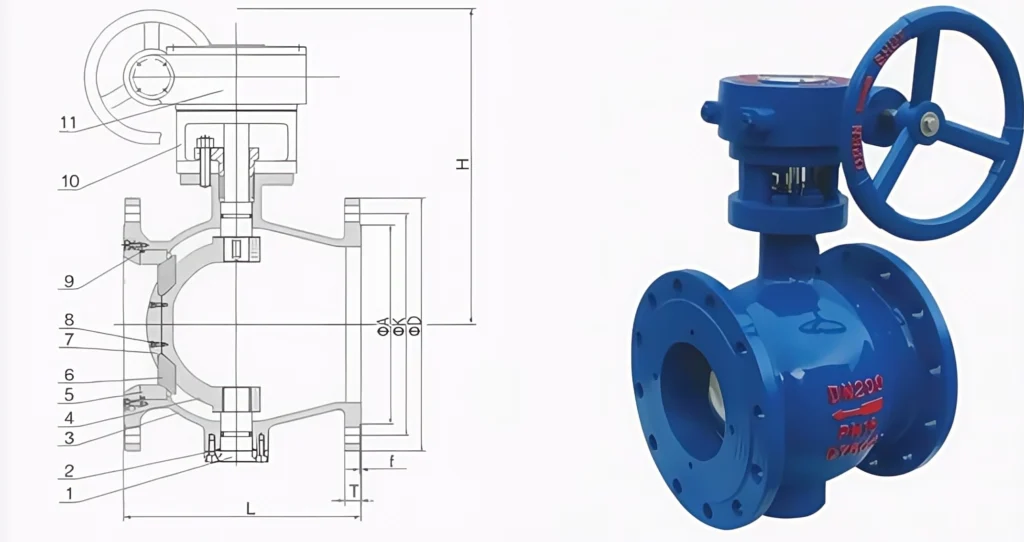

ADCERAX® C-Type Zirconia Ball Valve with Eccentric Design is engineered for demanding industrial operations where slurry, ash, and corrosive fluids cause rapid wear to conventional valves. Its zirconia ceramic sealing surfaces and eccentric rotation mechanism reduce friction, extend service life, and ensure Class VI sealing performance. This valve supports reliable flow control in mining, power generation, and chemical processing environments. It helps industrial operators lower maintenance costs and maintain stable production cycles.

Features of C-Type Zirconia Ball Valve with Eccentric Design

- Tests show zirconia ceramics reach HRA88+ hardness, nearly 8× harder than carbon steel, ensuring longer service under slurry.

- Field data from mining pipelines confirm >18 months average service life, compared to <6 months for metal valves.

- In abrasive fly ash systems, sealing stability reduces leakage incidents by 70%, extending maintenance intervals.

- The valve achieves ANSI/API Class VI zero-leakage sealing, validated in desulfurization slurry systems.

- Under pressure ratings up to PN40 / ANSI 300Lb, sealing integrity remains consistent without deformation.

- Independent trials show failure rates drop to <2% annually, compared with 15%+ in standard alloy valves.

- Zirconia ceramic structure withstands continuous exposure to pH 2–12 fluids, resisting acid and alkali attack.

- Thermal cycling from –20°C to +300°C demonstrates reliable sealing and no cracking after 500 cycles.

- In chemical catalyst slurries, performance tests report service life extended by 2–3×, reducing downtime and replacement costs.

Technical Properties for C-Type Zirconia Ball Valve with Eccentric Design

The C-Type Zirconia Ball Valve with Eccentric Design is defined by its advanced material properties and engineered stability.

| Property |

Pure Zirconia (Monoclinic) - Unstabilized |

Yttria-Stabilized Zirconia (YSZ) |

Magnesia-stabilized zirconia (Mg-PSZ) |

| Typical Purity |

High-purity raw material, but unstabilized for the final product |

High purity |

High purity |

| Crystal Phases (at RT) |

Monoclinic (stable up to ~1170°C); Tetragonal and Cubic at higher temperatures. |

