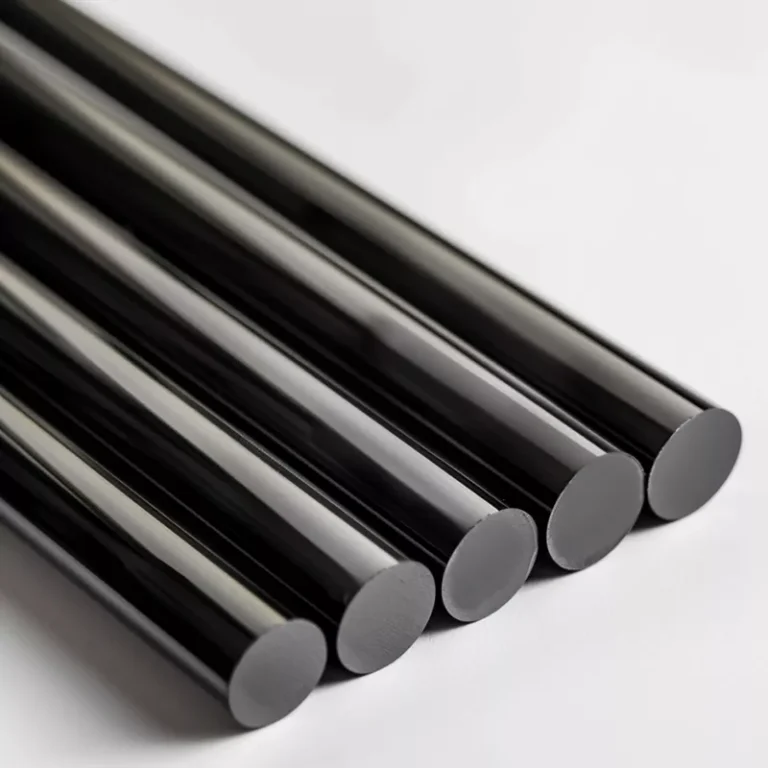

Silicon nitride rods are solid ceramic components made from Si₃N₄, a covalently bonded advanced ceramic known for its high strength, low thermal expansion, thermal shock resistance, and electrical insulation. These rods are commonly manufactured by isostatic pressing or injection molding followed by high-temperature sintering and optional precision grinding to achieve tight dimensional tolerances.

Silicon Nitride Rods Benefits

-

Dimensional stability under thermal cycling ensures the rod maintains straightness and tolerance even after repeated heating and cooling, preventing fixture misalignment and reducing recalibration efforts.

-

Non-wetting to aluminum minimizes metal adhesion and oxide buildup, allowing easier removal during maintenance and extending service intervals in die casting and melt-transfer zones.

-

High wear resistance supports long-term use in sliding, guiding, or indexing mechanisms such as positioning rods, pump shafts, and mechanical linkage points where abrasion is constant.

-

Electrical insulation maintained at elevated temperatures enables safe use in heating elements, resistance welding fixtures, and test setups without risk of short circuits or dielectric breakdown.

-

Precision end options (chamfer, step, through-hole, thread) allow rods to be installed directly into fixtures or holders without secondary machining, improving interchangeability and assembly accuracy.

Silicon Nitride Ceramic Rod

| Si3N4 Type | Gas pressure sintering Si3N4 | Hot pressing sintering Si3N4 | High thermal conductivity Si3N4 |

