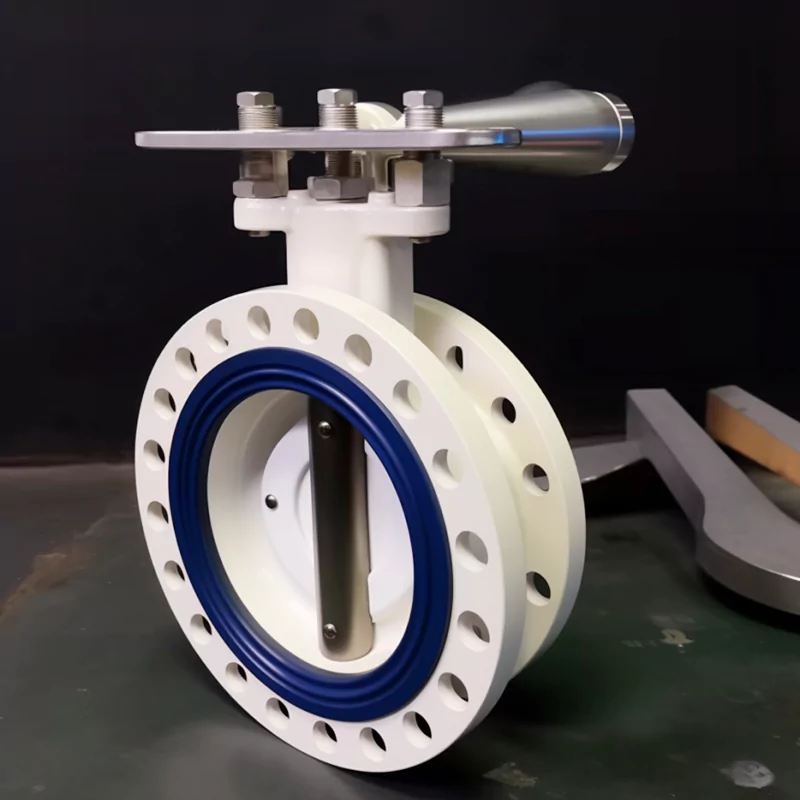

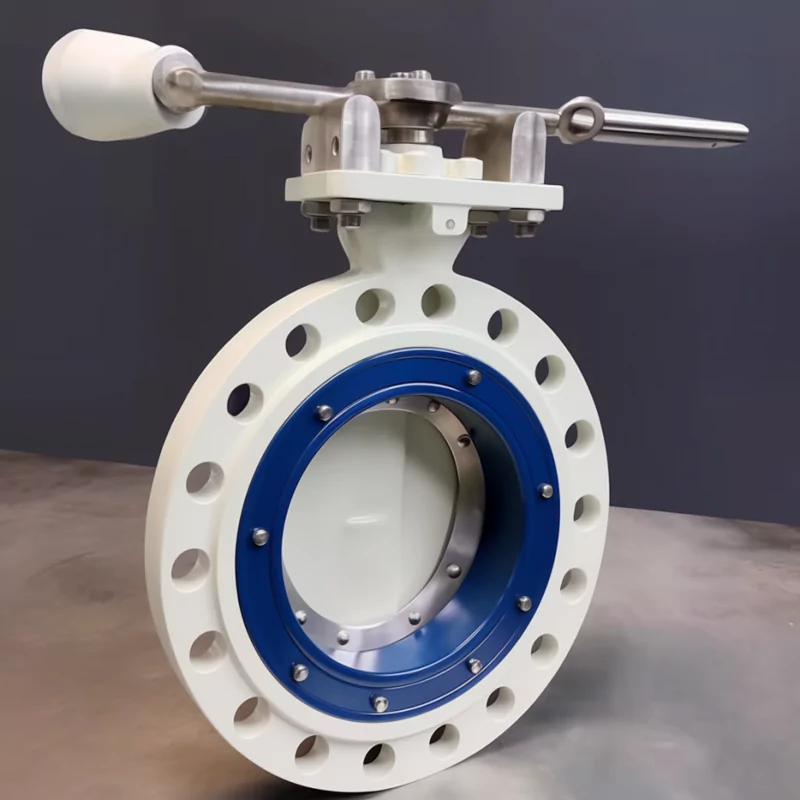

ADCERAX® Manual Zirconia Ceramic Butterfly Valve has a compact wafer-style body with a circular profile, typically made from cast steel, and a centrally mounted stem connected to a round zirconia ceramic disc. The disc surface appears smooth and dense, with a bright white or ivory tone that contrasts against the darker metallic housing. A handwheel or worm gear operator is fixed on the top, allowing visible manual adjustment of the stem. The overall structure is symmetrical and streamlined, with bolting holes evenly distributed around the flanged ends to support secure installation in industrial pipelines.

Features of Manual Zirconia Ceramic Butterfly Valve

- High Hardness 1200 HV: The zirconia disc reaches about 1200 HV, eight times higher than carbon steel, which minimizes wear in slurry pipelines. This hardness value enables extended service intervals beyond 12 months in ash transport lines.

- Flexural Strength 900–1200 MPa: With flexural strength up to 1200 MPa, the disc resists cracking under high particle impact. This mechanical resilience reduces replacement frequency by nearly 40% in mining operations.

- Service Lifetime Extension: Tests in lime slurry showed valve life exceeding 2× that of metal valves. Reduced downtime directly cuts maintenance costs by over USD 10,000/year in mid-scale plants.

- Acid and Alkali Stability: Zirconia ceramic remains stable in pH 2–12 media, outperforming stainless steel valves in aggressive pipelines. This stability secures continuous operation without contamination.

- Salt and Chloride Resistance: In chemical fertilizer production, zirconia withstands chloride attack with less than 1% material loss after 1000 hours. This ensures predictable sealing even in brine systems.

- Extended Clean Operation: The ceramic surface reduces scaling deposits by 30%, lowering cleaning frequency and ensuring consistent valve torque.

