High strength silicon nitride substrate is a Si₃N₄ ceramic base plate engineered for power-electronic packaging. It combines a stiff, low-CTE ceramic core with high dielectric integrity and is typically prepared for AMB/DBC copper metallization so SiC/IGBT devices can be solder- or braze-attached and survive thermal and power cycling.

High Strength Silicon Nitride Substrate Benefits

-

High bending strength resists cracking under reflow and thermal cycling

Flexural strength above 600 MPa prevents substrate fractures during soldering and −40 °C to 150 °C cycling. This reduces die attach failures and extends module service life. -

75–90 W/m·K thermal conductivity enables compact and cooler module design

Efficient heat transfer lowers junction-to-case resistance and supports high power density layouts. It helps maintain safe chip temperatures in SiC and IGBT devices. -

Dielectric strength ≥15 kV/mm supports thinner insulation and high-voltage safety

High insulation capability allows reduced substrate thickness without compromising creepage and clearance. Suitable for 800V EV systems, PV inverters, and industrial drives. -

Low CTE close to SiC minimizes thermal stress on copper and die interfaces

With 2.9–3.2×10⁻⁶/K, the CTE matches semiconductor and metallization layers. This reduces solder fatigue, delamination, and warpage under rapid heating and cooling. -

Precise flatness and thickness tolerance enhance metallization and solder bonding

Tight control of thickness (±0.05–0.10 mm) ensures uniform copper wetting and brazing quality. It stabilizes thermal performance and reduces assembly scrap rates.