| Density (g/cm3) | 3.2 | 3.3 | 3.25 |

| Flexture strength (MPa) | 700 | 900 | 600~800 |

| Young Modulus (GPa) | 300 | 300 | 300~320 |

| Poisson's ratio | 0.25 | 0.28 | 0.25 |

| Compressive strength (MPa) | 2500 | 3000 | 2500 |

| Hardness (GPa) | 15 | 16 | 15 |

| Fracture toughness (MPa*m1/2) | 5~7 | 6~8 | 6~7 |

| Maximum working temperature (℃) | 1100 | 1300 | 1100 |

| Thermal conductivity (W/m*K) | 20 | 25 | 80~100 |

| Thermal expansion coefficient (/℃) | 3*10-6 | 3.1*10-6 | 3*10-6 |

| Thermal shock resistance (ΔT ℃) | 550 | 800 | / |

Si3N4 Rods Specifications

Type1: Silicon Nitride Round Rods

| Silicon Nitride Round Rods | |||

| Item No. | Diameter (mm) | Length (mm) | Purity(%) |

| AT-SNR-0001 | 2 | 20 | 85-99 |

| AT-SNR-0002 | 2 | 50 | 85-99 |

| AT-SNR-0003 | 3 | 20 | 85-99 |

| AT-SNR-0004 | 3 | 50 | 85-99 |

| AT-SNR-0005 | 4 | 12 | 85-99 |

| AT-SNR-0006 | 4 | 50 | 85-99 |

| AT-SNR-0007 | 5 | 12 | 85-99 |

| AT-SNR-0008 | 6 | 12 | 85-99 |

| AT-SNR-0009 | 6 | 30 | 85-99 |

| AT-SNR-0010 | 6.75 | 22 | 85-99 |

| AT-SNR-0011 | 7.5 | 100 | 85-99 |

| AT-SNR-0012 | 8 | 30 | 85-99 |

| AT-SNR-0013 | 10 | 40 | 85-99 |

| AT-SNR-0014 | 10 | 100 | 85-99 |

| AT-SNR-0015 | 12 | 10 | 85-99 |

| AT-SNR-0016 | 12 | 40 | 85-99 |

| AT-SNR-0017 | 15 | 10 | 85-99 |

| AT-SNR-0018 | 15 | 40 | 85-99 |

| AT-SNR-0019 | 20 | 10 | 85-99 |

| AT-SNR-0020 | 20 | 40 | 85-99 |

| AT-SNR-0021 | 25 | 10 | 85-99 |

| AT-SNR-0022 | 25 | 40 | 85-99 |

| AT-SNR-0023 | 30 | 40 | 85-99 |

| AT-SNR-0024 | 2-80 | 20-200 | 85-99 |

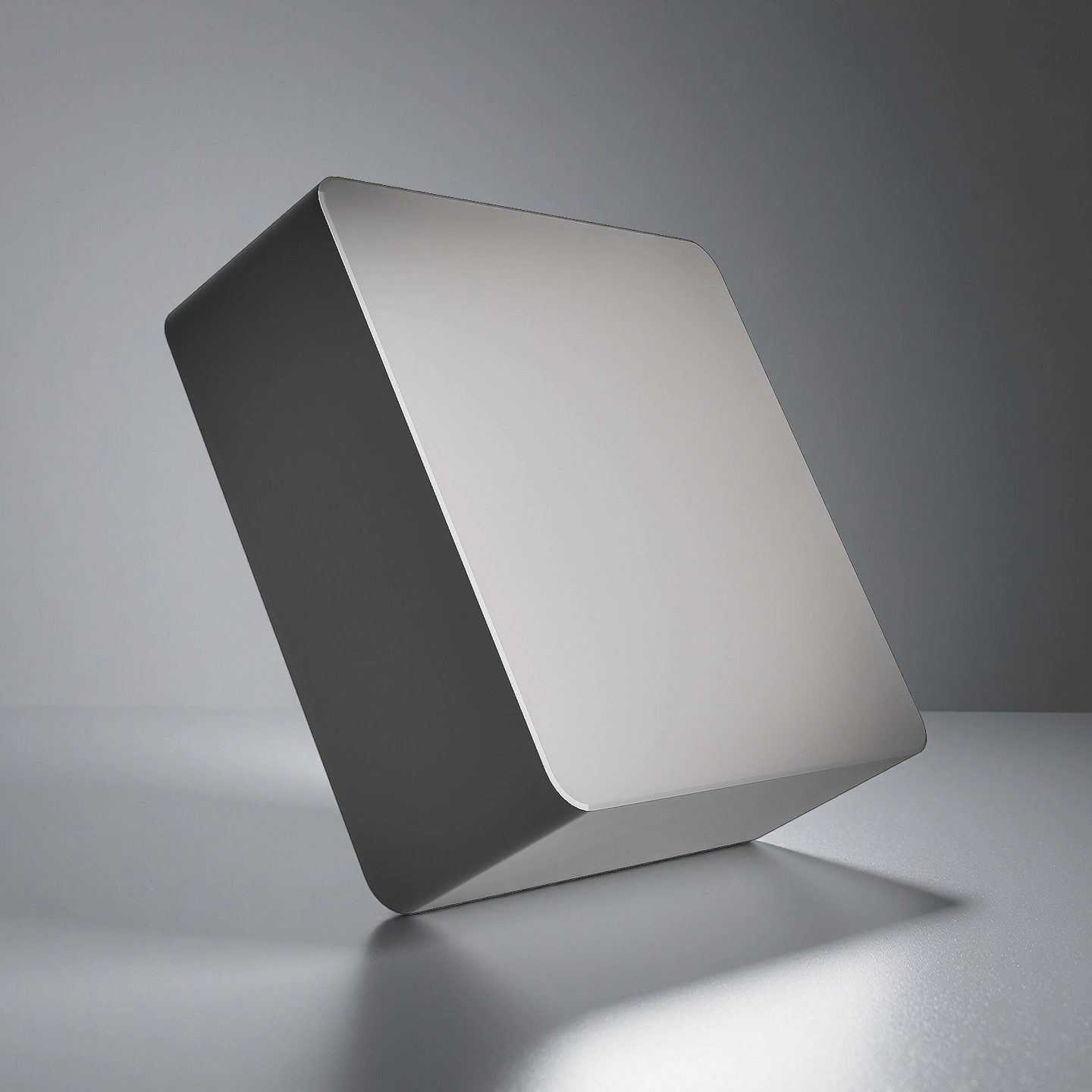

Type 2: Silicon Nitride Square Rods

![]()

| Silicon Nitride Square Rods | ||||

| Item No. | Width (mm) | Height (mm) | Length (mm) | Purity(%) |

| AT-SNR-1002 | 5 | 5 | 40 | 85-99 |

| AT-SNR-1003 | 10 | 10 | 70 | 85-99 |

| AT-SNR-1004 | 35 | 22 | 60 | 85-99 |

| AT-SNR-1005 | 40 | 32 | 100 | 85-99 |

| AT-SNR-1006 | 60 | 20 | 105 | 85-99 |

| AT-SNR-1007 | 75 | 75 | 90 | 85-99 |

Silicon Nitride Bar Packaging

- Each rod is individually wrapped in anti-static foam and sealed to prevent static discharge.

![]()