- Torque Control Accuracy: Manual gear operators provide steady torque transmission, with positioning repeatability of ±2°, allowing precise throttling in process lines.

- Installation Flexibility: Compact wafer and lug styles fit pipelines from DN50 to DN500, ensuring compatibility with existing ASME Class 150 standards. This flexibility simplifies retrofits and minimizes downtime.

- Low Leakage Rates: Independent tests confirmed leakage below 0.01% of rated flow at PN1.6 MPa. This minimizes product loss and secures safe operation in high-value chemical media.

Technical Properties for Manual Zirconia Ceramic Butterfly Valve

The Manual ZrO2 Butterfly Valve is designed with zirconia ceramic disc and seat, supported by strict testing of physical, chemical, thermal, and mechanical properties.

| Property |

Pure Zirconia (Monoclinic) - Unstabilized |

Yttria-Stabilized Zirconia (YSZ) |

Magnesia-stabilized zirconia (Mg-PSZ) |

| Typical Purity |

High-purity raw material, but unstabilized for the final product |

High purity |

High purity |

| Crystal Phases (at RT) |

Monoclinic (stable up to ~1170°C); Tetragonal and Cubic at higher temperatures. |

Primarily, Metastable Tetragonal can have a Cubic phase. |

Partially stabilized with tetragonal precipitates in a cubic matrix. |

| Density (g/cm³) |

5.65–6.05 |

5.85-6.1 |

~5.7 |

| Melting Point (°C) |

~2700-2715 |

Very High (similar to pure zirconia, but phase stability is key) |

Very High |

| Thermal Conductivity (W/m·K) |

Low (approx. 2-3) |

Low (approx. 2.5-3) |

Low (approx. 3) |

| Thermal Expansion Coefficient (10⁻⁶/K) |

~10 |

9.5-10 |

10 |

| Flexural Strength (MPa) |

Poor (due to phase transformation and brittleness) |

Up to 1000, 710-900 |

500 |

| Compressive Strength (MPa) |

Not typically used structurally |

~2000 |

~2500 |

| Fracture Toughness (MPa·m^0.5) |

Low (inherently brittle) |

Up to 10 (exceptionally high for ceramics due to transformation toughening), 8-9 |

