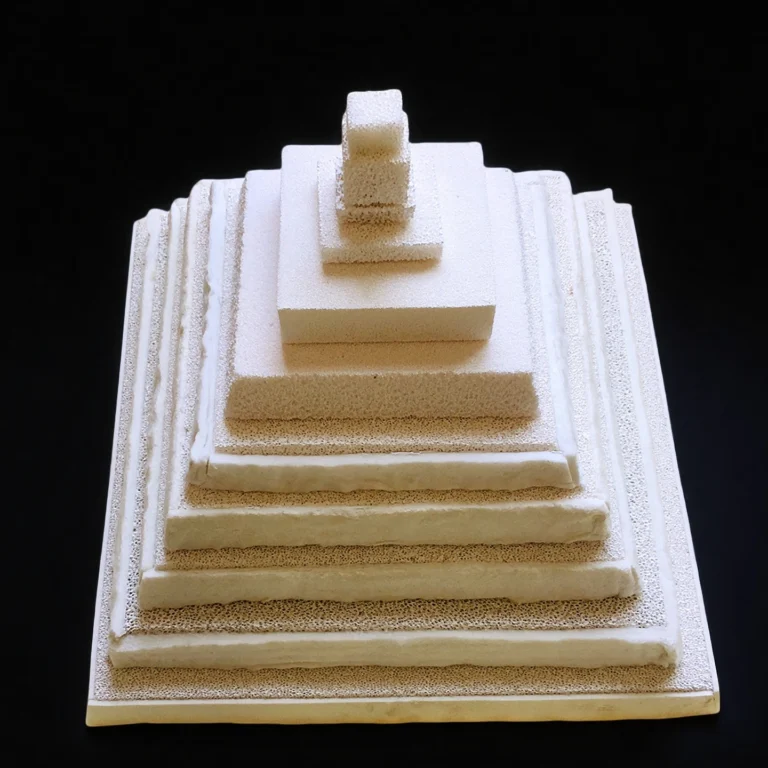

ADCERAX® Microporous Silicon Carbide Ceramic Foam Filter is engineered for high‑temperature metal filtration, gas purification, and chemical processing environments where stable performance is essential. Its three‑dimensional open‑cell SiC structure supports efficient removal of fine inclusions while maintaining consistent flow behavior under thermal and corrosive conditions. These characteristics make the material suitable for casting facilities, furnace systems, and industrial plants seeking reliable filtration solutions for continuous operations.

Engineering Performance Features of Microporous Silicon Carbide Ceramic Foam Filter

-

High‑Temperature Structural Stability

The filter maintains mechanical strength across extreme thermal gradients.

The material withstands continuous operation at 1500–1700°C, allowing stable filtration in steel, iron, and aluminum foundries. Its thermal expansion coefficient remains within 4.0–5.5 × 10⁻⁶ K⁻¹, ensuring predictable behavior during rapid heat cycling. High thermal shock tolerance verified to ISO 22846 at 1350°C ± 500°C supports uninterrupted industrial running conditions.

-

Consistent Microporous Architecture

The pore network delivers reliable filtration efficiency across industrial flow conditions.

Uniform pore distribution achieves ≥90% structural consistency, enabling repeatable impurity capture in molten metals or gases. Available pore sizes from 10 to 60 PPI allow targeted performance tuning for casting, chemical, or thermal applications. The open‑cell structure produces stable airflow or melt flow with controlled pressure drop based on verified porosity measurements.

-

Corrosion and Chemical Resistance

The SiC matrix maintains integrity when exposed to aggressive processing environments.

High‑purity silicon carbide resists degradation in strong acids, alkalis, and reactive solvent atmospheres, supporting extended operating cycles. Contact with molten aluminum, iron, copper, and magnesium remains stable due to the protective SiC–SiO₂ surface layer formed during sintering. Long‑term filtration performance is preserved through controlled microstructure density between 0.25–0.60 g/cm³, improving durability in corrosive or high‑load systems.

Technical Specifications of Microporous Silicon Carbide Ceramic Foam Filter

ADCERAX® Microporous Silicon Carbide Ceramic Foam Filter is defined by measurable thermal stability, mechanical strength, and chemical endurance, providing a reliable filtration structure suitable for demanding metallurgical, thermal‑processing, and gas‑solid separation environments.

