Porous alumina vacuum chuck is a precision holding platform made from sintered alumina ceramic with a uniformly porous surface. Instead of relying on discrete suction holes, the entire surface is filled with micro-pores (typically 5–30 µm in diameter), which allows vacuum pressure to be distributed evenly across the working area.

Porous Alumina Vacuum Chuck Benefits

- Uniform vacuum distribution — Full-area porosity minimizes localized pressure peaks and reduces visible suction artifacts on fragile substrates.

- Zoned vacuum control — Manifold channels allow segment activation for coupons, windows, and step-and-repeat processes without tooling changes.

- Optical surface options — White/black alumina and low-Ra finishes support back-lighting, glare control, and stable edge detection.

- Integrated datum features — Alignment pins, fiducials, countersinks, and reliefs improve placement repeatability and handling safety.

- Clean-usage orientation — Dense ceramic matrix and compatible cleaning methods support low particle generation compared with soft porous polymers.

Porous Alumina Vacuum Chuck Properties

| Property | Unit | 99.5% Al₂O₃ | 99.6% Al₂O₃ | 99.7% Al₂O₃ | 99.8% Al₂O₃ | 99.9% Al₂O₃ | 99.99% Al₂O₃ |

| Alumina content | % | 99.5 | 99.6 | 99.7 | 99.8 | 99.9 | 99.99 |

| Density | g/cm³ | 3.89 | 3.91 | 3.92 | 3.93 | 3.94 | 3.98 |

| Open porosity | % | 0 | – | – | – | – | – |

| Color | – | Ivory | Ivory | Ivory | Ivory | Ivory | Ivory |

| Water absorption | % | – | 0 | 0 | 0 | 0 | 0 |

| Young’s modulus (Elastic modulus) | GPa | 375 | 356 | 357 | 358 | 359 | 362 |

| Shear modulus | GPa | 152 | – | – | – | – | – |

| Bulk modulus | GPa | 228 | – | – | – | – | – |

| Poisson’s ratio | – | 0.22 | – | – | – | – | – |

| Compressive strength | MPa | 2600 | 2552 | 2554 | 2556 | 2558 | 2570 |

| Flexural strength | MPa | 379 | 312 | 313 | 314 | 315 | 320 |

| Fracture toughness | MPa·m¹ᐟ² | 4 | – | – | – | – | – |

| Hardness | GPa | 14.1 (≈1440 kg/mm²) | 23 | 24 | 25 | 26 | 30 |

| Thermal conductivity | W/m·K | 35 | 32–37 | 33–38 | 34–39 | 35–40 | 36–42 |

| Thermal shock resistance ΔT | °C | – | 222 | 223 | 224 | 225 | 228 |

| Maximum use temperature (no load) | °C | ≤1750 | 1755 | 1760 | 1765 | 1770 | 1800 |

| Coefficient of thermal expansion | 10⁻⁶/°C | 8.4 | – | – | – | – | – |

| Specific heat | J/kg·K | 880 | – | – | – | – | – |

| Volume resistivity | Ω·cm | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ | >1×10¹⁴ |

| Dielectric constant (relative permittivity) | – | 9.8 | 9.83 | 9.84 | 9.85 | 9.86 | 9.92 |

| Dielectric strength | kV/mm | 16.9 | 23.2 | 23.4 | 23.6 | 23.8 | 24 |

| Dissipation factor (loss factor @ 1 kHz) | – | 0.0002 | – | – | – | – | – |

Porous Alumina Vacuum Chuck Specifications

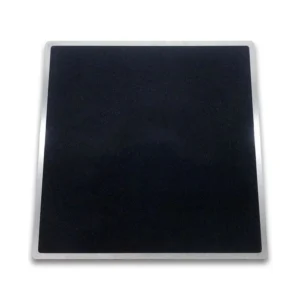

Type 1: Square Microporous Alumina Vacuum Chuck

| Square Microporous Alumina Vacuum Chuck | ||||

| Item NO. | Length (mm) | Width (mm) | Thickness (mm) | Material |

| AT-YHL-XP001 | 305 | 305 | 14 | 316 stainless steel + microporous ceramic (brown) |

| AT-YHL-XP002 | 305 | 305 | 14 | 316 stainless steel + microporous ceramic (brown) |

