A porous alumina plate is a sintered Al₂O₃ ceramic sheet or disc engineered with a controlled network of microscopic pores. The pore architecture (pore size and open porosity) allows air or fluids to pass through the body in a uniform and predictable manner.

Porous Alumina Plate Advantages

- Uniform suction & diffusion: Controlled pore size distribution improves vacuum chuck hold and plenum equalization across the plate.

- Thermal & chemical stability: Alumina withstands high temperatures and reactive atmospheres where polymers or metals risk deformation or contamination.

- Electrical insulation / low CTE: Safe near sensors or electronics; dimensional drift is minimal during heat cycles.

- Cleanability & re-use: Open-pore network supports solvent/ultrasonic cleaning routines for longer fixture life.

- Flatness-first design: Plate thickness, porosity and sintering cycle are balanced to keep working-face flatness in production use.

Porous Alumina Al2O3 Plate Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Alumina Porous Ceramic Plate Specifications

Type 1- Porous Alumina Disc

| Porous Alumina Disc | ||||

| Item No. | Diameter(mm) | Thickness(mm) | Hole Diameter(μm) | Purity (%) |

| AT-FT-5001 | 5.5 | 3 | 0.1 | 96 |

| AT-FT-5002 | 15 | 3 | 25 | 96 |

| AT-FT-5003 | 15 | 3 | 0.2 | 96 |

| AT-FT-5004 | 20 | 2 | 2 | 96 |

| AT-FT-5005 | 20.5 | 4 | 0.8 | 96 |

| AT-FT-5006 | 21 | 1 | 0.2 | 96 |

| AT-FT-5007 | 21 | 1 | 0.1 | 96 |

| AT-FT-5008 | 21 | 1 | 1 | 96 |

| AT-FT-5009 | 22 | 2 | 2 | 96 |

| AT-FT-5010 | 22 | 2 | 0.1 | 96 |

| AT-FT-5011 | 22 | 2 | 0.05 | 96 |