| Property |

Specification |

| Material Composition |

High‑purity Silicon Carbide (SiC) |

| Pore Size Range |

10–60 PPI |

| Pore Uniformity |

≥90% consistency |

| Density |

0.25–0.60 g/cm³ |

| Flexural Strength |

0.8–1.8 MPa |

| Compressive Strength |

1.0–4.5 MPa |

| Working Temperature |

1500–1700°C |

| Thermal Expansion Coefficient |

4.0–5.5 × 10⁻⁶ K⁻¹ |

| Thermal Shock Resistance |

ISO 22846 1350°C ± 500°C |

| Chemical Resistance |

Stable in strong acids and alkalis |

| Molten Metal Compatibility |

Compatible with Al, Fe, Cu, Mg |

| Heat Conduction |

Medium to high thermal conductivity |

Dimensions of Microporous Silicon Carbide Ceramic Foam Filter

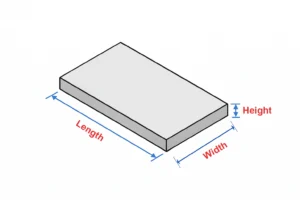

Type 1 -Round Microporous SiC Ceramic Foam Filter

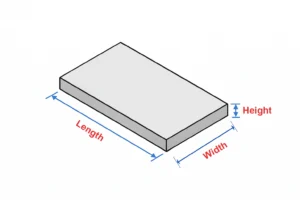

Type 2 -Square Microporous SiC Ceramic Foam Filter

|

Item |

Length*Width*Thickness (mm) |

Hole Diameter (μm) |

|

AT-SIC-PM067 |

60*60*6 |

3 |

|

AT-SIC-PM068 |

100*100*8 |

10 |

|

AT-SIC-PM069 |

100*100*10 |

13 |

|

AT-SIC-PM070 |

150*150*10 |

15 |

Packaging Instructions for Microporous Silicon Carbide Ceramic Foam Filter

Microporous Silicon Carbide Ceramic Foam Filter is packed in reinforced cartons with internal cushioning to prevent vibration and pore contamination during transport. Each unit is sealed in protective wrapping to avoid dust intrusion before installation. All packages are palletized and secured with moisture‑resistant covers to support safe handling and long‑distance shipment.

ADCERAX® Microporous Silicon Carbide Ceramic Foam Filter for Resolving High‑Temperature Filtration Challenges Across Critical Industrial Systems

The ADCERAX® Microporous Silicon Carbide Ceramic Foam Filter addresses operational issues that commonly arise in heavy‑duty casting lines, combustion environments, and corrosive chemical units. Its measurable thermal endurance, controlled pore structure, and chemical resistance allow industrial facilities to maintain stable filtration, reduce downtime, and safeguard product consistency under demanding processing conditions.

-

Microporous Silicon Carbide Ceramic Foam Filter in High‑Load Aluminum and Iron Casting Lines

✅Key Advantages

1. High Stability Under Rapid Melt Cycling

The filter maintains structural integrity during temperature fluctuations up to 1500–1700°C, preventing deformation in high‑load gating systems. Its low thermal expansion of 4.0–5.5 × 10⁻⁶ K⁻¹ ensures pore stability during batch changes and rapid furnace transitions.

2. Effective Inclusion Capture in Recycled Charge Melts

The ≥90% pore uniformity supports consistent removal of oxide films and fine solid inclusions arising from recycled or mixed‑grade charge. This stable pore geometry reduces micro‑turbulence within melt channels, improving casting uniformity across multiple consecutive pours.

3. Resistance to Thermal Shock Under High‑Throughput Conditions

Performance validated under ISO 22846 (1350°C ± 500°C) allows the filter to withstand sudden thermal shocks common in frequent ladle exchanges. This resilience prevents cracking and loss of pore integrity during rapid process acceleration.

✅ ️Problem Solved

High‑volume foundries often experience rising defect rates when filters fail under thermal fluctuation, especially during long production cycles with mixed scrap input. Variations in melt cleanliness and repeated temperature shifts during casting shifts frequently contribute to inclusions and flow instability. A European iron‑casting plant reported that pore deformation in previous filters increased internal inclusion defects by 5–7% across multi‑hour production runs. By switching to the ADCERAX® Microporous Silicon Carbide Ceramic Foam Filter, the facility maintained pore stability across full heat cycles and improved melt flow consistency in high‑load gating systems, significantly reducing process interruptions and stabilizing casting quality across sequential batches.

-

Microporous Silicon Carbide Ceramic Foam Filter in Industrial Combustion and High‑Dust Exhaust Streams

✅Key Advantages

1. Low Pressure Drop Under High Dust Accumulation

The open‑cell SiC architecture maintains airflow uniformity even as particulate loading increases, limiting pressure variation to within 5–8% over extended cycles. This performance supports burner efficiency in systems operating with continuous ash exposure.

2. High Dust‑Holding Capacity for Continuous‑Run Furnaces

A controlled density range of 0.25–0.60 g/cm³ allows the filter to retain fine combustion residues without collapsing or compressing. This stability reduces the frequency of filter replacements during continuous furnace operation.

3. Thermal Shock Survival in Variable Flame Conditions

Capability to withstand rapid thermal swings at ISO 22846 1350°C ± 500°C prevents failure during flame modulation, burner restarts, or fluctuating exhaust temperatures. The structure resists deformation that typically compromises airflow stability.

