ADCERAX® Manual Zirconia Ceramic Knife Gate Valve is designed for abrasive and corrosive media where reliability and long service life are critical. Its zirconia blade and sealing surfaces provide high hardness, wear resistance, and chemical stability, ensuring safe shut-off even in slurry, ash, and pulp pipelines. With a compact structure and low operating torque, the valve reduces downtime while supporting smooth manual operation. This makes it a preferred solution for industries such as power generation, mining, paper, and chemical processing.

Features of Manual Zirconia Ceramic Knife Gate Valve

- Zirconia ceramic is chemically inert against >90% of common acids and alkalis, ensuring fluid purity. This prevents contamination in pharmaceutical and chemical processing.

- In corrosion tests, ZrO₂ surfaces showed less than 0.01% mass loss after 1000 hours in NaOH solution. Such stability secures long-term sealing.

- Valves maintain reliable performance at operating temperatures up to 400 °C, enabling use in power plant steam and hot slurry lines.

- Manual operation requires 30–40% less torque compared with steel knife gate valves, thanks to zirconia’s self-lubrication. This improves field operability.

- Side flushing ports allow removal of deposits in under 5 minutes, reducing cleaning downtime during continuous production.

- Maintenance records show average mean time between servicing exceeds 18 months, improving lifecycle economics for industrial operators.

- The valve’s wear resistance helps maintain >95% sealing integrity after 12 months in pulp applications. Consistent sealing reduces operational fluid losses.

- Independent field reports show valves with zirconia components last 3–5 times longer in mining pipelines compared to metal-seated units. Extended service life minimizes shutdowns and maintenance costs.

- HRA88 hardness level makes the zirconia gate over 8× harder than carbon steel. This directly reduces wear under abrasive slurry and ash conditions.

Technical Properties for Manual Zirconia Ceramic Knife Gate Valve

The Manual ZrO2 Knife Gate Valve is engineered with advanced zirconia ceramic materials, ensuring durability under abrasive and corrosive service.

| Property | Pure Zirconia (Monoclinic) - Unstabilized | Yttria-Stabilized Zirconia (YSZ) | Magnesia-stabilized zirconia (Mg-PSZ) |

| Typical Purity | High-purity raw material, but unstabilized for the final product | High purity | High purity |

| Crystal Phases (at RT) | Monoclinic (stable up to ~1170°C); Tetragonal and Cubic at higher temperatures. | Primarily, Metastable Tetragonal can have a Cubic phase. | Partially stabilized with tetragonal precipitates in a cubic matrix. |

| Density (g/cm³) | 5.65–6.05 | 5.85-6.1 | ~5.7 |

| Melting Point (°C) | ~2700-2715 | Very High (similar to pure zirconia, but phase stability is key) | Very High |

| Thermal Conductivity (W/m·K) | Low (approx. 2-3) | Low (approx. 2.5-3) | Low (approx. 3) |

| Thermal Expansion Coefficient (10⁻⁶/K) | ~10 | 9.5-10 | 10 |

| Flexural Strength (MPa) | Poor (due to phase transformation and brittleness) | Up to 1000, 710-900 | 500 |

| Compressive Strength (MPa) | Not typically used structurally | ~2000 | ~2500 |

| Fracture Toughness (MPa·m^0.5) | Low (inherently brittle) | Up to 10 (exceptionally high for ceramics due to transformation toughening), 8-9 | 6 |

| Hardness (Vickers, HV1) | Moderate | 11-13 GPa, 1100-1220 kg/mm² | 1100 kg/mm² |

| Chemical Inertness | Excellent in acids and alkalis | Excellent | Excellent |

| Biocompatibility | Generally good, but stabilized forms are preferred for medical use | Excellent, widely used in dental and medical implants | Good |

| Typical Applications | Refractories (at high temperatures) | Structural ceramics, dental implants, oxygen sensors, cutting tools, thermal barrier coatings | Refractories, structural components requiring specific thermal properties |