High Strength Silicon Nitride Substrate Properties

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

High Strength Silicon Nitride Substrate Specifications

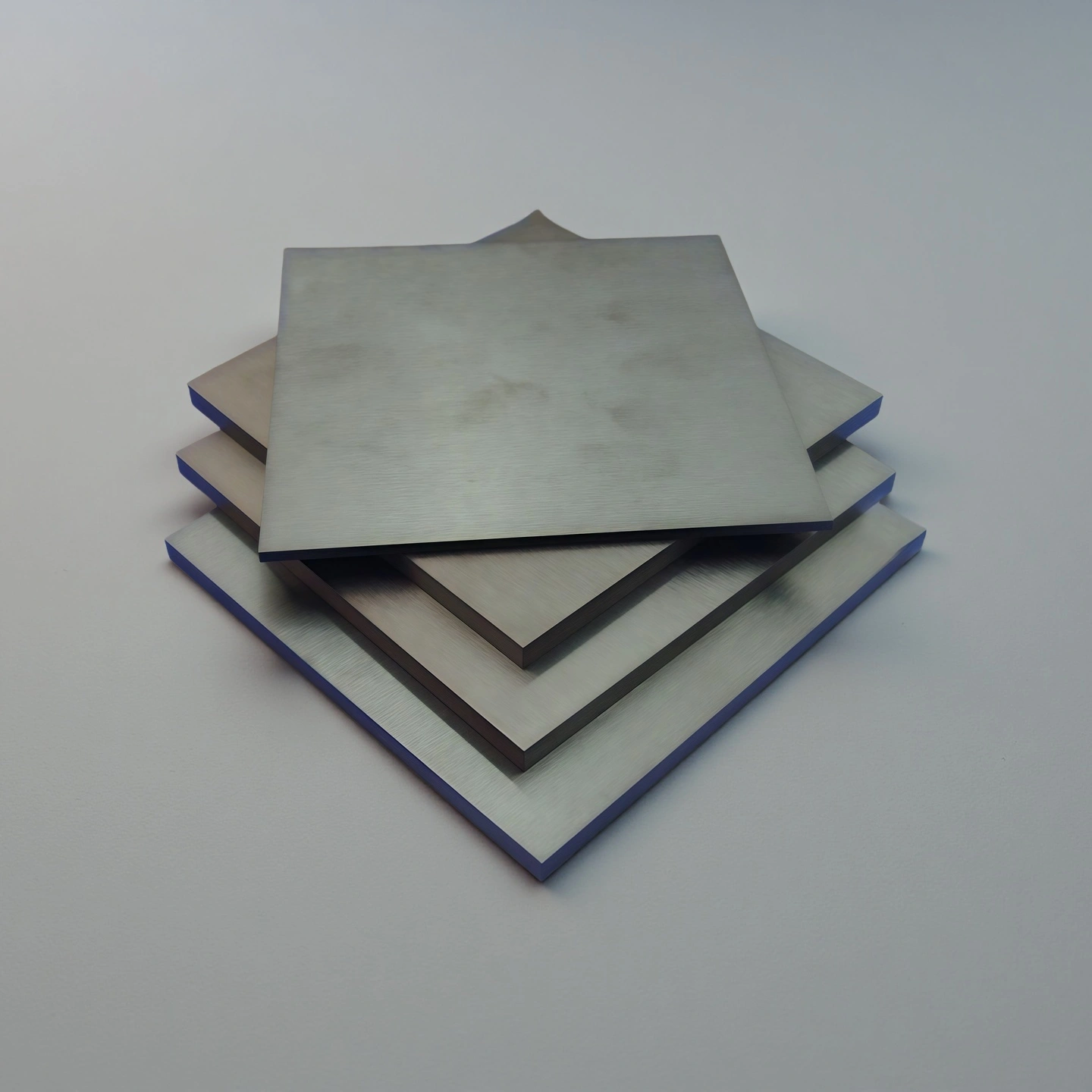

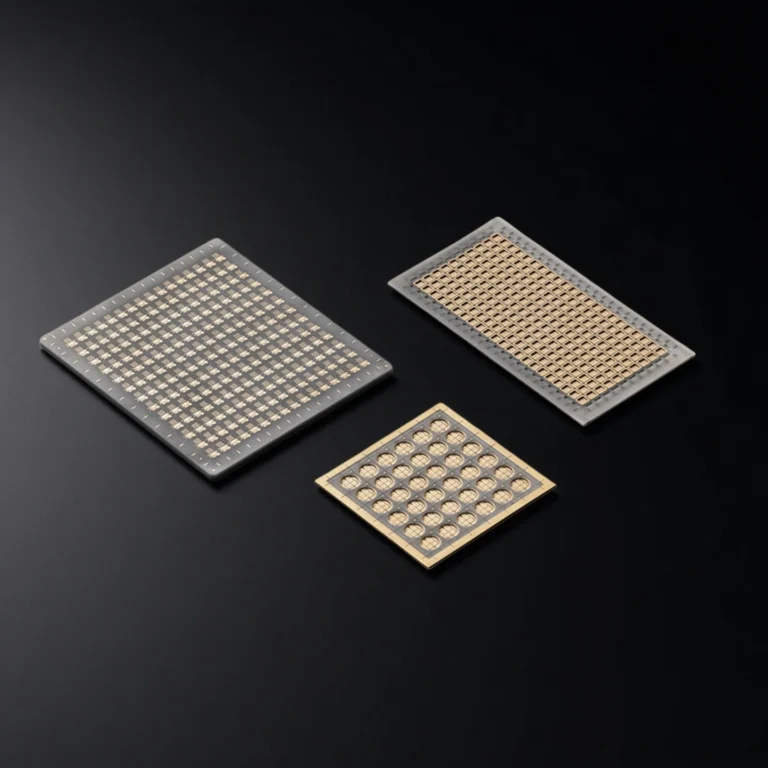

Type 1: Rectangular High Strength Silicon Nitride Substrate

| Rectangular Silicon Nitride Substrate | |||

| Item No. | Length(mm) | Width (mm) | Thickness (mm) |

| AT-DHG-JB001 | 10 | 10 | 0.32 |

| AT-DHG-JB002 | 20 | 20 | 0.32 |

| AT-DHG-JB003 | 30 | 30 | 4.0 |

| AT-DHG-JB004 | 40 | 40 | 0.5 |

| AT-DHG-JB005 | 50 | 50 | 0.32 |

| AT-DHG-JB006 | 50 | 50 | 0.635 |

| AT-DHG-JB007 | 50 | 50 | 1.0 |

| AT-DHG-JB008 | 50 | 50 | 2.0 |

| AT-DHG-JB009 | 50 | 50 | 4.0 |

| AT-DHG-JB010 | 50 | 50 | 9.0 |

| AT-DHG-JB011 | 100 | 100 | 0.32 |

| AT-DHG-JB012 | 100 | 100 | 0.5 |

| AT-DHG-JB013 | 100 | 100 | 0.635 |

| AT-DHG-JB014 | 100 | 100 | 1.0 |

| AT-DHG-JB015 | 100 | 100 | 4.0 |

| AT-DHG-JB016 | 100 | 100 | 9.0 |

| AT-DHG-JB017 | 114 | 114 | 0.32 |

| AT-DHG-JB018 | 114 | 114 | 0.5 |

| AT-DHG-JB019 | 114 | 114 | 0.635 |

| AT-DHG-JB020 | 114 | 114 | 1.0 |

| AT-DHG-JB021 | 190 | 138 | 0.32 |

| AT-DHG-JB022 | 190 | 138 | 0.5 |

| AT-DHG-JB023 | 190 | 138 | 0.635 |