Primarily, Metastable Tetragonal can have a Cubic phase. |

Partially stabilized with tetragonal precipitates in a cubic matrix. |

| Density (g/cm³) |

5.65–6.05 |

5.85-6.1 |

~5.7 |

| Melting Point (°C) |

~2700-2715 |

Very High (similar to pure zirconia, but phase stability is key) |

Very High |

| Thermal Conductivity (W/m·K) |

Low (approx. 2-3) |

Low (approx. 2.5-3) |

Low (approx. 3) |

| Thermal Expansion Coefficient (10⁻⁶/K) |

~10 |

9.5-10 |

10 |

| Flexural Strength (MPa) |

Poor (due to phase transformation and brittleness) |

Up to 1000, 710-900 |

500 |

| Compressive Strength (MPa) |

Not typically used structurally |

~2000 |

~2500 |

| Fracture Toughness (MPa·m^0.5) |

Low (inherently brittle) |

Up to 10 (exceptionally high for ceramics due to transformation toughening), 8-9 |

6 |

| Hardness (Vickers, HV1) |

Moderate |

11-13 GPa, 1100-1220 kg/mm² |

1100 kg/mm² |

| Chemical Inertness |

Excellent in acids and alkalis |

Excellent |

Excellent |

| Biocompatibility |

Generally good, but stabilized forms are preferred for medical use |

Excellent, widely used in dental and medical implants |

Good |

| Typical Applications |

Refractories (at high temperatures) |

Structural ceramics, dental implants, oxygen sensors, cutting tools, thermal barrier coatings |

