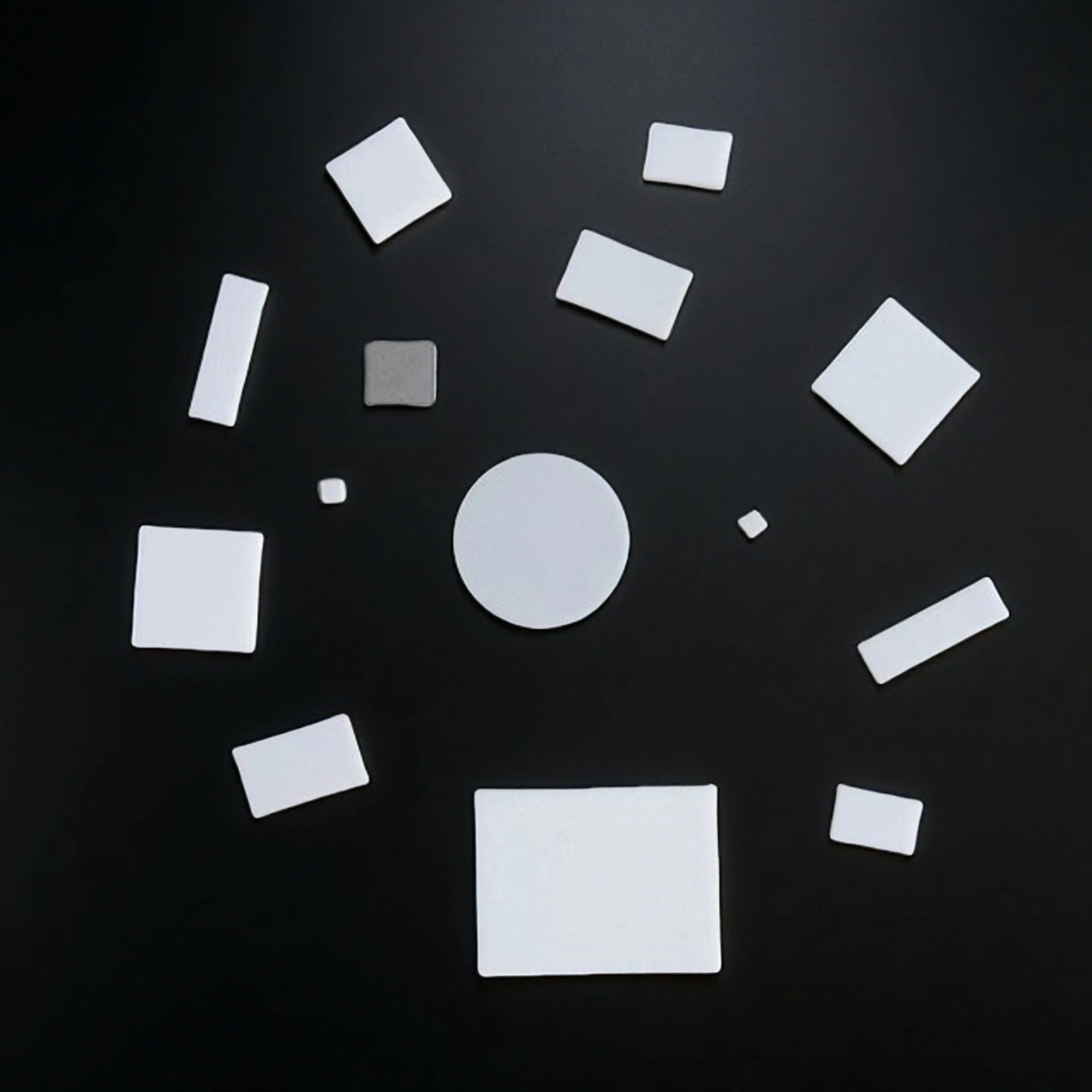

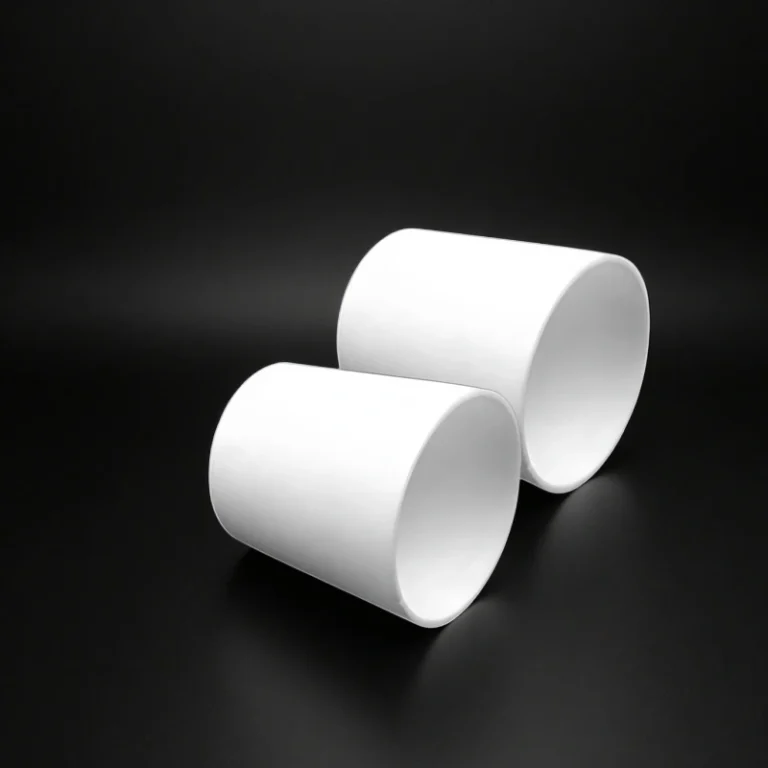

Beryllium Oxide (BeO) substrates are ceramic baseplates used as the electrical-insulating, heat-spreading foundation in high-power and high-frequency assemblies (RF/microwave power amplifiers, SiC/GaN power modules, laser/photonics packages, thick-film hybrid circuits).

Advantages of Beryllium Oxide Substrates

- High heat flux capability — ceramic k≈200–280 W/m·K enables compact die attach with reduced thermal resistance.

