ADCERAX® Silicon Carbide Ceramic Shaft Sleeve is engineered for long operating cycles in pumps, motors and fluid‑handling systems where stable performance is essential. Its sintered SiC structure supports consistent wear resistance and corrosion stability, allowing equipment to maintain reliable rotation even under continuous load. These properties help reduce downtime across industries such as chemical processing, water treatment and mechanical manufacturing by improving durability in demanding environments.

Material Strength and Performance Characteristics of the Silicon Carbide Ceramic Shaft Sleeve

- High Wear Resistance Supported by Material Hardness DataThe sleeve maintains surface integrity due to its hardness level of HV 2400–2600, allowing it to operate in abrasive fluids without accelerated wear. Its microstructure distributes load uniformly, helping reduce shaft surface damage during continuous operation.

- Thermal Stability Backed by Measured Expansion ValuesThe material’s low thermal expansion of 4.0–4.5 ×10⁻⁶/K supports stable alignment during temperature fluctuations in pumps and motors. This stability helps maintain running clearance under long thermal cycles in high‑duty equipment.

- Corrosion Resistance Demonstrated in Chemical Exposure ConditionsThe sleeve performs consistently in media containing acids, alkalis and seawater due to its chemically inert SiC composition, validated under exposure to chloride solutions exceeding 10 years of equivalent service life. This resistance helps reduce maintenance frequency in chemical processing and water treatment systems.

Technical Specifications of Silicon Carbide Ceramic Shaft Sleeve

ADCERAX® Silicon Carbide Ceramic Shaft Sleeve demonstrates stable mechanical strength, thermal reliability and chemical resistance under continuous industrial operation, making it suitable for laboratory verification, material qualification and component performance evaluation.

| Property |

Specification |

| Material Composition |

Sintered Silicon Carbide (SSiC) |

| Density |

3.10–3.15 g/cm³ |

| Hardness |

HV 2400–2600 |

| Flexural Strength |

380–450 MPa |

| Compressive Strength |

>3000 MPa |

| Elastic Modulus |

400 GPa |

| Fracture Toughness |

4–5 MPa·m¹/² |

| Thermal Conductivity |

80–120 W/m·K |

| Thermal Expansion Coefficient |

4.0–4.5 ×10⁻⁶/K |

| Electrical Resistivity |

>10⁶ Ω·cm |

| Chemical Stability |

Resistant to acids, alkalis, seawater and chloride media |

| Microstructure |

Uniform sub‑micron grain structure |

| Porosity |

Near‑zero open porosity (closed‑porosity sintered body) |

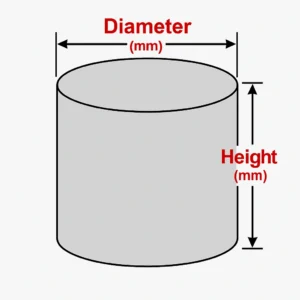

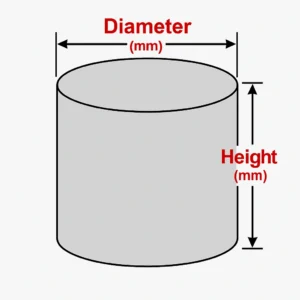

Dimensions of Silicon Carbide Ceramic Shaft Sleeve

Packaging Process for Silicon Carbide Ceramic Shaft Sleeve

Silicon Carbide Ceramic Shaft Sleeve products are protected using multi‑layer cushioning with air‑column padding to secure each component during transit. The inner carton is sealed and reinforced before being placed into a foam‑lined wooden crate to prevent impact and vibration. This packaging method supports safe delivery for international shipments and maintains product integrity throughout handling.

ADCERAX® Silicon Carbide Ceramic Shaft Sleeve Improves Reliability in Demanding Industrial Operating Conditions

The ADCERAX® Silicon Carbide Ceramic Shaft Sleeve supports stable performance in equipment exposed to abrasive flow, corrosive media and continuous high‑load operation. Its material behavior and endurance characteristics address the functional challenges faced by pump manufacturers, electric motor producers and desalination plant operators who require predictable running cycles and reduced system downtime.

