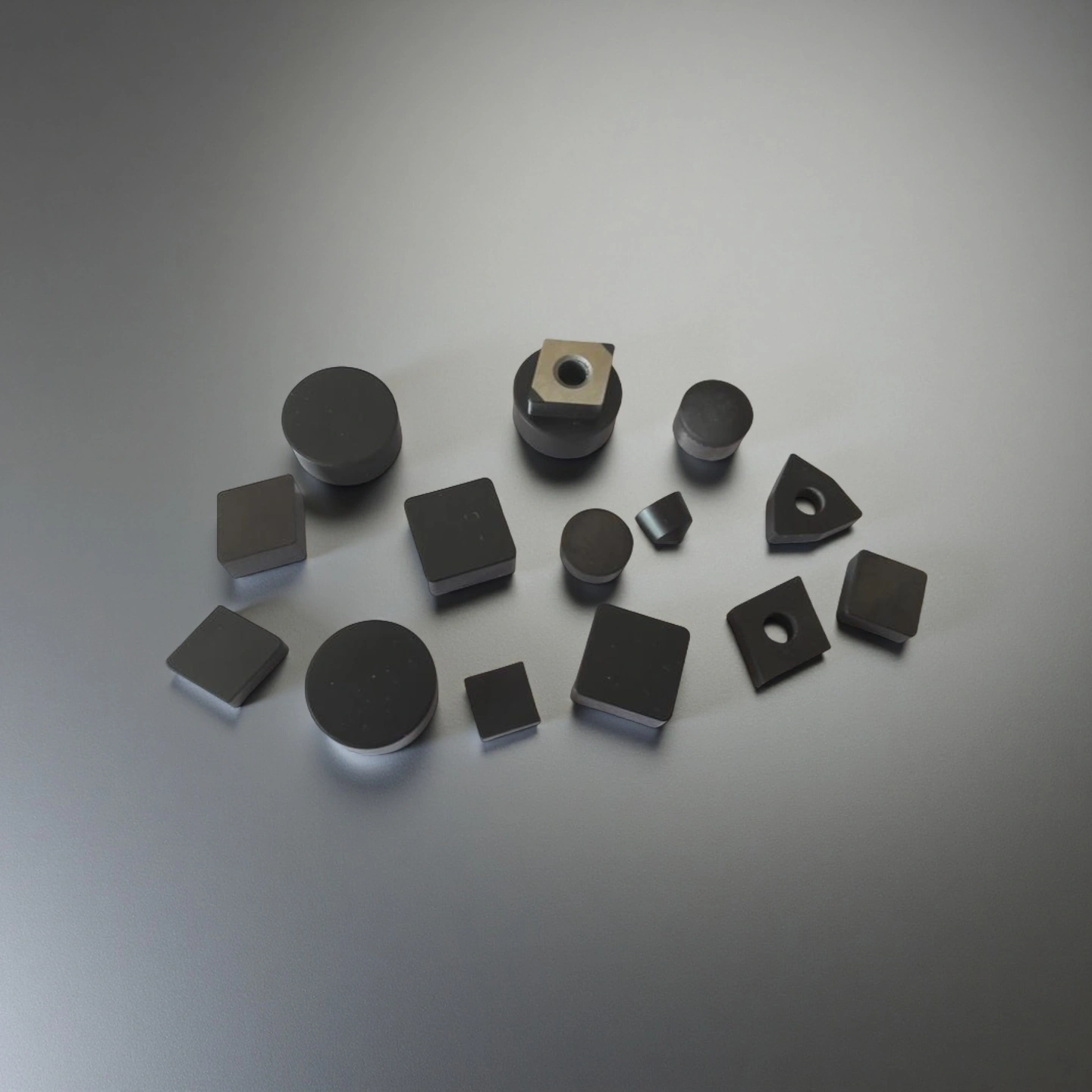

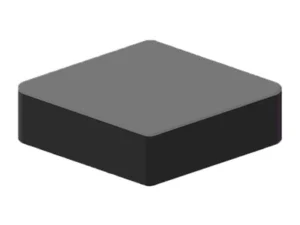

Cubic boron nitride cutting tools—often called PCBN inserts, solid CBN tips, or CBN-tipped brazed tools—are superhard tools designed for hard turning and high-temperature machining. They maintain edge strength where hardened steels (≈55–68 HRC), cast irons, and powder-metallurgy parts would quickly wear out carbide or many ceramics.