✅ ️Problem Solved

Combustion systems commonly experience airflow distortion when filters clog or deform under prolonged exposure to ash and thermal cycling, resulting in unstable burner output. A manufacturing plant managing high‑dust exhaust reported recurring pressure spikes of 20–30% when using conventional ceramic elements, leading to shortened maintenance intervals and reduced heat exchanger efficiency. After implementing the ADCERAX® Microporous Silicon Carbide Ceramic Foam Filter, the system maintained stable airflow despite elevated dust loads, avoided deformation during thermal modulation cycles, and extended continuous‑operation periods without unplanned shutdowns.

-

Microporous Silicon Carbide Ceramic Foam Filter in Corrosive Chemical Gas–Solid Filtration Units

✅Key Advantages

1. Chemical Stability in Acidic and Alkaline Gas Streams

The SiC matrix remains inert in the presence of strong acids, bases, and solvent vapors, preventing structural weakening over long durations. Its resistance extends to corrosive compounds often present in catalytic gas‑solid reactions.

2. Consistent Retention of Fine Particulates

With ≥90% pore uniformity, the filter maintains predictable impurity capture efficiency across extended chemical processing cycles. This stability supports precise control of particulate levels in corrosion‑intensive gas streams.

3. Mechanical Durability in Reactive Environments

Flexural strength between 0.8–1.8 MPa ensures the filter withstands constant exposure to corrosive flows and thermal variations. It avoids micro‑cracking and material erosion that commonly affect standard ceramic or metal filtration media.

✅ ️Problem Solved

Chemical units treating acid‑rich gases and solvent vapors often encounter premature degradation of traditional ceramic or metal elements, causing particulate breakthrough and inconsistent reaction purity. In one continuous gas‑solid filtration line, operators reported that metallic filters suffered surface corrosion and pore enlargement, raising fine‑particle leakage by 6–9% over prolonged operation. After adopting the ADCERAX® Microporous Silicon Carbide Ceramic Foam Filter, the system maintained pore stability and resisted corrosive damage, supporting consistent particulate retention while reducing unplanned downtime caused by filter deterioration.

ADCERAX® Microporous Silicon Carbide Ceramic Foam Filter User Guide for Safe and Consistent Operation

The Microporous Silicon Carbide Ceramic Foam Filter requires proper handling, installation, and maintenance to ensure stable filtration performance in high‑temperature and corrosive industrial environments. These guidelines help users reduce operational risks, extend service life, and maintain reliable filtration results across continuous production cycles.

-

Preparing the Microporous Silicon Carbide Ceramic Foam Filter Before Installation

1. Filters must remain in sealed protective packaging until installation to prevent dust accumulation inside the pore structure. Each unit should be visually inspected for surface cracks or handling damage before entering the process line. Any filter exposed to moisture or contamination should be replaced to avoid compromised filtration stability.

2. Before setup, ensure the filter is placed in a clean and debris‑free environment to avoid blocking the microporous network. Keeping the surroundings controlled supports predictable melt or gas flow when the filter is activated. Handle the filter with both hands to distribute weight and avoid stressing the edges.

3. Operators should maintain consistent temperature acclimation to prevent shock‑related stress. Allow the filter to reach ambient workshop temperature before use if previously stored in cold or humid areas. This step reduces the risk of unexpected thermal deformation during first contact with hot media.

-

Installing the Microporous Silicon Carbide Ceramic Foam Filter in Industrial Systems

1. Gradually warm the filter to prevent sudden thermal exposure, as smooth temperature transitions help reduce thermal stress during the first pour.

2. Use a heating range that aligns with the casting process so the filter reaches a thermally balanced state before molten metal arrives.

3. Maintain proper ventilation around the heating zone to protect workers and ensure consistent air‑to‑surface temperature equilibrium on the filter.

-

Operating the Microporous Silicon Carbide Ceramic Foam Filter Under Working Conditions

1. System flow rates must remain within the filter’s maximum recommended operating limits to prevent pore blockage and performance drop. Excessive velocity may push large particulates into the structure and cause early failure. Maintain constant monitoring during peak cycles.

2. During casting or gas‑solid filtration, inspect the filter’s performance periodically using process windows or sampling ports. Any unusual resistance, flow reduction, or discharge quality change indicates the need for system adjustment. Establish routine observation checkpoints during long casting runs.

3. In high‑temperature processing, prevent rapid temperature drops that may induce thermal stress fractures. Avoid adding cold media or introducing sudden airflow changes that can compromise mechanical strength. Maintain smooth transitions between process stages.

-

Maintaining and Replacing the Microporous Silicon Carbide Ceramic Foam Filter

1. After each production cycle, allow the filter to cool naturally to avoid structural fatigue. Forced cooling or quenching can reduce service life and cause micro‑cracking. Handle cooled filters with appropriate protective gloves to avoid accidental chipping.

2. Inspect the filter for accumulated impurities, surface deformation, or pore blockage. If saturation occurs, replace the filter immediately to maintain process purity and system efficiency. Extended operation beyond recommended loading may create downstream defects.

3. Store unused filters in a dry, dust‑free environment, protected from humidity and chemical vapors. Use original packaging or sealed containers to maintain pore cleanliness. Proper storage ensures consistent performance in subsequent operations.

![]()