6 |

| Hardness (Vickers, HV1) |

Moderate |

11-13 GPa, 1100-1220 kg/mm² |

1100 kg/mm² |

| Chemical Inertness |

Excellent in acids and alkalis |

Excellent |

Excellent |

| Biocompatibility |

Generally good, but stabilized forms are preferred for medical use |

Excellent, widely used in dental and medical implants |

Good |

| Typical Applications |

Refractories (at high temperatures) |

Structural ceramics, dental implants, oxygen sensors, cutting tools, thermal barrier coatings |

Refractories, structural components requiring specific thermal properties |

Specifications of Manual Zirconia Ceramic Butterfly Valve

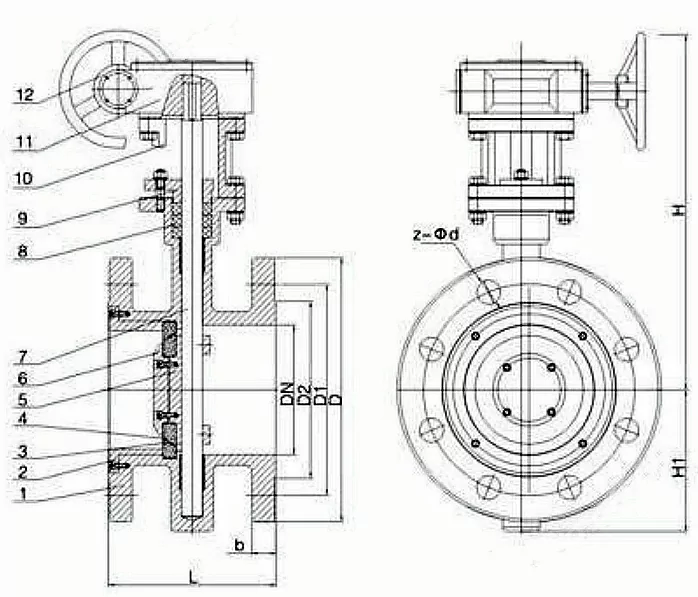

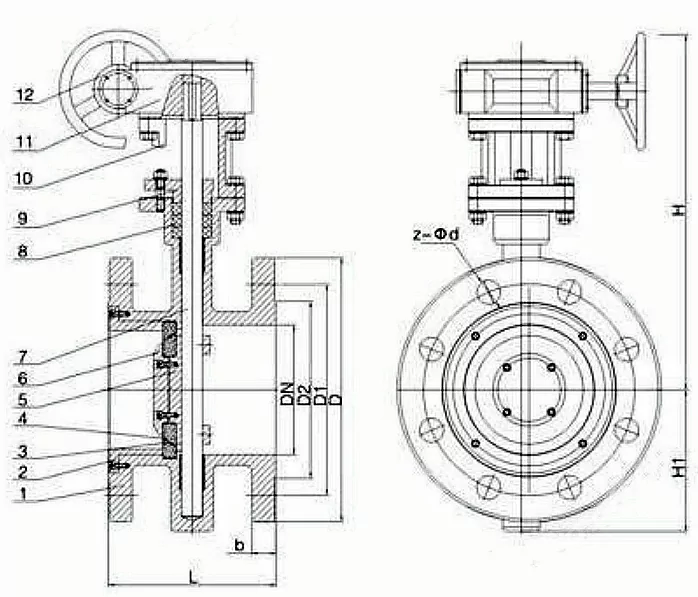

| No. |

Component Name |

Material |

No. |

Component Name |

Material |

| 1 |

Valve Body |

WCB (Cast Carbon Steel) |

7 |

Stem |

2Cr13 (Martensitic Stainless Steel) |

| 2 |

Retainer Ring |

Q235 (Carbon Structural Steel) |

8 |

Packing |

Flexible Graphite |

| 3 |

Valve Seat |

Structural Ceramic |

9 |

Packing Gland |

WCB (Cast Carbon Steel) |

| 4 |

Seal Ring |

Structural Ceramic |

10 |

Bracket |

WCB (Cast Carbon Steel) |

| 5 |

Disc |

WCB (Cast Carbon Steel) |

11 |

Drive Assembly |

Finished Component |

| 6 |

Pressure Plate |

Q235 (Carbon Structural Steel) |

12 |

Handwheel |

QT400 (Ductile Cast Iron) |

|

Model |

DN |

PN(MPa) |

L |

D |

D1 |

D2 |

H |

H1 |

z-d |

|

AT-ZVD-001 |

50 |

1.0 |

108 |

140 |

125 |

100 |

254 |

85 |

4-∅18 |

|

AT-ZVD-002 |

65 |

1.0 |

112 |

160 |

145 |

120 |

278 |

95 |

4-∅18 |

|

AT-ZVD-003 |

80 |

1.0 |

114 |

185 |

160 |

135 |

312 |

106 |

4-∅18 |

|

AT-ZVD-004 |

100 |

1.0 |

127 |

205 |

180 |

155 |

330 |

114 |

8-∅18 |

|

AT-ZVD-005 |

125 |

1.0 |

140 |

235 |

210 |

185 |

365 |

130 |

8-∅18 |

|

AT-ZVD-006 |

150 |

1.0 |

140 |

260 |

240 |

210 |

404 |

148 |

8-∅23 |

|

AT-ZVD-007 |

200 |

1.0 |

152 |

315 |

295 |

265 |

496 |

176 |

8-∅23 |

|

AT-ZVD-008 |

250 |

1.0 |

165 |

370 |

350 |

320 |

538 |

210 |

8-∅23 |

|

AT-ZVD-009 |

300 |

1.0 |

178 |

435 |

400 |

368 |

632 |

238 |

8-∅23 |