| AT-DHG-JB024 | 190 | 138 | 1.0 |

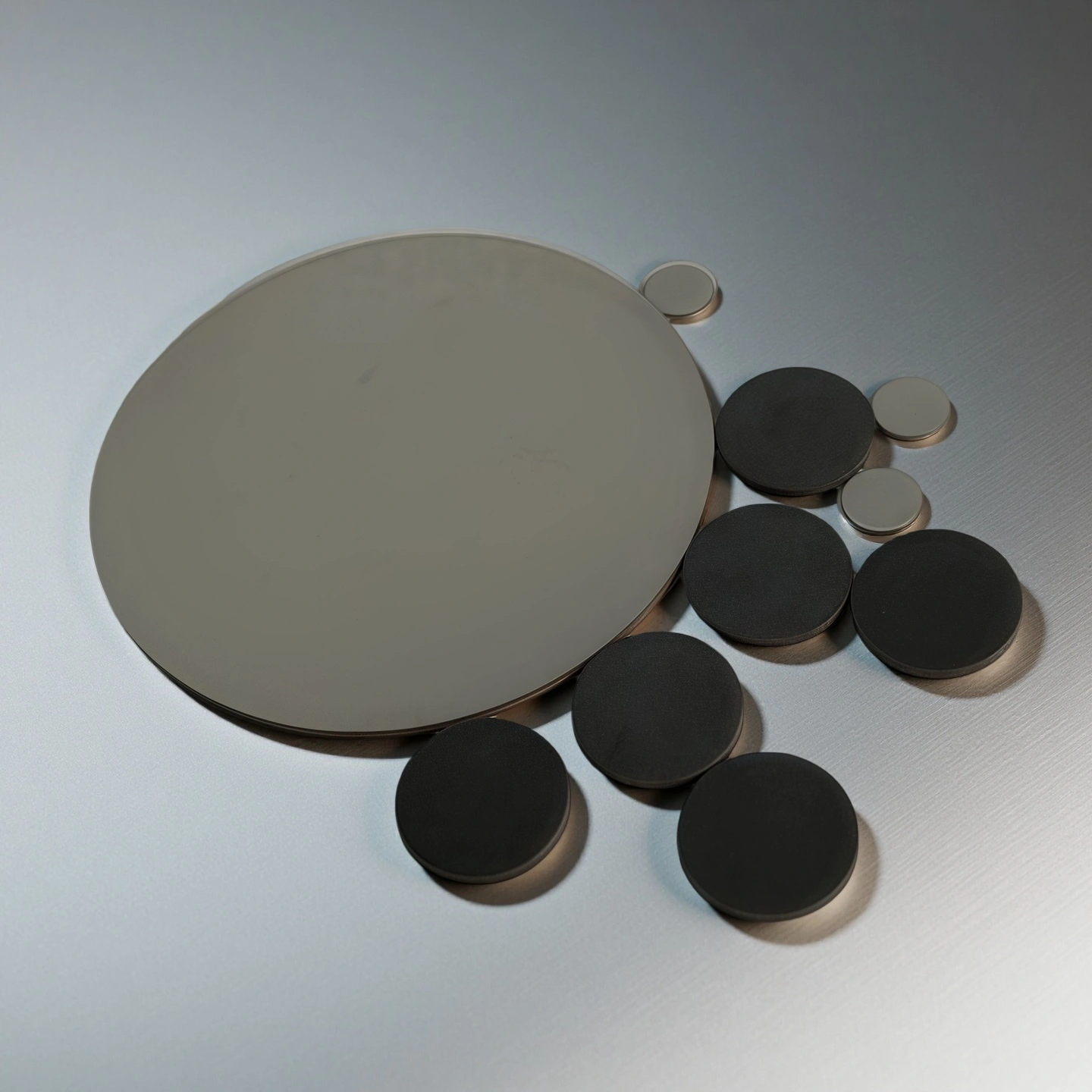

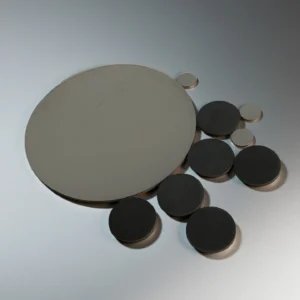

Type 2: Round High Strength Silicon Nitride Substrate

| Round Silicon Nitride Substrate | ||

| Item No. | Diameter(mm) | Thickness (mm) |

| AT-DHG-JB025 | 5 | 0.25 |

| AT-DHG-JB026 | 5 | 0.32 |

| AT-DHG-JB027 | 5 | 0.625 |

| AT-DHG-JB028 | 5 | 1 |

| AT-DHG-JB029 | 10 | 0.25 |

| AT-DHG-JB030 | 10 | 0.32 |

| AT-DHG-JB031 | 10 | 0.625 |

| AT-DHG-JB032 | 10 | 1 |

| AT-DHG-JB033 | 20 | 0.25 |

| AT-DHG-JB034 | 20 | 0.32 |

| AT-DHG-JB035 | 20 | 0.625 |

| AT-DHG-JB036 | 20 | 1 |

| AT-DHG-JB037 | 40 | 0.25 |

| AT-DHG-JB038 | 40 | 0.32 |

| AT-DHG-JB039 | 40 | 0.625 |

| AT-DHG-JB040 | 40 | 1 |

| AT-DHG-JB041 | 50 | 0.25 |

| AT-DHG-JB042 | 50 | 0.32 |

| AT-DHG-JB043 | 50 | 0.625 |

| AT-DHG-JB044 | 50 | 1 |

| AT-DHG-JB045 | 100 | 0.32 |

| AT-DHG-JB046 | 100 | 1 |

| AT-DHG-JB047 | 100 | 2 |

| AT-DHG-JB048 | 150 | 0.32 |

| AT-DHG-JB049 | 150 | 1 |

| AT-DHG-JB050 | 150 | 2 |

| AT-DHG-JB051 | 150 | 20 |

High Strength Silicon Nitride Substrate Packaging

- Each substrate is sealed in anti-static film

- Packed in foam-lined hard cartons to prevent breakage

![]()