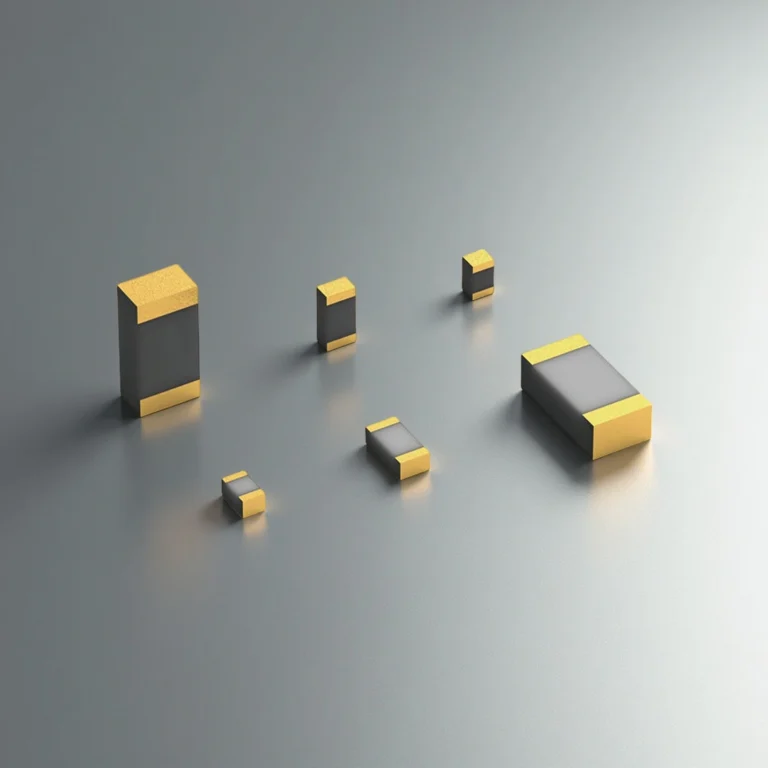

- Stable RF dielectric — εr≈6.5–7.2, low loss for repeatable line widths and pad capacitance.

- Controlled planarity — flatness and surface roughness tuned for uniform TIM/braze bond-lines.

- Metallization compatibility — Au/Ag/Ni/Au patterning suitable for thick-film, soldering, and active brazing.

- Feature integration — vias, slots, countersinks, and chamfers reduce secondary machining at the module level.