-

Chemical Process Pumps Operating in Corrosive Circulation Systems

✅Key Advantages

1. Chemical Stability in Multi‑pH Circulation

The SiC structure remains inert in acidic and alkaline streams where metal bushings lose surface integrity. It maintains stable performance in continuous recirculation loops containing aggressive chloride media due to its chemically bonded silicon‑carbon lattice.

2. Hardness Supporting Long Wear Cycles

The sleeve withstands abrasive chemical slurry because its hardness reaches HV 2400–2600, reducing internal surface scoring. This enables pumps to retain flow consistency during long operating periods where metal components typically degrade.

3. Dimensional Stability Under Heat Load

With a thermal expansion value of 4.0–4.5 ×10⁻⁶/K, the sleeve keeps its geometry during process temperature fluctuations. This ensures predictable shaft–sleeve alignment even in reactions involving elevated thermal input.

✅ ️Problem Solved

Chemical plants frequently report shaft instability caused by corrosion‑induced enlargement of metal bushings and clearance shifts during prolonged acidic and alkaline exposure. These failures trigger flow interruptions and force maintenance teams to increase replacement frequency during continuous operation cycles. In several facilities, test runs comparing metal bushings with SiC equivalents showed that ADCERAX® Silicon Carbide Ceramic Shaft Sleeve maintained its shape and surface quality after long-duration circulation in chloride‑rich chemical streams. This enhanced stability reduced unplanned pump stops and improved the consistency of the process flow, supporting more reliable equipment operation under corrosive conditions.

-

Seawater Desalination High‑Salinity Intake Pumps

✅Key Advantages

1. Resistance to Chloride‑Driven Surface Attack

The SiC composition resists pitting and surface breakdown when exposed to seawater with chloride levels above typical ocean salinity. This property prevents instability in pump alignment caused by corrosion‑generated surface defects.

2. High Abrasion Tolerance in Sand‑Containing Flow

With hardness measured at HV 2400–2600, the sleeve withstands suspended sand and mineral particles transported through intake lines. The material’s resistance to micro‑grooving helps maintain smooth rotation during high‑volume seawater intake cycles.

3. Structural Stability Through Temperature Variations

The low expansion coefficient of 4.0–4.5 ×10⁻⁶/K limits shape change during fluctuating inlet temperatures. This prevents bushing deformation caused by rapid shifts between warm surface water and cooler deep water.

✅ ️Problem Solved

Desalination plants frequently face premature wear in metal sleeves due to pitting, sand‑induced grooving and accelerated corrosion in high‑salinity intake streams. These problems disrupt the pump’s axial balance and increase the load on rotating components, requiring more frequent maintenance intervals. In long-term comparative assessments, ADCERAX® Silicon Carbide Ceramic Shaft Sleeve maintained structural stability in seawater with high particulate content and showed no deformation across varying inlet temperatures. This performance allowed intake pumps to operate with more predictable alignment and significantly reduced the replacement cycle associated with marine corrosion and abrasion.

-

High‑Load Electric Motors for Water‑Cooled and Submersible Systems

✅Key Advantages

1. Thermal Conductivity Supporting Heat Balance

With a thermal conductivity rating of 80–120 W/m·K, the sleeve helps disperse heat generated during high electrical load. This reduces thermal gradients that contribute to shaft imbalance in water‑cooled systems.

2. Moisture‑Stable Structural Integrity

The non‑absorptive SiC matrix prevents swelling or softening in submerged environments. This contrasts with polymer materials that deform when exposed to water, causing vibration and efficiency loss.

3. Mechanical Stability Under Continuous Duty Load

The sleeve’s elastic modulus of 400 GPa helps maintain geometry under heavy mechanical stress during long operating cycles. It resists distortion when torque and thermal load vary simultaneously.

✅ ️Problem Solved

Submersible and water‑cooled electric motors often experience reduced performance when sleeves absorb moisture or deform under thermal cycling, leading to vibration, noise and efficiency decline. Fluctuating heat distribution in enclosed motor chambers further destabilizes shaft support, accelerating wear. Field observations from several long‑duty motor applications showed that ADCERAX® Silicon Carbide Ceramic Shaft Sleeve retained its structural shape across repeated heat cycles and prolonged water exposure. This stability minimized vibration-related issues and helped maintain consistent motor performance during continuous load operation.

