Magnesium oxide crucible is a high-temperature container made from refractory-grade MgO (magnesia), designed for melting, calcining, or holding materials under extreme heat or alkaline conditions. It belongs to the family of oxide ceramics known for chemical inertness, high melting point (≈ 2800 °C), and resistance to basic slags or metal oxides

Advantages of the MgO Ceramic Crucible

- Alkaline melt compatibility — MgO matrix resists basic slags where Al₂O₃ picks up chemistry.

- Low contamination — high-purity MgO reduces silica/alumina ingress in purity-critical syntheses.

- Shape coverage — cylindrical/conical/boat geometries plus lids improve handling and volatilization control.

- Dimensional repeatability — managed OD/ID/wall tolerances for fixture fit and thermal cycling.

- Thick-wall options — enhanced integrity for larger charges and longer soaks.

Magnesium Oxide Crucibles Properties

1. High Purity Magnesium Oxide Crucibles

| Properties | Unit | Value |

| Material | % | 99 MgO |

| Density | g/m³ | 3.5 |

| Bulk Density | g/m³ | 2.8 |

| ApparentPorosity | % | 20 |

| Compressive Strength | MPa | 50 |

| FlexuralStrength | MPa | 16 |

| Refractoriness | SK | 42< |

| Thermal Conductivity | W/(m.K) | 5 |

| Coefficient of thermal expansion (20~1000℃) | 10-6/K | 13 |

| Operating temperature | Max (℃) | 2200 |

| Room temperature | Room temperature (℃) | 1800 |

2. Chemical Composition of Magnesium/Magnesia–Alumina Crucibles (%)

| Type | MgO | SiO₂ | Al₂O₃ | CaO | Fe₂O₃ |

|---|---|---|---|---|---|

| M Type (Magnesia) | ≥97.5 | ≤0.70 | ≤0.10 | ≤1.10 | ≤0.46 |

| MA Type (Magnesia–Alumina) | ≥74.5 | ≤0.74 | ≤22.2 | ≤1.20 | ≤0.51 |

2. Physical Properties of Magnesium/Magnesia–Alumina Crucible

| Property | Unit | M Type (Magnesia) | MA Type (Magnesia–Alumina) |

|---|---|---|---|

| Porosity | % | 14–19 | 18–22 |

| Cold Crushing Strength (at room temp.) | MPa | ≥19.6 | ≥14.7 |

| Thermal Expansion Coefficient (20–1300 °C) | ×10⁻⁶ /K | ≤13 | ≤9 |

| Thermal Shock Resistance (cycles at 1200 °C) | N | ≥40 | ≥40 |

| Bulk Density | kg/m³ | 2.9–3.1 × 10³ | 2.8–3.05 × 10³ |

| Maximum Service Temperature | °C | 1750 | 1750 |

Specifications of MgO Crucibles

Type 1: Cylindrical Magnesium Oxide Crucible

| Cylindrical Magnesium Oxide Crucible | ||||

| Item | Outer Diameter(mm) | Inner Diameter(mm) | Height(mm) | MgO(%) |

| AT-MG-GG1001 | 7.6 | 5.5 | 4.7 | 99 |

| AT-MG-GG1002 | 10 | 7 | 5 | 99 |

| AT-MG-GG1003 | 12 | 8.5 | 27.5 | 99 |

| AT-MG-GG1004 | 15 | 12 | 6 | 99 |

| AT-MG-GG1005 | 18.5 | 14.5 | 5 | 99 |

| AT-MG-GG1006 | 21 | 19 | 54 | 99 |

| AT-MG-GG1007 | 23 | 19 | 80 | 99 |

| AT-MG-GG1008 | 25 | 21 | 50 | 99 |

| AT-MG-GG1009 | 30 | 22 | 25 | 99 |

| AT-MG-GG1010 | 30 | 25 | 92 | 99 |

| AT-MG-GG1011 | 32 | 26 | 100 | 99 |

| AT-MG-GG1012 | 35 | 30 | 50 | 99 |

| AT-MG-GG1013 | 40 | 31 | 59 | 99 |

