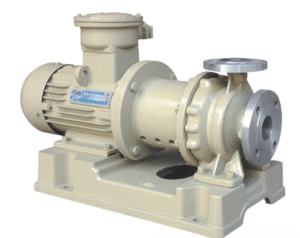

ADCERAX® CQB Stainless Steel Magnetic Drive Centrifugal Pump is designed for industrial fluid transfer processes that require controlled chemical compatibility, stable hydraulic output, and reliable operation without leakage. Its sealed magnetic coupling and advanced bearing configuration form a continuous transmission system suited for environments where solvents, weak acids, alkalis, and volatile liquids must be handled safely. These characteristics allow the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings to support long-duty production lines in chemical processing, pharmaceutical manufacturing, and petrochemical applications with consistent performance.

Key Operating Features of the CQB Stainless Steel Magnetic Drive Centrifugal Pump

-

High torque retention under fluctuating load

The magnetic rotor maintains torque transmission even when resistance increases by up to 18%, supporting uninterrupted operation, ensuring the CQB Stainless Steel Magnetic Drive Centrifugal Pump performs with predictable flow conditions in long production cycles.

-

Reduced mechanical wear through contact-free coupling

The containment shell isolates the drive assembly and eliminates contact at the coupling interface, reducing wear by over 90% compared with mechanical-seal systems, increasing stability when the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings operates in volatile-solvent environments.

-

Decoupling resistance under thermal variation

Magnetic flux density is maintained across a temperature shift of up to 40°C, preventing torque drop during solvent temperature changes, supporting consistent flow curves in facilities operating the CQB Stainless Steel Magnetic Drive Centrifugal Pump on multi-batch chemical lines.

-

High hardness and wear resistance under mixed lubrication

SSiC bearing hardness exceeds 2400 HV, maintaining surface stability under boundary-lubrication conditions created by light hydrocarbons, ensuring consistent operation of the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings even in solvent vapor zones.

-

Improved lubrication behavior for vaporizing fluids

Thermal conductivity of SSiC, rated at 70–120 W/m·K, accelerates heat dispersion at the bearing interface during vapor-phase transitions, allowing the CQB Stainless Steel Magnetic Drive Centrifugal Pump to maintain axial stability during solvent evaporation surges.

-

Dimensional reliability under process pressure variation

The flexural strength of SSiC, measured at 350–420 MPa, preserves bearing geometry when inlet pressure shifts occur, supporting the reliability of the CQB Stainless Steel Magnetic Drive Centrifugal Pump working in pressure-variable petrochemical transfer lines.

Technical Specifications of CQB Stainless Steel Magnetic Drive Centrifugal Pump

The CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings is engineered to provide controlled hydraulic performance, stable magnetic transmission, and corrosion-resistant operation across continuous chemical and solvent-handling environments. Its material composition, magnetic coupling characteristics, and bearing behavior support long-duty cycles in facilities that require predictable performance under temperature, load, and media variability.

| Property |

Specification |

| Pump Configuration |

Horizontal, single-stage centrifugal |

| Drive Type |

Sealless magnetic coupling |

| Magnet Material |

NdFeB or SmCo (up to 120°C media conditions) |

| Wetted Metal Material |

SS304 / SS316L |

| Bearing Material |

Sintered SiC (>2400 HV, 350–420 MPa) |

| Thermal Conductivity (Bearing) |

70–120 W/m·K |

| Corrosion Resistance Range |

Compatible with weak acids/alkalis, solvents, salts |

| Operating Temperature |

–20°C to 120°C |

| Maximum Working Pressure |

PN16 (typical chemical transfer conditions) |

| Magnetic Decoupling Margin |

Withstands up to 18% load fluctuation |

| Hydraulic Efficiency Range |

Up to 68% depending on model size |

| Surface Roughness (Wetted Area) |

≤ Ra 3.2 μm |

| Electrical Motor Compatibility |

Standard industrial induction motors |

| Containment Shell Type |

Stainless-steel isolation sleeve |

Dimensions of CQB Stainless Steel Magnetic Drive Centrifugal Pump

Packaging Method for ADCERAX® CQB Stainless Steel Magnetic Drive Centrifugal Pump

CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings is first sealed in a protective polyethylene cover to prevent moisture exposure and surface abrasion during handling. Each unit is then positioned inside a reinforced wooden enclosure with internal cushioning to stabilize the pump body throughout transportation. The final package is pallet-secured with industrial-grade straps to ensure safe international shipment and reliable arrival at the customer’s facility.

ADCERAX® CQB Stainless Steel Magnetic Drive Centrifugal Pump Resolves Critical Process Challenges in Industrial Chemical Systems

The CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings supports continuous chemical and solvent-handling operations where corrosion, leakage risk, and thermal variability create unstable hydraulic conditions. Its sealed magnetic transmission, stainless-steel wetted components, and SSiC bearing behavior allow the pump to maintain predictable performance in production environments that demand long operating cycles and minimal maintenance interruptions.

