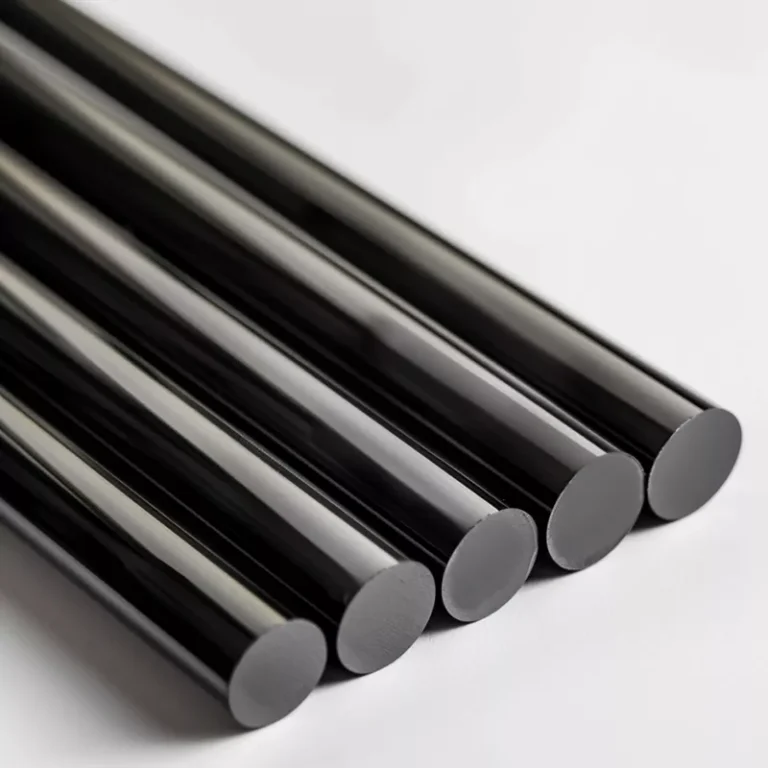

Black alumina ceramic rods provide strong dimensional stability, smooth finished surfaces, and excellent heat resistance. The black finish is not only aesthetic but also functional, aiding in light absorption control, particularly in laser-based systems or IR discs. These components are commonly used in applications requiring low reflectivity and high insulation, such as optical sensors or electronic control blocks.

Black Alumina Ceramic Rod Benefits

-

Integrated mechanical and optical function

The black alumina ceramic rod combines the strength and wear resistance of technical alumina with a low-reflective black body for light shielding in sensor and optical housings. -

High strength in compact cross-sections

Flexural strength in the 300–400 MPa range allows smaller-diameter rods to carry higher loads than many engineering plastics or glass components, improving stiffness in compact equipment. -

Stable at elevated temperatures

The alumina matrix maintains structure and electrical insulation up to roughly 1550–1650 °C in air, enabling rods to work inside furnaces, heaters and hot zones where metallic shafts may oxidize. -

Dimensional accuracy and straightness

Precision ground black alumina rods can be supplied with tight diameter tolerances and controlled straightness over the full length, supporting repeatable alignment and low-friction guiding. -

Electrical insulation with chemical durability

The alumina base provides high dielectric strength and resistance to many corrosive media, allowing rods to function as insulating supports in chemically aggressive or high-voltage environments.

Black Aluminium Oxide Ceramic Rod Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Black Alumina Ceramic Rod Specifications