| AT-YHL-XP003 | 420 | 275 | 20 | Aluminum alloy + microporous ceramic |

| AT-YHL-XP004 | 450 | 200 | 20 | SKD61 + porous ceramic |

| AT-YHL-XP005 | 520 | 520 | 20 | Aluminum alloy + microporous ceramic |

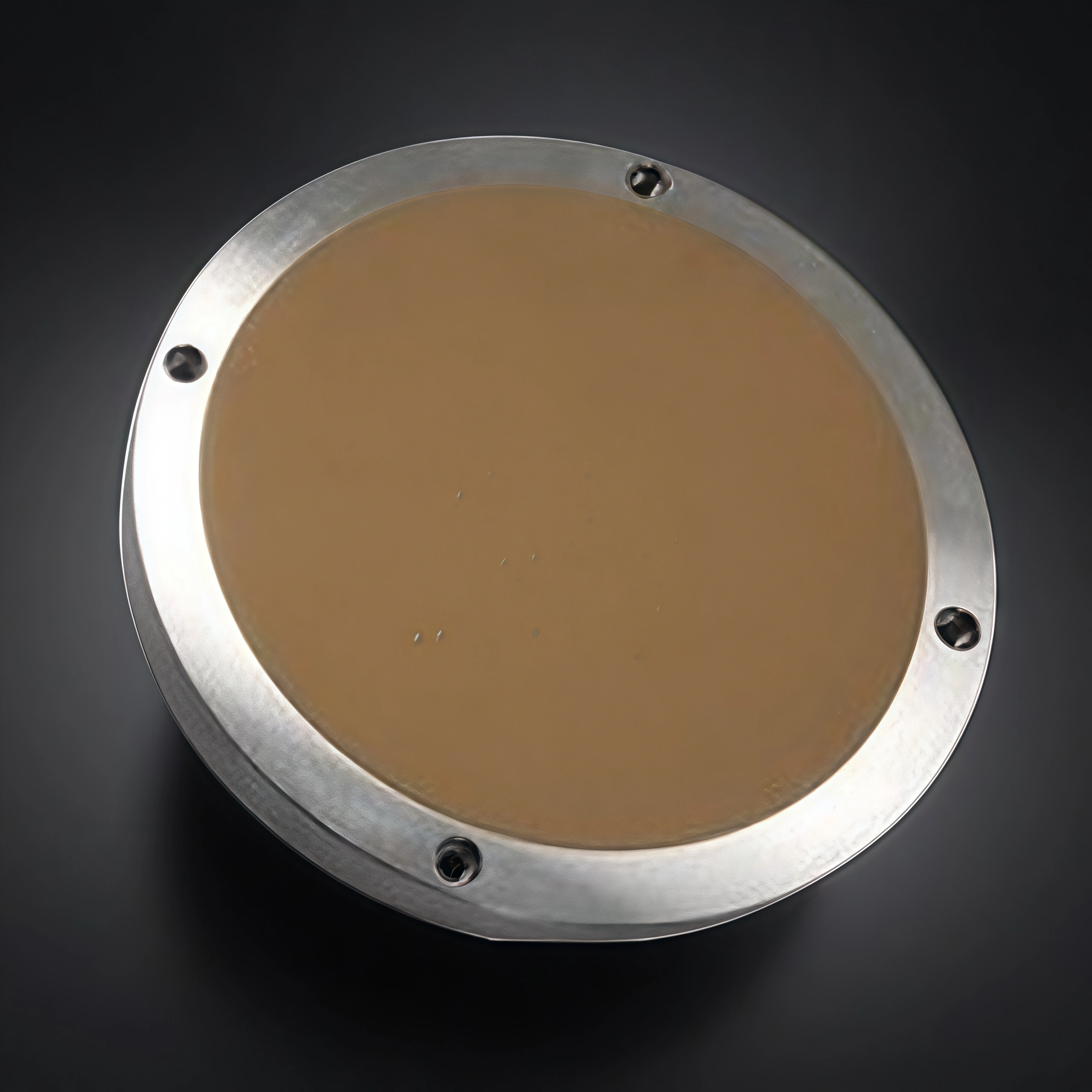

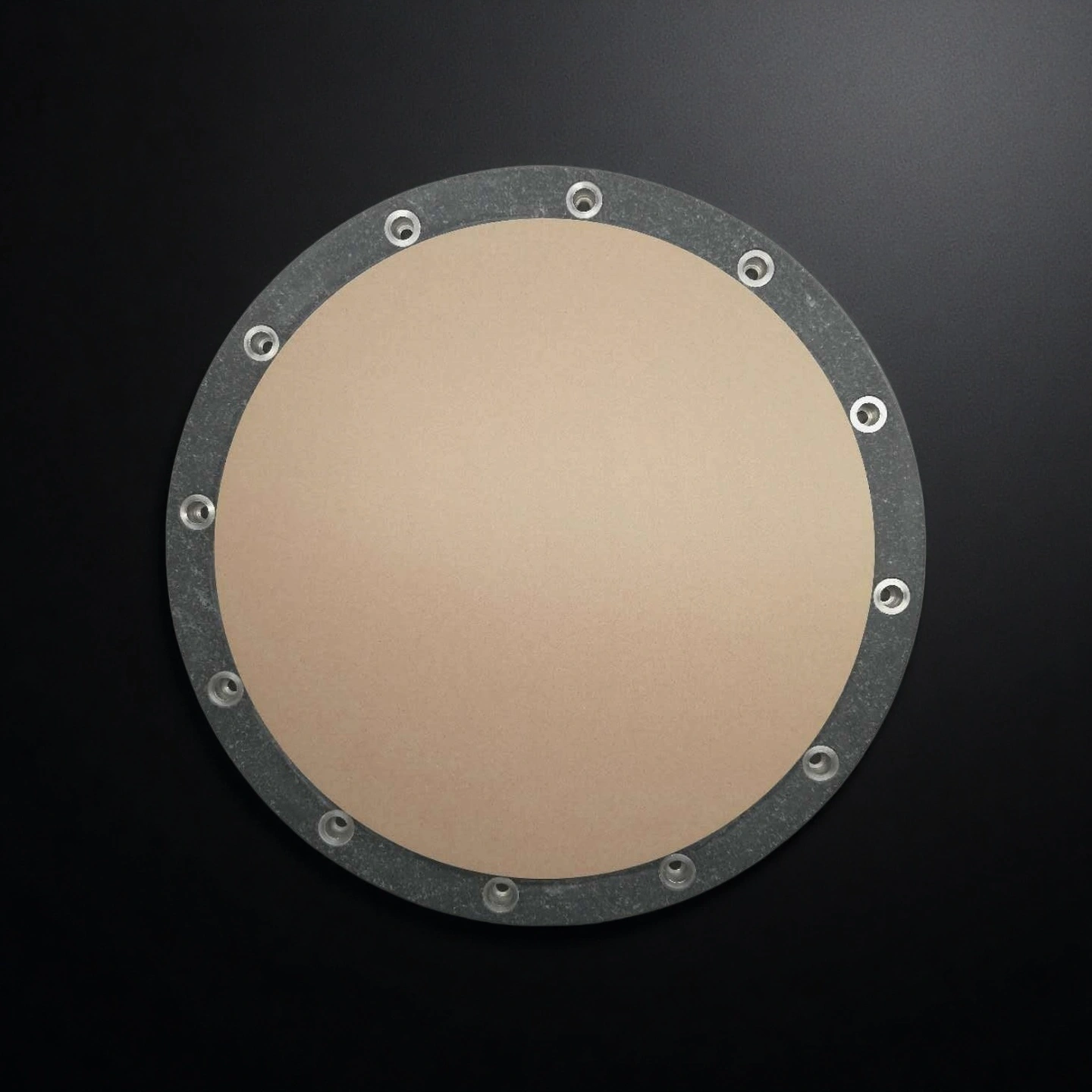

Type 2: Round Microporous Alumina Vacuum Chuck

| Round Microporous Alumina Vacuum Chuck | |||

| Item NO. | Diameter (mm) | Thickness (mm) | Material |

| AT-YHL-XP006 | 174 | 10 | 316 stainless steel + microporous ceramic |

| AT-YHL-XP007 | 220 | 35 | Only alumina ceramic |

