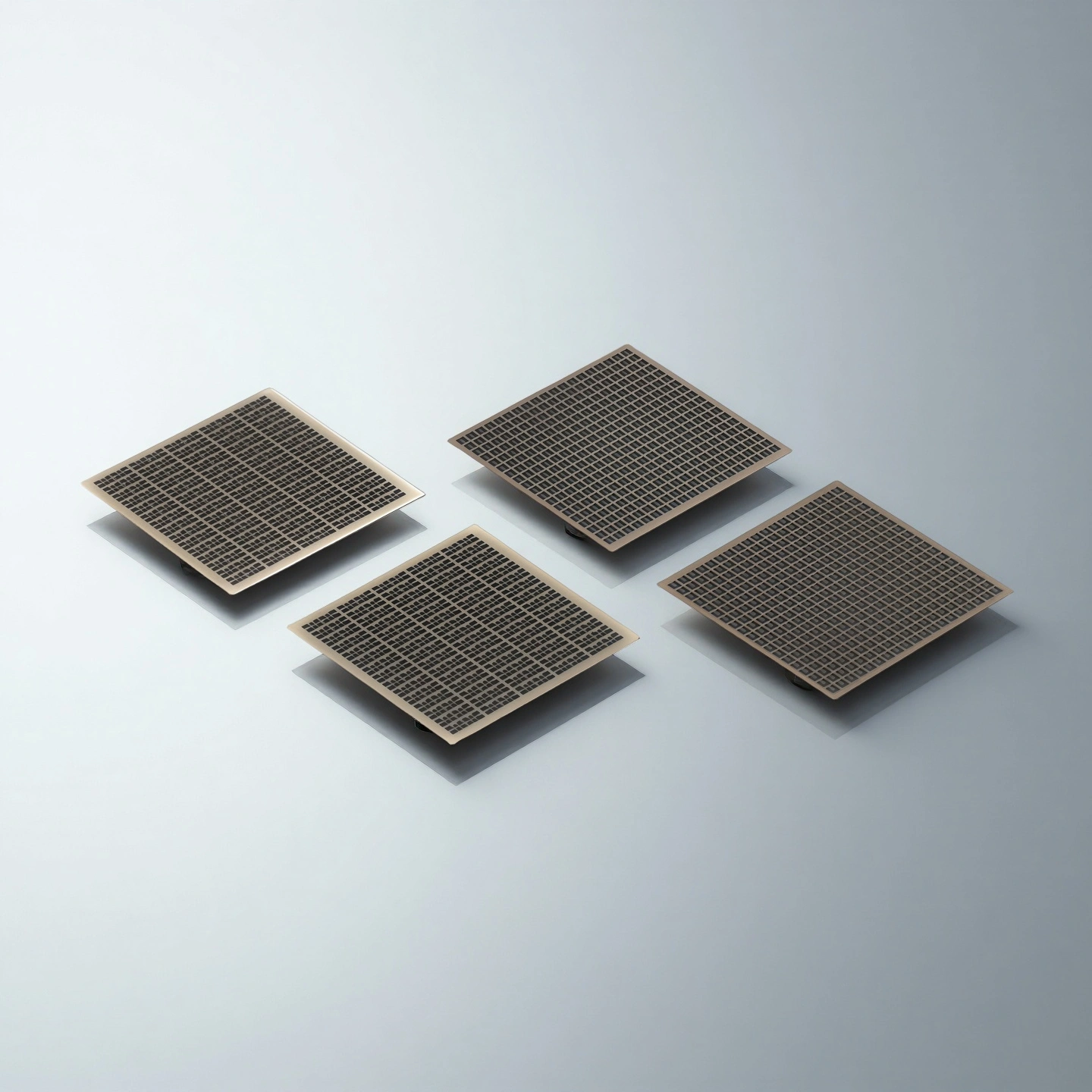

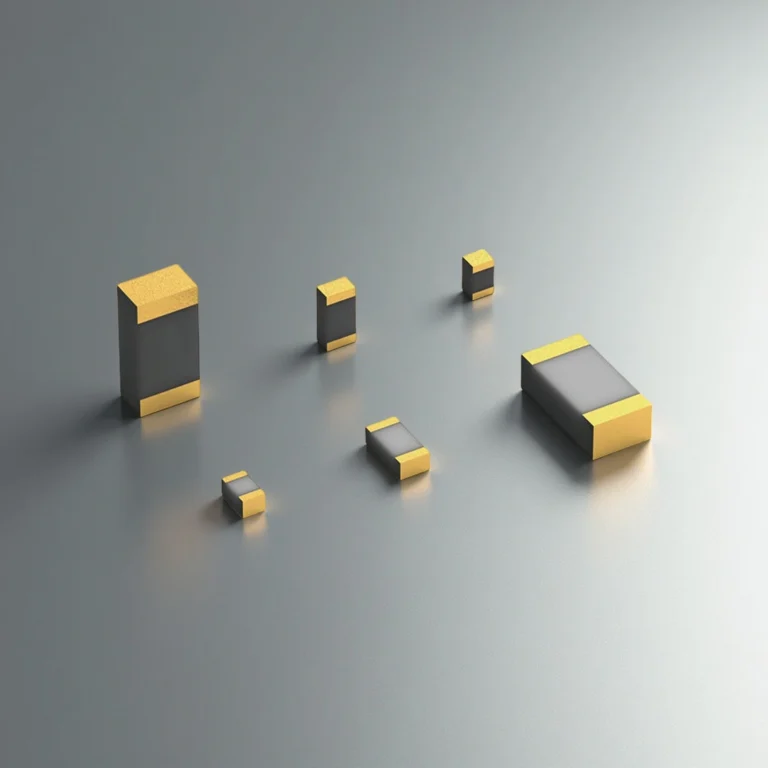

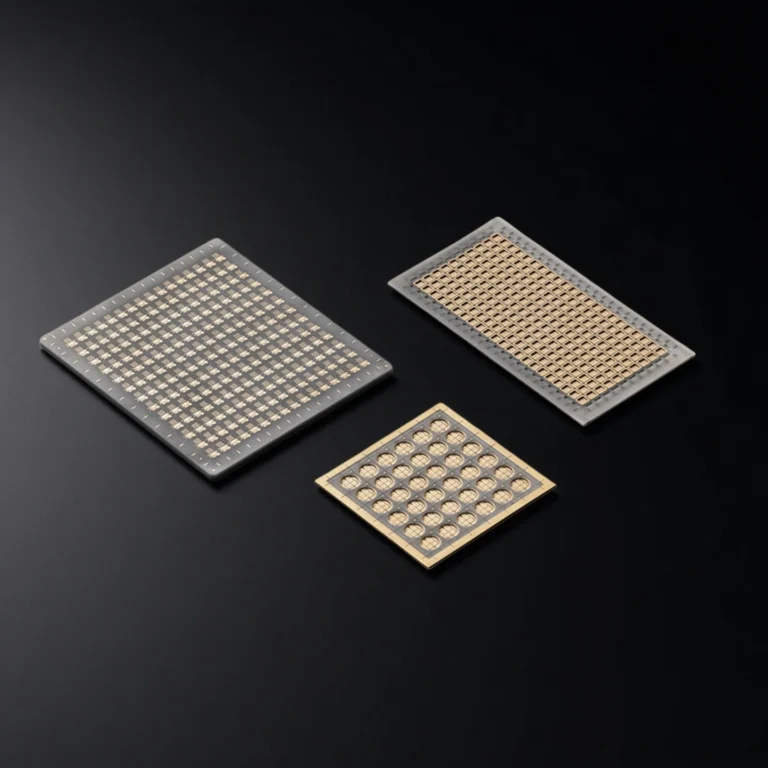

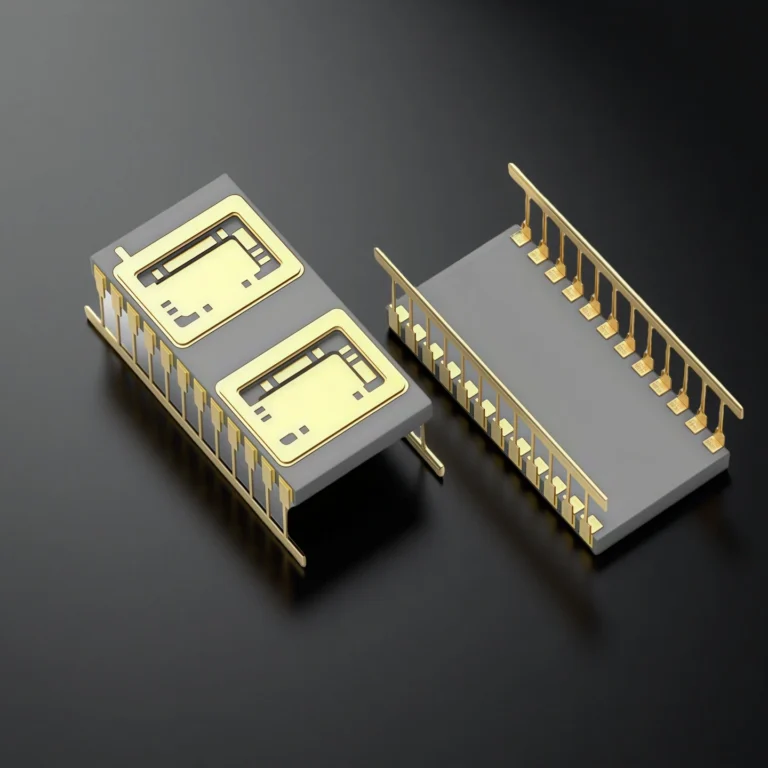

An optical communication module AlN substrate is a high-thermal-conductivity aluminum nitride ceramic submount or base plate used inside optical transceivers and optical communication modules (such as SFP, QSFP, OSFP, TOSA/ROSA, BOSA, AOC/ACC, and silicon photonics engines).

Optical Communication Module AlN Substrate Benefits

-

Thermal path matched to high-speed optics

The optical communication module AlN substrate maintains high thermal conductivity in a thin profile, helping keep laser diode and SiPh junction temperatures several degrees lower than standard alumina-based submounts at comparable power levels. -

CTE compatibility with optical chips

The AlN substrate offers a thermal expansion behavior close to silicon and GaAs, which supports long-term reliability for die attach and reduces the risk of solder fatigue or die cracking under temperature cycling. -

High flatness and tight dimensional tolerances