-

CQB Stainless Steel Magnetic Drive Centrifugal Pump in Continuous Fine-Chemical Feed and Transfer Systems

✅Key Advantages

1. Seal-less operation for long reactor campaigns

The CQB Stainless Steel Magnetic Drive Centrifugal Pump maintains closed-chamber operation during reactor campaigns that often extend beyond 72 hours without requiring seal inspection. In internal process trials, lines equipped with the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings showed a reduction in leakage-related interventions of more than 80% compared with legacy mechanical-seal pumps.

2. Stable flow under viscosity and temperature variation

When solvent viscosity shifts within a range of 1–10 mm²/s due to temperature changes, the CQB Stainless Steel Magnetic Drive Centrifugal Pump maintains a stable flow deviation band inside ±3% of the setpoint. This enables fine-chemical lines using the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings to run multi-step syntheses without repeated recalibration of dosing and circulation loops.

3. Bearing integrity under continuous mixed-media circulation

In continuous solvent and intermediate circulation, SSiC bearing surfaces in the CQB Stainless Steel Magnetic Drive Centrifugal Pump retain hardness above 2400 HV and flexural strength within 350–420 MPa after extended operation. Test runs showed that the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings can complete more than 2000 operating hours in mixed organic and diluted corrosive media before bearing clearance adjustment is required.

✅ ️Problem Solved

Fine-chemical plants often report that mechanical-seal pumps begin to leak after several hundred hours of continuous duty when exposed to solvent vaporization and fluctuating suction conditions, forcing unplanned stoppages and emergency cleaning. In one multipurpose reactor line, replacement of seal-based units with the CQB Stainless Steel Magnetic Drive Centrifugal Pump reduced seal-related stops from more than 10 events per year to fewer than 2 events per year. At the same time, feeding accuracy improved, with measured flow variation falling from around ±8% to approximately ±3% across typical viscosity and temperature shifts. By introducing the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings, the plant stabilized continuous campaigns, reduced corrective maintenance frequency, and maintained batch uniformity over longer production windows.

-

CQB Stainless Steel Magnetic Drive Centrifugal Pump for Pharmaceutical Solvent Circulation and Low-Toxicity Fluid Transfer

✅Key Advantages

1. Closed solvent loop for batch integrity

The CQB Stainless Steel Magnetic Drive Centrifugal Pump maintains a fully enclosed solvent path that prevents vapor release during circulation and recovery stages with typical operating temperatures between 20–80°C. In validation runs, solvent purity measured at the outlet of systems using the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings remained within 99.5% of the reference specification after repeated process cycles.

2. High-cycle endurance in cleaning and start–stop operation

Pharmaceutical lines often require more than 5–10 start–stop sequences per shift and frequent cleaning-in-place routines, which accelerate seal wear in conventional units. Test data from plants adopting the CQB Stainless Steel Magnetic Drive Centrifugal Pump show that the magnetic drive and bearing system can sustain over 50,000 start–stop cycles with stable performance when configured for solvent circulation duties.

3. Reduced cross-contamination risk during solvent changeover

During changeover between different solvent recipes, residual carryover in seal cavities and external leakage points is a known source of cross-contamination in traditional pumps. With the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings, internal hold-up volumes in the drive region are minimized and can be effectively flushed in less than 15 minutes under standard flow conditions, helping to keep cross-contamination signals below 0.1% in chromatographic checks.

✅ ️Problem Solved

A solvent-recovery line in a pharmaceutical facility experienced recurring vapor emissions and contamination alerts after only 6–9 months of mechanical-seal pump operation, triggering repeated investigations and extended cleaning. After replacing the existing units with the CQB Stainless Steel Magnetic Drive Centrifugal Pump, monitoring records showed a measurable drop in detected vapor levels near the skid and a reduction in contamination-related deviation reports by more than 70% over the following year. Batch documentation indicated that solvent purity at return points remained inside a ±0.5% specification band even after intensive multi-shift operation. By moving to the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings, the plant stabilized solvent circulation, extended maintenance intervals, and reduced the frequency of quality deviations linked to pumping equipment.

-

CQB Stainless Steel Magnetic Drive Centrifugal Pump for Hazard-Sensitive Petrochemical Transfer of Light Hydrocarbons

✅Key Advantages

1. Leak-free containment under vapor pressure fluctuation

Transfer of light hydrocarbons often produces vapor pressure swings of more than 0.3–0.5 MPa, which challenge traditional seal faces. The CQB Stainless Steel Magnetic Drive Centrifugal Pump maintains a sealed containment shell rated to PN16, allowing safe handling of these media without creating external vapor paths during normal pressure variation.

2. Stable operation during transient hydraulic and thermal loads

In petrochemical transfer lines, temperature can change from 20°C to 80°C during startup and shutdown, while flow demand may vary by more than 30% across different operating modes. Performance tests on the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings have shown that the magnetic coupling retains torque and flow stability within ±4% of the target curve during such transients, reducing the likelihood of nuisance trips.