Refractories, structural components requiring specific thermal properties |

Specifications of C-Type Zirconia Ball Valve with Eccentric Design

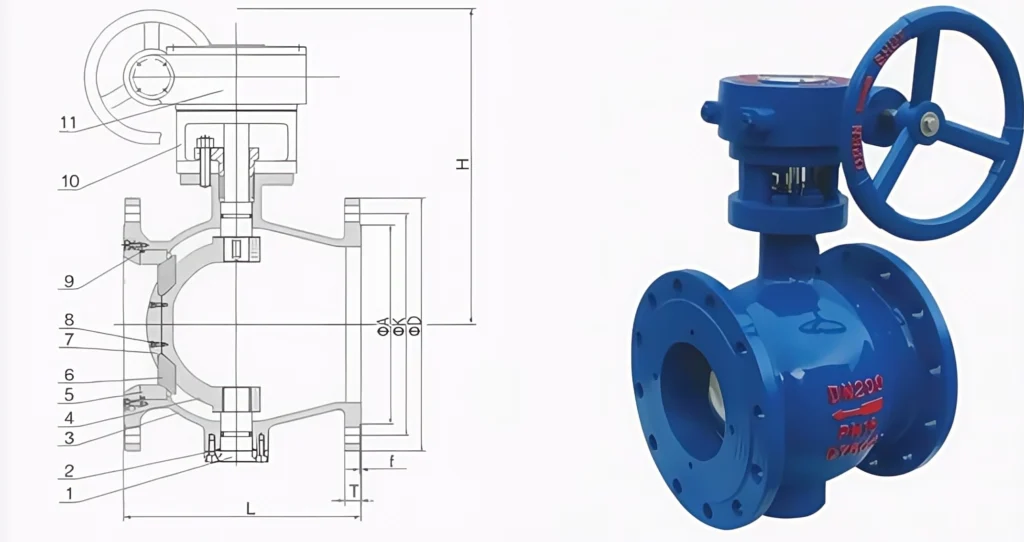

| Part No. |

Parts |

Material |

| 1 |

Valve Body |

WCB |

| 2 |

Middle Body |

WCB |

| 3 |

Gland Flang |

Engineering Ceramic |

| 4 |

Valve Seat |

Engineering Ceramic |

| 5 |

Ball |

Engineering Ceramic |

| 6 |

Bushing |

Engineering Ceramic |

| 7 |

Stem |

2Cr13 |

| 8 |

Packing |

Flexible Graphite |

| 9 |

Packing Gland |

WCB |

| 10 |

Lever |

WCB |

|

Zirconia Ceramic Lined Eccentric Half Ball Valve |

|

Item NO. |

DN |

PN (Mpa) |

H (mm) |

L (mm) |

D (mm) |

D1 (mm) |

D2 (mm) |

n-d |

C (mm) |

F (mm) |

|

AT-CVP-001 |

50 |

1.6 |

230 |

124 |

165 |

125 |

100 |

4-∅18 |

16 |

3 |

|

AT-CVP-002 |

65 |

1.6 |

237 |

145 |

185 |

145 |

120 |

4-∅18 |

18 |

3 |

|

AT-CVP-003 |

80 |

1.6 |

260 |

165 |

200 |

160 |

135 |

8-∅18 |

20 |

3 |

|

AT-CVP-004 |

100 |

1.6 |

270 |

194 |

220 |

180 |

156 |

8-∅18 |

20 |

3 |

|

AT-CVP-005 |

125 |

1.6 |

320 |

210 |

250 |

210 |

185 |

8-∅22 |

22 |

3 |

|

AT-CVP-006 |

150 |

1.6 |

340 |

229 |

285 |

240 |

211 |

8-∅22 |

26 |

3 |

|

AT-CVP-007 |

200 |

1.6 |

390 |

243 |

340 |

295 |

265 |

8-∅23 |

26 |

3 |

|

AT-CVP-008 |

250 |

1.6 |

420 |

297 |

405 |

355 |

319 |

8-∅26 |

30 |

3 |

|

AT-CVP-009 |

300 |

1.6 |

510 |

338 |

460 |

410 |

375 |

8-∅26 |

30 |

4 |

Packaging of C-Type Zirconia Ball Valve with Eccentric Design

Each C-Type Zirconia Ball Valve with Eccentric Design is first secured in protective foam lining to prevent impact damage during transit. The product is then sealed in reinforced cartons and placed into strong wooden crates for export. This ensures that the C-Type Zirconia Ball Valve arrives safely with full protection against vibration, moisture, and handling stress.

Addressing Industrial Challenges with ADCERAX® C-Type Zirconia Ball Valve with Eccentric Design

The C-Type Zirconia Ball Valve with Eccentric Design is applied in critical flow systems where abrasive particles, corrosive fluids, and high thermal loads challenge conventional valve materials. The following industry-specific cases illustrate how its features directly resolve pain points faced by end users.

-

High-Solids Slurry Pump Discharge

✅Key Advantages

1. Eccentric Seat Disengagement — The semi-ball separates from the seat during opening, cutting rubbing contact in high-velocity discharge lines. Start-up torque drops by 30–40%, while sealing life extends to 18–24 months versus <6 months for alloy valves.

2. Abrasion-Tolerant Zirconia Sealing — Zirconia hardness reaches HRA88+, resisting quartz and ore particle impact. Leakage incidents fall by ≈70% in pump discharge service, stabilizing uptime under >25% solids.

3. Automation Stability at Velocity — Smooth eccentric motion prevents torque spikes that stall actuators. Sites report actuator trip events reduced by >50% at line velocities of 4–6 m/s.

✅ ️Problem Solved

At a copper concentrator handling 3,200 m³/h slurry with 28–32% solids, alloy ball valves leaked after 5 months and triggered weekly stoppages. After installing the ADCERAX® C-Type Zirconia Ball Valve with Eccentric Design, mean time to failure reached 19 months, and leakage events fell from 6 to 1 per quarter. Peak operating torque dropped from 260 Nm to 165 Nm (-37%), enabling reliable automated control. Maintenance and downtime savings exceeded USD 120,000/year, with payback inside the first maintenance cycle.

-

Crystallizing Chemical Process Lines

✅Key Advantages

1. Anti-Scale Motion Path — Eccentric opening breaks crystal bridges and sheds deposits during travel. Torque rise remained <10% after 1,000 on-off cycles in saturated brine at 60°C, with seat wear under 0.02 mm.

2. Corrosion & Chloride Tolerance — Zirconia components remain stable in pH 2–12 and chloride brines at 200–300 g/L. Class VI tightness held after 500 thermal cycles between –20°C and +300°C.

3. Lower Actuator Load — Reduced friction allows smaller or existing actuators to run reliably. Average operating torque decreased 25–35% on 2″–6″ crystallizer loops, eliminating oversizing and nuisance trips.