Optical communication module AlN substrates can be manufactured with controlled flatness and typical dimensional tolerances in the ±0.02–0.05 mm range, supporting automated pick-and-place and active alignment processes inside optical modules. -

Fine metallization patterns for dense layouts

The product supports fine-line metallization and via structures for compact optical communication module layouts, including differential signal routing and ground shielding around TOSA/ROSA or SiPh regions. -

Thin and robust for compact pluggable formats

The combination of high flexural strength and thin thickness capability allows the optical communication module AlN substrate to fit into constrained QSFP, OSFP and small-form-factor designs without compromising mechanical stability.

Optical Communication Module AlN Substrate Properties

| Property Content | Unit | Unit | ALN-170 | ALN-200 | ALN-230 |

| Basic Properties | Color | gray | light yellow | light yellow | |

| Density | g/cm³ | 3.2-3.3 | 3.2-3.3 | 3.2-3.3 | |

| Surface Roughness | μm | 0.2-0.75 | 0.2-0.75 | 0.2-0.8 | |

| Camber | length ‰ | ≤3‰ | ≤3‰ | ≤3‰ | |

| Hardness | HV | 1100 | 1100 | 1100 | |

| Thermal Properties | Max Operating Temperature | °C | 1100 | 1100 | 1100 |

| Thermal Conductivity | W/m·K | 170-190 | 190-220 | 220-230 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(20-400°c) | 4-5 | 4-5 | 4-5 | |

| Coefficient of Thermal Expansion | 10⁻⁶/K(400-800°c) | 5-6 | 5-6 | 5-6 | |

| Mechanical Properties | Flexural Strength | MPa | 300-400 | 350-450 | 400-500 |

| Tensile Strength | MPa | 200-300 | 250-350 | 280-380 | |

| Compressive Strength | MPa | 2000-3000 | 2200-3200 | 2500-3500 | |

| Electrical properties | Dielectric Constant | at 1MHz | 8-9 | 8-9 | 8-9 |

| Dielectric strength | KV/mm | ≥15 | ≥15 | ≥15 | |

| Volume resistivity | 20℃ Ω.cm | ≥1014 | ≥1014 | ≥1014 |

Optical Communication Module AlN Substrate Specifications

| Aluminum Nitride Substrate | |||||||

| Item no. | Substrate Dimension | Thickness | Machinable Aperture | Fine Line Resolution | Surface Roughness | Metal Hole Protrusion Height | Direction Identifier |

| AT-GT001 | 50.8*50.8±0.15 | 0.2-3.0mm | Φ0.008mm | ≥100μm | ≤0.05μm | ≤3μm | with |

Optical Communication Module Aluminum Nitride Substrate Packaging

- Each optical communication module AlN substrate is separated in multi-cavity plastic trays or blister packs to avoid edge chipping and pad surface contact.