Packaging of Manual Zirconia Ceramic Butterfly Valve

Each Manual Zirconia Ceramic Butterfly Valve is packed using bubble wrap, cartons, and wooden cases to ensure protection during transport. Palletized cartons provide stability for bulk shipments of them to international destinations. Strong wooden crates prevent damage and guarantee safe delivery of every Manual ZrO2 Butterfly Valve to industrial clients.

Solving Application Challenges with ADCERAX® Manual Zirconia Ceramic Butterfly Valve

The Manual ZrO2 Butterfly Valve is specifically used in industries where large-diameter pipelines, moderate pressure ranges, and abrasive or corrosive media require quick shutoff and reliable throttling. These scenarios depend on butterfly valve geometry for compact design, easy installation, and stable manual control.

-

Cooling Water and Slurry Recycling Loops

✅Key Advantages

1. Scale Build-Up Reduced — The zirconia sealing surface cuts deposit adhesion by ≈30%, extending cleaning intervals from 2 weeks → 3+ weeks. Lower fouling keeps torque stable under continuous recirculation.

2. Wear Rate Suppressed — Disc hardness near 1200 HV sustains service beyond 12 months in slurry loops where metal valves fail at 4–6 months. Fewer changeouts mean steadier loop availability.

3. Lower Manual Effort — Worm-gear operator achieves setpoint repeatability of ±2° with 20–35% lower handle torque versus prior installs. Operators complete on-line adjustments faster and safer.

✅ ️Problem Solved

A 300 MW station’s DN300 recycling loop recorded 5 unplanned stoppages/year due to scaling and seat wear. After installing the ADCERAX® Manual Zirconia Ceramic Butterfly Valve, cleaning frequency fell by ≈30%, valve life extended to >12 months, and torque alarms dropped to 0 in two quarters. The site logged ~48 h less downtime/year and maintenance savings of US$18–22k, driven by fewer interventions and stable sealing.

-

Low-Pressure Gas Scrubbing Towers

✅Key Advantages

1. Acid-Mist Corrosion Resistance — Stable from pH 2–12 with chloride mass loss <1%/1000 h, sustaining leak rate <0.01% of rated flow at PN1.6. Scrubber uptime remains predictable.

