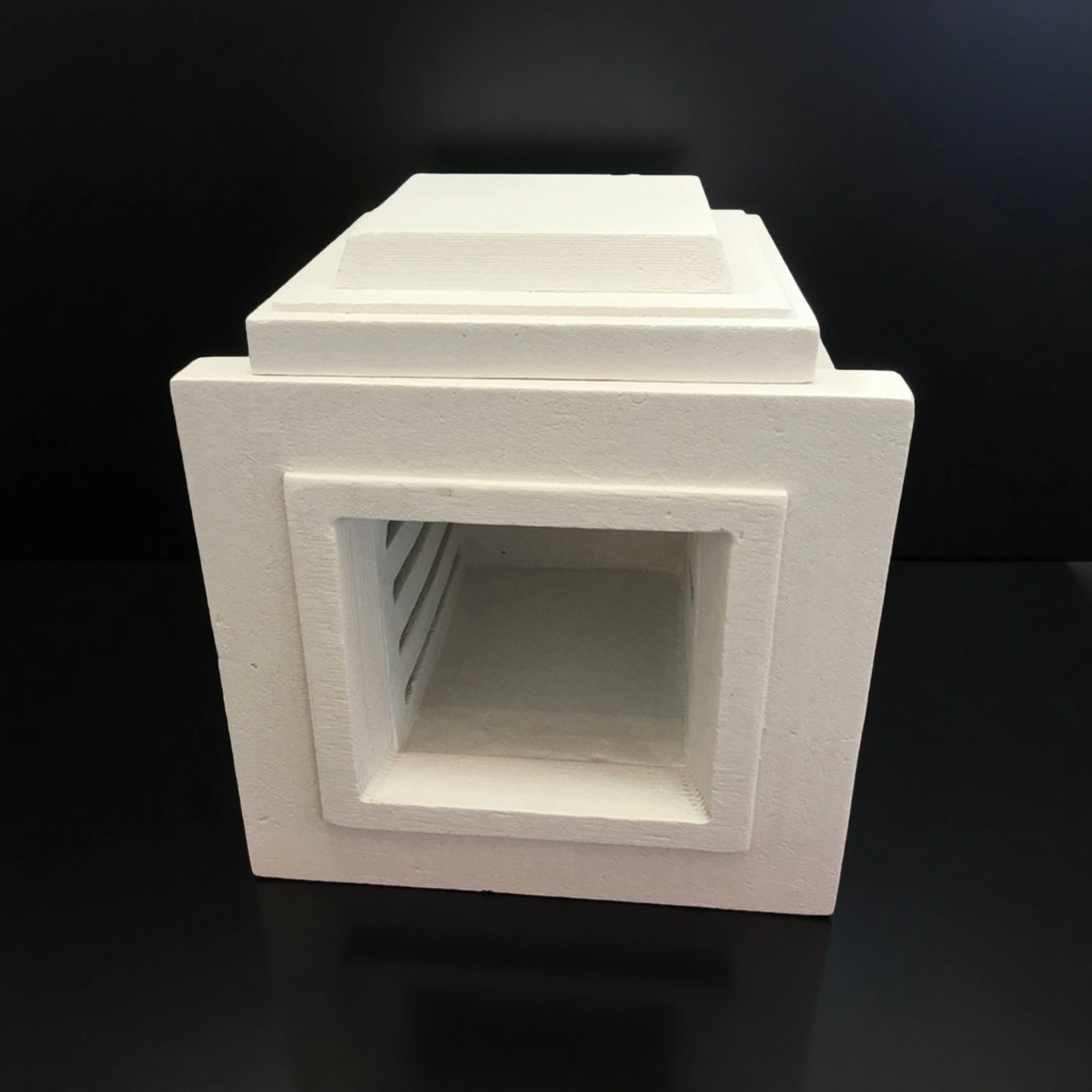

Aluminum silicate fiber shaped parts are rigid, vacuum-formed ceramic fiber components made from alumino-silicate (Al₂O₃–SiO₂) fibers and small amounts of binders. Instead of being supplied as flat blanket or board, the fiber slurry is formed in a mold by vacuum to create three-dimensional shapes.

Aluminum Silicate Ceramic Fiber Shaped Parts Benefits

-

Near-net-shape furnace components

Complex burner blocks, door plugs, inspection blocks and transition pieces are formed to shape, reducing on-site cutting of boards and blankets and shortening installation time. -

Low thermal mass and energy savings

The low density matrix stores far less heat than brick or castable, which helps shorten heating and cooling cycles and reduces fuel or power consumption in batch and cyclic furnaces. -

High temperature stability with controlled shrinkage

Grades matched to 1260–1430 °C service exhibit limited permanent linear change after long-term exposure, maintaining fit in burner tiles, doors and peep holes. -

Improved lining life at critical interfaces

Carefully designed shaped parts protect steel shells and castable back-up at openings where gas velocity, mechanical impact or thermal gradients are most severe. -

Flexibility across multiple processes

The same family of aluminum silicate fiber shaped parts can be used in heat-treatment furnaces, aluminum melting lines, glass forehearths, boilers and incinerators, simplifying spares management.

Aluminum Silicate Fiber Shaped Parts Properties

| Aluminum Silicate Ceramic | ||

| Parameter | Typical Value | Notes / Industrial Relevance |

| Material Composition | Al₂O₃–SiO₂ | Silicate-based refractory matrix |

| Working Temperature | 1000–1400°C | Depends on density & grade |

| Bulk Density | 200–400 kg/m³ | Lower density = better insulation |

| Thermal Conductivity | 0.08–0.22 W/m·K | Measured at 600–1000°C |

| Linear Shrinkage | ≤ 2% at 1000–1300°C | Ensures dimensional stability |

| Cold Crushing Strength | 0.6–1.2 MPa | Resistance to mechanical load |

| Thermal Shock Resistance | High | Suitable for rapid heating cycles |

| Water Absorption | Low | Supports clean installation |

| Available Thickness | 10–75 mm | Custom thickness on request |

| Available Forms | Boards, blocks, custom-machined shapes | Supports OEM engineering designs |

Aluminum Silicate Ceramic Fiber Shaped Parts Specifications

| Item No. | Chemical Composition | Diameter (mm) | Thickness (mm) | Purity |

| AT-GSL-BZ1001 | Standard | Customize | ||

| AT-GSL-GC1001 | High-Purity | Customize | ||

| AT-GSL-GL1001 | High-Alumina | Customize | ||

| AT-GSL-HG1001 | Zirconia-Containing | Customize | ||

Aluminum Silicate Fiber Shaped Parts Packaging

- Each aluminum silicate fiber shaped part is wrapped in plastic or shrink film to control dust and moisture during transport.