✅ ️Problem Solved

A fertilizer plant’s crystallizer loop suffered monthly valve seizures and incomplete sealing due to salt deposition, causing >12 hours/month of lost production. With the ADCERAX® C-Type Zirconia Ball Valve with Eccentric Design, there were 0 seizures in 9 months, and peak torque fell from 280 Nm to 180 Nm (-36%). Batch changeover delays dropped by 45%, and unplanned maintenance calls decreased by >70%. The line achieved payback in 7 months through reduced downtime and actuator reliability.

-

Municipal Sludge Treatment Pipelines

✅Key Advantages

1. Self-Cleaning Semi-Ball Geometry — The eccentric semi-ball sweeps fibers and rags past the seat instead of trapping them. Clog events drop by 60–75% while maintaining sealing with particle sizes up to 3 mm.

2. Leak-Tight Under Grit — Zirconia sealing resists sand and grit abrasion that damages soft seats. Complaint tickets for leakage fall by ≈70%, and Class VI performance is sustained over >500 thermal cycles.

3. Extended Service Continuity — Lower wear and stable torque extend replacement intervals. MTBF increases from 4 months to >24 months, cutting maintenance labor by 40–55% year over year.

✅ ️Problem Solved

A municipal WWTP (150,000 m³/d) reported gate and butterfly valve jams twice weekly on sludge transfer lines carrying 2–4% solids with grit. After switching to the ADCERAX® C-Type Zirconia Ball Valve with Eccentric Design, clogs fell to 2 per month, and leakage complaints dropped by 72%. Maintenance hours declined by 52%, improving staffing efficiency during peak loads. Annual OPEX savings exceeded USD 45,000, while compliance interruptions were reduced to zero.

User Guide for C-Type Zirconia Ball Valve with Eccentric Design

The C-Type Zirconia Ball Valve with Eccentric Design requires proper handling, installation, and maintenance to achieve its full service life and performance benefits. This guide provides practical recommendations that help operators reduce failure risks, ensure Class VI sealing, and optimize lifecycle costs across demanding industrial applications.

-

Installation Recommendations

1. Check integrity before installation — Inspect the valve body and sealing surfaces for visible cracks, scratches, or shipping damage. Any defect should be reported before use to avoid leakage during operation.

2. Ensure correct orientation — The C-Type Zirconia Ball Valve must be aligned with the pipeline flow direction indicated by arrows on the body. Incorrect placement may compromise sealing performance.

3. Avoid mechanical shock — Heavy impact during lifting or welding around the valve can damage ceramic components. Always use cushioned slings and low-vibration tools when handling the valve.

-

Operation Guidelines

1. Follow recommended torque — Over-torqueing can stress ceramic parts, while under-torqueing may reduce sealing. Use calibrated actuators with preset torque values aligned to technical documentation.

2. Cycle regularly under standby — The C-Type Zirconia Ball Valve with Eccentric Design should be cycled once every two weeks in standby lines. This prevents seat adhesion and ensures smooth eccentric motion.

3. Avoid sudden pressure surges — Rapid pressurization or cavitation may shorten the valve’s lifespan. Maintain controlled flow startup to extend service intervals.

-

Maintenance Practices

1. Schedule routine inspections — Inspect sealing performance and actuator response every 3–6 months. Early detection of abnormal wear prevents unexpected downtime.

2. Replace wear parts on time — Seats and rings are subject to natural wear. Use genuine zirconia spares to retain the original HRA88+ hardness and Class VI sealing performance.

3. Monitor torque increase — Rising torque indicates crystallization or deposit buildup. Prompt cleaning will extend service life and maintain automation reliability.

-

Storage and Handling Advice

1. Store in dry conditions — Keep the C-Type Zirconia Ball Valve with Eccentric Design in a clean, moisture-free warehouse. Relative humidity should stay below 60% to avoid corrosion of metallic parts.

2. Use protective packaging — Always retain foam and crate packaging when in storage. This ensures protection from vibration and dust intrusion.

3. Handle with dedicated tools — Avoid rolling or dragging the valve. Use forklifts or lifting belts to prevent stress points on the ceramic components.