Cubic Boron Nitride Cutting Tools Benefits

-

Edge Integrity at High Temperature

Maintains hardness above 4,000 HV up to 1,000 °C; optimized micro-hone/T-land edge forms resist crater wear in continuous hard turning (58–64 HRC). -

Tough Grades for Interrupted Cuts

Metal-binder PCBN grades absorb cutting shocks on cast iron or PM parts, cutting edge-failure rate by 20–40 % versus full-ceramic grades. -

Surface Finish Control

Fine-grain PCBN (1–5 µm) and tight R tolerance ±0.02 mm deliver Ra < 0.4 µm and roundness < 10 µm in finish turning. -

Cost-per-Part Efficiency

Optimized grade–geometry pairing extends tool life 2–5× vs. carbide while stabilizing cycle time and reducing changeovers. -

Dimensional Traceability

Each insert laser-coded and lapped to ±0.005 mm for repeatable R/thickness, supporting Cp/Cpk > 1.6 in volume production.

Cubic Boron Nitride (CBN) Cutting Tools Properties

| Parameter | Typical Range/Value | Description & Application Relevance |

|---|---|---|

| Hardness (Vickers HV) | 4,500 – 5,000 HV | Second only to diamond; ensures wear resistance at ≥ 58 HRC materials such as bearing steel, tool steel, and hardened gears. |

| Thermal Stability | Up to 1,200 °C in air | Retains cutting-edge strength at elevated temperatures where carbide and ceramics soften or oxidize. |

| Thermal Conductivity | 80 – 130 W/m·K | Enables effective heat dissipation from cutting zone, improving finish and tool life in dry/minimum-fluid cutting. |

| Coefficient of Thermal Expansion | (4.5 – 5.5) × 10⁻⁶ /K | Low expansion ensures dimensional stability and reduced distortion during high-speed cutting. |

| Fracture Toughness (KIC) | 5 – 8 MPa·m¹ᐟ² | Balanced strength against micro-chipping, especially for interrupted cuts or rough cast surfaces. |

| Density | 3.45 – 3.48 g/cm³ | Moderate density suitable for brazed or solid insert configurations. |

| CBN Volume Fraction | 45 – 90 vol% | Higher CBN → better wear resistance for continuous cuts; lower → higher toughness for interrupted cuts. |

| Workpiece Hardness Range | 45 – 70 HRC | Ideal for hardened steels, gray/nodular cast iron, and powder-metallurgy components. |

| Achievable Surface Roughness (Ra) | 0.2 – 0.8 µm | Depending on radius and feed rate, suitable for finish or semi-finish hard turning. |

| Expected Tool Life Extension | 2 – 5× vs. Coated Carbide | Proven in production lines for gears, bearings, and hydraulic parts. |

CBN Cutting Tools Specifications

| Cubic Boron Nitride Cutting Tools | ||||||

| Item NO. | ISO Standard Designation | Cutting Edge Length(mm) | Inner Cutting Circle Dia.(mm) | Thickness(mm) | Standing edge | |

