ADCERAX® Conical Zirconia Crucible is engineered for demanding furnace and reactor environments where curved geometries are required for stable thermal distribution. Produced from high-density stabilized zirconia, it delivers reliable performance in reducing, oxidizing, and inert atmospheres up to 2200 °C. The arc form enhances compatibility with complex heating layouts, improves energy efficiency, and minimizes thermal stress during repeated cycles. This makes the Arc Shaped Zirconia Crucible a preferred choice for metallurgical processes, chemical reactors, and high-temperature research facilities.

Features of Conical Shaped Zirconia Crucible

- Operational Temperature up to 2200 °C: The crucible maintains structure at continuous service above 2000 °C. This allows extended furnace runs without premature failure.

- Thermal Shock Endurance: Proven resistance to heating/cooling cycles at rates below 5 °C/min. This prevents cracking during rapid transitions in controlled processes.

- Stable Bulk Density ≥ 4.5 g/cm³: High density minimizes heat penetration losses. This ensures uniform distribution across curved furnace walls.

- ZrO₂ Content ≥ 92%: High zirconia composition resists corrosion from molten alloys. This extends service life in metallurgical systems.

- Low Impurity Index (Fe₂O₃ ≤ 0.5%): Reduced impurities protect melts from contamination. This supports clean outcomes in alloy development.

- Apparent Porosity ≤ 0.5%: Dense microstructure limits gas or liquid infiltration. This maintains crucible integrity under reactive atmospheres.

Technical Properties for Conical Zirconia Crucible

The Arc Shaped Zirconia Crucible combines advanced ceramic engineering with high-purity stabilized zirconia to ensure consistent performance under extreme furnace and reactor conditions.

| Property | Specification |

| ZrO₂ Purity | ≥ 92% (stabilized zirconia base) |

| Bulk Density | ≥ 4.5 g/cm³ (high structural integrity) |

| Apparent Porosity | ≤ 0.5% (dense microstructure) |

| Fe₂O₃ Content | ≤ 0.5% (low impurity level) |

| SiO₂ Content | ≤ 0.5% (controlled secondary oxide) |

| Maximum Operating Temperature | 2200 °C continuous service |

| Thermal Expansion Coefficient | 9–11 × 10⁻⁶ /K (room temperature to 1000 °C) |

| Flexural Strength | ≥ 350 MPa (at room temperature) |

| Thermal Conductivity | 2.5–3.0 W/m·K (at 1000 °C) |

| Electrical Resistivity | ≥ 10¹² Ω·cm (at room temperature) |

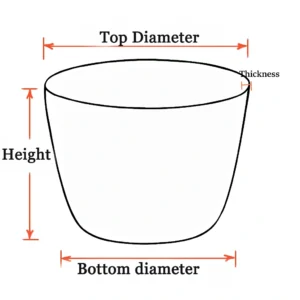

Dimensions of Conical Zirconia Crucible

| Cylindrical ZrO2 Crucible | ||||||

| Item No. | Top Diamete(mm) | Bottom Diameter(mm) | Height(mm) | Wall Thickness(mm) | Volume(ml) | Purity(%) |

| AT-YHG-H001 | 27 | 14 | 22 | 1.5 | 5 | 95 |

| AT-YHG-H002 | 36 | 20 | 42 | 3 | 60 | 95 |

| AT-YHG-H003 | 57 | 30 | 45 | 3 | 60 | 95 |

| AT-YHG-H004 | 59 | 45 | 52 | 2.5 | 80 | 95 |

| AT-YHG-H005 | 62 | 34 | 50 | 3 | 80 | 95 |

| AT-YHG-H006 | 82 | 58 | 80 | 4.2 | 300 | 95 |

| AT-YHG-H007 | 80 | 70 | 115 | 4.8 | 400 | 95 |

| AT-YHG-H008 | 100 | 65 | 110 | 5.5 | 500 | 95 |

| AT-YHG-H009 | 25 | 15 | 28 | 1.3 | 5 | 95 |

| AT-YHG-H010 | 29 | 18 | 34 | 1.5 | 10 | 95 |

| AT-YHG-H011 | 32 | 23 | 33 | 1.5 | 15 | 95 |

| AT-YHG-H012 | 36 | 23 | 41 | 1.7 | 20 | 95 |

| AT-YHG-H013 | 36 | 25 | 42 | 1.7 | 25 | 95 |

| AT-YHG-H014 | 38 | 25 | 45 | 1.7 | 30 | 95 |

| AT-YHG-H015 | 45 | 30 | 46 | 2 | 40 | 95 |

| AT-YHG-H016 | 48 | 30 | 52 | 2 | 50 | 95 |

| AT-YHG-H017 | 58 | 33 | 66 | 2 | 70 | 95 |

| AT-YHG-H018 | 58 | 35 | 68 | 2 | 100 | 95 |

| AT-YHG-H019 | 67 | 42 | 78 | 2.5 | 150 | 95 |

| AT-YHG-H020 | 73 | 44 | 86 | 2.5 | 200 | 95 |

| AT-YHG-H021 | 79 | 46 | 96 | 2.5 | 250 | 95 |

| AT-YHG-H022 | 83 | 50 | 106 | 2.5 | 300 | 95 |

| AT-YHG-H023 | 91 | 56 | 108 | 2.5 | 400 | 95 |

| AT-YHG-H024 | 100 | 60 | 118 | 3 | 500 | 95 |

| AT-YHG-H025 | 59 | 35 | 71 | 2.8 | 100 | 95 |

| AT-YHG-H026 | 49 | 30 | 54 | 2.7 | 50 | 95 |

| AT-YHG-H027 | 38 | 25 | 45 | 2.7 | 30 | 95 |

| AT-YHG-H028 | 75 | 46 | 78 | 3.5 | 250 | 95 |

| AT-YHG-H029 | 100 | 60 | 70 | 4 | 375 | 95 |

Packaging for Conical Zirconia Crucible

Each Conical Zirconia Crucible is first wrapped in protective film to avoid surface damage during transit. The crucibles are then packed into reinforced cartons and placed inside wooden crates for secure international shipping. This ensures that every ConicalZirconia Ceramic Crucible arrives in safe condition, ready for furnace and reactor applications.