| AT-FT-5012 | 26.2 | 3 | 1 | 96 |

| AT-FT-5013 | 28 | 3 | 10 | 96 |

| AT-FT-5014 | 28 | 4 | 1 | 96 |

| AT-FT-5015 | 28.5 | 3 | 0.8 | 96 |

| AT-FT-5016 | 28.5 | 3 | 1 | 96 |

| AT-FT-5017 | 28.5 | 5 | 1 | 96 |

| AT-FT-5018 | 29 | 2 | 0.8 | 96 |

| AT-FT-5019 | 29 | 3 | 0.5 | 96 |

| AT-FT-5020 | 29 | 6 | 0.2 | 96 |

| AT-FT-5021 | 31.5 | 3.5 | 0.2 | 96 |

| AT-FT-5022 | 31.5 | 4.5 | 1 | 96 |

| AT-FT-5023 | 38 | 2 | 2 | 96 |

| AT-FT-5024 | 38 | 2 | 0.1 | 96 |

| AT-FT-5025 | 38 | 2 | 0.05 | 96 |

| AT-FT-5026 | 38.5 | 3 | 1 | 96 |

| AT-FT-5027 | 47 | 5 | 30 | 96 |

| AT-FT-5028 | 47.5 | 3 | 0.2 | 96 |

| AT-FT-5029 | 47.5 | 4 | 30 | 96 |

| AT-FT-5030 | 47.7 | 2.5 | 0.2 | 96 |

| AT-FT-5031 | 47.7 | 3.5 | 0.2 | 96 |

| AT-FT-5032 | 47.7 | 4.5 | 50 | 96 |

| AT-FT-5033 | 48.5 | 3 | 0.2 | 96 |

| AT-FT-5034 | 48.5 | 5 | 0.2 | 96 |

| AT-FT-5035 | 49.5 | 4.5 | 30 | 96 |

| AT-FT-5036 | 49.5 | 4.5 | 50 | 96 |

| AT-FT-5037 | 50 | 2 | 0.2 | 96 |

| AT-FT-5038 | 52 | 3 | 2 | 96 |

| AT-FT-5039 | 52 | 3 | 0.1 | 96 |

| AT-FT-5040 | 52 | 3 | 0.05 | 96 |

| AT-FT-5041 | 66 | 3 | 2 | 96 |

| AT-FT-5042 | 66 | 3 | 0.1 | 96 |

| AT-FT-5043 | 66 | 3 | 0.05 | 96 |

| AT-FT-5044 | 88 | 3 | 2 | 96 |

| AT-FT-5045 | 88 | 3 | 0.1 | 96 |

| AT-FT-5046 | 88 | 3 | 0.05 | 96 |

| AT-FT-5047 | 108 | 3.5 | 2 | 96 |

| AT-FT-5048 | 108 | 3.5 | 0.1 | 96 |

| AT-FT-5049 | 108 | 3.5 | 0.05 | 96 |

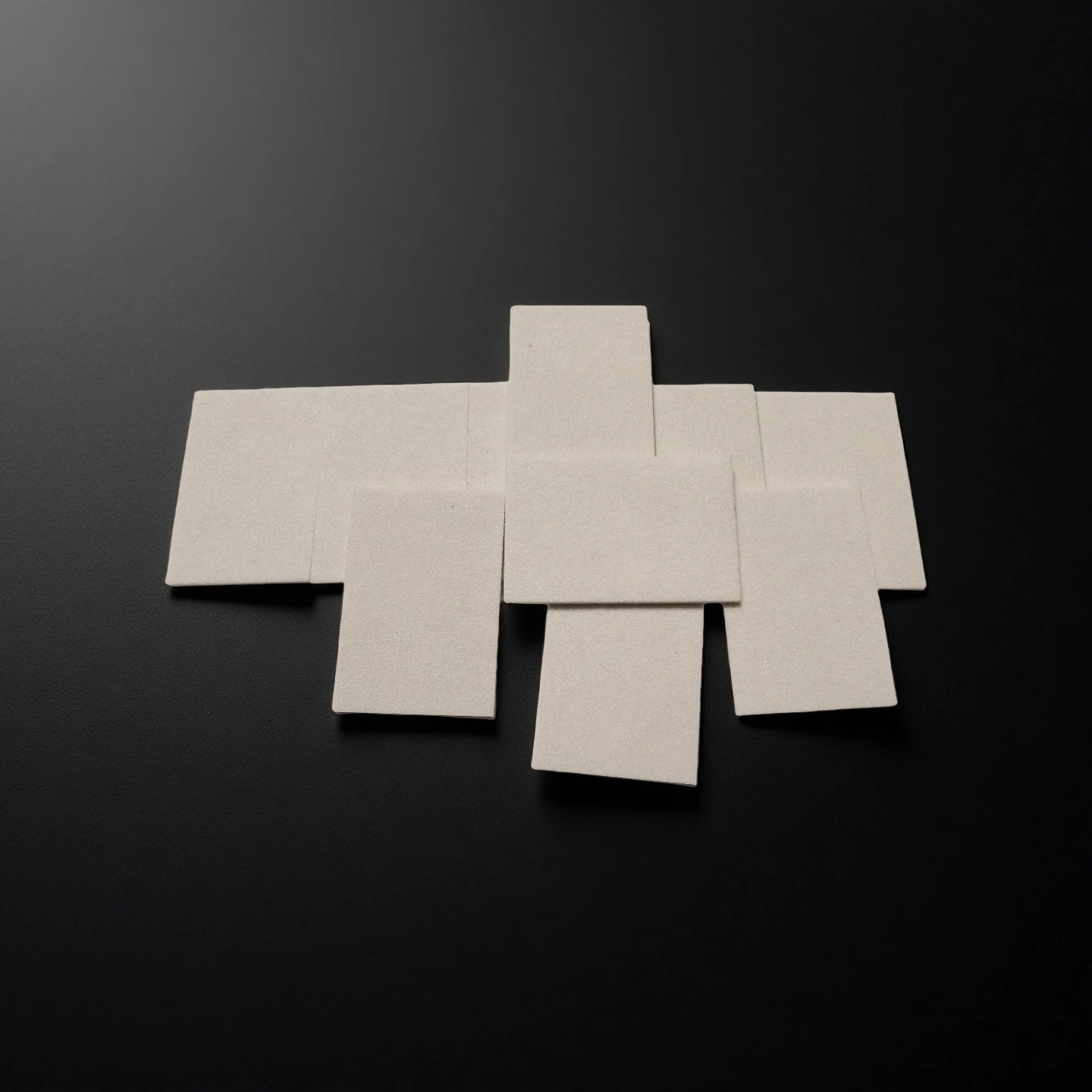

Type 2- Porous Alumina Ceramic Sheet

| Porous Alumina Ceramic Sheet | |||||

| Item No. | Length(mm) | Width(mm) | Thickness(μm) | Hole Diameter (mm) | Purity (%) |