| AT-MG-GG1014 | 40 | 31 | 70 | 99 |

| AT-MG-GG1015 | 45 | 33 | 70 | 99 |

| AT-MG-GG1016 | 48 | 42 | 68 | 99 |

| AT-MG-GG1017 | 50 | 40 | 115 | 99 |

| AT-MG-GG1018 | 50 | 40 | 143 | 99 |

| AT-MG-GG1019 | 60 | 50 | 100 | 99 |

| AT-MG-GG1020 | 68.5 | 60 | 107.5 | 99 |

| AT-MG-GG1021 | 70 | 60 | 110 | 99 |

| AT-MG-GG1022 | 85 | 72 | 13 | 99 |

| AT-MG-GG1023 | 99 | 92 | 130 | 99 |

| AT-MG-GG1024 | 107 | 82 | 128 | 99 |

Type 2: Square Magnesium Oxide Crucible

| Square Magnesium Oxide Crucible | ||||

| Item | Outer Diameter(mm) | Inner Diameter(mm) | Height(mm) | MgO(%) |

| AT-MG-GG2001 | 27 | 25 | 21 | 99 |

| AT-MG-GG2002 | 50 | 24 | 20 | 99 |

| AT-MG-GG2003 | 77 | 63 | 19 | 99 |

| AT-MG-GG2004 | 99 | 39 | 18 | 99 |

| AT-MG-GG2005 | 116 | 46 | 34 | 99 |

| AT-MG-GG2006 | 148 | 33 | 22 | 99 |

| AT-MG-GG2007 | 149 | 33 | 22 | 99 |

Type 3: Magnesium Crucibles /Magnesium-aluminum Crucibles

| Magnesium Crucibles /Magnesium-aluminum Crucibles | |||||

| Item NO. | Outer Diameter(mm) | Inner Diameter(mm) | Outer Height(mm) | Inner Height(mm) | Volume(kg) |

| AT-M(MA)-1001 | 42 | 30 | 60 | 54 | 0.2 |

| AT-M(MA)-1002 | 50 | 37 | 100 | 93 | 0.3 |

| AT-M(MA)-1003 | 42 | 26 | 140 | 130 | 0.4 |

| AT-M(MA)-1004 | 55 | 35 | 135 | 120 | 0.5 |

| AT-M(MA)-1005 | 70 | 50 | 100 | 80 | 0.7 |

| AT-M(MA)-1006 | 70 | 50 | 140 | 125 | 1 |

| AT-M(MA)-1007 | 100 | 80 | 100 | 85 | 1.2 |

| AT-M(MA)-1008 | 100 | 80 | 150 | 140 | 1.3 |

| AT-M(MA)-1009 | 70 | 50 | 195 | 185 | 1.5 |

| AT-M(MA)-1010 | 80 | 60 | 145 | 135 | 1.8 |

| AT-M(MA)-1011 | 85 | 70 | 165 | 150 | 2 |

| AT-M(MA)-1012 | 118 | 90 | 180 | 150 | 4.5 |

| AT-M(MA)-1013 | 130 | 106 | 200 | 180 | 8.5 |

| AT-M(MA)-1014 | 130 | 106 | 225 | 200 | 9.5 |

| AT-M(MA)-1015 | 135 | 110 | 230 | 220 | 11 |

| AT-M(MA)-1016 | 140 | 116 | 245 | 220 | 13 |

| AT-M(MA)-1017 | 150 | 120 | 240 | 225 | 14 |

| AT-M(MA)-1018 | 160 | 130 | 225 | 210 | 15 |

| AT-M(MA)-1019 | 150 | 120 | 300 | 285 | 18 |

| AT-M(MA)-1020 | 160 | 130 | 280 | 265 | 20 |

| AT-M(MA)-1021 | 170 | 140 | 280 | 265 | 23 |

| AT-M(MA)-1022 | 160 | 130 | 335 | 315 | 24 |

| AT-M(MA)-1023 | 175 | 140 | 325 | 300 | 25 |

| AT-M(MA)-1024 | 180 | 150 | 340 | 300 | 28 |

| AT-M(MA)-1025 | 175 | 140 | 380 | 355 | 30 |

| AT-M(MA)-1026 | 215 | 165 | 300 | 270 | 35 |

| AT-M(MA)-1027 | 230 | 178 | 330 | 285 | 50 |

| AT-M(MA)-1028 | 230 | 178 | 380 | 340 | 60 |

| AT-M(MA)-1029 | 245 | 200 | 410 | 370 | 75 |

| AT-M(MA)-1030 | 250 | 205 | 520 | 480 | 120 |

| AT-M(MA)-1031 | 335 | 285 | 520 | 475 | 200 |

| AT-M(MA)-1032 | 400 | 330 | 645 | 600 | 300 |

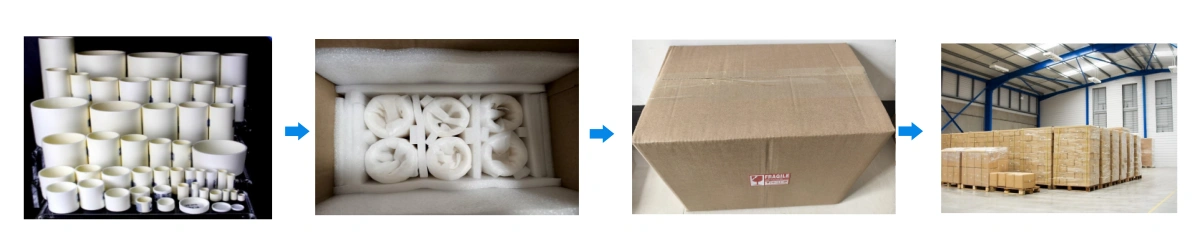

Magnesium Oxide Crucible Packaging

- Cleanroom bag + cushioned tray to limit abrasion and dust.

- Lid and stand packed separately with corner protection.

- Outer carton with foam blocks; large sizes may use inner compartments.