Beo Ceramic Substrate Properties

| Property | Be-97 | Be-99 |

| BeO Purity | ≧97% | ≧99% |

| Density (g/cm3) | ≧2.85 | ≧2.85 |

| Hardness (Hv) | 1200 | 1250 |

| Maximum Working Temperature (℃) | 1600 | 1650 |

| Flexural Strength (MPa) | 170 | 190 |

| Fracture Toughness (MPa*m1/2) | 2.5~3.5 | 2.5~3.5 |

| Dielectric Constant (at 1MHz) | 6.5 | 7 |

| Breakdown Voltage (kV/mm) | 15 | 20 |

| Thermal Conductivity (W/m*K) | 220-240 | 260-310 |

| Thermal Expansion Coefficient (/℃) | 7~8.5*10-6 | 7~8.5*10-6 |

Specifications of Beo Substrates

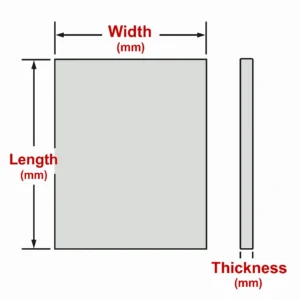

Type 1-Square Beo Substrates

| Item | Length*Width(mm) | Thickness(mm) |

| AT-BeO-J1001 | 50.8*50.8 | 0.38 |

| AT-BeO-J1002 | 76.2*76.2 | 0.38 |

| AT-BeO-J1003 | 101.6*101.6 | 0.38 |

| AT-BeO-J1004 | 114.3*114.3 | 0.38 |

| AT-BeO-J1005 | 32.1*9 | 0.5 |

| AT-BeO-J1006 | 40*9 | 0.5 |

| AT-BeO-J1007 | 45*2.5 | 0.5 |

| AT-BeO-J1008 | 50.8*50.8 | 0.5 |

| AT-BeO-J1009 | 76.2*76.2 | 0.5 |

| AT-BeO-J1010 | 101.6*101.6 | 0.5 |

| AT-BeO-J1011 | 114.3*114.3 | 0.5 |

| AT-BeO-J1012 | 7*6 | 0.635 |

| AT-BeO-J1013 | 40*30 | 0.635 |

| AT-BeO-J1014 | 42*42 | 0.635 |

| AT-BeO-J1015 | 50.8*50.8 | 0.635 |

| AT-BeO-J1016 | 76.2*76.2 | 0.635 |

| AT-BeO-J1017 | 101.6*101.6 | 0.635 |

| AT-BeO-J1018 | 114.3*114.3 | 0.635 |

| AT-BeO-J1019 | 25.5*19.5 | 1 |

| AT-BeO-J1020 | 27*18.2 | 1 |

| AT-BeO-J1021 | 36.7*9.7 | 1 |

| AT-BeO-J1022 | 46.8*22.4 | 1 |

| AT-BeO-J1023 | 50.8*50.8 | 1 |

| AT-BeO-J1024 | 76.2*76.2 | 1 |

| AT-BeO-J1025 | 101.6*101.6 | 1 |

| AT-BeO-J1026 | 114.3*114.3 | 1 |

| AT-BeO-J1027 | 12.7*10 | 1.5 |

| AT-BeO-J1028 | 30*30 | 1.5 |

| AT-BeO-J1029 | 50.8*50.8 | 1.5 |

| AT-BeO-J1030 | 76.2*76.2 | 1.5 |

| AT-BeO-J1031 | 101.6*101.6 | 1.5 |

| AT-BeO-J1032 | 114.3*114.3 | 1.5 |

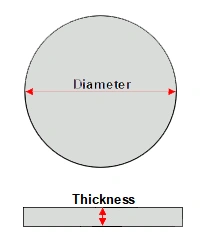

Type 2-Round Beo Substrates

| Item | Diameter(mm) | Thickness(mm) |

