An High purity Alumina Deposition Ring is a high-purity alumina ceramic ring installed inside PVD, CVD or other vacuum coating chambers. It sits around the substrate or at the edge of the process zone and is machined to match the chamber geometry so that it guides process gas flow, defines the coating aperture and shields nearby metal parts from direct deposition.

High Purity Alumina Deposition Ring Benefits

-

Process-oriented ring geometry – The Alumina Deposition Ring can be machined so that its cross-section, gas ports, cut-outs and step features follow the original chamber blueprint, including nearby shields and electrodes. This geometry match helps keep gas residence time, plasma boundary and coating aperture consistent after every replacement, which means less process re-tuning and more repeatable coating profiles over long production campaigns.

-

High-temperature stability – The alumina body keeps its shape and electrical insulation over repeated deposition and cleaning cycles within the typical alumina use range, so ring flatness and fit do not drift when the chamber is ramped up and down. This allows the ring to stay aligned with fixtures and substrates, reducing mechanical stress on clamps and seals and supporting stable film properties run after run.

-

Low particle and erosion behaviour – The dense, fine-grained alumina used for the deposition ring has high hardness and wear resistance compared with common refractory linings, so it is less prone to edge chipping and surface erosion in the coating zone. Combined with controlled chamfers and appropriate surface finishing, this helps limit loose particles inside the chamber and supports lower defect density on coated parts.

-

Electrical insulation in high-voltage environments – Alumina’s high dielectric strength allows the Alumina Deposition Ring to sit close to bias electrodes, powered targets or feedthroughs while maintaining the isolation gap to grounded metal parts. This reduces the risk of surface tracking and arc paths around the ring, giving process engineers more margin when setting bias voltage, power levels and pulse parameters.

-

Compatibility with vacuum and reactive gases – The Alumina Deposition Ring resists attack from typical process gases and vapours used in metal and dielectric film deposition, as well as from many acid or alkaline solutions used during chamber cleaning. Because the ceramic is chemically inert and contains no metallic binders, it contributes little contamination to the chamber environment, helping to keep film composition and optical or electrical properties within the specified window.

High Purity Alumina Ceramic Deposition Ring Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

High Purity Alumina Ceramic Deposition Ring Specifications

| Alumina Deposition Ring | ||

| Item No. | Diameter (mm) | Thickness (mm) |

| AT-HP-MH01 | Customize | |

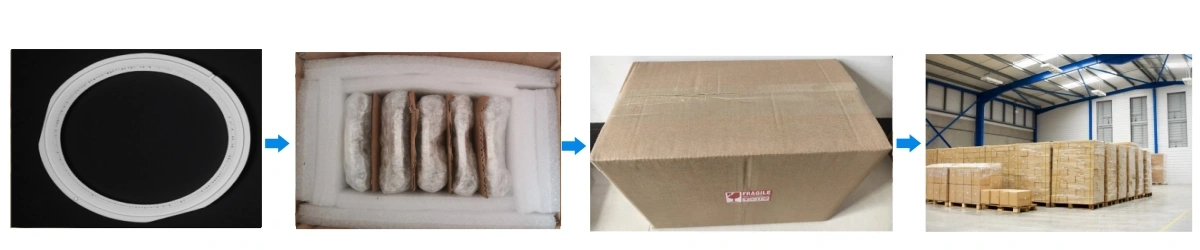

High Purity Alumina Deposition Ring Packaging

- Each Alumina Deposition Ring is wrapped with soft contact protection around the sealing and locating surfaces to reduce edge chipping during transport.