| AT-FT-6001 | 10 | 10 | 1 | 0.05 | 96-98 |

| AT-FT-6001 | 20 | 20 | 1 | 25 | 96-98 |

| AT-FT-6001 | 25 | 25 | 3 | 0.2 | 96-98 |

| AT-FT-6001 | 30 | 30 | 1 | 2 | 96-98 |

| AT-FT-6001 | 30 | 30 | 2 | 0.8 | 96-98 |

| AT-FT-6001 | 35 | 35 | 1 | 0.2 | 96-98 |

| AT-FT-6001 | 40 | 40 | 1 | 0.1 | 96-98 |

| AT-FT-6001 | 40 | 40 | 5 | 1 | 96-98 |

| AT-FT-6001 | 50 | 50 | 1.5 | 2 | 96-98 |

| AT-FT-6001 | 50 | 50 | 5 | 0.1 | 96-98 |

| AT-FT-6001 | 60 | 60 | 1 | 0.05 | 96-98 |

| AT-FT-6001 | 70 | 70 | 2 | 1 | 96-98 |

| AT-FT-6001 | 70 | 70 | 3 | 10 | 96-98 |

| AT-FT-6001 | 80 | 80 | 3 | 1 | 96-98 |

| AT-FT-6001 | 80 | 80 | 5 | 0.8 | 96-98 |

| AT-FT-6001 | 80 | 110 | 5 | 1 | 96-98 |

| AT-FT-6001 | 100 | 70 | 1.2 | 1 | 96-98 |

| AT-FT-6001 | 100 | 84 | 1.5 | 0.8 | 96-98 |

| AT-FT-6001 | 100 | 90 | 2.2 | 0.5 | 96-98 |

| AT-FT-6001 | 100 | 100 | 2.5 | 0.2 | 96-98 |

| AT-FT-6001 | 100 | 100 | 3.5 | 0.2 | 96-98 |

| AT-FT-6001 | 108 | 100 | 1.5 | 1 | 96-98 |

| AT-FT-6001 | 100 | 100 | 2.5 | 2 | 96-98 |

| AT-FT-6001 | 100 | 100 | 3.2 | 0.1 | 96-98 |

| AT-FT-6001 | 100 | 100 | 3.5 | 0.05 | 96-98 |

| AT-FT-6001 | 100 | 100 | 4 | 1 | 96-98 |

| AT-FT-6001 | 100 | 100 | 5 | 30 | 96-98 |

| AT-FT-6001 | 109 | 109 | 1 | 0.2 | 96-98 |

| AT-FT-6001 | 110 | 80 | 4 | 1 | 98 |

| AT-FT-6001 | 110 | 110 | 5 | 0.2 | 96-98 |

| AT-FT-6001 | 114 | 114 | 1 | 0.2 | 96-98 |

| AT-FT-6001 | 120 | 120 | 1 | 0.5 | 96-98 |

| AT-FT-6001 | 120 | 120 | 3 | 0.2 | 96-98 |

| AT-FT-6001 | 125 | 125 | 2 | 0.2 | 96-98 |

| AT-FT-6001 | 127 | 127 | 1 | 0.8 | 96-98 |

| AT-FT-6001 | 127 | 127 | 1.5 | 0.8 | 96-98 |

| AT-FT-6001 | 138 | 190 | 1 | 0.2 | 96-98 |

| AT-FT-6001 | 138 | 190 | 1 | 2 | 96-98 |

| AT-FT-6001 | 150 | 150 | 1.8 | 0.1 | 96-98 |

| AT-FT-6001 | 150 | 150 | 1 | 0.05 | 96-98 |

| AT-FT-6001 | 150 | 150 | 1.5 | 2 | 96-98 |

| AT-FT-6001 | 150 | 150 | 2 | 0.1 | 96-98 |

| AT-FT-6001 | 150 | 150 | 3 | 0.5 | 96-98 |

| AT-FT-6001 | 150 | 150 | 5 | 2 | 96-98 |

| AT-FT-6001 | 160 | 170 | 2.5 | 0.1 | 96-98 |

| AT-FT-6001 | 180 | 180 | 2 | 0.8 | 96-98 |

| AT-FT-6001 | 180 | 180 | 3 | 2 | 96-98 |

| AT-FT-6001 | 180 | 180 | 5 | 0.1 | 96-98 |

| AT-FT-6001 | 200 | 140 | 2 | 0.5 | 96-98 |

| AT-FT-6001 | 200 | 165 | 3 | 30 | 96-98 |

| AT-FT-6001 | 200 | 200 | 5 | 50 | 96-98 |

| AT-FT-6001 | 220 | 220 | 2 | 1 | 96-98 |

Type 3- Black porous alumina sheet

| Black Microporous Alumina Plate | |||

| Item No. | size(inches) | Hole Diameter | Porosity |

| AT-AO-WK001 | 2、3、4、5、6、8、12 | 1-100um | 30-50% |

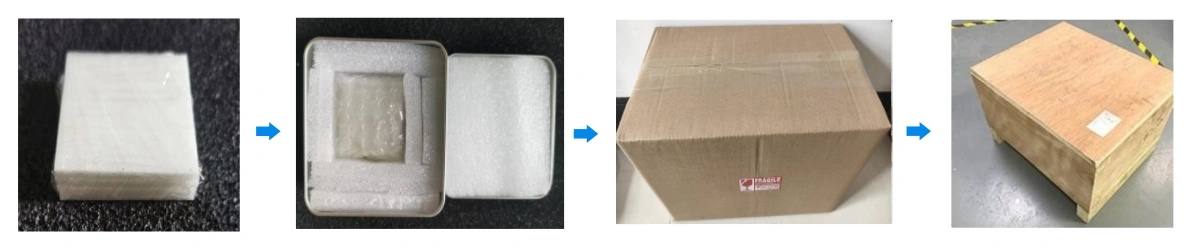

Porous Alumina Plate Packaging

- Shock-absorb foam trays; PE wrap to keep pores clean;