2. Precise Manual Throttling — Gear drive holds ±2° position accuracy; flow repeatability within ±3% Cv in tower recycle headers. Operators maintain target pH and ΔP with fewer corrections.

3. Lightweight for Large Diameters — Wafer body reduces installed weight by ≈30–50% vs. equivalent ball valves at DN200–DN300, enabling single-crew manual handling.

✅ ️Problem Solved

A chemical scrubber line reported quarterly leakage incidents and frequent re-packing. With ADCERAX® Manual Zirconia Ceramic Butterfly Valve, corrosion-related leaks fell from 4/quarter → 0/quarter over 9 months. Position drift stayed within ±2°, and spare-part spend dropped ~35%, while tower emission compliance held steady without emergency shuts.

-

Pulp and Slurry Flow Balancing

✅Key Advantages

1. Longer Wear Life in Pulp — Zirconia disc at ≈1200 HV doubled service from 6 months → 12–14 months on choke lines, cutting operator interventions by ≈45%. Flow balance stays consistent.

2. Compact Retrofit Geometry — Wafer style clears crowded racks and reduces support steel; typical installed mass is 25–40% lower than heavy alternatives, easing manual repositioning.

3. Fast Manual Set-Up — Smooth handwheel action trims line-change time from 15 min → 6–8 min with ±2° repeatability, improving balance across parallel circuits.

✅ ️Problem Solved

A pulp mill with four parallel slurry lines faced frequent rebalance work and valve wear. After adopting the ADCERAX® Manual Zirconia Ceramic Butterfly Valve, monthly adjustments fell by ≈40%, changeover time halved, and valve life reached 12+ months. The mill reported ~2% throughput stability gain and avoided US$10–15k/year in unplanned maintenance.

User Guide for Manual Zirconia Ceramic Butterfly Valve

The Manual Zirconia Ceramic Butterfly Valve requires proper installation, operation, inspection, and maintenance to ensure safe and long-lasting performance. Following these guidelines helps customers reduce downtime, avoid damage, and maximize the efficiency of their valve systems.

-

Installation Guidelines

1. Correct Orientation — Always install the valve with the flow direction clearly marked to prevent uneven wear. Incorrect orientation can reduce service life by up to 40%.

2. Secure Mounting — Ensure the flange bolts are tightened evenly across all sides. Uneven force can cause leaks or seat misalignment, increasing failure risk.

3. Shock Protection — Avoid impact during installation or transport. Sudden shocks can damage the zirconia disc and compromise the valve’s sealing ability.

-

Operating Practices

1. Smooth Operation — Turn the handwheel or gear slowly to prevent pressure surges. Rapid actuation increases wear and may shorten lifespan by 20–30%.

2. Pressure Range Compliance — Operate strictly within the rated PN1.0–1.6 MPa to maintain stability. Exceeding pressure ratings risks seat cracking and unsafe leakage.

3. Temperature Awareness — Monitor medium temperature carefully, especially in hot fluid service. Exceeding 200 °C without a high-temperature model can cause seal failure.

-

Inspection Routines

1. Leak Checks — Inspect the sealing area every 3 months to confirm no leakage. Small leaks can escalate into significant maintenance costs if ignored.

2. Torque Monitoring — Track the torque needed for opening and closing. A 20% increase usually signals scaling or deposit build-up inside the valve.

3. Component Condition — Regularly assess the disc and seat surfaces for abrasion. Early detection allows part replacement before full valve failure occurs.

-

Maintenance Recommendations

1. Cleaning Intervals — Flush the system with clean water or neutral solution every 6 months. This prevents abrasive particles from embedding and damaging the seat.

2. Seal Replacement — Replace the ceramic seal once visible erosion exceeds 1 mm depth. Continued operation risks leakage and potential production stoppage.

3. Storage Precautions — Store the valve in a dry, dust-free location. Exposure to high humidity for long periods can corrode metal components like bolts and stems.