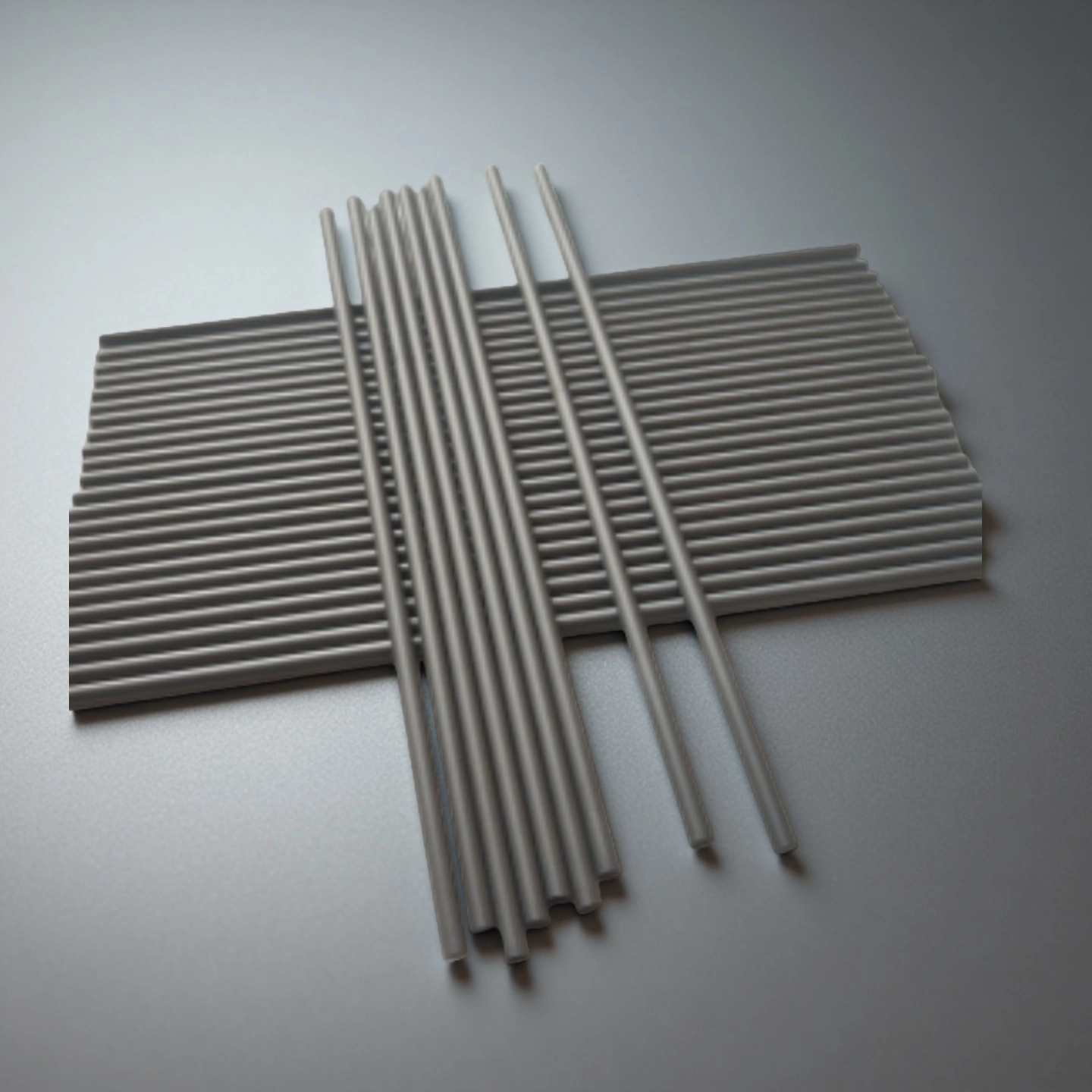

Type 1: Round Black Alumina Ceramic Rod

| Round Black Alumina Ceramic Rod | |||

| Item No. | Diameter (mm) | Length (mm) | Purity (%) |

| AT-BAR-1001 | 5 | 10-500 | 92-96 |

| AT-BAR-1002 | 8 | 10-500 | 92-96 |

| AT-BAR-1003 | 10 | 10-500 | 92-96 |

| AT-BAR-1004 | 12 | 10-500 | 92-96 |

| AT-BAR-1005 | 20 | 10-500 | 92-96 |

| AT-BAR-1006 | 25 | 300 | 92-96 |

| AT-BAR-1007 | 30 | 10-500 | 92-96 |

| AT-BAR-1008 | 40 | 10-500 | 92-96 |

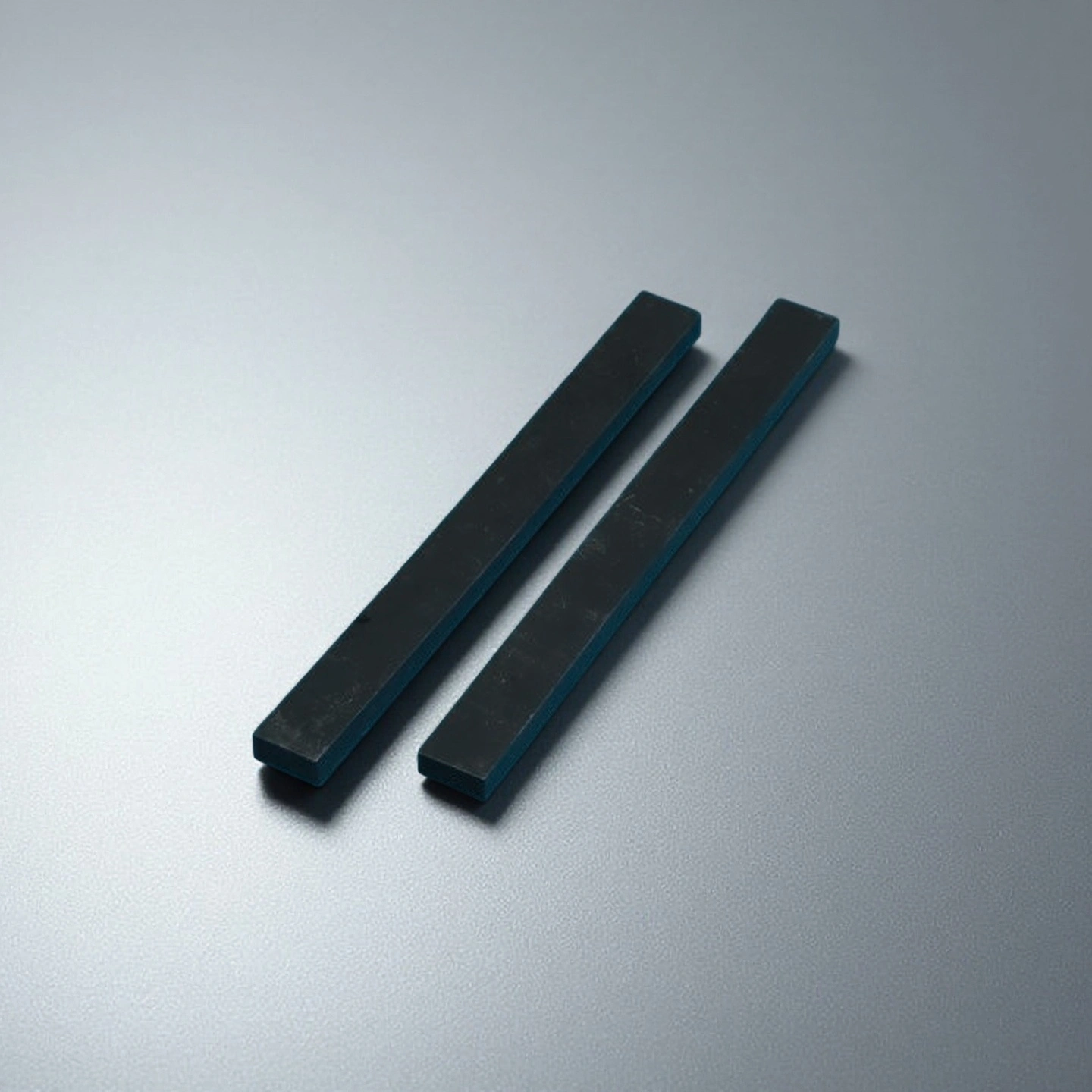

Type 2: Square Black Alumina Ceramic Rod

| Square Black Alumina Ceramic Rod | ||||

| Item No. | Cross-Section Width (mm) | Cross-Section Height (mm) | Length (mm) | Purity (%) |

| AT-BAR-2001 | 3 | 3 | 10-500 | 92-96 |

| AT-BAR-2002 | 5 | 3 | 10-500 | 92-96 |

| AT-BAR-2003 | 7 | 7 | 10-500 | 92-96 |

| AT-BAR-2004 | 9 | 5 | 10-500 | 92-96 |

| AT-BAR-2005 | 10 | 10 | 10-500 | 92-96 |

| AT-BAR-2006 | 15 | 8 | 10-500 | 92-96 |

| AT-BAR-2007 | 20 | 15 | 10-500 | 92-96 |

Black Al₂O₃ Ceramic Rod Packaging

- Every batch of black alumina rods is packed in shock-insulated foam trays with moisture barrier wrapping.