| AT-YHL-XP008 | 230 | 16 | 316 stainless steel + microporous ceramic |

| AT-YHL-XP009 | 239 | 12 | Aluminum alloy + microporous ceramic |

| AT-YHL-XP010 | 240 | 12 | 316 stainless steel + microporous ceramic |

| AT-YHL-XP011 | 286 | 20 | Only alumina ceramic |

| AT-YHL-XP012 | 320 | 16 | 316 stainless steel + microporous ceramic |

| AT-YHL-XP013 | 325 | 12 | Aluminum alloy + microporous ceramic |

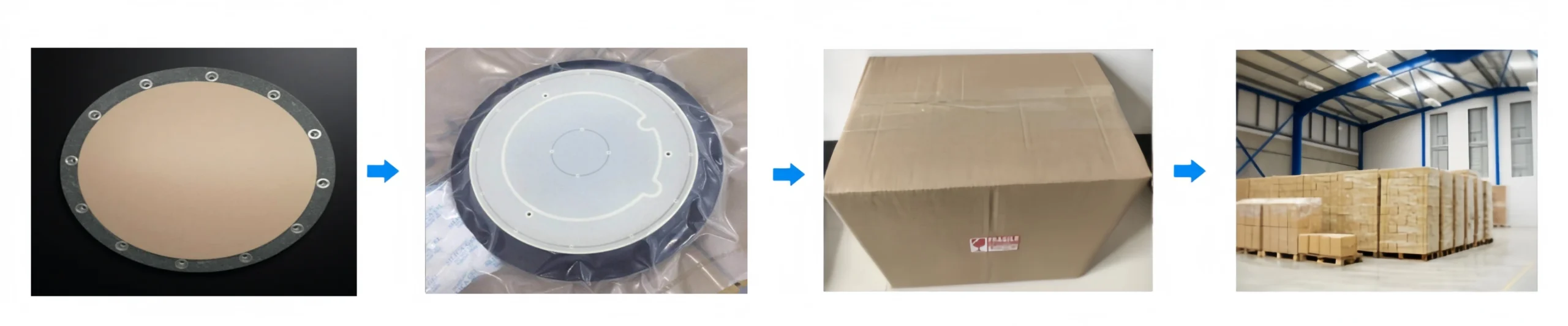

Porous Alumina Vacuum Chuck Packaging

- Clean pack:Vacuum wrap → anti-shock foam → rigid carton;