| AT-CNGN1204 | CNGN1204 | 12.9 | 12.7 | 4.76 | S01020 S02015 S02020 |

|

| AT-CNGN1207 | CNGN1207 | 12.9 | 12.7 | 7.94 | ||

| AT-CNGN1608 | CNGN1608 | 16.1 | 15.875 | 8.0 | ||

| AT-DNGN1104 | DNGN1104 | 11.6 | 9.525 | 4.76 | T01020 T02020 S01020 S02020 |

|

| AT-RCGV0605 | RCGV0605 | 6 | 6.35 | 5.00 | S01020 S02020 S03025 S05020 |

|

| AT-RCGV0907 | RCGV0907 | 9 | 9.525 | 7.94 | ||

| AT-RCGV1207 | RCGV1207 | 12 | 12.7 | 7.94 | ||

| AT-RCGV1510 | RCGV1510 | 15 | 15.875 | 10.00 | ||

| AT-RCGV1910 | RCGV1910 | 19 | 19.05 | 10.00 | ||

| AT-RCGV2012 | RCGV2012 | 20 | 20 | 12.00 | ||

| AT-RCGV2512 | RCGV2512 | 25 | 25.4 | 12.00 | ||

| AT-RCGX0605 | RCGX0605 | 6.35 | 6.35 | 5 | S01020 S02020 S03025 S05020 |

|

| AT-RCGX0907 | RCGX0907 | 9.525 | 9.525 | 7.94 | ||

| AT-RCGX1207 | RCGX1207 | 12.7 | 12.7 | 7.94 | ||

| AT-RCGV1510 | RCGV1510 | 15.875 | 15.875 | 10 | ||

| AT-RCGX1910 | RCGX1910 | 19.05 | 19.05 | 10 | ||

| AT-RNGN090400 | RNGN090400 | 9 | 9.525 | 4.76 | T01020 T02020 S01020 S02020 S03025 S05020 |

|

| AT-RNGN120400 | RNGN120400 | 12 | 12.7 | 4.76 | ||

| AT-RNGN120700 | RNGN120700 | 12 | 12.7 | 7.94 | ||

| AT-RNGN150700 | RNGN150700 | 15 | 15.875 | 7.94 | ||

| AT-RNGN160800 | RNGN160800 | 16 | 16 | 8 | ||

| AT-RNGN190700 | RNGN190700 | 19 | 19.05 | 7.94 | ||

| AT-RNGN201000 | RNGN201000 | 20 | 20 | 10 | ||

| AT-RNGN250700 | RNGN250700 | 25 | 25.4 | 7.94 | ||

| AT-RNGN251000 | RNGN251000 | 25 | 25.4 | 10 | ||

| AT-RNGN251200 | RNGN251200 | 25 | 25.4 | 12 | ||

| AT-SCGN0903 | SCGN0903 | 9.525 | 9.525 | 3.18 | T01020 T02020 S01020 S02020 |

|

| AT-SCGN0904 | SCGN0904 | 9.525 | 9.525 | 4.76 | ||

| AT-SCGN1204 | SCGN1204 | 12.7 | 12.7 | 4.76 | ||

| AT-SNGN0903 | SNGN0903 | 9.525 | 9.525 | 3.18 | T01020 T02020 S01020 S02020 |

|

| AT-SNGN0904 | SNGN0904 | 9.525 | 9.525 | 4.76 | ||

| AT-SNGN1204 | SNGN1204 | 12.7 | 12.7 | 4.76 | ||

| AT-SNGN1208 | SNGN1208 | 12.7 | 12.7 | 8 | ||

| AT-SNGN1608 | SNGN1608 | 16 | 16 | 8 | ||

| AT-SNGN2010 | SNGN2010 | 20 | 20 | 10 | ||

| AT-TNGN1103 | TNGN1103 | 11 | 6.35 | 3.18 | T01020 T02020 S01020 S02020 |

|

| AT-TNGN1604 | TNGN1604 | 16.5 | 9.525 | 4.76 | ||

| AT-TNGN1603 | TNGN1603 | 16.5 | 9.525 | 3.18 | ||

| AT-WNGN0804 | WNGN0804 | 8.7 | 12.7 | 4.76 | T01020 T02020 S01020 S02020 |

|

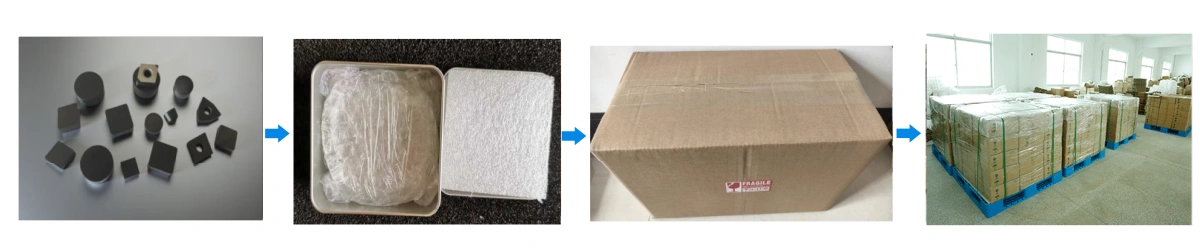

CBN Carbide Cutting Tools Packaging

- Each cutting tool is individually packed in anti-static foam and sealed for protection.