| AT-BeO-J2001 | 20 | 1.0 |

| AT-BeO-J2002 | 26 | 1.0 |

| AT-BeO-J2003 | 30 | 1.0 |

| AT-BeO-J2004 | 35 | 1.0 |

| AT-BeO-J2005 | 50 | 1.0 |

| AT-BeO-J2006 | 52 | 1.0 |

| AT-BeO-J2007 | 60 | 1.0 |

| AT-BeO-J2008 | 75 | 1.0 |

| AT-BeO-J2009 | 100 | 1.0 |

| AT-BeO-J2010 | 110 | 1.0 |

| AT-BeO-J2011 | 20 | 1.2 |

| AT-BeO-J2012 | 26 | 1.2 |

| AT-BeO-J2013 | 30 | 1.2 |

| AT-BeO-J2014 | 35 | 1.2 |

| AT-BeO-J2015 | 50 | 1.2 |

| AT-BeO-J2016 | 52 | 1.2 |

| AT-BeO-J2017 | 60 | 1.2 |

| AT-BeO-J2018 | 75 | 1.2 |

| AT-BeO-J2019 | 100 | 1.2 |

| AT-BeO-J2020 | 110 | 1.2 |

| AT-BeO-J2021 | 20 | 1.5 |

| AT-BeO-J2022 | 26 | 1.5 |

| AT-BeO-J2023 | 30 | 1.5 |

| AT-BeO-J2024 | 35 | 1.5 |

| AT-BeO-J2025 | 50 | 1.5 |

| AT-BeO-J2026 | 52 | 1.5 |

| AT-BeO-J2027 | 60 | 1.5 |

| AT-BeO-J2028 | 75 | 1.5 |

| AT-BeO-J2029 | 100 | 1.5 |

| AT-BeO-J2030 | 110 | 1.5 |

| AT-BeO-J2031 | 20 | 2.0 |

| AT-BeO-J2032 | 26 | 2.0 |

| AT-BeO-J2033 | 30 | 2.0 |

| AT-BeO-J2034 | 35 | 2.0 |

| AT-BeO-J2035 | 50 | 2.0 |

| AT-BeO-J2036 | 52 | 2.0 |

| AT-BeO-J2037 | 60 | 2.0 |

| AT-BeO-J2038 | 75 | 2.0 |

| AT-BeO-J2039 | 100 | 2.0 |

| AT-BeO-J2040 | 110 | 2.0 |

| AT-BeO-J2041 | 20 | 2.5 |

| AT-BeO-J2042 | 26 | 2.5 |

| AT-BeO-J2043 | 30 | 2.5 |

| AT-BeO-J2044 | 35 | 2.5 |

| AT-BeO-J2045 | 50 | 2.5 |

| AT-BeO-J2046 | 52 | 2.5 |

| AT-BeO-J2047 | 60 | 2.5 |

| AT-BeO-J2048 | 75 | 2.5 |

| AT-BeO-J2049 | 100 | 2.5 |

| AT-BeO-J2050 | 110 | 2.5 |

| AT-BeO-J2051 | 20 | 3.0 |

| AT-BeO-J2052 | 26 | 3.0 |

| AT-BeO-J2053 | 30 | 3.0 |

| AT-BeO-J2054 | 35 | 3.0 |

| AT-BeO-J2055 | 50 | 3.0 |

| AT-BeO-J2056 | 52 | 3.0 |

| AT-BeO-J2057 | 60 | 3.0 |

| AT-BeO-J2058 | 75 | 3.0 |

| AT-BeO-J2059 | 100 | 3.0 |

| AT-BeO-J2060 | 110 | 3.0 |

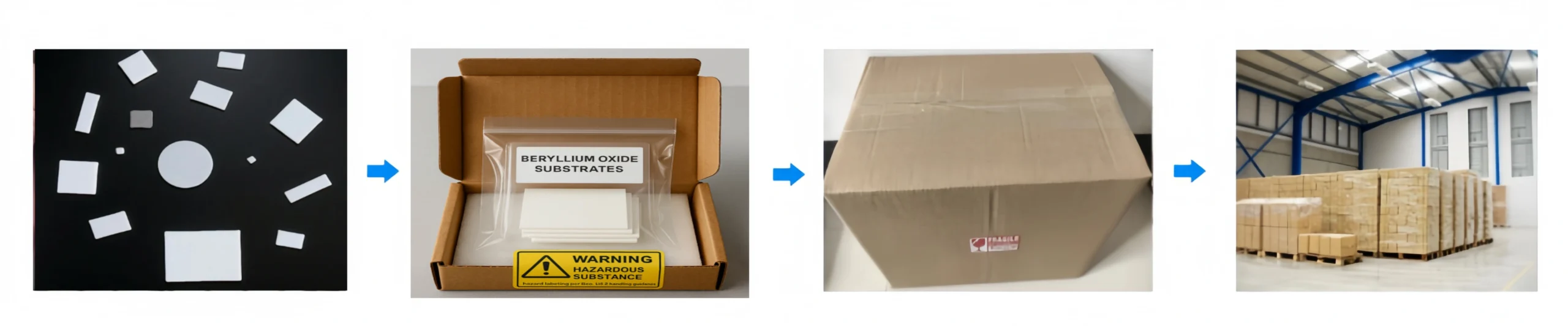

Beryllium Oxide Substrates Packing

- Clean-room bag + shock-absorbing tray; hazard labeling per BeO HSE handling guidance.