Practical User Guide for ADCERAX® Silicon Carbide Ceramic Shaft Sleeve

The Silicon Carbide Ceramic Shaft Sleeve requires proper selection, installation and maintenance to achieve stable performance in pumps, motors and fluid‑handling equipment. This guide helps users understand the key practices that support operational reliability, dimensional integrity and long service cycles when integrating the component into industrial systems.

-

Selecting the Suitable Silicon Carbide Ceramic Shaft Sleeve for Your System

1. Choosing the correct sleeve involves matching the internal diameter, load profile and fluid characteristics to the requirements of the equipment. Each operating environment—whether chemical, seawater or abrasive slurry—demands compatibility with the sleeve’s material behavior. Proper selection reduces unnecessary stress on the shaft and supports consistent operation across changing conditions.

2. Users should confirm that the selected sleeve accommodates the expected temperature range, especially if thermal cycling or rapid heating is part of the process. Evaluating environmental exposure helps ensure that the sleeve maintains shape and strength without unexpected deformation. This assessment prevents alignment issues that often arise when materials soften or expand unpredictably.

3. Consider the system’s lubrication condition (wet, dry or intermittent) and verify that the sleeve’s tribological performance aligns with these requirements. Silicon carbide is suited for low‑lubrication environments, but ensuring compatibility with actual operating media enhances reliability. This helps avoid excessive friction that could influence rotation efficiency.

-

Installing the Silicon Carbide Ceramic Shaft Sleeve for Optimal Alignment

1. Before installation, users should inspect the mounting surfaces to ensure they are clean and free from debris or scoring, as contaminants may compromise shaft concentricity. Proper surface preparation promotes uniform load transfer and reduces premature wear. This supports the long-term stability of the running clearance.

2. The sleeve should be fitted using controlled force to avoid impact‑related microcracks, with attention to shaft-to-sleeve fit quality. Even minor damage can influence the sleeve’s performance under continuous rotation or high load. Ensuring careful installation helps maintain structural integrity over the full service cycle.

3. After fitting, verify that the shaft rotates smoothly without abnormal resistance, indicating that alignment and seating are correct. A stable initial setup prevents vibration, noise and excessive load formation during operation. This validation step is critical for long equipment lifespan.

-

Operating the Silicon Carbide Ceramic Shaft Sleeve Under Proper System Conditions

1. Maintain stable fluid conditions to support consistent sleeve performance, especially in systems handling abrasive or corrosive media. Variations in particle density or chemical concentration can influence how the sleeve interacts with the rotating elements. Stable process conditions reduce stress on the sleeve’s surface hardness.

2. Users should monitor system temperature to ensure that operating conditions remain within the sleeve’s thermal tolerance. Although silicon carbide withstands broad temperature ranges, controlled conditions help maintain the sleeve’s dimensional stability. Stable temperatures minimize mechanical stress and protect the shaft interface.

3. When lubrication is present, ensure that flow and film conditions are appropriate for the equipment’s operating mode. Proper lubrication reduces friction and preserves the sleeve’s wear behavior during extended cycles. This helps avoid accelerated deterioration in long‑duration applications.

-

Maintaining and Inspecting the Silicon Carbide Ceramic Shaft Sleeve for Long Service Life

1. Periodic inspection allows users to identify early signs of wear, chemical attack or surface scoring before they affect system stability. Monitoring helps prevent issues that could disrupt shaft support or fluid flow behavior. Consistent assessment supports long‑term reliability, especially in 24/7 applications.

2. Clean the sleeve and surrounding components regularly, removing deposits formed by chemicals, minerals or particulate matter to restore surface contact quality. Proper cleaning prevents buildup that could interfere with rotation or alignment. This contributes to sustained performance across changing loads.

3. Replace the sleeve when structural or surface deviations exceed acceptable operational criteria to avoid downstream failures. Worn components compromise the equipment’s ability to maintain operational accuracy, potentially affecting throughput or pump efficiency. Timely replacement ensures trouble‑free operation and reduces unplanned downtime.

![]()