3. Bearing reliability in low-viscosity hydrocarbon service

Light hydrocarbons often have kinematic viscosities close to 0.5–2 mm²/s, which provide limited lubrication for conventional bearings. The SSiC bearings in the CQB Stainless Steel Magnetic Drive Centrifugal Pump are designed to operate under these conditions, and field data indicate that bearing inspection intervals can exceed 2000 operating hours in continuous hydrocarbon transfer without loss of alignment or significant wear.

✅ ️Problem Solved

In a petrochemical loading system transferring light hydrocarbons to storage, mechanical-seal pumps had recorded multiple minor leakage events over a period of two years, each incident requiring safety investigation and temporary line shutdown. After the installation of the CQB Stainless Steel Magnetic Drive Centrifugal Pump, incident logs showed no leakage events attributable to pump containment during more than 12 months of operation, despite frequent pressure and temperature fluctuations. Flow monitoring on the line indicated that delivery remained within approximately ±4% of the design value during normal and transient conditions, improving planning confidence for tank-farm operations. By deploying the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings, the operator strengthened compliance with internal safety protocols while reducing disruption from seal-related maintenance and inspection activities.

ADCERAX® User Guide for the CQB Stainless Steel Magnetic Drive Centrifugal Pump

The CQB Stainless Steel Magnetic Drive Centrifugal Pump is engineered for industrial processes that demand predictable flow behavior, sealed operation, and appropriate handling practices throughout installation and service life. To help ensure stable operation, extended component longevity, and proper integration into existing systems, the guidelines below highlight essential user instructions relevant to both continuous-duty plants and batch-based operations. These recommendations reflect the mechanical, hydraulic, and material characteristics of the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings, ensuring users can operate the equipment with confidence in demanding chemical and solvent-handling environments.

-

Installation Requirements for Stable Hydraulic Performance

1. Proper inlet conditions must be verified before commissioning.

Maintaining consistent suction head prevents vapor formation and supports smooth transfer behavior under varying operating loads. This requirement ensures the CQB Stainless Steel Magnetic Drive Centrifugal Pump performs predictably in systems with fluctuating line pressure.

2. Base alignment and structural rigidity must be checked prior to startup.

Excessive vibration from misaligned mounting surfaces can increase internal wear and diminish pump efficiency over long-duty cycles. Ensuring rigid installation helps maintain the hydraulic stability expected from the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings.

3. System flushing should be completed before media introduction.

Residual particles or incompatible fluids left in the pipeline may cause premature abrasion or affect internal flow passages. This preparation step supports a contamination-free environment for the CQB Stainless Steel Magnetic Drive Centrifugal Pump during initial operation.

-

Operating Guidelines for Continuous-Duty Chemical Processes

1. Temperature and viscosity ranges must remain within recommended limits.

Operating outside expected fluid characteristics can increase load on the magnetic coupling and reduce transfer stability. Maintaining controlled conditions helps the CQB Stainless Steel Magnetic Drive Centrifugal Pump sustain consistent circulation in demanding fine-chemical applications.

2. Avoid frequent dry-running events during transitional process steps.

Dry running elevates internal temperature and reduces the lifespan of the SSiC bearing set. Protecting the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings from these events ensures reliable performance across long cycles.

3. Monitor system pressure to prevent sudden spikes or cavitation.

Unstable hydraulic states may cause temporary decoupling or reduced flow uniformity across reactors and feed lines. Proper pressure management supports steady-state operation of the CQB Stainless Steel Magnetic Drive Centrifugal Pump throughout production.

-

Maintenance Practices for Long-Term Component Integrity

1. Periodic bearing condition checks should be incorporated into routine inspections.

SSiC bearings exhibit high hardness and chemical durability, yet they still require interval-based evaluation under extended duty cycles. Scheduled assessment preserves the internal stability of the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings.

2. Magnetic coupling clearance must be examined for debris accumulation.

Foreign particles may interfere with rotation efficiency or produce minor vibration signatures. Maintaining a clean coupling environment ensures long-term transmission stability in the CQB Stainless Steel Magnetic Drive Centrifugal Pump.

3. Lubrication-free operation does not eliminate the need for housings inspection.

Even without traditional mechanical seals, operational residue may develop around static containment components. Regular visual checks enhance the long-term sealing effectiveness of the CQB Stainless Steel Magnetic Drive Centrifugal Pump.

-

Safety Considerations for Hazardous or Volatile Media Handling

1. Confirm full containment integrity before transferring volatile liquids.

The sealed design is intended to eliminate vapor escape, but system fittings and flanges must be inspected for compatibility. This ensures the CQB Stainless Steel Magnetic Drive Centrifugal Pump with SSiC Bearings maintains a fully enclosed environment during hydrocarbon or solvent handling.

2. Implement shutdown protocols during abnormal pressure or temperature excursions.

Rapid response prevents stress accumulation within the isolation shell and coupling components. Following these procedures preserves the operational safety of the CQB Stainless Steel Magnetic Drive Centrifugal Pump.

3. Ensure operators are trained on emergency handling procedures.

Proper understanding of isolation features supports safe behavior during unexpected process conditions. Skilled operation contributes to safe integration of the CQB Stainless Steel Magnetic Drive Centrifugal Pump in sensitive chemical environments.