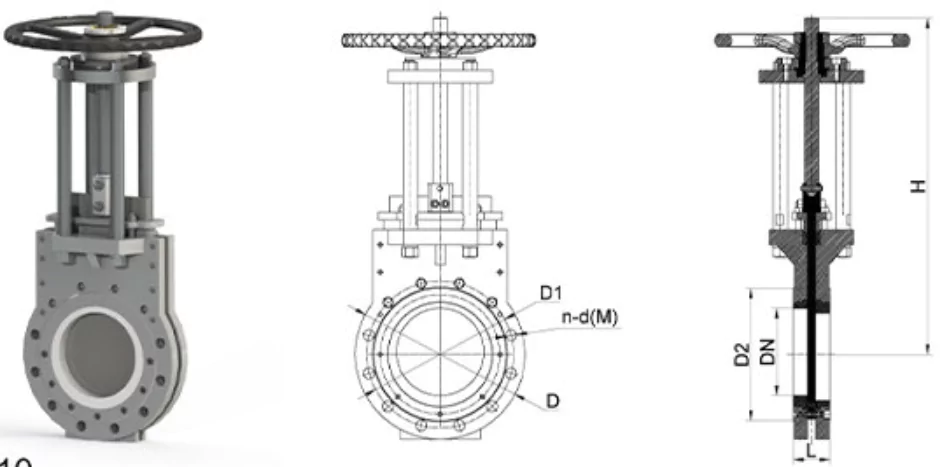

Specifications of Manual Zirconia Ceramic Knife Gate Valve

| Item Name | Model | DN(mm) | L | D | D1 | D2 | n-d(M) | H |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S001 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 355 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S002 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 393 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S003 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 398 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S004 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 467 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S005 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 479 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S006 | 150 | 65 | 285 | 240 | 210 | 8-18(16) | 545 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S007 | 200 | 75 | 340 | 295 | 265 | 8-22(20) | 676 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S008 | 250 | 75 | 395 | 350 | 320 | 12-22(20) | 782 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S009 | 300 | 80 | 445 | 400 | 370 | 12-22(20) | 894 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S010 | 350 | 85 | 505 | 460 | 428 | 16-22(20) | 999 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S011 | 400 | 85 | 565 | 515 | 480 | 16-22(20) | 1266 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S012 | 450 | 95 | 615 | 565 | 530 | 20-26(22) | 1350 |

| Manual ZrO2 Knife Gate Valve-P10 | AT-ZV1-S013 | 500 | 100 | 670 | 620 | 582 | 20-26(22) | 1415 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S014 | 50 | 60 | 165 | 125 | 100 | 4-18(16) | 355 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S015 | 65 | 60 | 185 | 145 | 120 | 4-18(16) | 393 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S016 | 80 | 65 | 200 | 160 | 135 | 8-18(16) | 398 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S017 | 100 | 65 | 220 | 180 | 135 | 8-18(16) | 467 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S018 | 125 | 65 | 250 | 210 | 185 | 8-18(16) | 479 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S019 | 150 | 65 | 285 | 240 | 210 | 8-22(20) | 545 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S020 | 200 | 75 | 340 | 295 | 265 | 12-22(20) | 676 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S021 | 250 | 75 | 405 | 355 | 320 | 12-26(22) | 782 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S022 | 300 | 80 | 460 | 410 | 370 | 12-26(22) | 894 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S023 | 350 | 85 | 520 | 470 | 428 | 12-26(22) | 999 |

| Manual ZrO2 Knife Gate Valve-P16 | AT-ZV1-S024 | 400 | 85 | 580 | 525 | 480 | 16-30(27) | 1266 |

| Note: Nominal Diameter: DN50–DN500; Nominal Pressure: 1.0 MPa–1.6 MPa; Operating Temperature: -20 °C–250 °C; Connection Type: Wafer; Actuation Method: Manual | ||||||||

Packaging of Manual Zirconia Ceramic Knife Gate Valve

The Manual Zirconia Ceramic Knife Gate Valve is first sealed in reinforced cartons to prevent surface damage during handling. Valves are then secured in multilayer plywood cases with protective padding for safe stacking and international transport. The final packaging ensures each of them arrives intact, clean, and ready for installation.